Chain porphyrin polymer and synthetic method thereof

A porphyrin polymer and polymer technology, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, special compound water treatment, etc., can solve the problem of unsatisfactory treatment effect, difficulty in meeting discharge standards, etc. problem, achieve the effect of improving the catalytic effect and solving the secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

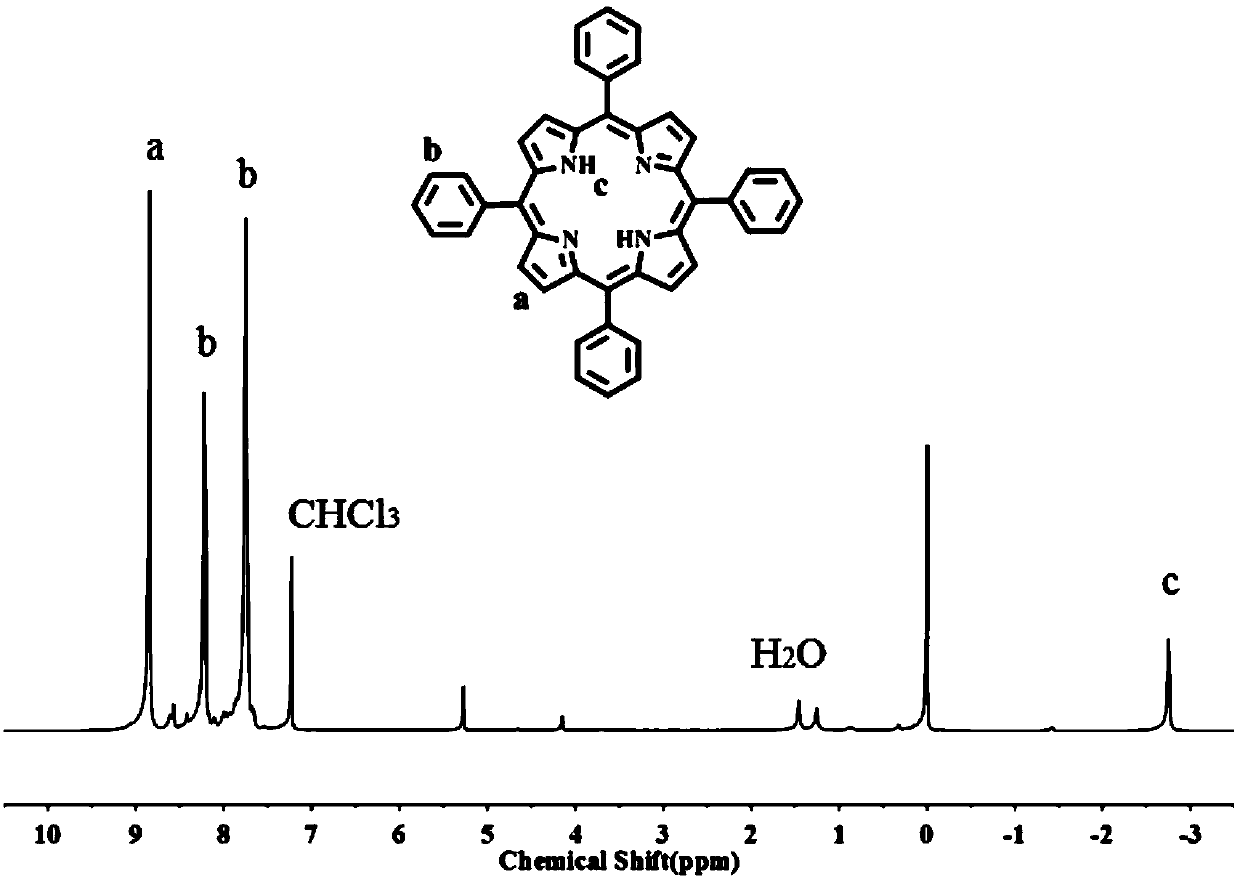

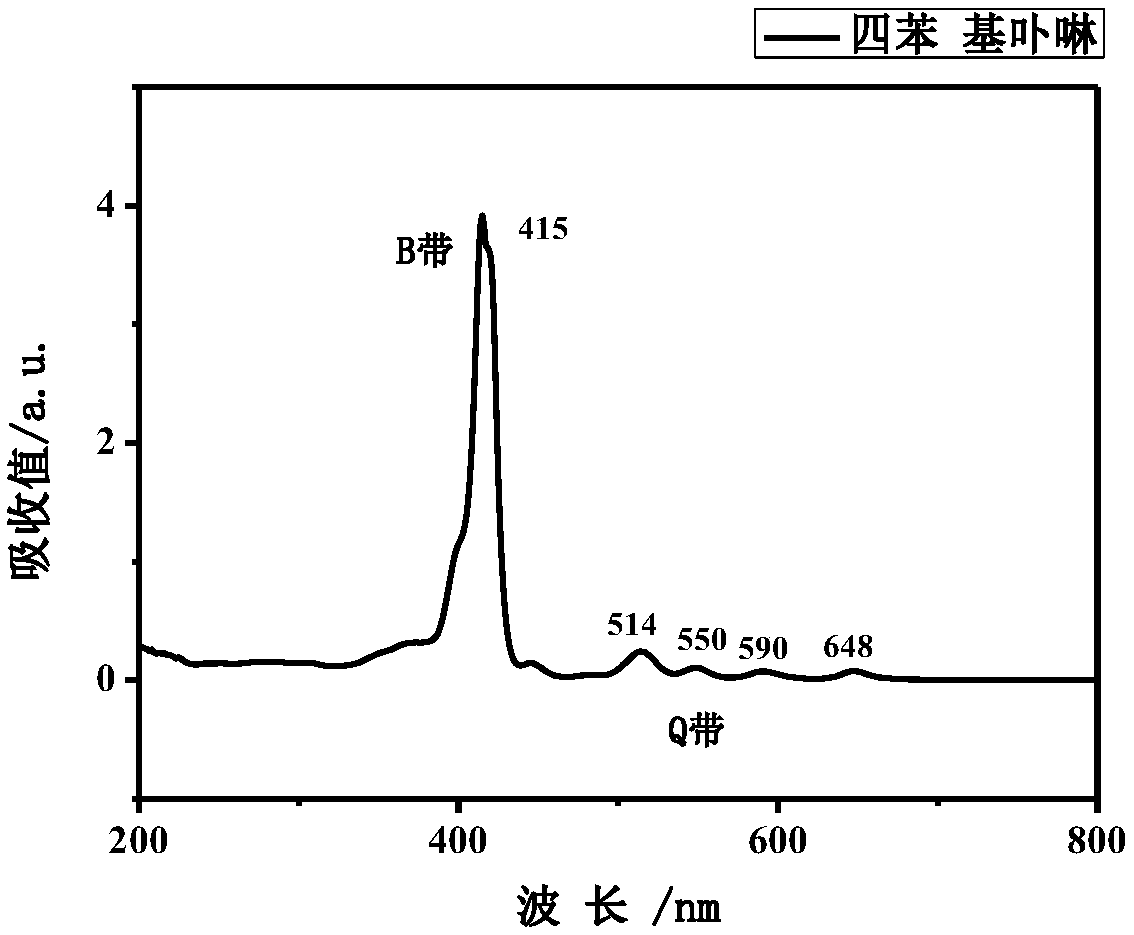

[0021] A kind of chain porphyrin polymer of the present invention and its synthetic method are described in detail below.

[0022] First, the Adler method was used to prepare TPP, and the specific process was as follows:

[0023] Add propionic acid (120mL), DMSO (6mL) and benzaldehyde (5mL, 0.05mol) into a three-necked flask equipped with a reflux device, heat to reflux temperature (135°C), and slowly add freshly distilled pyrrole ( 3.5mL 0.05mol), after the dropwise addition, reflux for 30min. The reaction mixture was cooled to room temperature, filtered under reduced pressure, and the filter cake was washed with methanol until the filtrate was colorless, then washed with hot water until neutral, and vacuum-dried at 80°C for 12 hours to obtain a purple crude tetraphenylporphyrin. The crude product was subjected to column chromatography using CH 2 Cl 2 As eluent, further purification, yield: 2.39g, 31.12%.

[0024] The reaction formula is:

[0025]

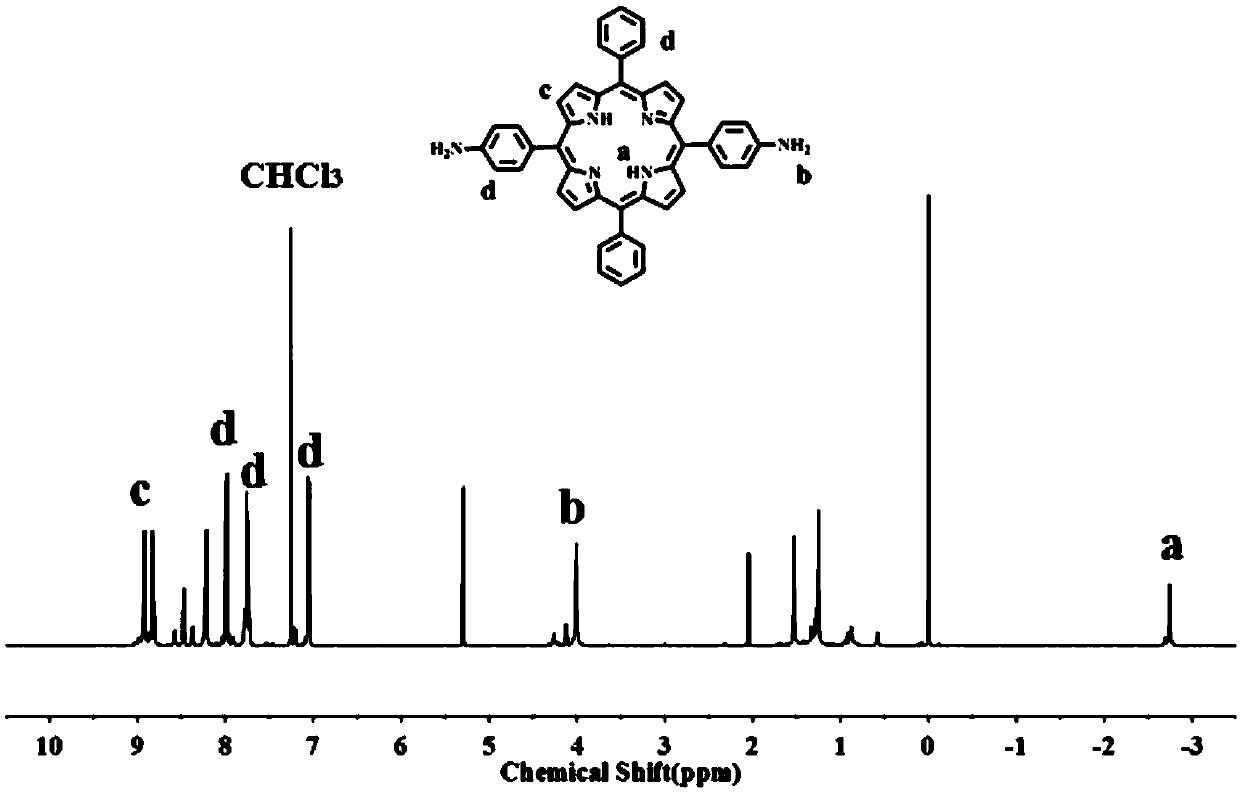

[0026] Secondly, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com