High-temperature-resistant high-density formate polysulfonate drilling fluid and preparation method thereof

A polysulfonate drilling and formate technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult control of drilling fluid rheology, high solid content, high cycle pressure loss, etc., to overcome density The effects of low adjustment ability, low solid phase content, and improved salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a density of 2.4g / cm 3 High temperature resistant high density formate polysulfide drilling fluid, which is prepared by the following steps:

[0025] Put 30m in the circulation tank 3 For fresh water, add 0.6t of bentonite, fully stir and then pre-hydrate at rest. The pre-hydration time must not be less than 24 hours to obtain pre-hydrated bentonite slurry;

[0026] In the state of full stirring (high-speed stirring with a rotation speed of 8000-12000 rpm), add 0.6t potassium hydroxide, 0.9t high temperature resistant sulfonate polymer acrylamide and 2- Acrylamide-2-methylsulfonic acid copolymer (molecular weight greater than 5 million), 6t sulfonated treatment agent (3t sulfonated phenolic resin, 1.5t sulfonated lignite resin and 1.2t sulfonated humic acid chromium mixed), 18t high Softening point sulfonated asphalt (softening point 180°C), 3t emulsifier SP-80, 2t potassium carbonate, after fully stirring, add 30t formate, and finally add hig...

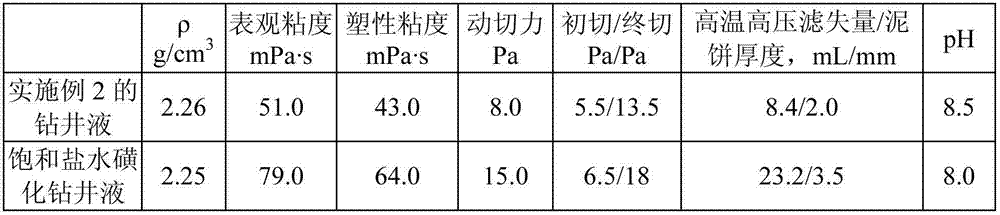

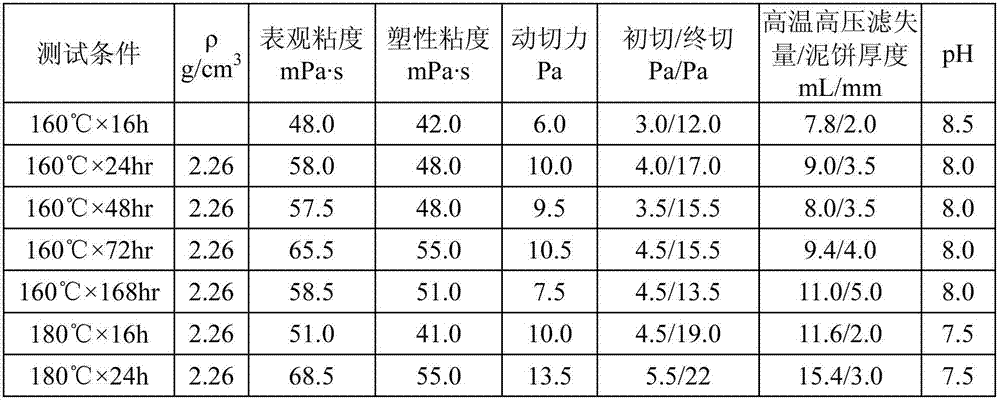

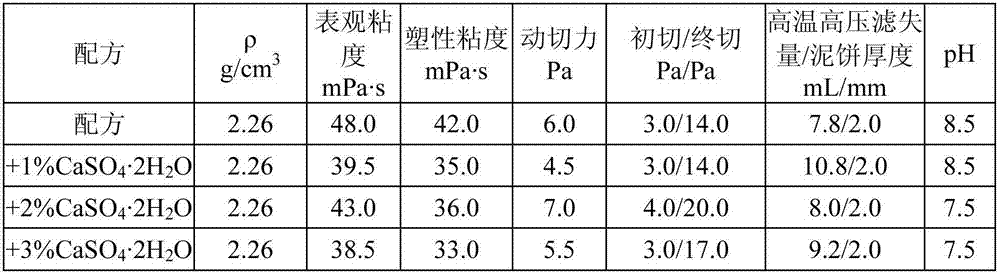

Embodiment 2

[0028] This embodiment provides a density of 2.25g / cm 3 High temperature resistant high density formate polysulfide drilling fluid, which is prepared by the following steps:

[0029] Put 30m in the circulation tank 3 For fresh water, add 0.9t of bentonite, fully stir and then pre-hydrate at rest. The pre-hydration time must not be less than 24 hours to obtain pre-hydrated bentonite slurry;

[0030] In the state of full stirring (high-speed stirring with a rotation speed of 8000-12000 rpm), add 0.4t potassium hydroxide, 0.6t high temperature resistant sulfonate polymer acrylamide and 2- Acrylamide-2-methylsulfonic acid copolymer (molecular weight greater than 5 million), 4t sulfonated treatment agent (mixed with 2t sulfonated phenolic resin, 1.2t sulfonated lignite resin and 0.8t sulfonated humic acid chromium), 14t high Softening point sulfonated asphalt (softening point 180°C), 2t emulsifier SP-80, 2t potassium carbonate, after fully stirring, add 21t of formate, and finall...

Embodiment 3

[0032] This embodiment provides a density of 1.80g / cm 3 High temperature resistant high density formate polysulfide drilling fluid, which is prepared by the following steps:

[0033] Put 30m in the circulation tank 3 For fresh water, add 1.2t of bentonite, fully stir and then pre-hydrate at rest. The pre-hydration time should not be less than 24 hours to obtain pre-hydrated bentonite slurry;

[0034] In the state of full stirring (high-speed stirring with a rotation speed of 8000-12000 rpm), add 0.4t potassium hydroxide, 0.4t high temperature resistant sulfonate polymer acrylamide and 2- Acrylamide-2-methylsulfonic acid copolymer (molecular weight greater than 5 million), 4t sulfonated treatment agent (mixed with 2t sulfonated phenolic resin, 1.2t sulfonated lignite resin and 0.8t sulfonated humic acid chromium), 6t high Softening point sulfonated asphalt (softening point 180°C), 2t emulsifier SP-80, 2t potassium carbonate, after fully stirring, add 21t formate, and finally ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com