High-temperature-resistance low-friction weighted clean fracturing fluid and preparation method thereof

A clean fracturing fluid, high temperature resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor compatibility of weighting agents, poor temperature resistance, and reduce friction, and achieve an increase in apparent viscosity. and structural strength, good temperature and shear resistance, and enhance the effect of association

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

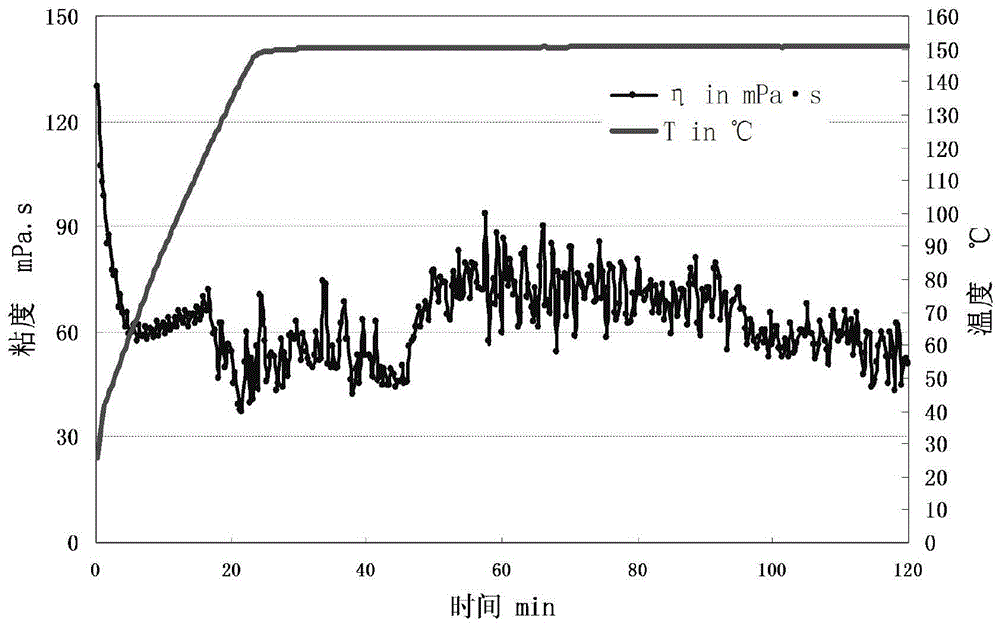

[0053] KCl-weighted clean fracturing fluid formula and evaluation of temperature and shear resistance at 150°C:

[0054] The components of the weighted cleaning fracturing fluid are, by weight percentage, respectively: 0.6% of high temperature resistant thickener, 0.2% of high temperature stabilizer, 17% of weighting agent, and the balance is clear water. The weighting agent uses KCl as a raw material to prepare a weighted clean fracturing fluid base fluid; add a system synergist with a weight percentage of 0.5% to the weighted clean fracturing fluid base fluid, and mix well to obtain a low-viscosity, high-viscoelastic weighting agent Clean fracturing fluid with a density of 1.12g / cm 3 .

[0055] Using a high temperature rheometer at 170s -1 , under the condition of 150°C, the temperature and shear resistance test was carried out for 120 minutes on the clean fracturing fluid aggravated by KCl, and the test curve is as follows figure 1 shown.

[0056] It can be seen from th...

Embodiment 2

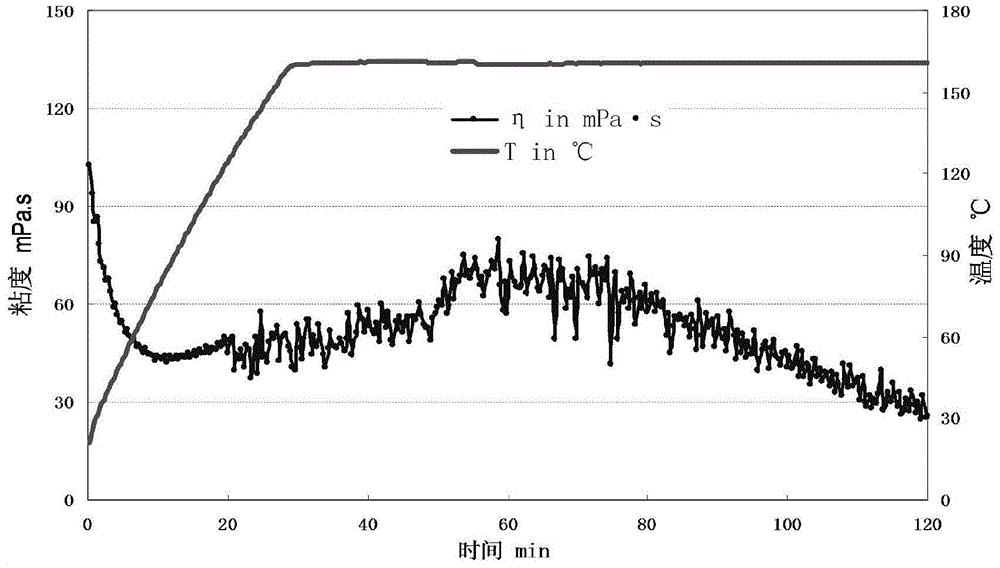

[0058] NaNO 3 Heavy clean fracturing fluid formulation and 170°C temperature and shear performance evaluation:

[0059] The components of the weighted clean fracturing fluid are: 0.7% anti-high temperature thickener, 0.3% high temperature stabilizer, weighting agent NaNO 3 42%, the balance is clear water, to prepare a weighted clean fracturing fluid base fluid; add a system synergist with a weight percentage of 0.7% in the weighted clean fracturing fluid base fluid, and mix well to obtain low viscosity and high viscoelasticity A weighted clean fracturing fluid with a density of 1.32g / cm 3 .

[0060] Using a high temperature rheometer at 170s -1 , for NaNO at 170°C 3 The aggravated clean fracturing fluid was subjected to the temperature and shear resistance test for 120 minutes, and the test curve was as follows figure 2 shown.

[0061] From the rheological curve at 170°C, it can be seen that at 170s -1 In the case of continuous shear, the viscosity of the aggravated cl...

Embodiment 3

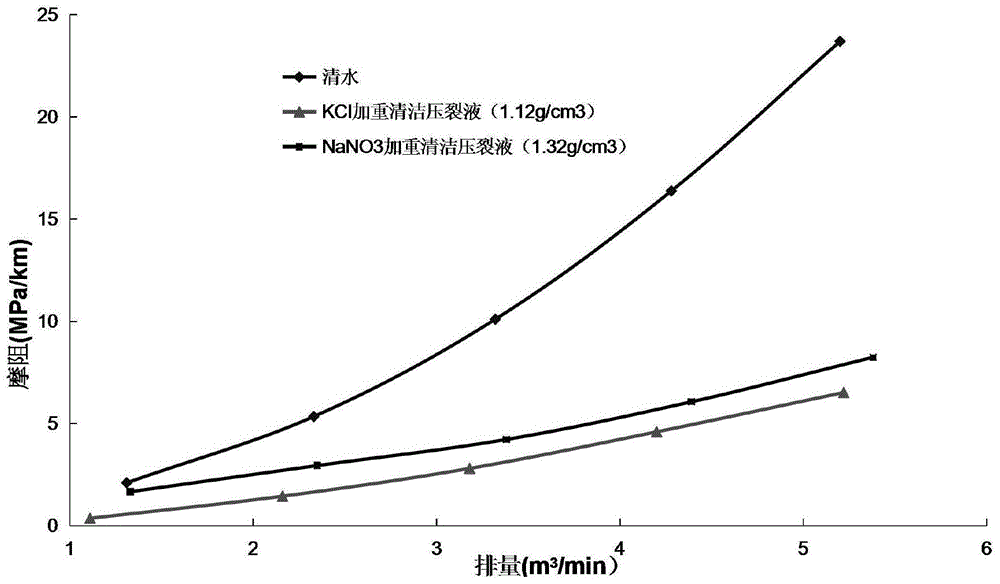

[0063] On-site construction friction performance test of aggravated clean fracturing fluid:

[0064] The on-site construction friction test was carried out by using the aggravated clean fracturing fluid and clear water in Example 1 and Example 2, and the variation curves of several kinds of fluid friction with displacement are as follows image 3 shown.

[0065] Among them: the test string adopts 3-1 / 2″ (inner diameter: 76mm) × 2000m smooth oil pipe, and carries two pressure gauges into the well to test the bottom hole pressure.

[0066] By polynomial fitting of the friction curves of the three groups of liquids, the polynomial of the change of the liquid friction with the displacement is obtained, and the liquid friction at the specified displacement is calculated, and then the resistance reduction rate of the fracturing fluid is calculated. Examples 1 and 1 2. Table 1 shows the calculation results of the resistance reduction rate of the weighted fracturing fluid at differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com