Patents

Literature

55results about How to "Solve the problem of secondary pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

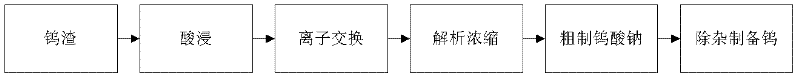

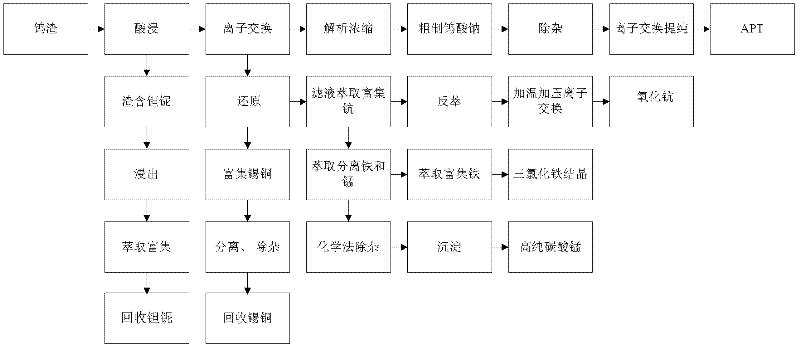

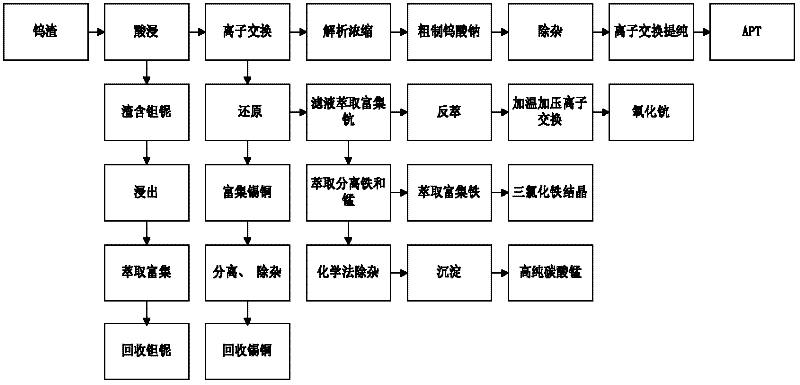

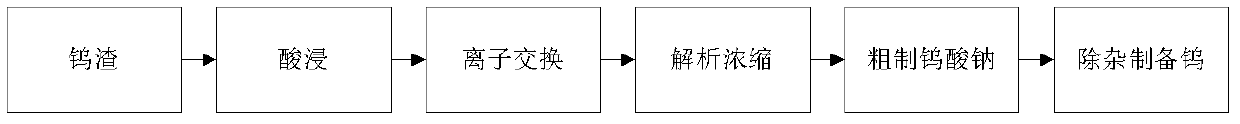

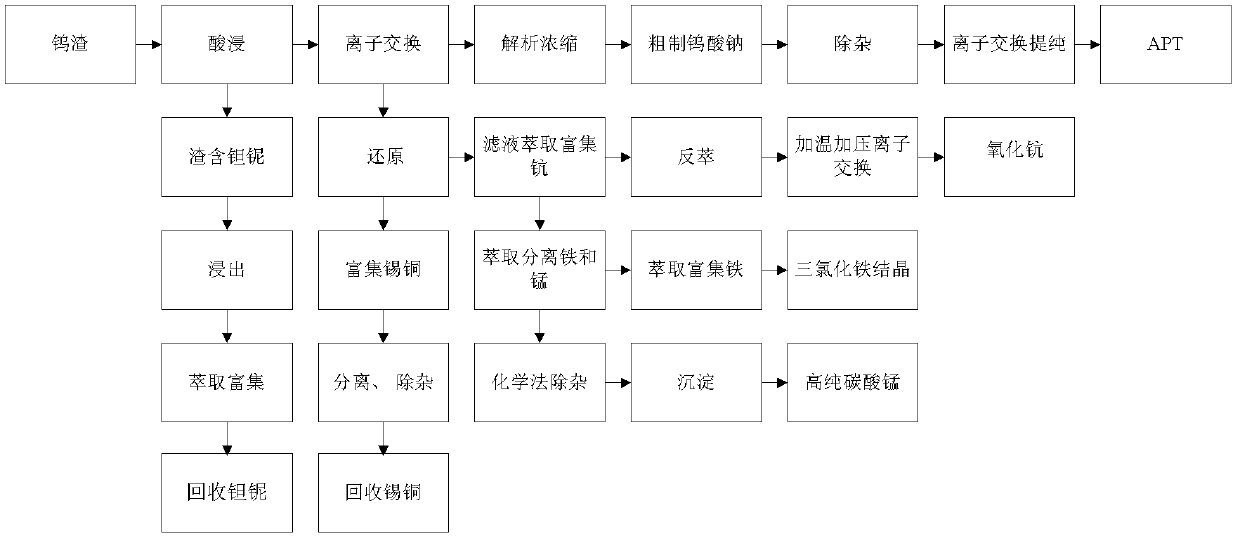

Tungsten slag treatment method

ActiveCN102212697ASolve the problem of secondary pollutionReduce recycling costsProcess efficiency improvementSlagFiltration

The invention discloses a tungsten slag treatment method. The tungsten slag treatment method comprises the following steps of: dissolving: mixing tungsten slag and 15 to 30 percent HCl solution of 50 to 65 DEG C, adding a tungsten stabilizing agent, and performing filtration after the reaction is finished to obtain acid solution; and reclaiming tungsten: adsorbing the tungsten in the acid solution by adopting weak alkali acrylic acid series anion exchange resin to obtain tail solution I, resolving the exchange resin by using sodium hydroxide solution to obtain sodium tungstate, and reclaimingthe tungsten from the sodium tungstate. By using the technical scheme, the tungsten slag is leached at a low temperature under normal pressure by adopting the HCl solution, and the tungsten is directly reclaimed by a one-step method under the acid condition; and the process is simple and low in reclamation cost.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

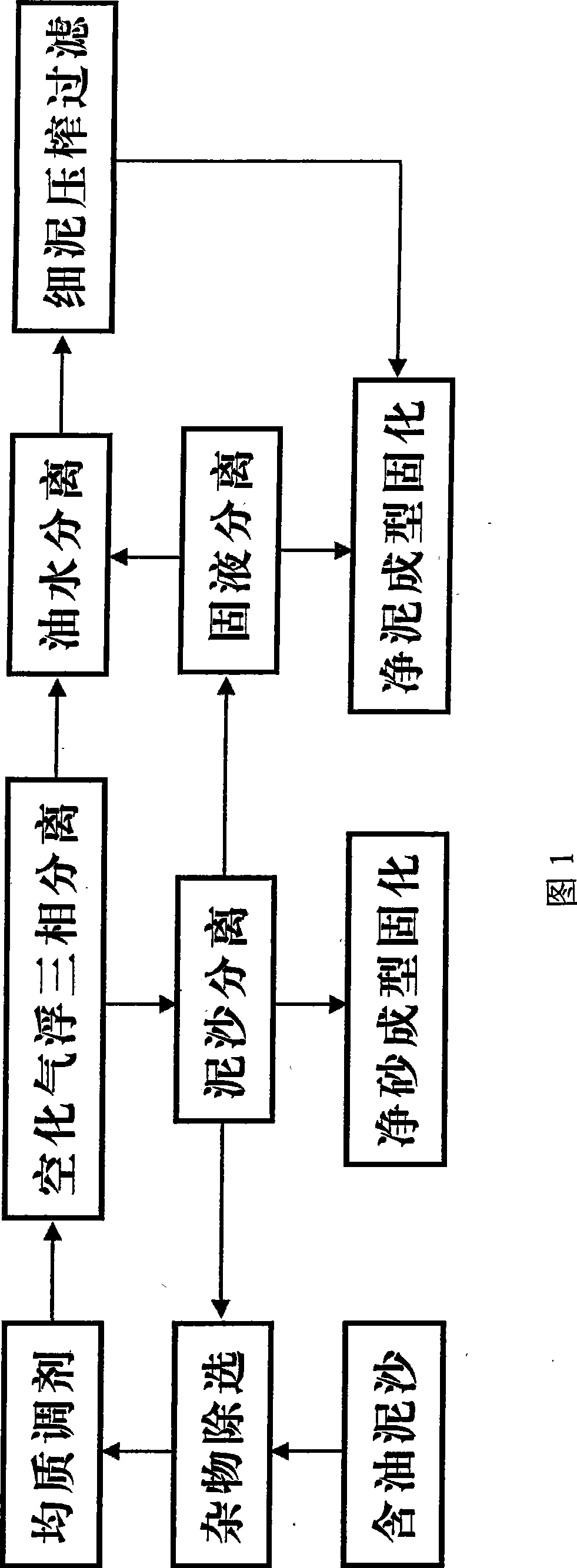

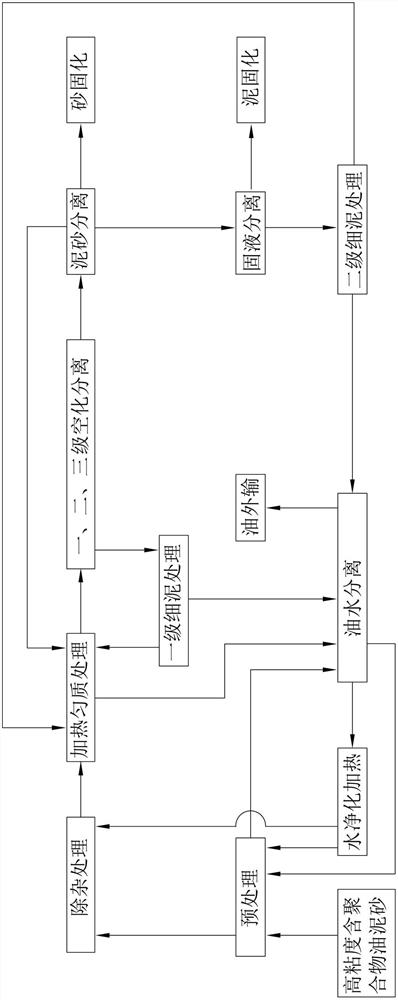

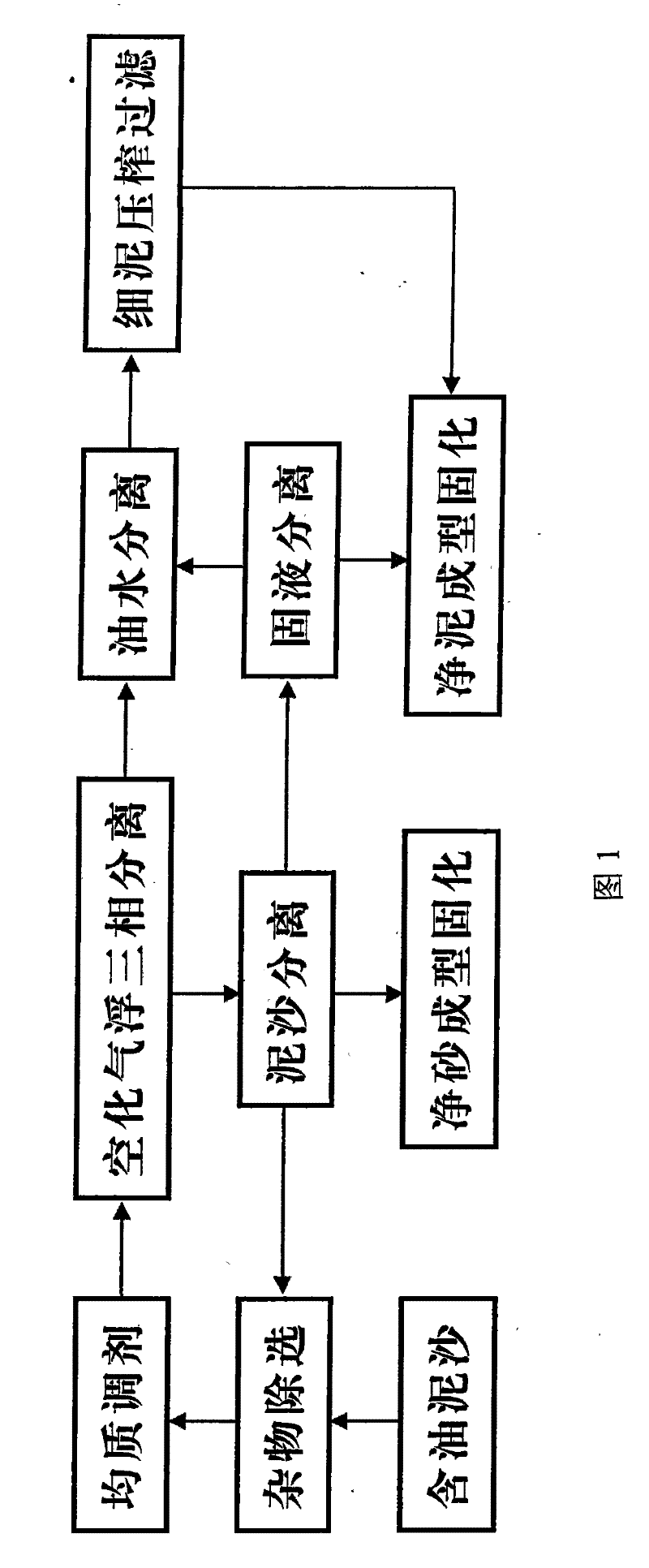

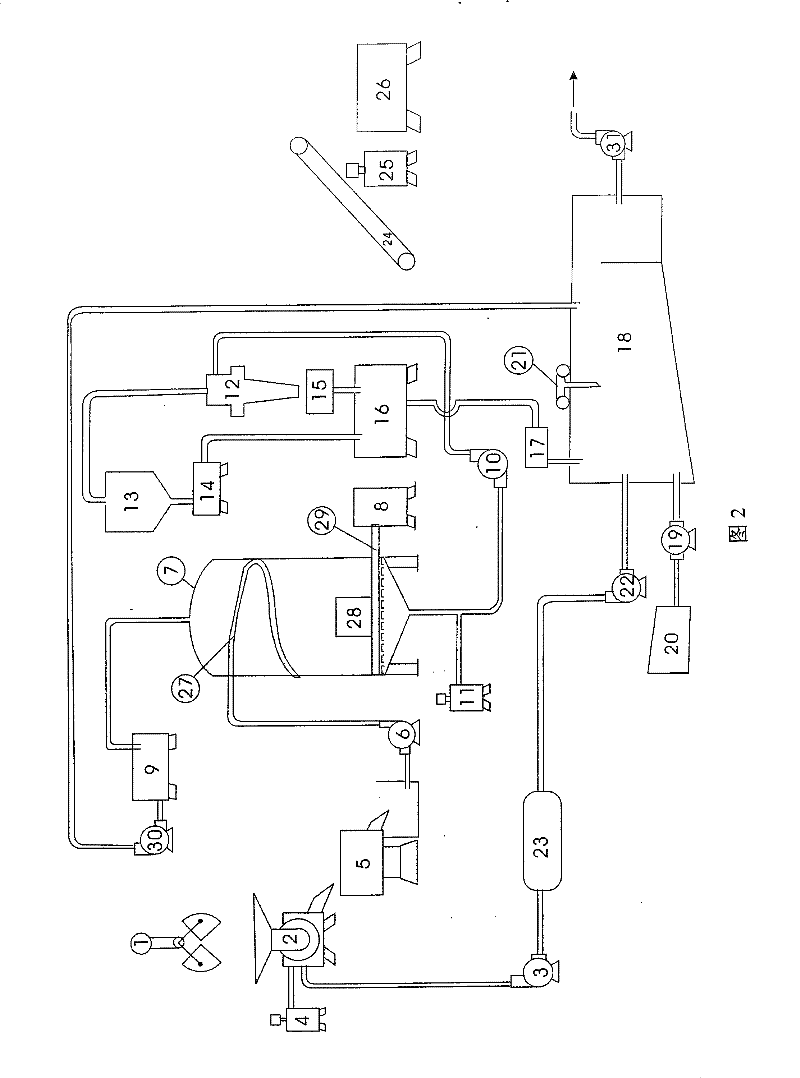

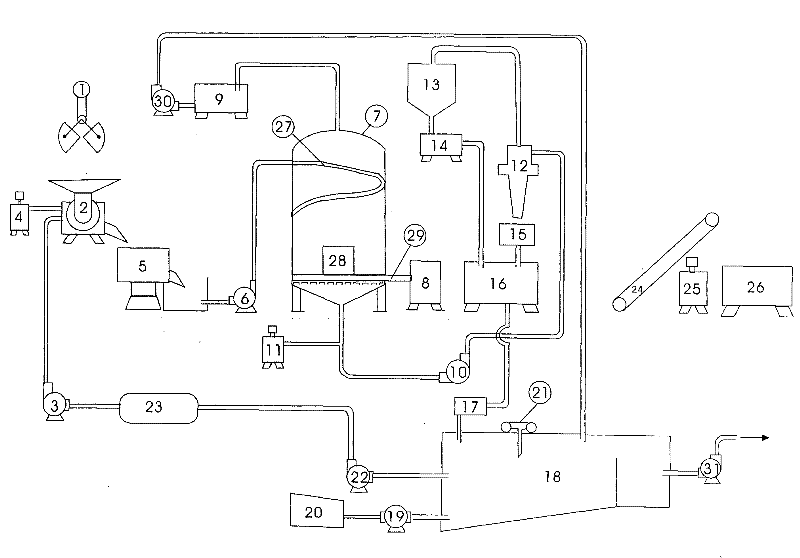

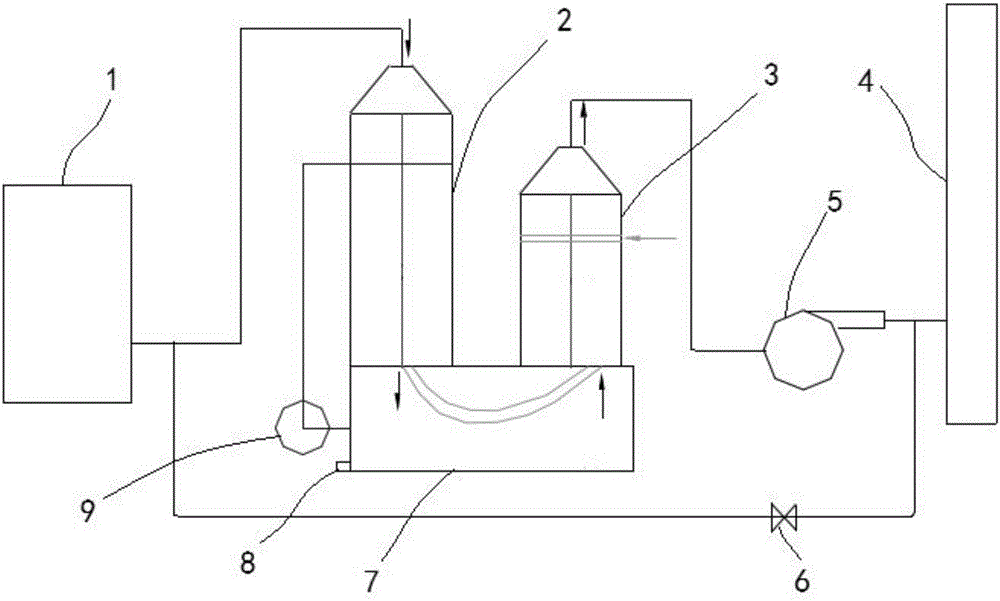

Pollution-free oil-containing mud cleaning treatment method and treatment system thereof

InactiveCN101428247ASolve the problem of secondary pollutionSimple purification processWet separationResource recoverySlurry

The invention relates to a pollution-free oily sediment purification treatment method and a treatment system, and the implementation steps are as follows: adopting a mechanical feeding device for conveying oily sediment to a miscellany removing and sorting device, filtering out and removing the miscellanies therein, perfusing hot water and a reagent into the oily sediment; evenly regulating the oily sediment through mechanical rolling; treating oil, water and sediment in an input tank through a cavitation and air flotation three-phase separator, so as to realize the three-phase separation of the oil, the water and the sediment, and discharging most of the separated oil; separating the sediment through a cyclone separator, and discharging net sand; separating slurry through a centrifuge, discharging net mud; separating fine mud from the water through a pressing filter, discharging net fine mud; separating the oil-water through natural ascending and descending, outputting the oil, and continuously heating water for the cyclic utilization; and curling and molding the discharged net sand and net mud according to routine. The invention realizes the resource recovery of crude oil in oily sediment and reduces the cost for purifying and treating oily sediment effectively, and the purified sediment is made into cured resin used for building materials.

Owner:TIANJIN TAIXING ENG TECH CO LTD

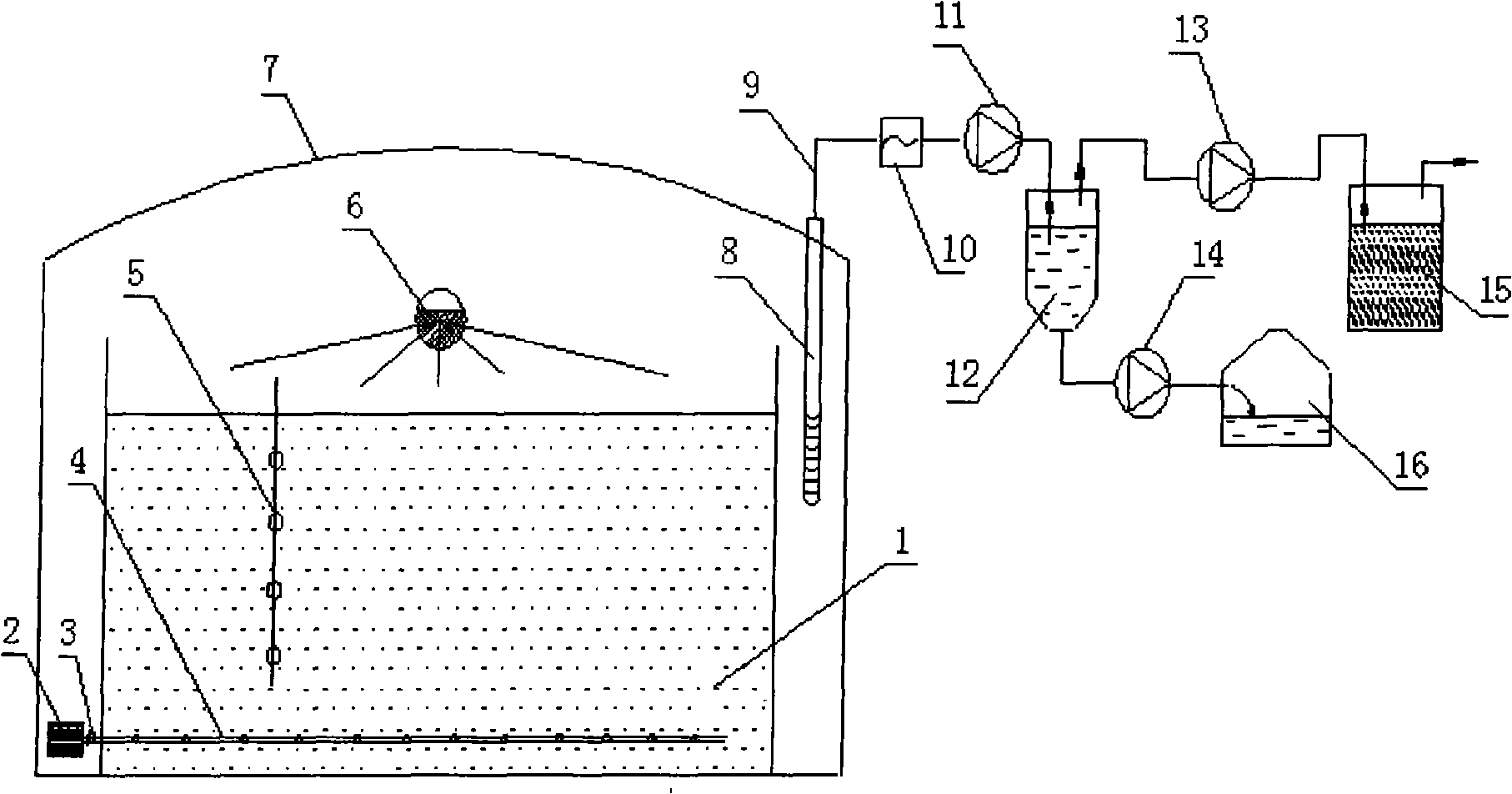

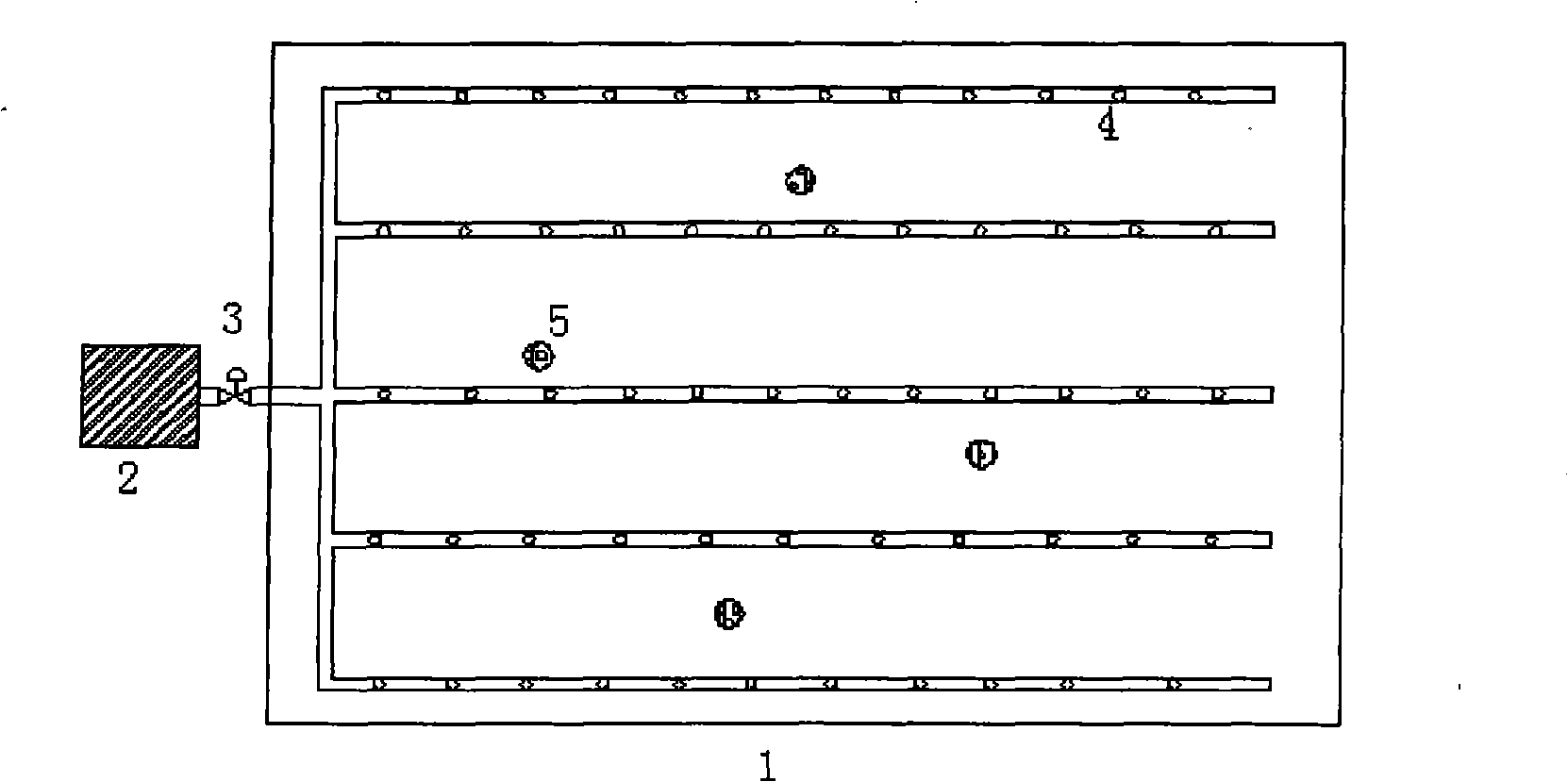

Heterotopia repairing system of volatile organic pollution soil and processing method thereof

InactiveCN101357369AReinforced design is simpleIn line with China's national conditionsContaminated soil reclamationRestoration devicePollution soil

The invention relates to a system for the ectopic restoration of volatile organic polluted soil and a disposing method thereof. The system for the ectopic restoration of the volatile organic polluted soil comprises a soil restoring bed, a ventilation pipeline system, a liquid charging system, a detecting system, an induced draught system and a closed-circuit tail gas collecting and disposing system. The soil restoring bed is a closed system. The ventilation pipeline system and the detecting system are arranged in the soil restoring bed. The liquid charging system is arranged above the soil restoring bed. The soil restoring bed is connected with the closed-circuit tail gas collecting and disposing system by the induced draught system. Polluted soil is used as a carrier to be connected with the soil restoring bed, the ventilation pipeline system and the detecting system. The system and the method can be used as an economical and feasible ectopic soil ventilation and microorganism degradation coupling restoration device of project application scale and a control method thereof, the control and the restoration technology are organically combined and improved according to local conditions, so as to achieve the unification of the factors such as expense, effect, operability, etc.

Owner:TIANJIN UNIV

Organic-inorganic compound fertilizer particles and preparation method thereof

ActiveCN103910553ASimple production processRaw materials are easy to getFertilizer mixturesNutrientInorganic fertilizer

The invention discloses organic-inorganic compound fertilizer particles and a preparation method thereof. The organic-inorganic compound fertilizer particles comprise the following components in parts by weight: 25-45 parts of powder, 25-35 parts of plant ash and 5-10 parts of adhesive and the balance of one or several of a nitrogen fertilizer, a phosphate fertilizer, a potash fertilizer and trace-element fertilizers, wherein the powder is generated by performing microbiological treatment on kitchen wastes; the plant ash is prepared by combusting crop straws, drying, milling and screening. The organic-inorganic compound fertilizer particles are granular; because the inorganic fertilizer is coated with the fertilizer particles, and the plant ash has a good adsorption effect, so that the nutrient release speed is low, and the organic-inorganic compound fertilizer particles have a certain slow release benefits.

Owner:中节能国豪生物环保有限公司

Environment-friendly and energy-saving type diatom ooze coating and preparation method thereof

InactiveCN105399369ASolve the problem of secondary pollutionSolve pollutionCelluloseMethyl palmoxirate

The invention discloses an environment-friendly and energy-saving type diatom ooze coating. The coating comprises raw materials as follows: ash calcium powder, titanium dioxide, quartz sand, a thermal-insulating and reflective function material, nano-titanium dioxide, diatomite, hydroxypropyl methyl cellulose, sodium carboxymethyl starch, EVA (ethylene / vinyl acetate) glue powder, color powder and a mildew preventive. The environment-friendly and energy-saving type diatom ooze coating has excellent reflecting and emitting functions and formaldehyde decomposition capacity through application of the thermal-insulating and reflective function material and the nano-titanium dioxide, and the reflectivity, the hemisphere emissivity and the formaldehyde decomposition rate reach 0.85, 0.89 and 85% or higher respectively; compared with existing diatom ooze coatings, the environment-friendly and energy-saving type diatom ooze coating can reduce the room temperature by 4-5 DEG C, saves 40% of energy and solves the problem of secondary pollution and the like caused by re-releasing of formaldehyde and the like in a dry environment. The invention further discloses a preparation method of the environment-friendly and energy-saving type diatom ooze coating.

Owner:南通市乐佳涂料有限公司

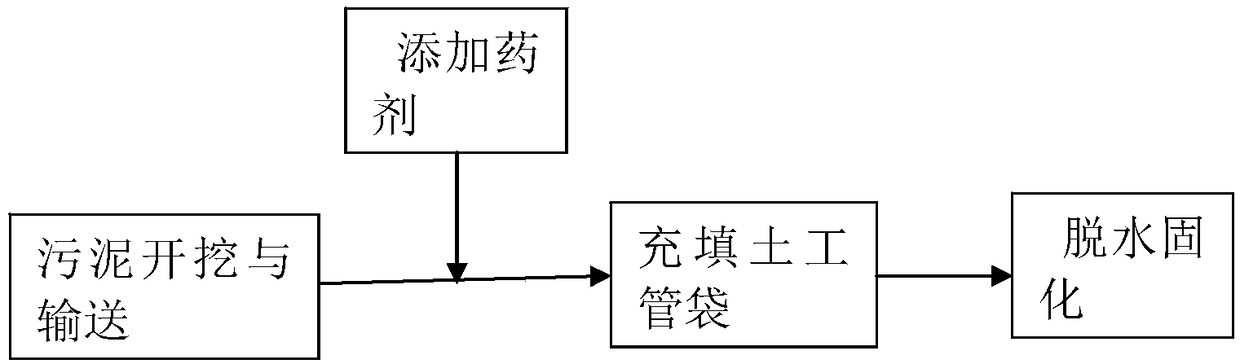

Construction method for dredging ditch sediment based on hydraulic punching and filling geotechnical pipe bag

InactiveCN108978577AContinuityClosedSludge treatment by de-watering/drying/thickeningClimate change adaptationSurface cleaningCut and fill

The invention relates to a construction method for dredging ditch sediments based on a hydraulic punching and filling geotechnical pipe bag and belongs to the technical field of dredging constructionof sediments in stinky water body ditches. The construction method for dredging the ditch sediments based on the hydraulic punching and filling geotechnical pipe bag includes the following steps of temporary storage yard construction, surface cleaning, sectional construction of cofferdam, construction drainage, assembly of a mud conveying pipeline, hydraulic punching and dredging of the sediments,adding medicament, geotechnical pipe bag filling, sludge dewatering and solidification and transportation or reuse of solidified soil. For the construction method, earth excavation is completed withthe help of hydraulic cutting; soil is then filled by a mud pump through the mud conveying pipeline to a large geotechnical pipe bag; in the dredging pipes, dredging mud and the medicament are fully stirred to produce a flocculation group to be precipitated in a geotechnical pipe belt, and then dehydration and solidification treatment of the sediments is achieved. The construction method for dredging the ditch sediments based on the hydraulic punching and filling geotechnical pipe bag has the advantages of continuity, integrated operation of dredging, conveying and filling, low cost, high construction efficiency, sealing property, no secondary pollution during transportation, good environmental protection performance, high construction precision, good effect, convenient operation and savedworking space.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

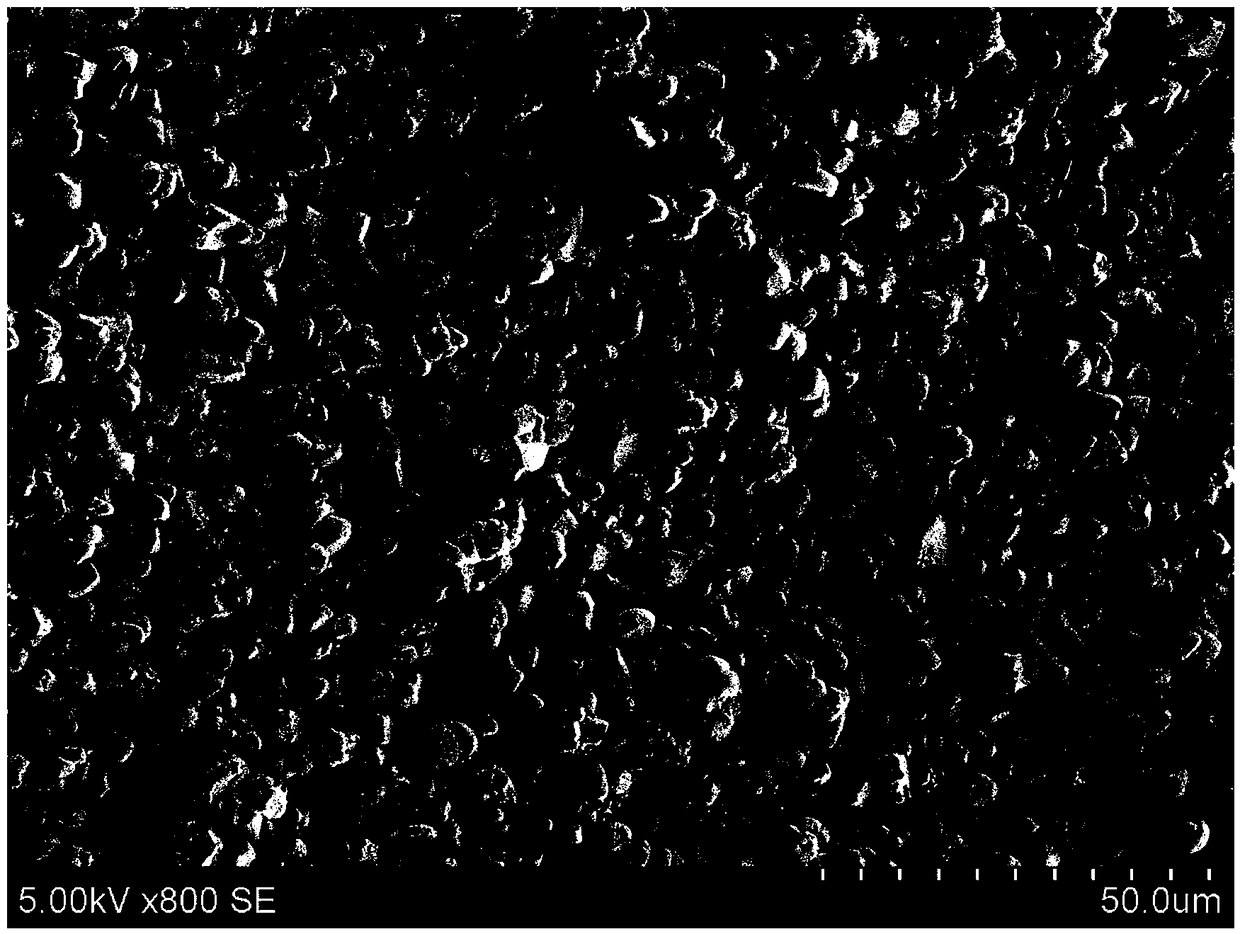

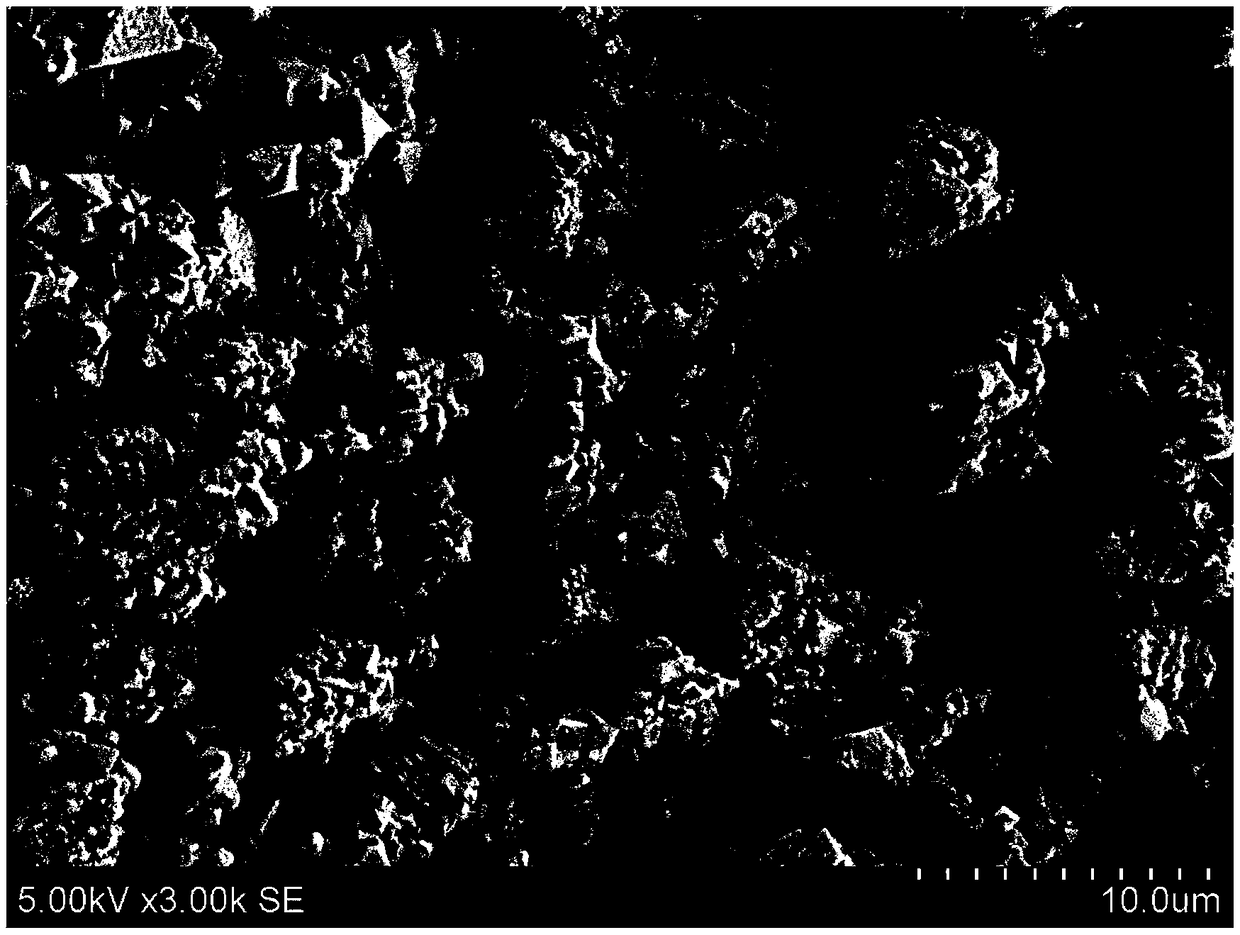

Stripping method for cathode material and current collector of waste ternary power lithium battery

InactiveCN109473748APerfect coating technologySmall particle size and easy to reuniteWaste accumulators reclaimingBattery recyclingEngineeringCathode material

The invention discloses a stripping method for a cathode material and a current collector of a waste ternary power lithium battery and belongs to the technical field of resource regeneration. The method comprises the steps of safety pretreatment, stripping of a battery housing, heat preservation, ultrasonic treatment and subsequent steps. According to the stripping method, a battery cathode pole piece is placed at a suitable temperature and thermally insulated for a certain period of time based on the thermal decomposition temperature of a cathode material binder so that the compacted binder is thermally decomposed, and then the cathode material and the current collector are efficiently and completely separated through ultrasonic treatment. The separated current collector is smooth in surface, no cathode material is remained, the current collector can be reused as a raw material for aluminum production, and the dried cathode material can be recycled and regenerated through a subsequenttreatment process.

Owner:BEIJING UNIV OF TECH

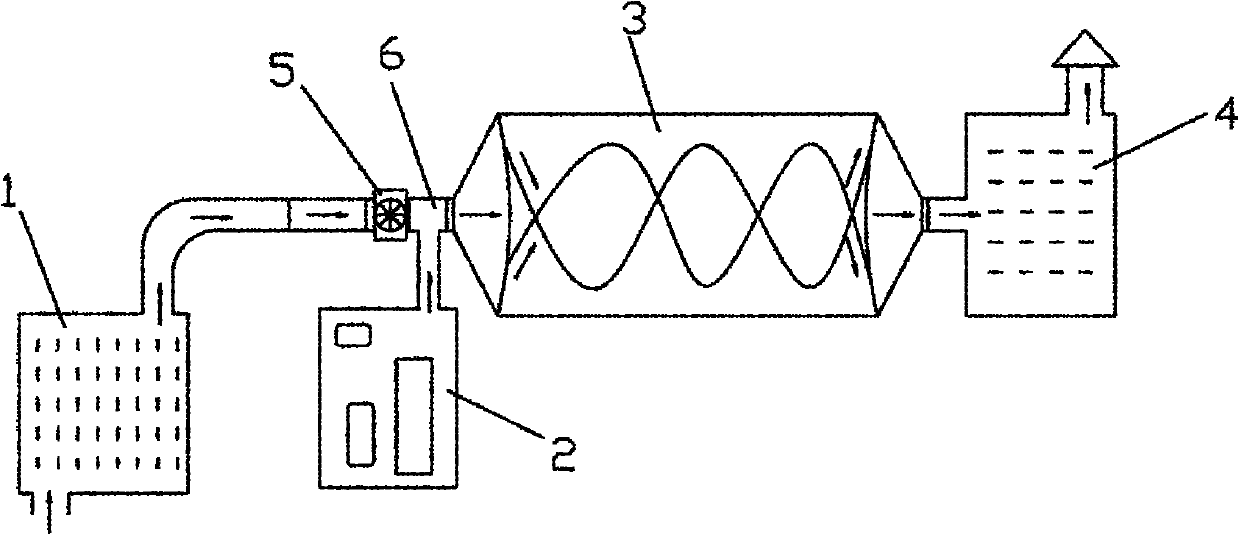

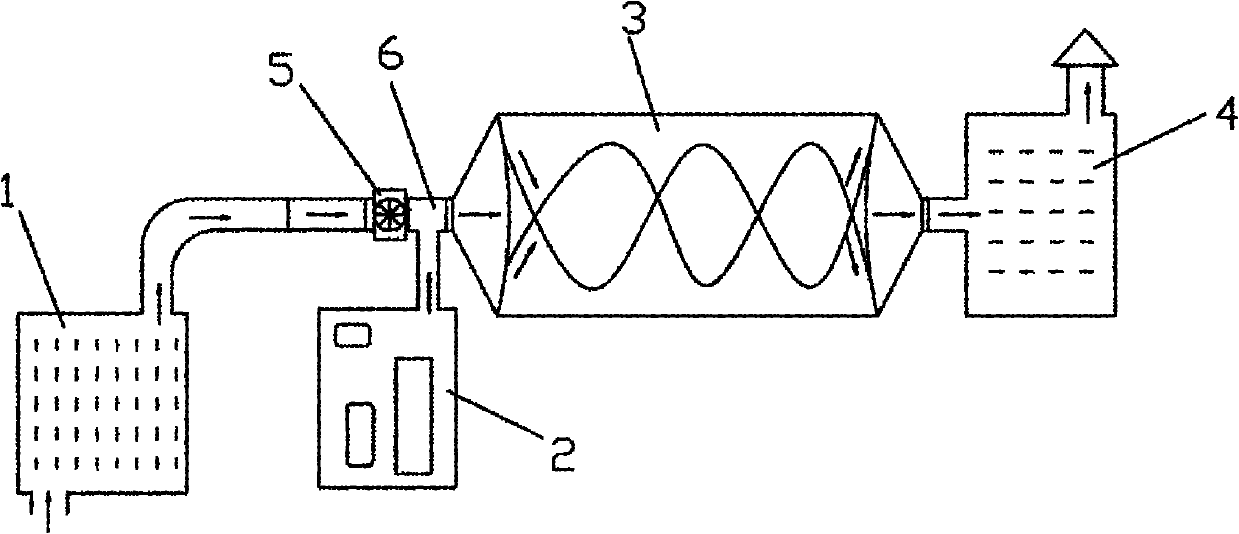

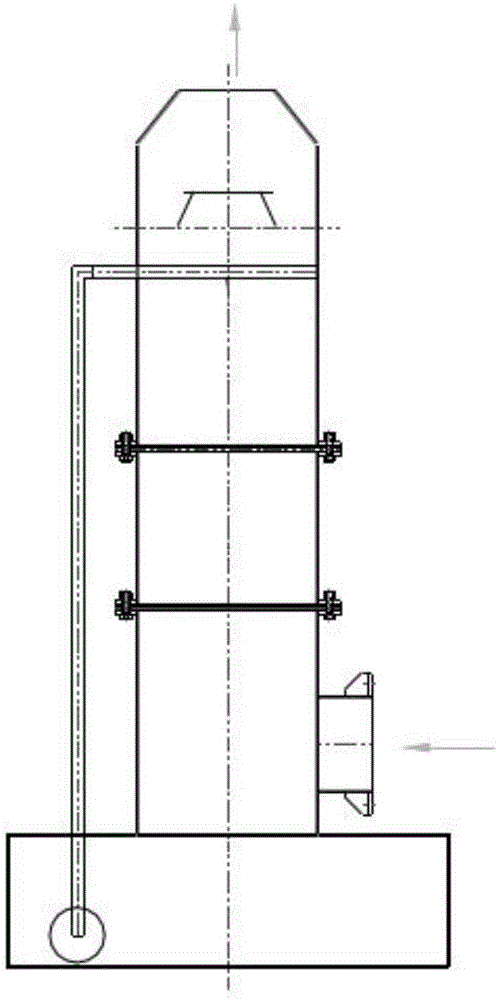

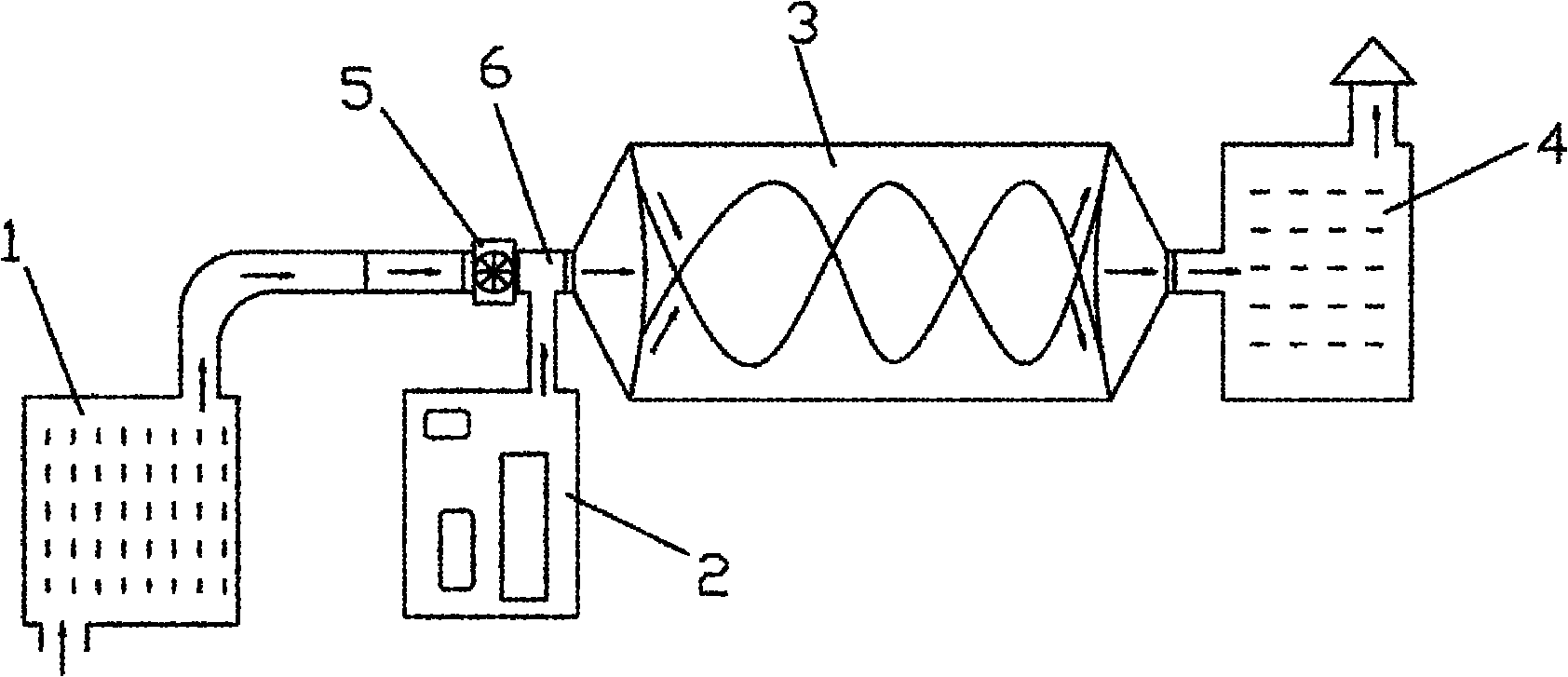

Rubber-mixing waste gas deodorizing and purifying device and method through dry oxidation

InactiveCN102000484AHigh removal rateOvercoming the disadvantages of insufficient exposureDispersed particle filtrationGaseous substancesBaghouseExhaust fumes

The invention relates to a rubber-mixing waste gas deodorizing and purifying device and method through dry oxidation. The purifying device comprises a bag collector, an ozone generator, an oxidation reactor and a gas adsorptive oxidation device, wherein the bag collector is connected to the air outlet of the oxidation reactor through a draught fan; the ozone generator is connected to the air outlet of the oxidation reactor; the air outlet of the oxidation reactor is connected to the gas adsorptive oxidation device through a pipeline; and the gas adsorptive oxidation device is provided with a purified gas exhaust outlet. The purifying method comprises the following steps: introducing the rubber-mixing waste gas into the bag collector to carry out flue gas dust removal; generating ozone through the ozone generator; mixing the gas which is purified by the bag collector with the ozone to perform an oxidation reaction; and adsorptively oxidizing the gas which is subject to the oxidation reaction. The rubber-mixing waste gas deodorizing and purifying method has a simple device, stable operation, high purification efficiency and low cost, and does not have the problem of secondary pollution.

Owner:浙江中兵环保股份有限公司

Biological organic fertilizer for aquaculture and preparation method thereof

InactiveCN105272468ASolve the problem of secondary pollutionInhibition of reproductionFertilizer mixturesAquatic animalOxygen

The invention discloses a biological organic fertilizer for aquaculture and a preparation method thereof. The biological organic fertilizer is prepared by the following materials in parts by weight: 10 to 80 parts of special organic fertilizer, 0.8 to 20 parts of auxiliary materials, and 1 part of fermenting agent. The biological organic fertilizer has the advantages that the special organic fertilizer for aquaculture is prepared by the fermentation of chicken manure, duck manure, pigeon manure and other auxiliary materials through the biological fermentation technique, and aims at the problems of existing shortage of domestic protein feed resources, a large feeding amount of aquaculture protein feed, high cost, easy pollution to culture water by remained feed and manure of aquatic animals, and the like; the organic fertilizer can be fed to the aquatic animals or be used as the culture medium to culture diatom and spirulina in an oriented way in the aquaculture process, the harmful matters in water are converted into the harmless sub-structure, and a large amount of oxygen is released, so that the aquaculture water is purified, a large amount of foods is provided for the cultured animals, and the feeding amount of protein feed is reduced.

Owner:钦州市中航科技咨询有限公司

Method for producing agricultural chitosan and active calcium fertilizer by utilizing crawfish

ActiveCN102050886ASimple production processSolve the problem of secondary pollutionAnimal corpse fertilisersClimate change adaptationFleshFertilizer

The invention discloses a method for producing agricultural chitosan and an active calcium fertilizer by utilizing crawfish, which comprises the following steps of: mixing residual bodies of the crawfish from which flesh is removed with mixed acid solution, performing leaching at 30 to 60 DEG C, performing solid-liquid separation after the leaching is finished, and washing and drying a solid part to obtain the agricultural chitosan; and mixing a liquid part with washing liquid, and concentrating the mixed solution to obtain the active calcium fertilizer. The method for producing the agricultural chitosan and the active calcium fertilizer by utilizing the crawfish ensures a simple production process, avoids pollutions to the environment, solves the problems of secondary pollutions of crawfish deep-processing and high cost of the agricultural chitosan, and can realize the deferred production of the novel active calcium fertilizer.

Owner:SHANGHAI GUANFA MARINE BIOTECH CO LTD

Method for treating silt, sludge and/or nocuous hurtful solid waste by employing biological cured protease and use of product thereof

ActiveCN101250018ASolve the problem of secondary pollutionTimely and effective curing treatmentSolid waste managementCement productionProteinase activitySludge

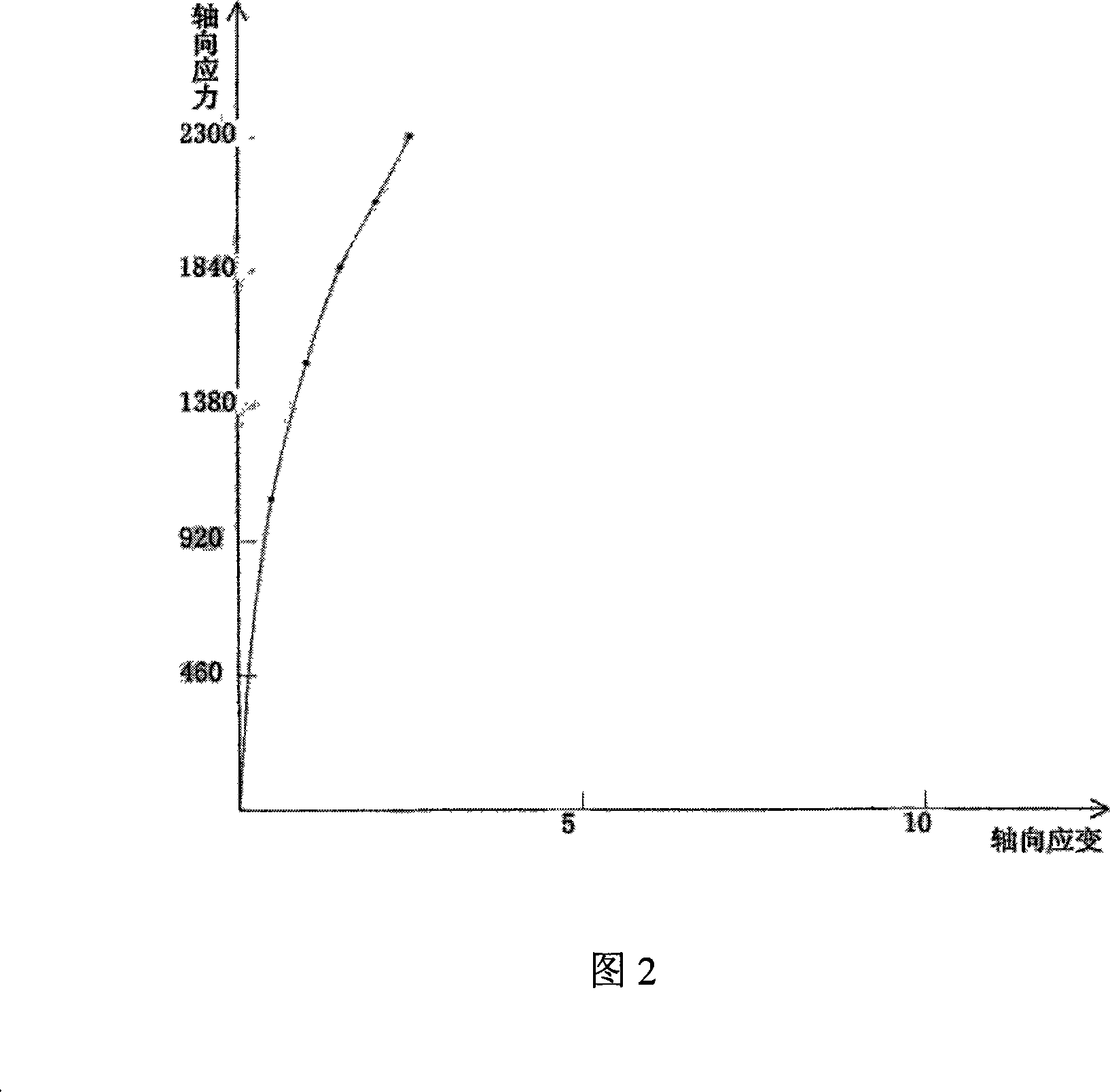

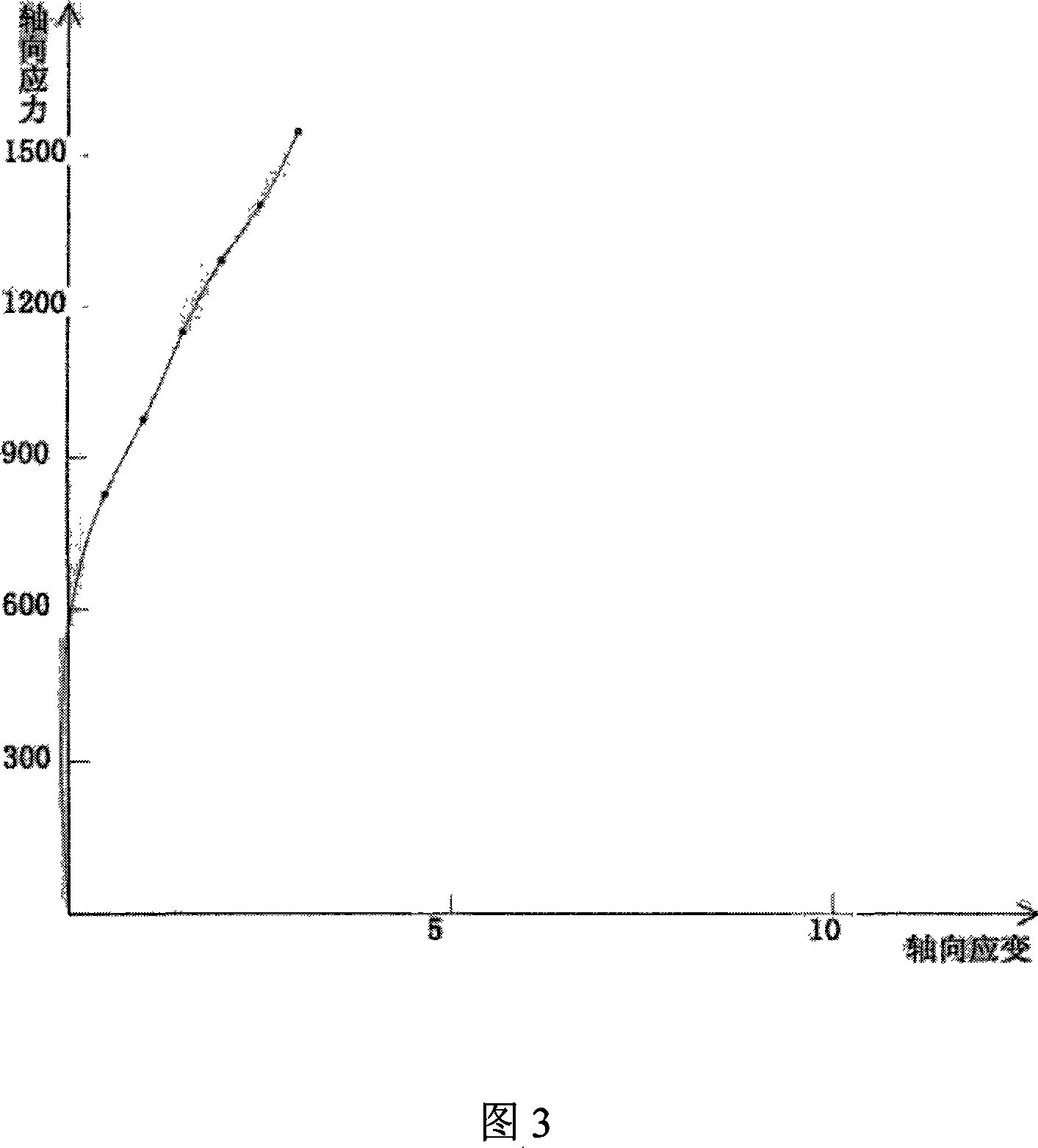

The invention relates to a method for treating silt, sludge and / or poisonous harmful solid wastes by bio-solidified protease, and also relates to usage of obtained object by the treatment method. A method for treating silt, sludge and / or poisonous harmful solid wastes by bio-solidified protease is characterized in that the method comprises steps of 1) controlling-water and drying the silt, the sludge and / or the poisonous harmful solid wastes disintegrated by certain particle size for solidification, 2) preparing the silt, the sludge and / or the poisonous harmful solid wastes for solidification to form soil sample under being processed, 3) diluting stock solution of the bio-solidified protease by water into diluted solution of the bio-solidified protease, then adding to the soil sample to uniformly stir and mix into enzyme-soil mixture with optimum moisture content,4) stowing the enzyme-soil mixture and enclosing. The method resolves the treatment problem of the present silt, sludge and poisonous harmful solid wastes.

Owner:顾全

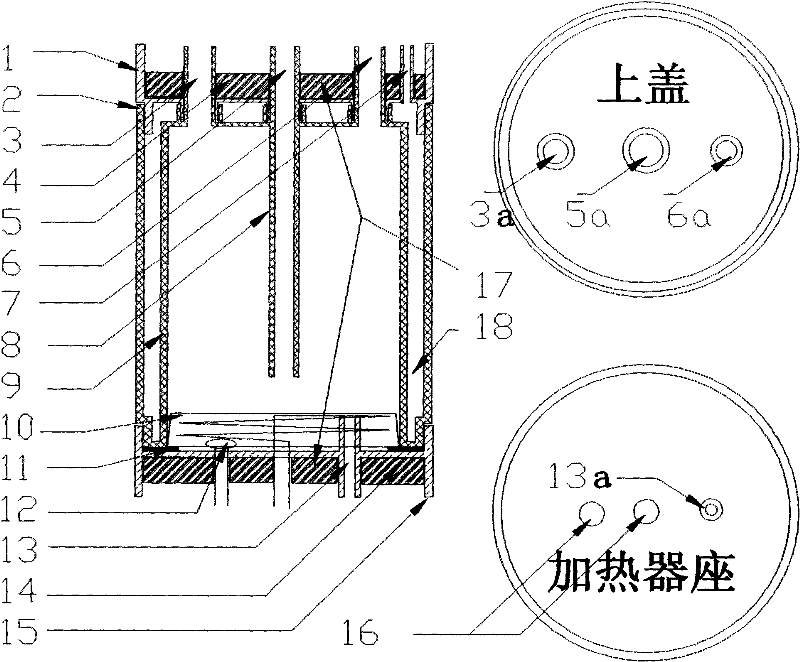

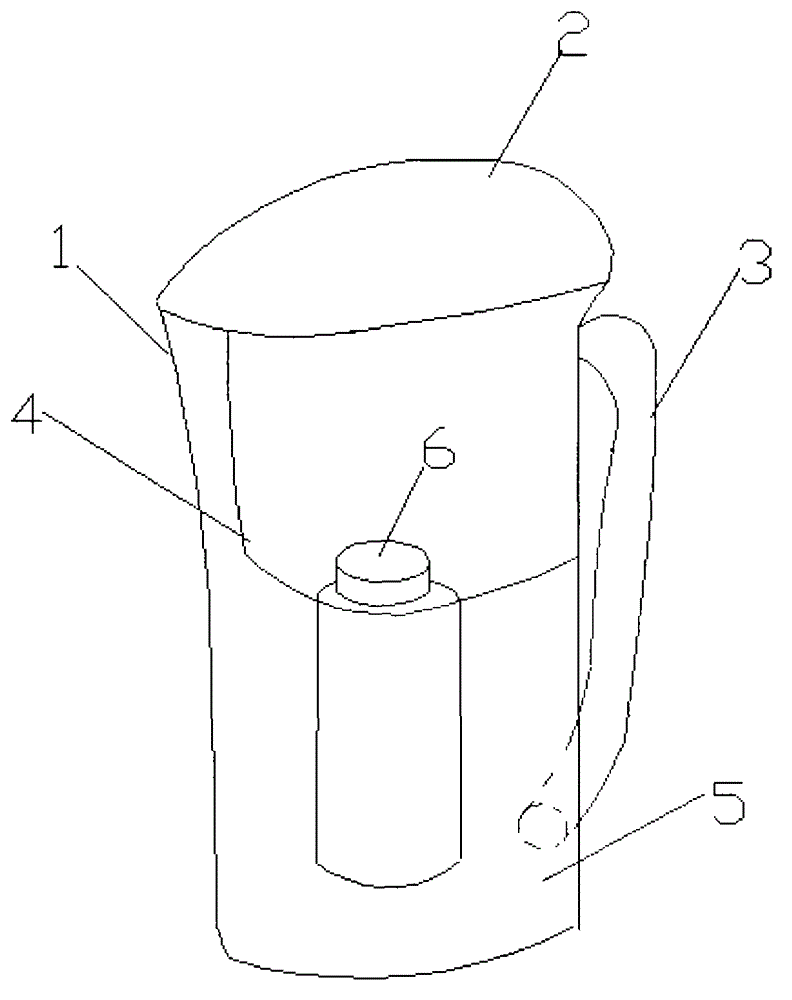

Vacuum hot liner of injection type water dispenser

InactiveCN102160758AShorten the timeReduce heating effectWater/sewage treatment by magnetic/electric fieldsBeverage vesselsEngineeringHome appliance

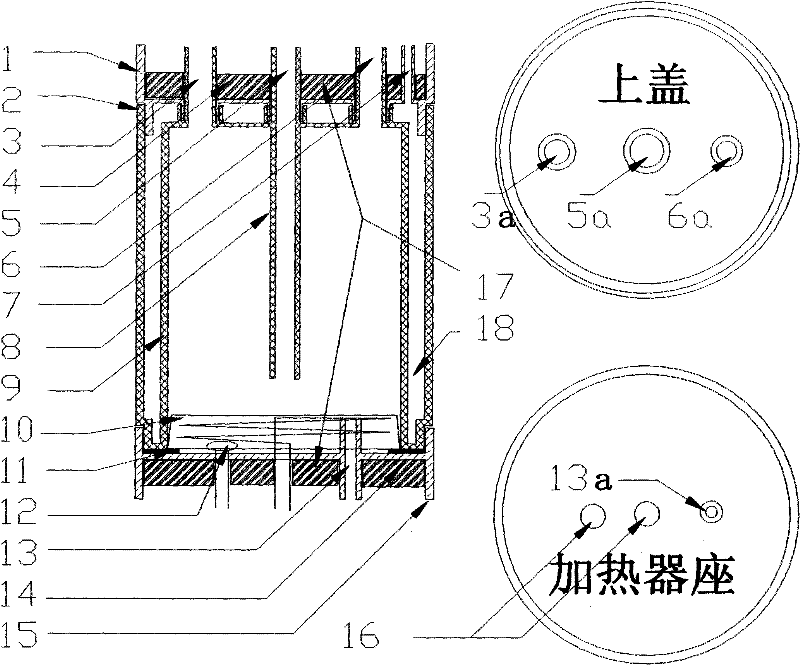

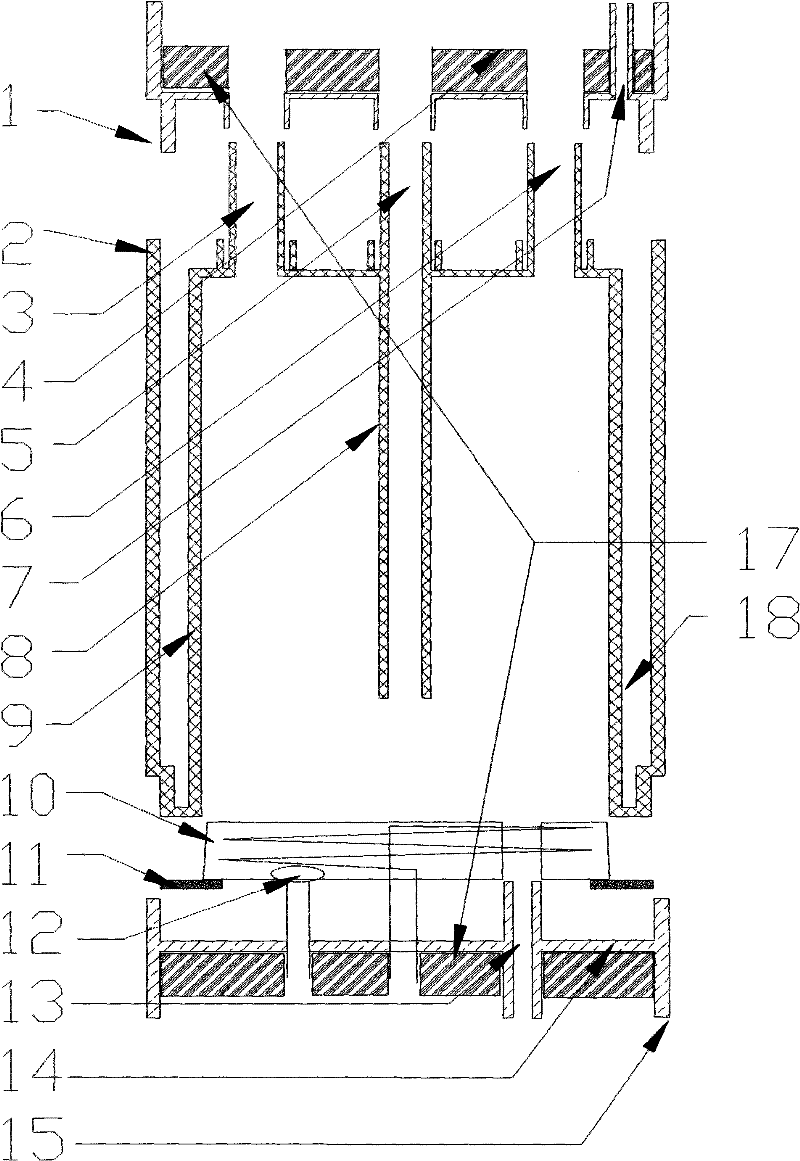

The invention relates to the field of water home appliances and heaters, in particular relating to a vacuum hot liner of an injection type water dispenser. The vacuum hot liner comprises an upper cover, a vacuum liner body, a magnetizer, an electric baking pan, a temperature controller, a base and other main parts. The upper cover and the vacuum liner body are injected and molded by an outer wall and an inner wall, and the vacuum liner body is formed through ultrasonic heat seal and evacuation by virtue of a vacuum exhaust tube. The vacuum liner body and the base are spirally twisted together so as to form a hot liner main body. An upper magnet installing position and a lower magnet installing position are arranged above the upper cover and below the base respectively, so as to form a magnetization device with a vacuum hot liner. An installing position of the electric baking pan is arranged above the base. The bottom surface of the electric baking pan is provided with a temperature controller. The upper cover is provided with a steam exhaust tube. The vacuum hot liner is additionally provided with a telescopic self-decompression air bag, thus forming a hot liner of the water dispenser. The hot liner has functions of fully-closed heating, vacuum heat insulation, and magnetized soft water.

Owner:宁波龙巍环境科技有限公司

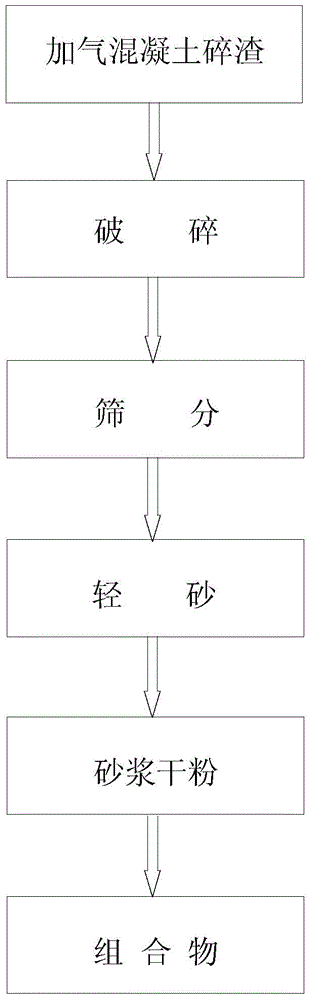

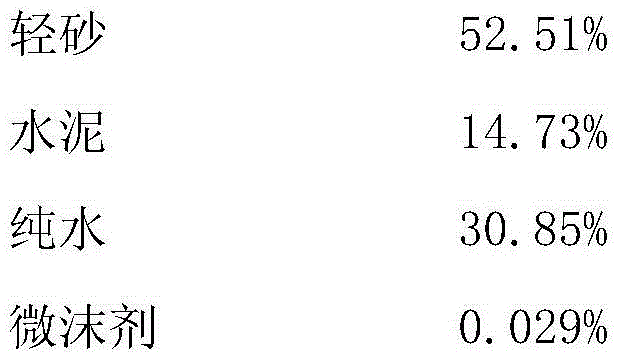

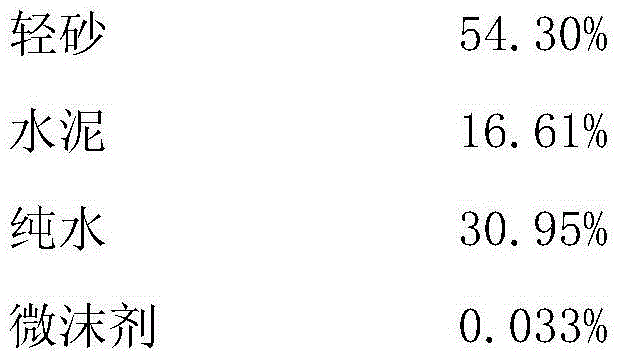

Aerated concrete debris-based masonry mortar for thermal-insulation masonry and preparation method thereof

InactiveCN103553488ASimple production processEasy maintenanceThermal insulationConstruction aggregate

The invention discloses an aerated concrete debris-based masonry mortar for thermal-insulation masonry and a preparation method thereof. According to the invention, aerated concrete block broken waste which is used as a base material undergoes crushing and screening to prepare a mortar aggregate-lightweight sand dry powder; and cement, pure water and a micro-foaming agent are added in proportion to prepare a hydraulic gelled composition. By the above technical scheme, the defect that various mortars for present self-insulation wall masonry has large heat conductivity coefficient and poor thermal insulation performance, it is easy to form cold / heat bridge effect in masonry walls and the overall thermal insulation performance of self-insulation walls is reduced is overcome. The masonry mortar provided by the invention is suitable for thermal insulation masonry or wall masonry, is more suitable for self-insulation masonry or wall masonry, and also can be used for troweling, plastering and seaming.

Owner:HUNAN UNIV OF SCI & TECH

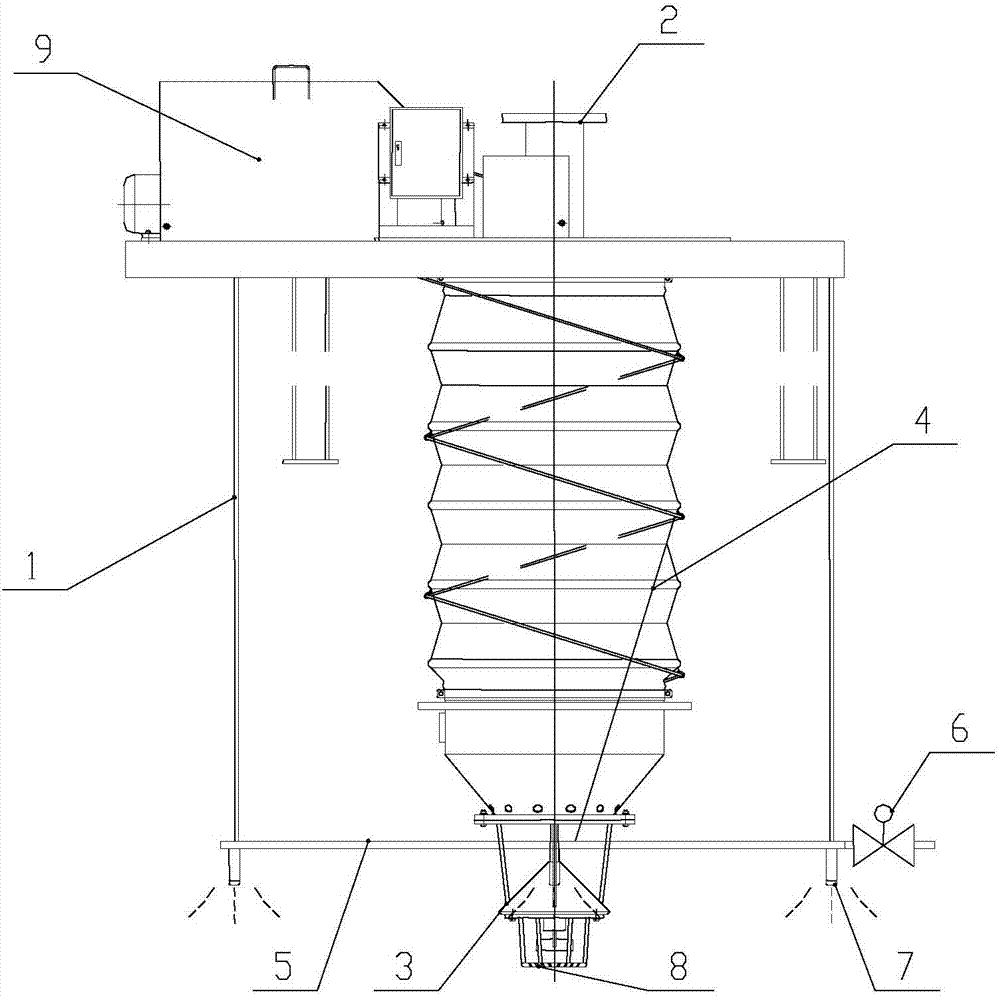

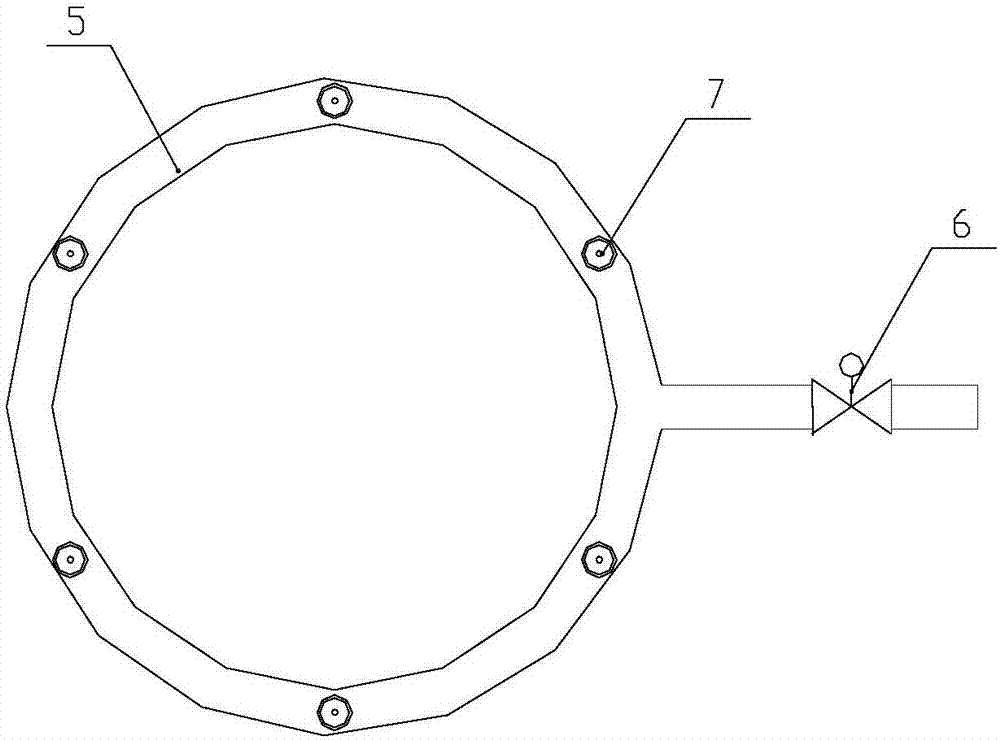

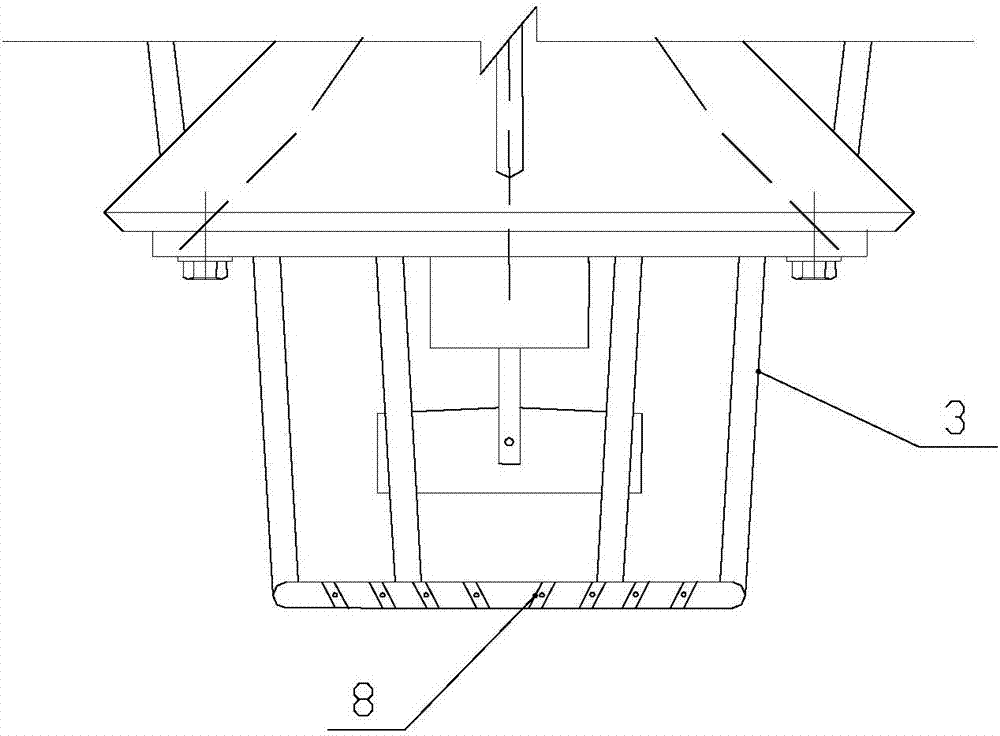

Water curtain type dust-free ash discharge device

PendingCN107126793ASolve the problem of secondary pollutionAvoid driftingDispersed particle filtrationUsing liquid separation agentSpray nozzleEngineering

The invention discloses a water curtain type dust-free ash unloading device, which comprises a frame, an ash inlet located above the frame, and an ash unloading nozzle for outputting dust. The cylinder is connected with the ash inlet; under the frame, there is a ring-shaped water supply pipe located on the outside of the telescopic cylinder. The water inlet of the ring-shaped water supply pipe is equipped with an electric ball valve, and several high-pressure nozzles are evenly distributed on the ring-shaped water supply pipe. , the high-pressure nozzle sprays to form an annular water mist under the annular water supply pipe. In the present invention, the annular water mist sprayed by the high-pressure nozzle provided on the annular water supply pipe is used. The annular water mist is located around the ash discharge nozzle, which effectively avoids the secondary dust problem during the ash discharge process and solves the problem of the existing unloading device. The problem of secondary pollution is easy to occur; at the same time, the present invention realizes water mist dust suppression outside the equipment, effectively eliminating the dust compaction phenomenon inside the equipment, thereby eliminating the impact of the dust compaction phenomenon on the equipment.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

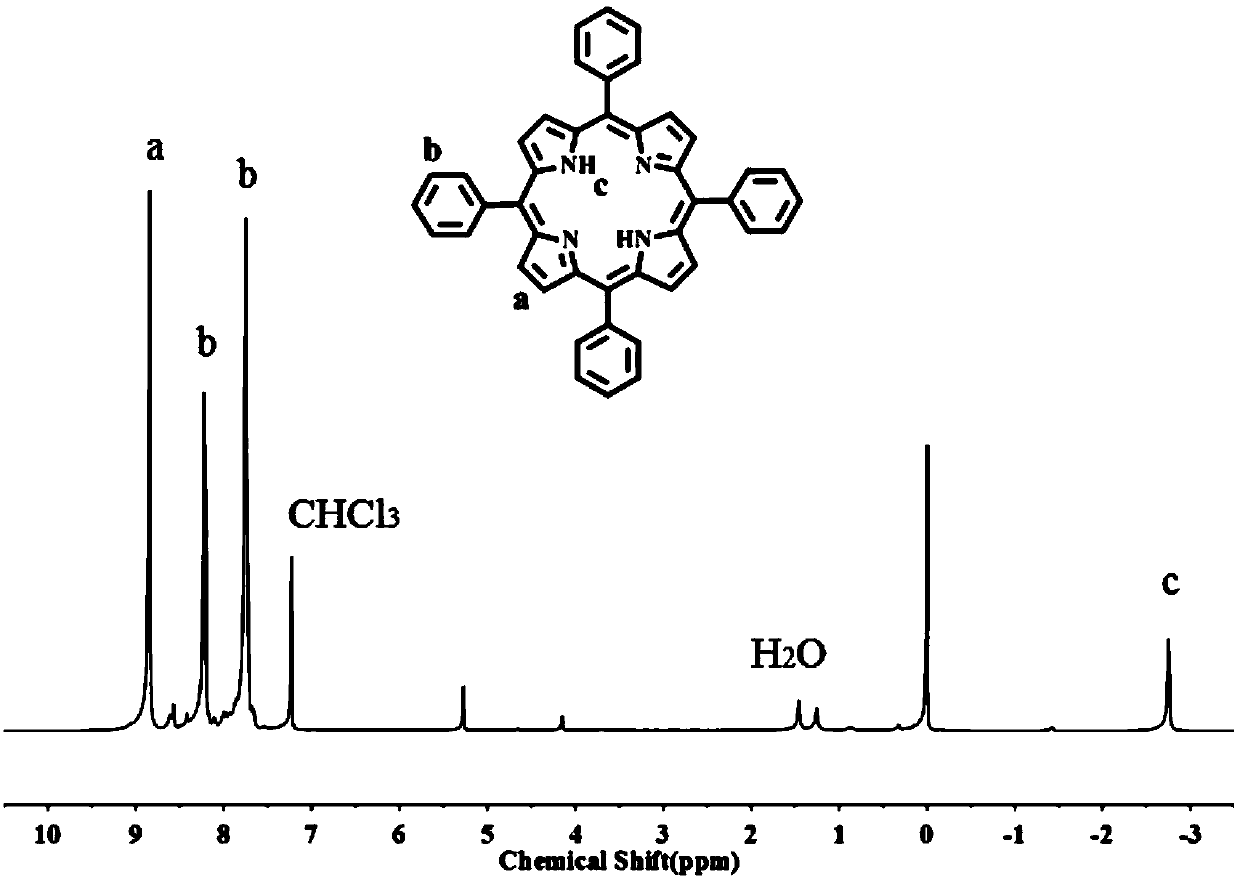

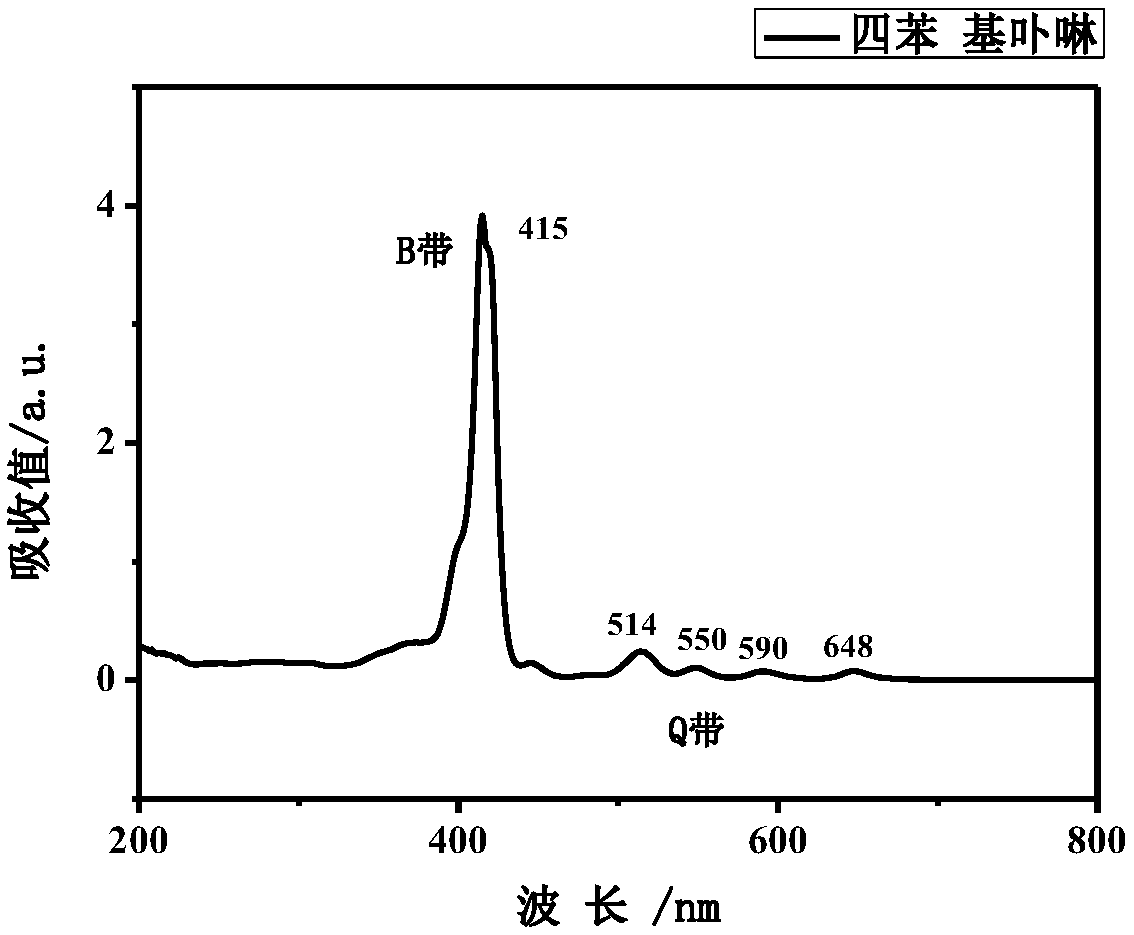

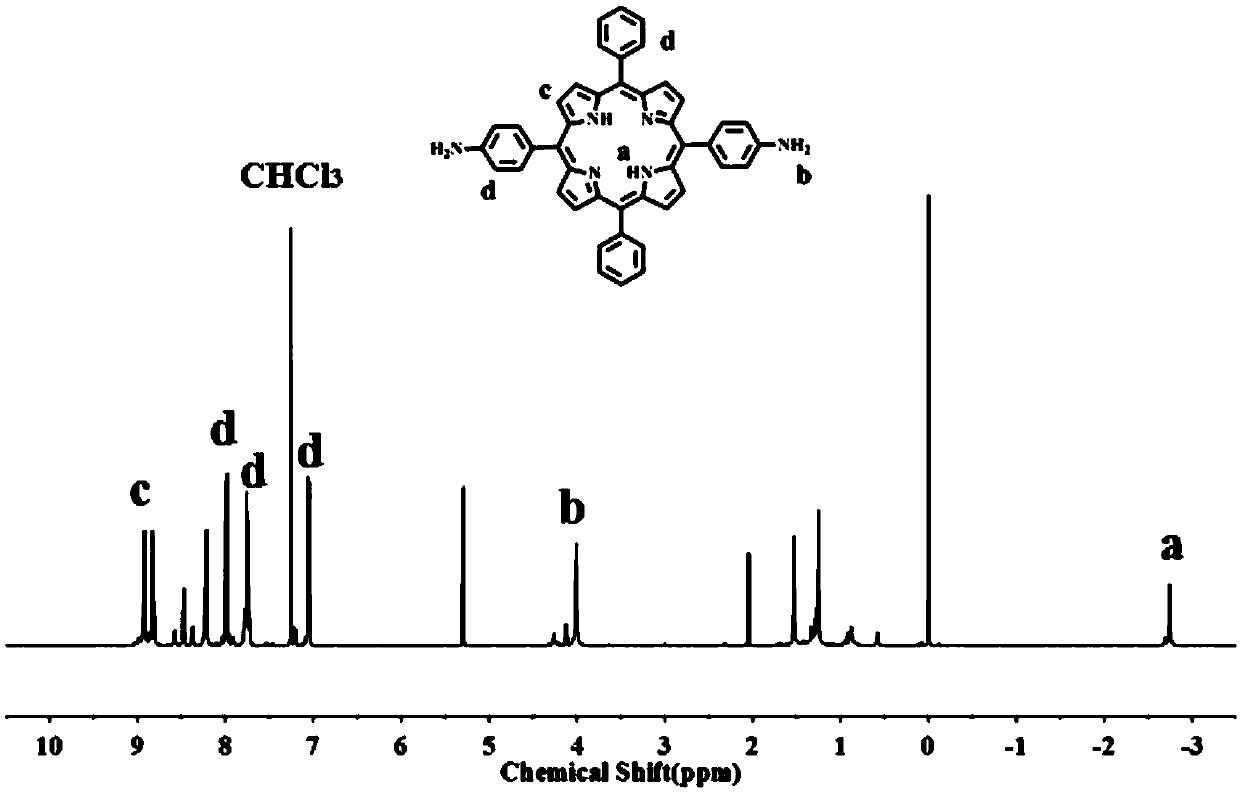

Chain porphyrin polymer and synthetic method thereof

InactiveCN110317205AVisible light catalyticImprove stabilityOrganic chemistryWater/sewage treatment by irradiationPolymer scienceStructural unit

A chain porphyrin polymer is a chain-structure polymer formed by alternate chaining of diaminophenyl porphyrin and terephthalaldehyde through aldehyde ammonia condensation polymerization. The chain porphyrin polymer and a preparation method thereof belongs to the field of macromolecular syntheses. The chain porphyrin polymer is used for catalyzing and degrading organic pollutants in wastewater. Asynthetic method of the chain porphyrin polymer utilizing macromolecular condensation polymerization reaction, wherein tetraphenylporphyrin is nitrified through fuming nitric acid to obtain dinitrophenyl porphyrin, then the dinitrophenyl porphyrin is reduced to the diaminophenyl porphyrin, under protection of N2, the diaminophenyl porphyrin obtained from separating by column chromatography and terephthalaldehyde are catalyzed by glacial acetic acid and subjected to terephthalaldehyde condensation to form Schiff base (-C=N-), and the chain-structure polymer with phenyl porphyrin as a structureunit is generated. The synthesized chain porphyrin polymer is high in thermal stability, recyclable and promising in application prospect.

Owner:CHANGCHUN UNIV OF SCI & TECH

Fertilizer and water type bait for aquaculture and preparation method thereof

InactiveCN105272494ASolve the problem of secondary pollutionInhibition of reproductionFertilizer mixturesAquatic animalAquatic product

The invention discloses a fertilizer and water type bait for aquaculture and a preparation method thereof. The fertilizer and water type bait is prepared by the following materials in parts by weight: 10 to 80 parts of special organic fertilizer, 0.8 to 20 parts of auxiliary materials, 1 part of fermenting agent, and 2-20 parts of microalgae. The fertilizer and water type bait has the advantages that the special organic fertilizer for aquaculture is prepared by the fermentation of chicken manure, duck manure, pigeon manure and other auxiliary materials through the biological fermentation technique, and aims at the problems of shortage of existing state protein feed resources, a large feeding amount of aquaculture protein feed, high cost, easy pollution to culture water by remained feed and manure of aquatic animals, and the like; the organic fertilizer can be fed to the aquatic animals or be used as the culture medium to culture diatom and spirulina in an oriented way in the aquaculture process, the harmful matters in water are converted into the harmless sub-structure, and a large amount of oxygen is released, so that the culture water is purified, a large amount of foods is provided for the cultured animals, and the feeding amount of protein feed is reduced.

Owner:钦州市中航科技咨询有限公司

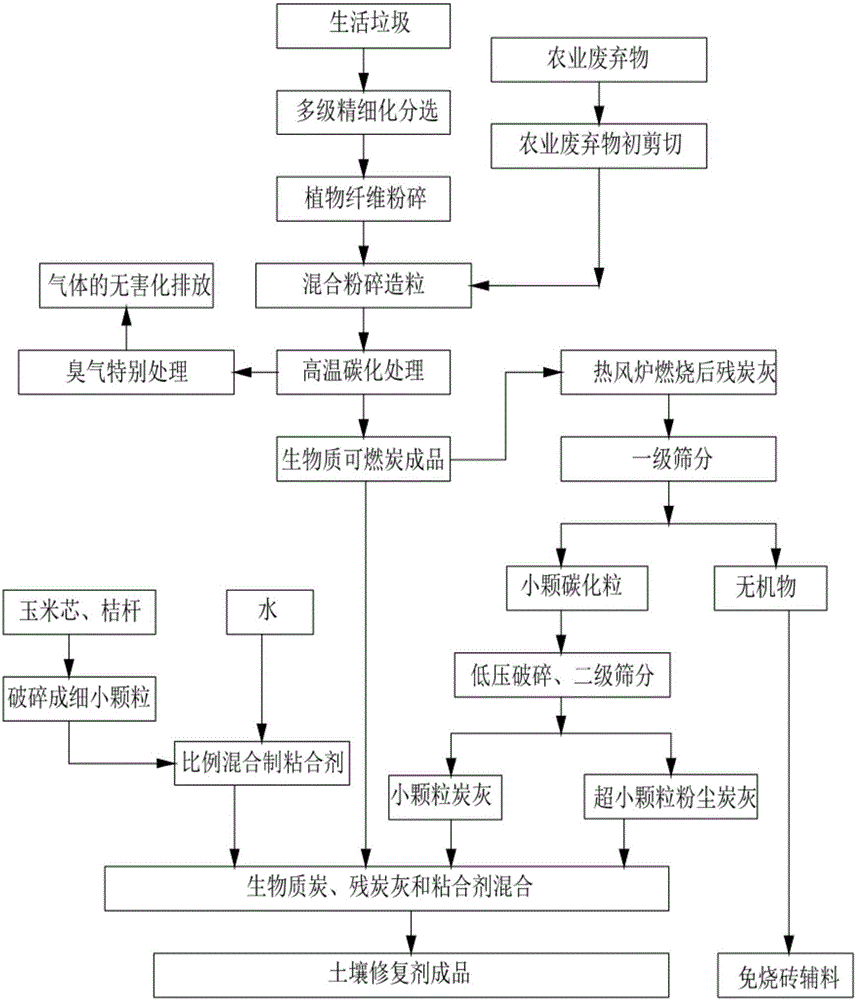

Method for preparing soil remediation agent through biomass charcoal and residual ashes

InactiveCN106433686AAvoid mixingImprove adsorption capacityAgriculture tools and machinesOrganic fertilisersFiberSoil remediation

The invention discloses a method for preparing a soil remediation agent through biomass charcoal and residual ashes. The method comprises six environment-friendly processes including the following steps of multistage refinement separating; smashing plant fiber; mixing, smashing and pelleting plant fiber powder and agricultural straw waste particles; carbonizing plant fiber and straw mixing particles; burning biomass combustible carbon for preparing ashes; sieving carbon ash particles and preparing the soil remediation agent with the biomass charcoal. The method is characterized by refinement separating organic fibers in household garbage and agricultural straw wastes, mixing and smashing, preparing to obtain the biomass charcoal through a hot blast stove, sieving the carbon ash particles, and mixing with the biomass charcoal to prepare the remediation agent. The method has the remarkable effects that resourceful treatment of the household garbage and the agricultural straw wastes is realized, the secondary pollution problem is effectively solved, the environment is protected due to no emission is generated during a production process, and the harmonious coexistence of mankind existence, agricultural production, soil ecological remediation and circulation ecology is really realized.

Owner:重庆冠虹环保科技有限公司

Method for preparing high-quality and odorless regenerated rubber

InactiveCN104004223ASolve the problem of secondary pollutionReduce wearPlastic recyclingMagnetic separationPulverizerEngineering

The invention discloses a method for preparing high-quality and odorless regenerated rubber. The method comprises the steps of crushing and magnetic separation and chemical desulfurization, wherein the step of crushing and magnetic separation comprises the processes of crushing lumpy tires by a coarse crusher, sieving, so as to obtain coarse granules, carrying out first-time magnetic separation and second-time magnetic separation, so as to obtain pure coarse rubber granules and recovered steel wires, crushing the pure coarse rubber granules by a crushing machine, and then, sieving, thereby obtaining tread rubber powder; the step of chemical desulfurization comprises the processes of adding the tread rubber powder and auxiliaries, wherein a formula comprises the following ingredients in parts by weight: 1,200-2,000 parts of tread rubber powder, 120-200 parts of vegetable oil asphalt, 2-10 parts of activator, 10-40 parts of carbonate and 100-400 parts of water. According to the method, iron wires can be effectively separated, so that the wear to equipment is reduced, and the quality of the prepared tread rubber powder is good; the existing softener is replaced with the vegetable oil asphalt, and meanwhile, carbonate is added, so that the prepared product reaches the class-A recycled rubber standard of the national standard, is environmental-friendly and odorless and is not subjected to bluing.

Owner:CHONGQING JUYI RUBBER PROD

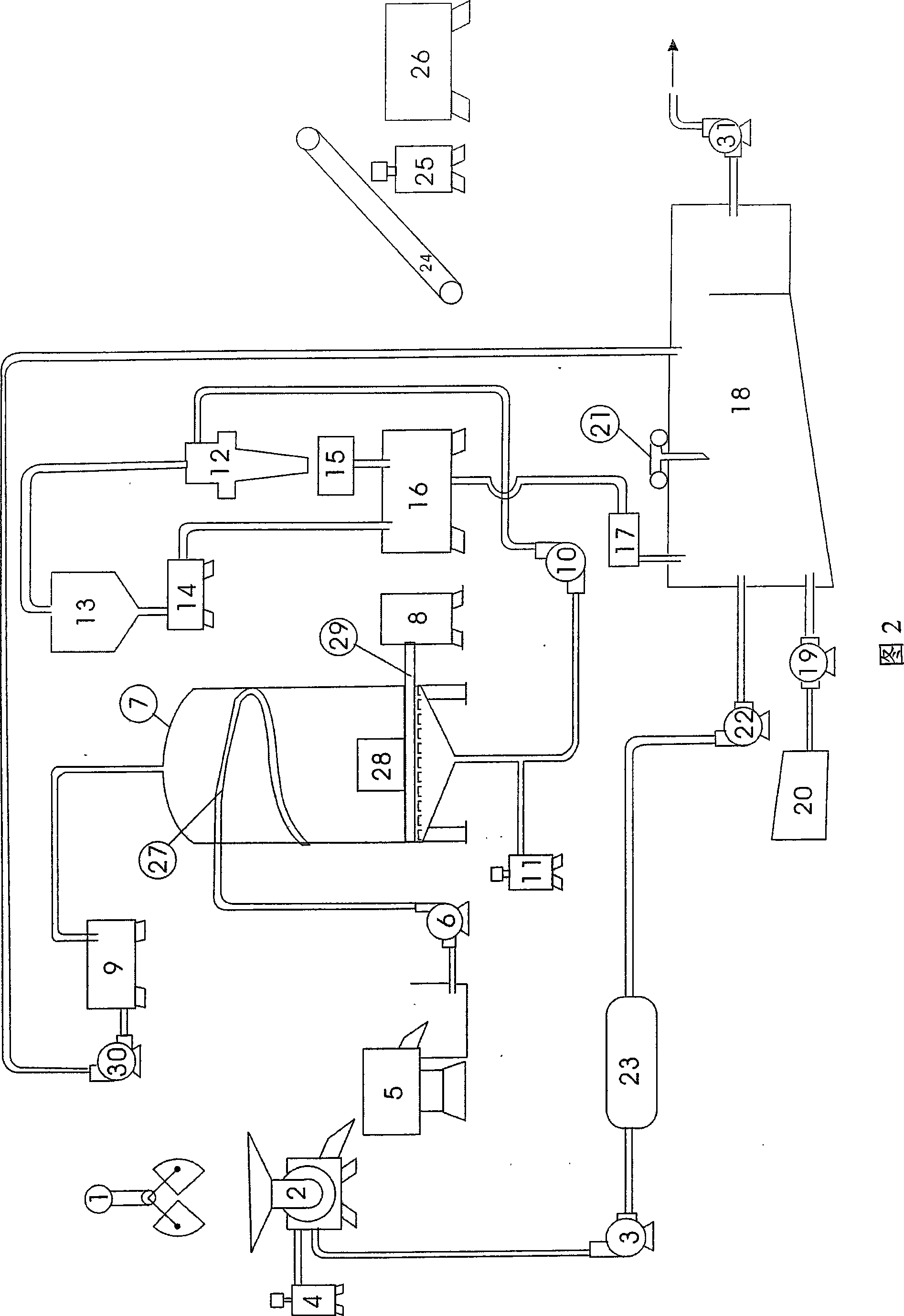

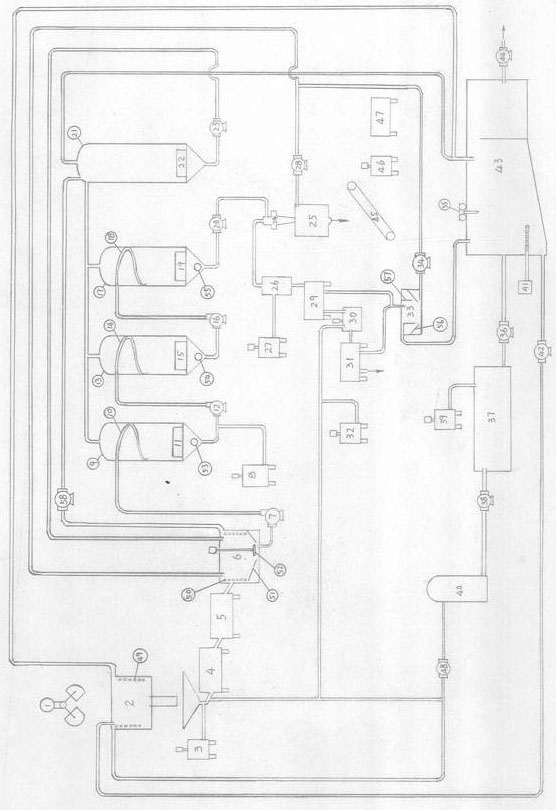

Treatment method and treatment system capable of realizing zero-emission purification of high-viscosity polymer-containing oil silt

PendingCN111807677ASolve the failure to meet the standard utilizationSolve the problem of secondary pollutionWater/sewage treatment by centrifugal separationSludge treatment by thermal conditioningPre treatmentBuilding material

The invention relates to a treatment method and a treatment system for zero-emission purification of high-viscosity polymer-containing oil silt. The treatment method comprises the following implementation steps that: heating and overflowing are conducted in a pretreatment tank; water and chemicals are added into primary and secondary impurity removal machines to remove impurities; heating, homogenizing and overflowing are conducted in a heating homogenizing tank; a slurry pump is connected in series with a first-stage cavitation oil removal separation tank, a second-stage cavitation oil removal separation tank and a third-stage cavitation oil removal separation tank to treat the oil silt; a material from an upper outlet of a fine sand cyclone separator supplies liquid to centrifuges through a centrifugal machine liquid supply buffer tank, and a lower outlet discharges clean sand through a clean sand dehydration device; a primary fine mud treatment tank is used for receiving and treating oil water overflowing around; the effluent of the first-stage centrifuge and the effluent of the second-stage centrifuge enter a second-stage fine mud treatment tank to be treated; secondary centrifugal treatment is conducted on the fine mud through a mud stirring tank, and then clean mud is discharged; an aeration system and an oil scraping machine are mounted in an oil-water separation tank; awater pump is connected with a sewage treatment tank to form closed circulation through a heating furnace, and oil is output; and a building material cured product is prepared from clean silt. According to the invention, zero-emission purification treatment is completely achieved, and the problem of secondary pollution caused by purification treatment of the high-viscosity polymer-containing oilsilt is solved.

Owner:TIANJIN TAIXING ENG TECH CO LTD

Pollution-free oil-containing mud cleaning treatment method and treatment system thereof

InactiveCN101428247BSolve the problem of secondary pollutionSimple purification processWet separationResource recoverySlurry

The invention relates to a pollution-free oily sediment purification treatment method and a treatment system, and the implementation steps are as follows: adopting a mechanical feeding device for conveying oily sediment to a miscellany removing and sorting device, filtering out and removing the miscellanies therein, perfusing hot water and a reagent into the oily sediment; evenly regulating the oily sediment through mechanical rolling; treating oil, water and sediment in an input tank through a cavitation and air flotation three-phase separator, so as to realize the three-phase separation of the oil, the water and the sediment, and discharging most of the separated oil; separating the sediment through a cyclone separator, and discharging net sand; separating slurry through a centrifuge, discharging net mud; separating fine mud from the water through a pressing filter, discharging net fine mud; separating the oil-water through natural ascending and descending, outputting the oil, and continuously heating water for the cyclic utilization; and curling and molding the discharged net sand and net mud according to routine. The invention realizes the resource recovery of crude oil in oily sediment and reduces the cost for purifying and treating oily sediment effectively, and the purified sediment is made into cured resin used for building materials.

Owner:TIANJIN TAIXING ENG TECH CO LTD

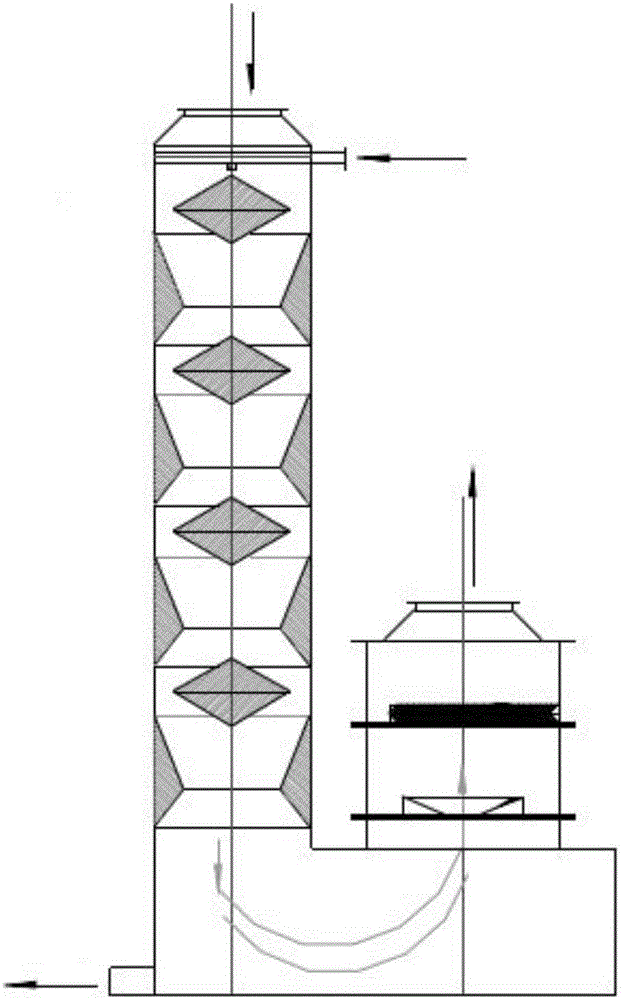

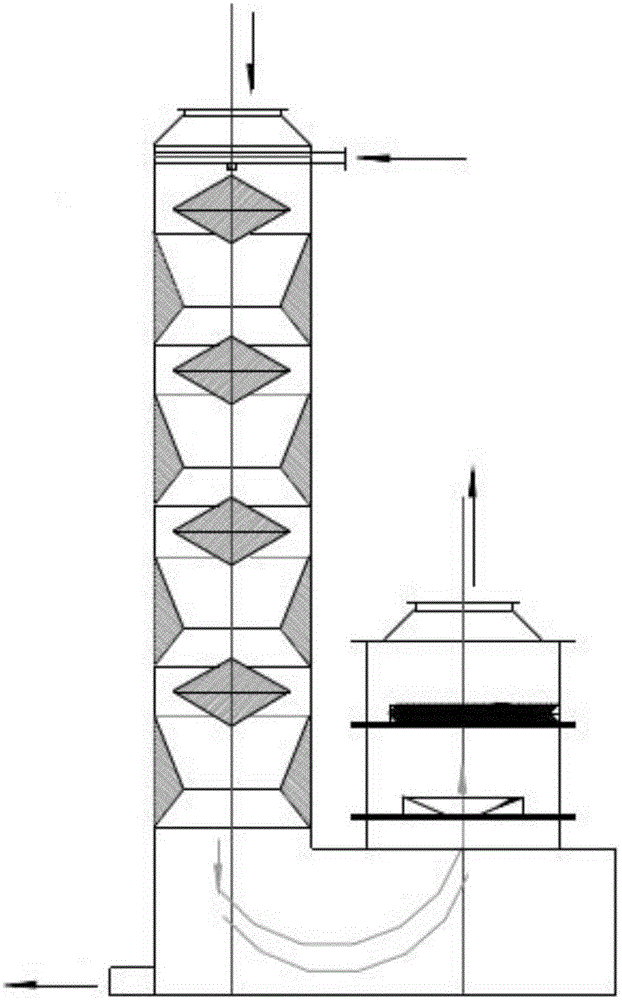

DC composite tower electrostatic dust collection integrated flue gas treatment system

PendingCN106039971ASmall footprintLow investment costDispersed particle separationExternal electric electrostatic seperatorParticulatesEngineering

The invention discloses a DC composite tower electrostatic dust collection integrated flue gas treatment system including a DS multi-phase desulfurization tower and a CST turbogrid tower; the top end of the DS multi-phase desulfurization tower communicates with a boiler via a pipeline, and the lower end of the DS multi-phase desulfurization tower is arranged on a sedimentation tank and communicates with the sedimentation tank; the lower end of the CST turbogrid tower is arranged on the sedimentation tank and communicates with the sedimentation tank, and the top end of the CST turbogrid tower is connected with a wet electric dust collector via a pipeline; the wet electric dust collector is connected with a draught fan via a pipeline, and the draught fan communicates with a chimney via a pipeline; the lower part of the sedimentation tank is provided with a sewage port; the middle part of the sedimentation tank is connected into the upper part of the DS multi-phase desulfurization tower via a circulating pump; the pipeline between the draught fan and the chimney and the pipeline between the boiler and the DS multi-phase desulfurization tower communicate with each other via a circulating wind pipe. The problem of secondary pollution caused by discharge of aerosol particulate matters carried by wet desulfurization flue gas is solved; the system reduces the land occupation area when single towers are used in series, investment costs are saved, and the operation reliability of the system is enhanced.

Owner:ANHI SHENGYUN HEAVY MACHINERY CO LTD

Tungsten slag treatment method

ActiveCN102212697BSolve the problem of secondary pollutionReduce recycling costsProcess efficiency improvementSlagFiltration

The invention discloses a tungsten slag treatment method. The tungsten slag treatment method comprises the following steps of: dissolving: mixing tungsten slag and 15 to 30 percent HCl solution of 50 to 65 DEG C, adding a tungsten stabilizing agent, and performing filtration after the reaction is finished to obtain acid solution; and reclaiming tungsten: adsorbing the tungsten in the acid solution by adopting weak alkali acrylic acid series anion exchange resin to obtain tail solution I, resolving the exchange resin by using sodium hydroxide solution to obtain sodium tungstate, and reclaimingthe tungsten from the sodium tungstate. By using the technical scheme, the tungsten slag is leached at a low temperature under normal pressure by adopting the HCl solution, and the tungsten is directly reclaimed by a one-step method under the acid condition; and the process is simple and low in reclamation cost.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

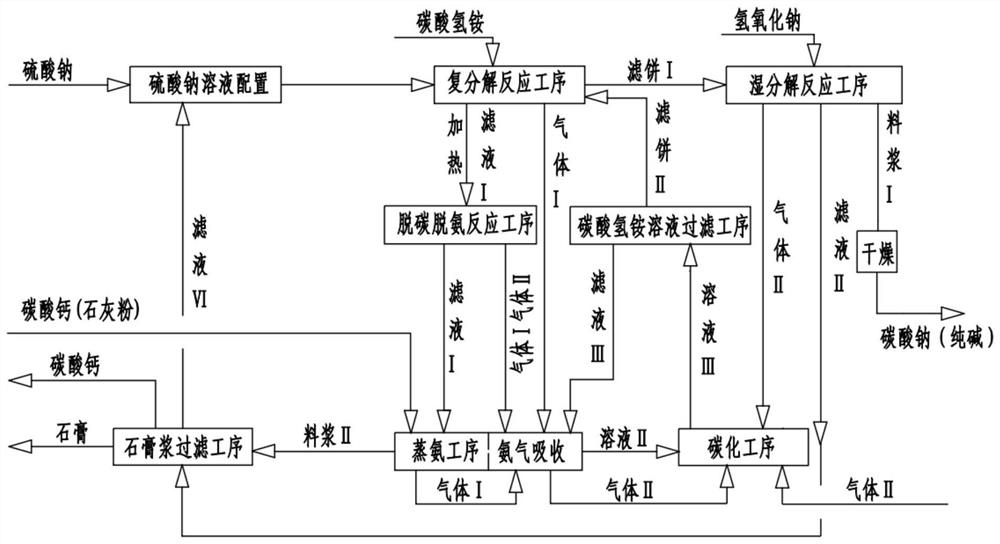

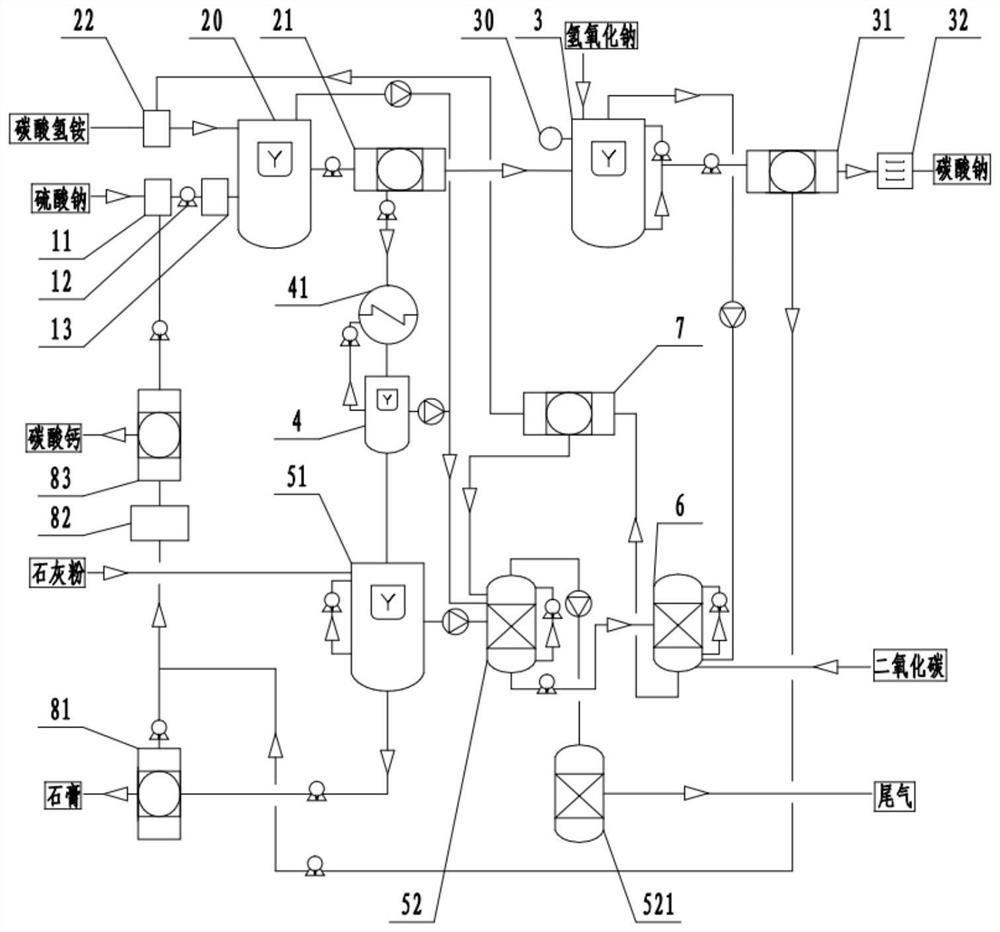

Novel process for preparing sodium carbonate and byproduct gypsum by using sodium sulfate and carbon dioxide as raw materials

PendingCN114455612ASolve the problem of secondary pollutionReduce processing energy consumptionCalcium/strontium/barium sulfatesCarbonate preparationSodium acid carbonateAmmonium sulfate

The invention relates to the technical field of sodium carbonate preparation, and discloses a novel process for preparing sodium carbonate and byproduct gypsum by taking sodium sulfate and carbon dioxide as raw materials, the process combines a double decomposition reaction of sodium sulfate and ammonium bicarbonate and a wet decomposition process of sodium bicarbonate to prepare sodium carbonate, and the other product ammonium sulfate of the double decomposition reaction reacts with lime powder to obtain gypsum; ammonia gas and carbon dioxide generated by the process are synthesized into ammonium bicarbonate for cyclic utilization through ammonia gas absorption and carbonization processes. According to the scheme, a large amount of chemical by-product anhydrous sodium sulphate (sodium sulfate) is used as a raw material, sodium carbonate with large capacity and demand in the glass market is produced through double decomposition reaction and wet decomposition reaction, and the problem of chloride ion treatment and secondary pollution caused by chloride ion treatment are completely eradicated from the source; and the method has the advantages of mild reaction conditions, low investment, low operation cost and high profitability, and can be widely applied to production of sodium carbonate.

Owner:GUIZHOU EAST CHINA ENG

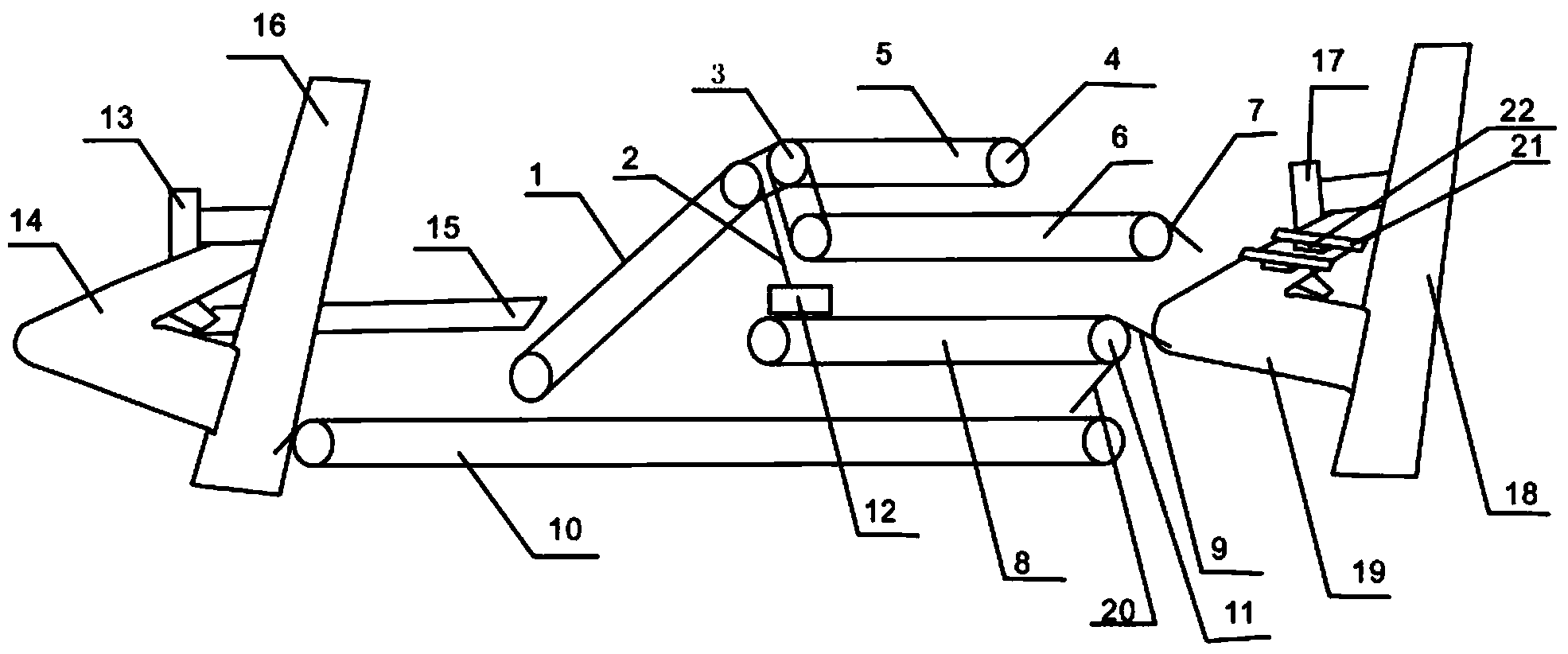

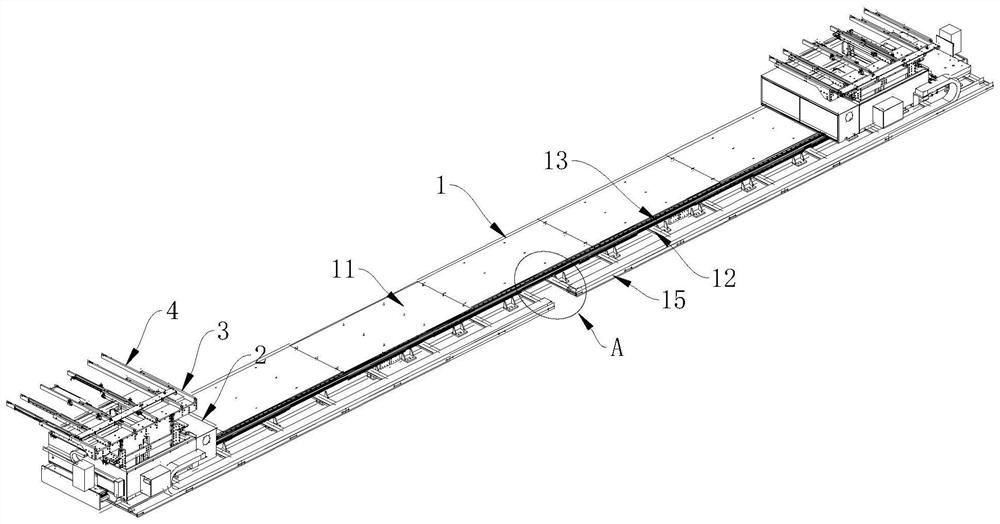

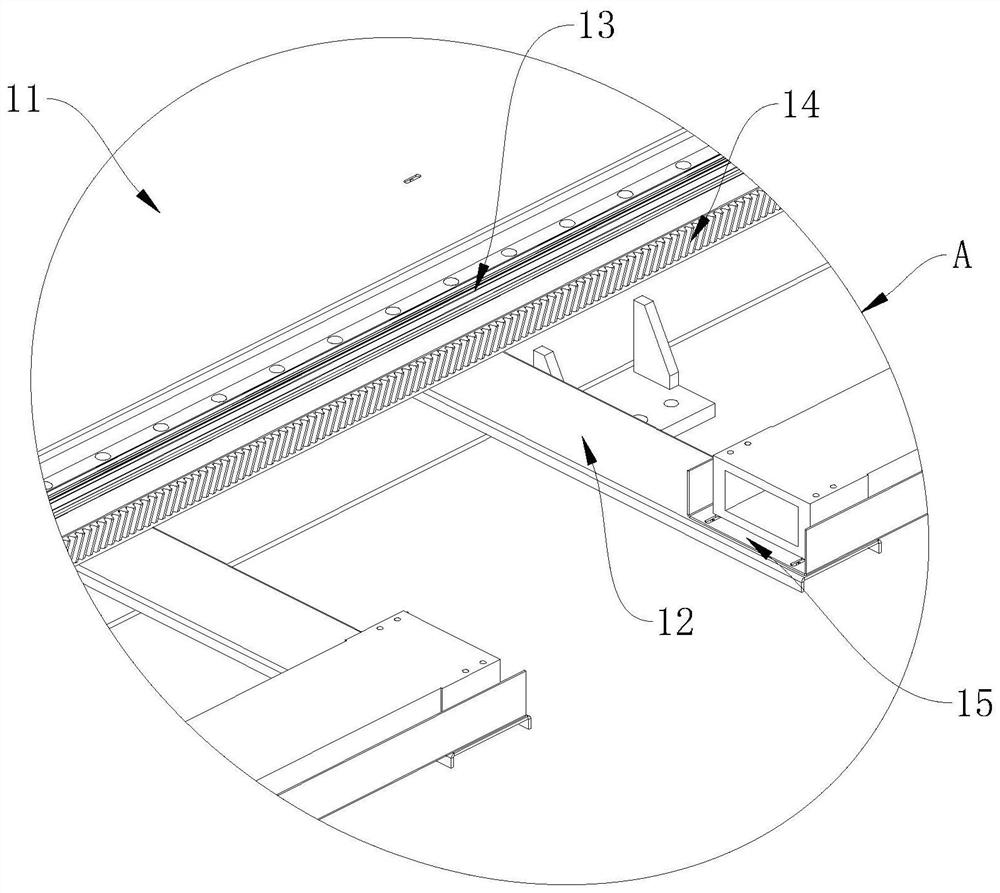

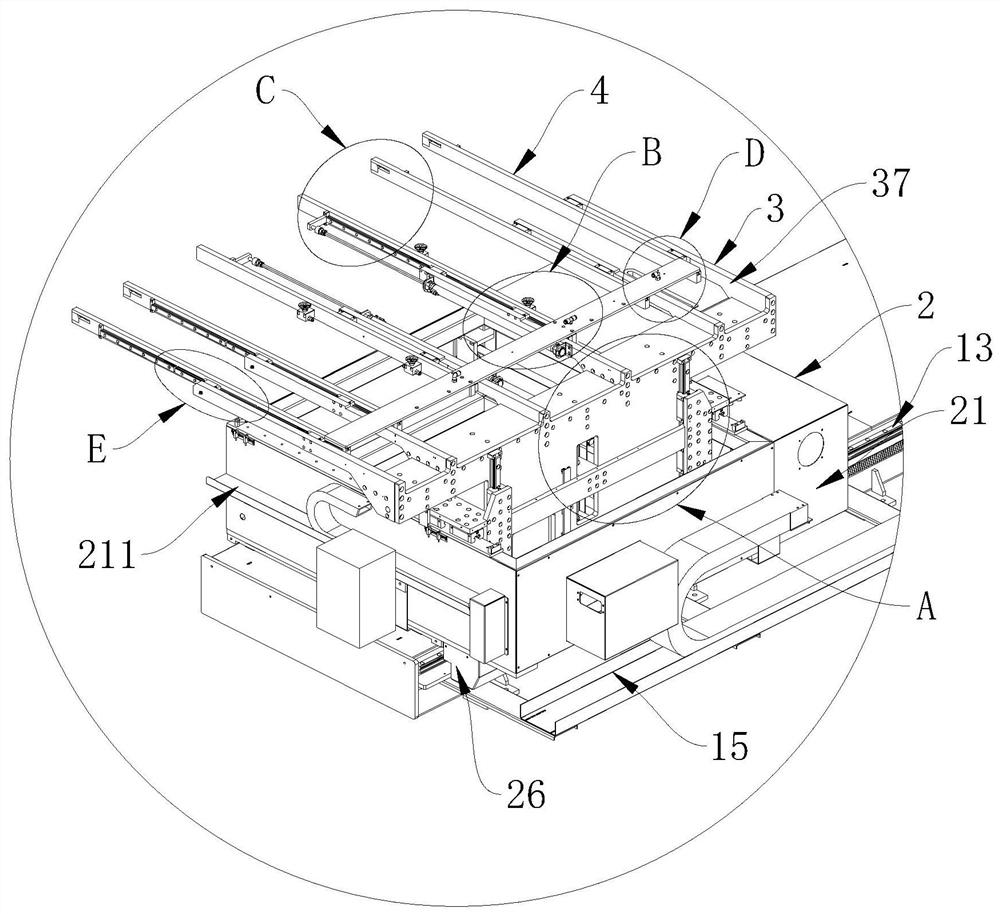

Automatic feeding and blanking device for large-size cover plates

ActiveCN113526124ASolve secondary pollutionImprove reliabilityConveyor partsStructural engineeringAutonomation

The invention discloses an automatic feeding and blanking device for large-size cover plates, and relates to the technical field of automatic equipment. The feeding and blanking device comprises a mopping assembly, a lifting table assembly, a horizontal supporting arm assembly and a telescopic supporting arm assembly; at least one lifting table assembly is arranged at the top of the mopping assembly; the horizontal supporting arm assembly and the telescopic supporting arm assembly are sequentially arranged at the top of the lifting table assembly; and the mopping assembly is used for bearing the lifting table assembly, so that the lifting table assembly moves on the mopping assembly to transfer products. The device achieves the functions of automatic feeding, blanking and automatic circulation of CG and TP cover plates on an automatic production line; the use requirements of customers are met; in the unique material taking mode of supporting arms, the difficult problem of secondary pollution of the products is effectively solved, and the difficult problems that the products are deformed, warped and drooped are effectively solved; automatic equipment is high in reliability; the product quality is guaranteed; and the feeding and blanking device has relatively high universality.

Owner:SHENZHEN PINGXIAN OPTOELECTRONICS EQUIP

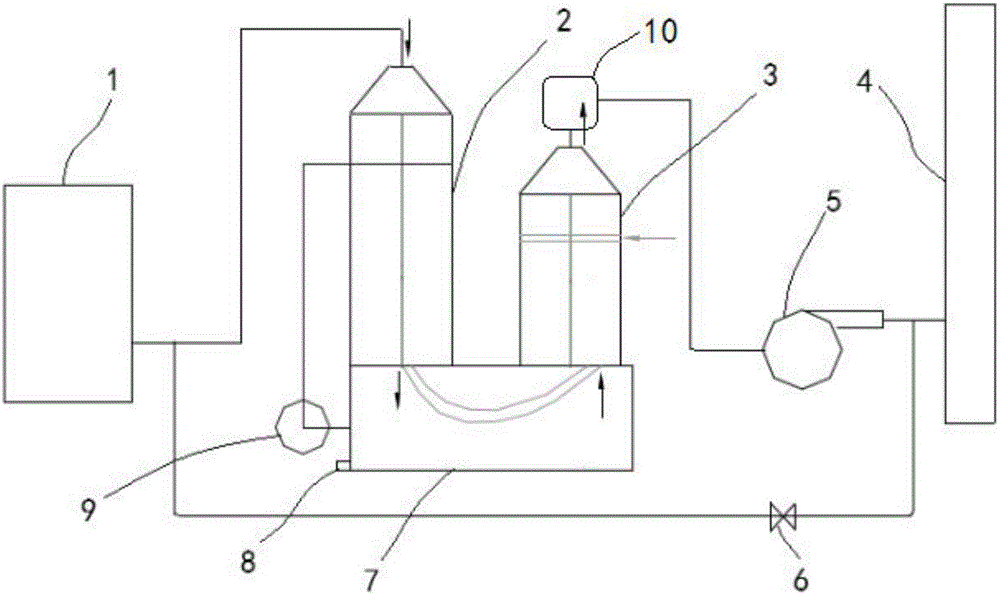

Portable water purification kettle with photocatalysis function

InactiveCN102743013AHigh activitySolve the secondary pollution of the environmentTravelling sacksWater/sewage treatment by irradiationPhotocatalysisActive carbon

The invention relates to a drinking water device and discloses a portable water purification kettle with a photocatalysis function. The portable water purification kettle comprises a kettle body, a kettle cover, a handle and a filter core, wherein the upper part of the filter core is positioned in an upper water storage chamber of the kettle body, the lower part of the filter core is positioned in a lower water storage chamber of the kettle body, the lower water storage chamber of the kettle body is communicated with a water outlet of the water kettle, the kettle body belongs to a kettle body containing photocatalysis materials, the cross section of the kettle body is in a flat shape, an oval shape or a rectangular shape, the kettle body is in a transparent body, the bottom of the kettle body is provided with a rubber gasket, the kettle cover is glidingly connected with the top of the kettle body, a casing of the filter core belongs a casing containing photocatalysis material, and an active carbon filtering layer, a fiber membrane filtering layer and a photocatalyst-titanium dioxide filtering layer are arranged inside the filter core. The portable water purification kettle has the advantages that water activity can be enhanced, human bodies can better drink more water molecules with vitality, through the photocatalysis effect, the original residue of water per se is changed into carbon dioxide and water, the functions of recirculation and reutilization are realized, and the secondary environment pollution problem can be effectively solved.

Owner:李复兴

Environment-friendly bio-organic fertilizer production formula and preparation process

InactiveCN108586084ASolve intractableSolve the problem of secondary pollutionBio-organic fraction processingBioloigcal waste fertilisersPotassiumNutrient solution

The invention discloses an environment-friendly bio-organic fertilizer production formula which mainly comprises, by weight, 1 part of corn bran, 1 part of candy pomace, 3 parts of waste mushroom sticks, 2 parts of plant ash and an appropriate amount of plant nutrient solution. The plant nutrient solution mainly comprises, in percent, 18.5%-21.5% of amino acid, 5.5%-6.0% of nitrogen, 0.8%-1.1% ofphosphorus, 0.65%-0.85% of potassium, 20.5%-22% of organic matters and 0.8%-0.9% of reducing sugar. Raw materials of an environment-friendly bio-organic fertilizer are rich in nutrient, wide in sourceand low in cost, and the problem of secondary pollution of industrial and agricultural production is solved.

Owner:菱花农业生态科技(山东)有限公司

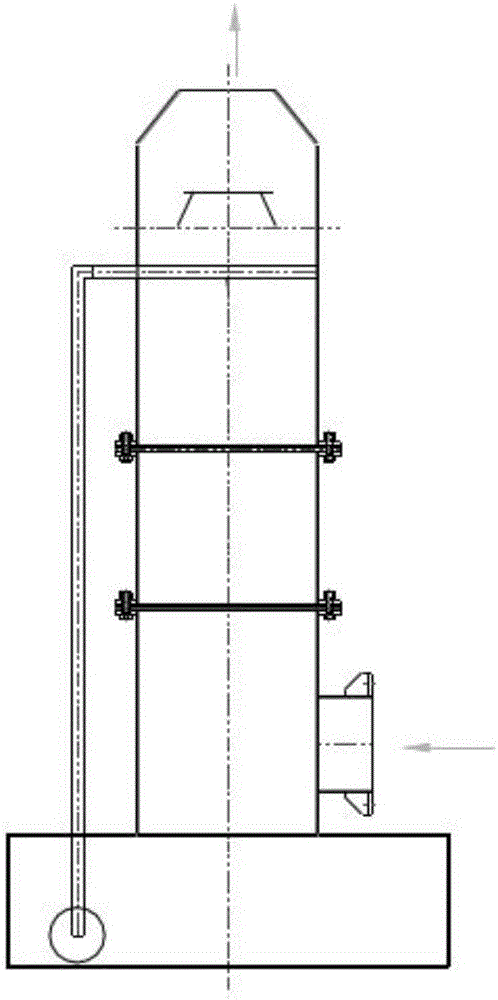

DC composite tower sulfur dioxide treatment system

PendingCN106110868AOvercomes disadvantages when used aloneImprove availabilityCombination devicesGas treatmentSewageTower

The invention discloses a DC composite tower sulfur dioxide treatment system. The DC composite tower sulfur dioxide treatment system comprises a DS multiphase desulphurization tower and a CST turbogrid tower, wherein the top end of the DS multiphase desulphurization tower is communicated with a boiler by virtue of a pipeline, and the lower end of the DS multiphase desulphurization tower is arranged on a settling pond and communicated with the settling pond; the lower end of the CST turbogrid tower is arranged on the settling pond and communicated with the settling pond; the top end of the CST turbogrid tower is connected with a draught fan by virtue of a pipeline, and the draught fan is communicated with a chimney by virtue of a pipeline; a sewage opening is formed in the lower part of the settling pond; the middle part of the settling pond accesses the upper part of the DS multiphase desulphurization tower by virtue of a circulating pump; and the pipelines between the draught fan and the chimney and between the boiler and the DS multiphase desulphurization tower are communicated by virtue of a circulating wind pipe. A DC composite tower solves the problem of secondary pollution caused by the emission of wet desulphurization exhaust gas carrying aerosol particles; and the DC composite tower sulfur dioxide treatment system reduces the floor occupation area when various single towers are used in serial connection, saves the investment expense and improves the system operation reliability.

Owner:ANHI SHENGYUN HEAVY MACHINERY CO LTD

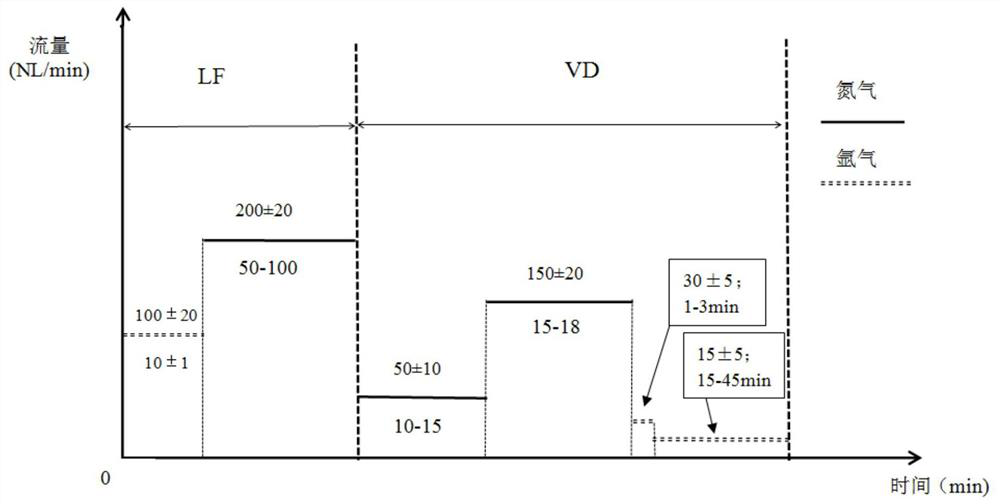

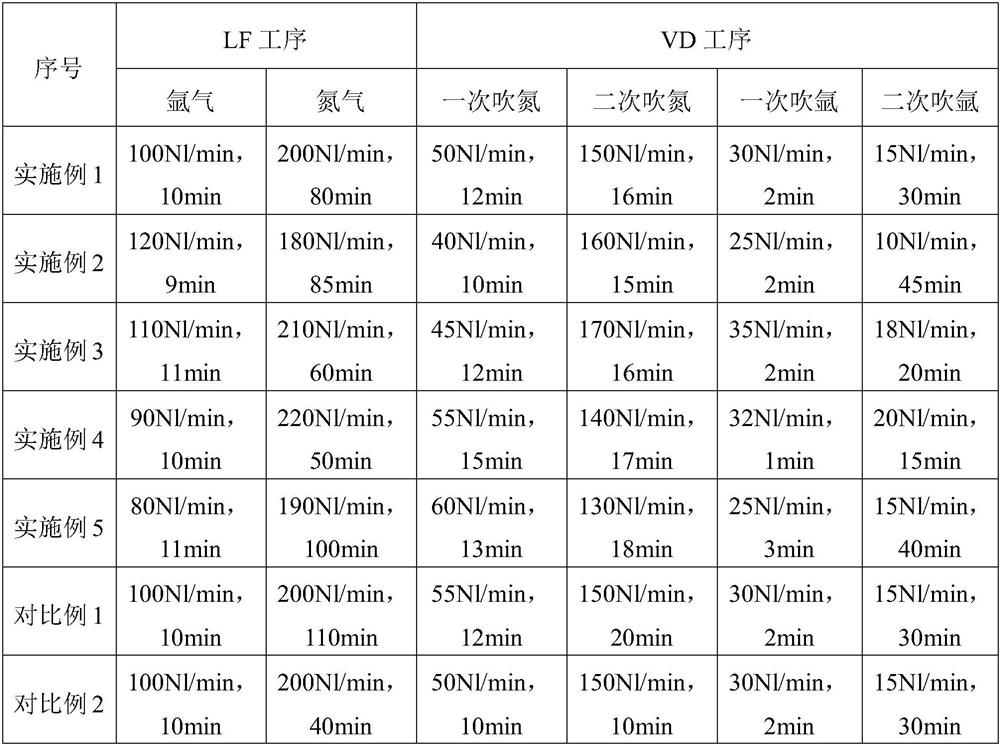

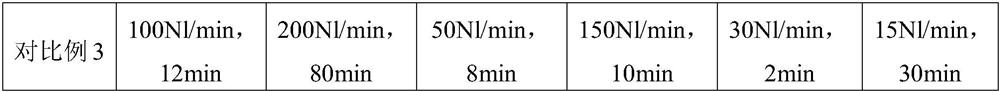

A kind of trapezoidal nitrogen blowing nitrogen control method

The invention discloses a trapezoidal nitrogen blowing and nitrogen control method, which includes LF refining process and VD vacuum degassing process; wherein, the LF refining process includes sequentially blowing argon and nitrogen into molten steel; the VD vacuum degassing process includes vacuuming stages, In the vacuum maintenance stage and the normal pressure stage, the molten steel is blown with nitrogen for the first time in the vacuum pumping stage, the second nitrogen blowing, the first argon blowing in the vacuum maintenance stage, and the second argon blowing in the normal pressure stage; finally to obtain nitrogen-containing steel. The invention can realize precise control of nitrogen element, can solve the problem of precise control of nitrogen in molten steel and secondary pollution of molten steel, and does not affect the control of hydrogen and oxygen in molten steel.

Owner:NANJING IRON & STEEL CO LTD

Rubber-mixing waste gas deodorizing and purifying device and method through dry oxidation

InactiveCN102000484BHigh removal rateOvercoming the disadvantages of insufficient exposureDispersed particle filtrationGaseous substancesBaghouseExhaust fumes

The invention relates to a rubber-mixing waste gas deodorizing and purifying device and method through dry oxidation. The purifying device comprises a bag collector, an ozone generator, an oxidation reactor and a gas adsorptive oxidation device, wherein the bag collector is connected to the air outlet of the oxidation reactor through a draught fan; the ozone generator is connected to the air outlet of the oxidation reactor; the air outlet of the oxidation reactor is connected to the gas adsorptive oxidation device through a pipeline; and the gas adsorptive oxidation device is provided with a purified gas exhaust outlet. The purifying method comprises the following steps: introducing the rubber-mixing waste gas into the bag collector to carry out flue gas dust removal; generating ozone through the ozone generator; mixing the gas which is purified by the bag collector with the ozone to perform an oxidation reaction; and adsorptively oxidizing the gas which is subject to the oxidation reaction. The rubber-mixing waste gas deodorizing and purifying method has a simple device, stable operation, high purification efficiency and low cost, and does not have the problem of secondary pollution.

Owner:浙江中兵环保股份有限公司

A kind of filter agent for treating sewage produced by printing and dyeing sludge and its manufacturing method

InactiveCN107473322BRealize resource utilizationProtect environmentWater contaminantsWater/sewage treatment by flocculation/precipitationChemical oxygen demandSludge

The invention relates to a filtering agent for treating sewage in dyeing sludge production and a manufacturing method thereof. The method is characterized by comprising the following steps: preparing dyeing sludge into powder in the manner of high-temperature incinerating, breaking, sorting, magnetic separation, grinding and screening, and then adopting a biaxial paddle mixing stirrer for mixing and stirring the powder with blast furnace residue powder, oxalic acid, a chemical oxygen demand removing agent, an ammonium nitrogen removing agent and a heavy metal capturer, comprehensively compounding and cycling the material in the machine under a mechanical effect and in a widely staggering manner without dead angle, thereby achieving the purpose of uniformly dispersing the mixed filtering agent; conveying the uniformly mixed filtering agent into a special storage silo; and adopting a full-automatic electronic metering weighting packager system for packaging and then preparing into a filtering agent product. The test proves that the product meets the requirement of natural industrial standard and has the advantages of no pollution, low cost, high benefit, capabilities of solving the problem of secondary pollution of the dyeing sludge, protecting the ecological environment and saving land, and the like.

Owner:广州中滔绿由环保科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com