DC composite tower electrostatic dust collection integrated flue gas treatment system

A flue gas treatment system, electrostatic precipitator technology, applied in external electrostatic separators, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as affecting desulfurization efficiency of desulfurization towers, inoperability of reaction towers, and easy clogging of sieve holes, etc. Achieve the effect of enhancing operational reliability, saving investment costs and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

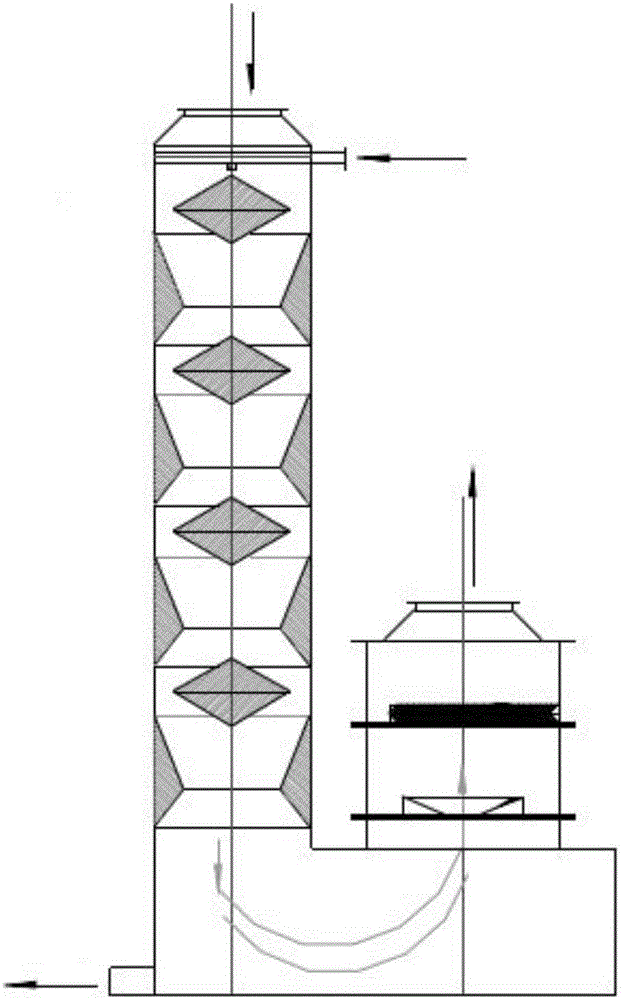

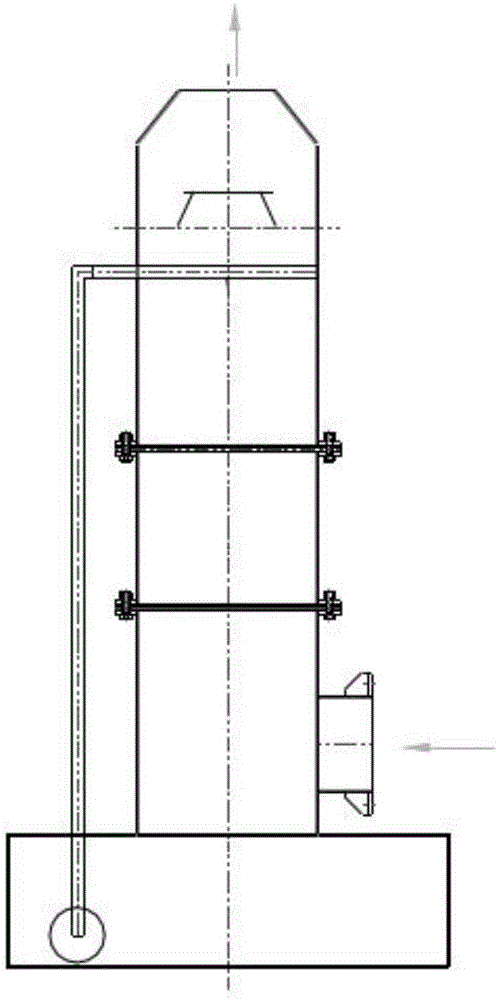

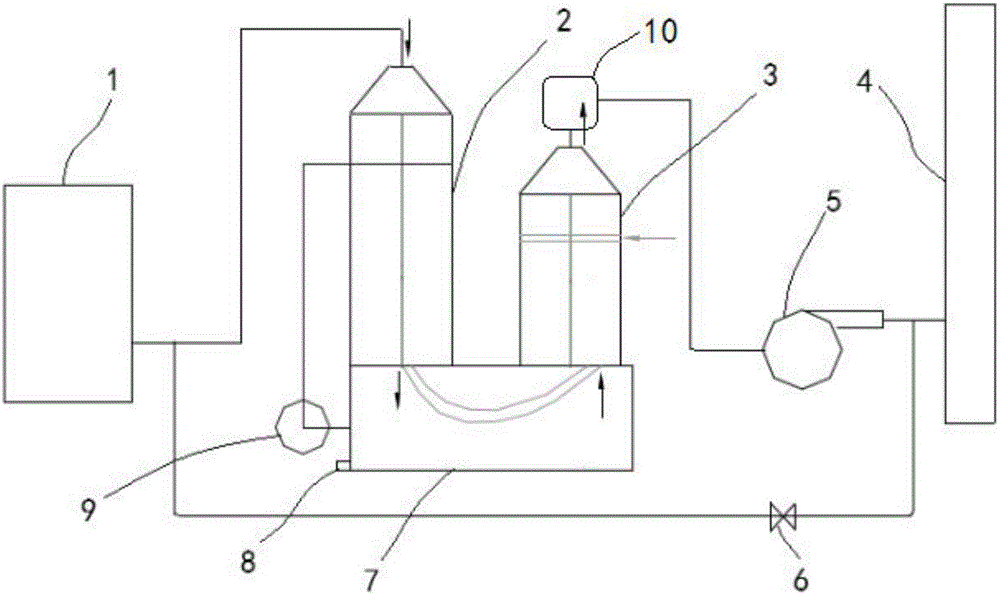

[0018] A DC composite tower electrostatic precipitator integrated flue gas treatment system, such as image 3 As shown, it includes a DS multiphase desulfurization tower 2 and a CST through-flow plate tower 3; the top of the DS multiphase desulfurization tower 2 is connected to the boiler 1 through a pipeline, and the lower end of the DS multiphase desulfurization tower 2 is set on the sedimentation tank 7 and communicated with it;

[0019] The lower end of the CST through-flow plate tower 3 is set on the sedimentation tank 7 and communicated with it; the top of the CST through-flow plate tower 3 is connected to the wet electrostatic precipitator 10 through the pipeline, and the wet electrostatic precipitator 10 is connected to the induced draft fan 5 through the pipeline, and the induced draft fan 5 communicate with the chimney 4 through the pipeline;

[0020] The lower part of the sedimentation tank 7 is provided with a sewage outlet 8; the middle part of the sedimentation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com