Novel process for preparing sodium carbonate and byproduct gypsum by using sodium sulfate and carbon dioxide as raw materials

A technology for carbon dioxide and by-product gypsum, applied in carbonate preparations, calcium/strontium/barium sulfate, inorganic chemistry, etc., can solve the problems of low production efficiency and long production process, achieve low operating costs, and reduce wastewater treatment. Energy consumption, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The differences in substrate materials, treatment conditions and product yields in Examples 1-3 and Comparative Examples 1-3 are shown in Table 1. Taking Example 1 as an example, a new process for preparing soda ash by-product gypsum with sodium sulfate and carbon dioxide as raw materials is described.

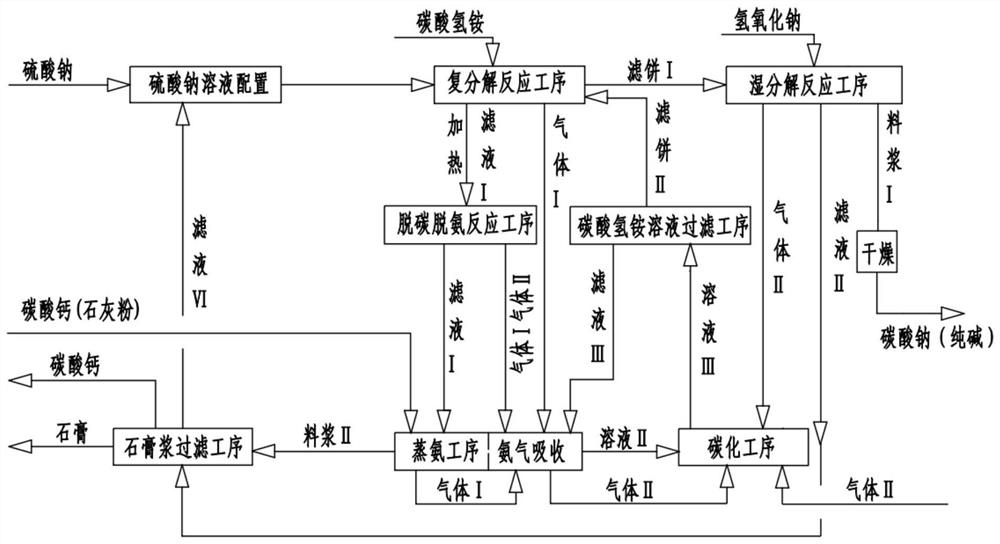

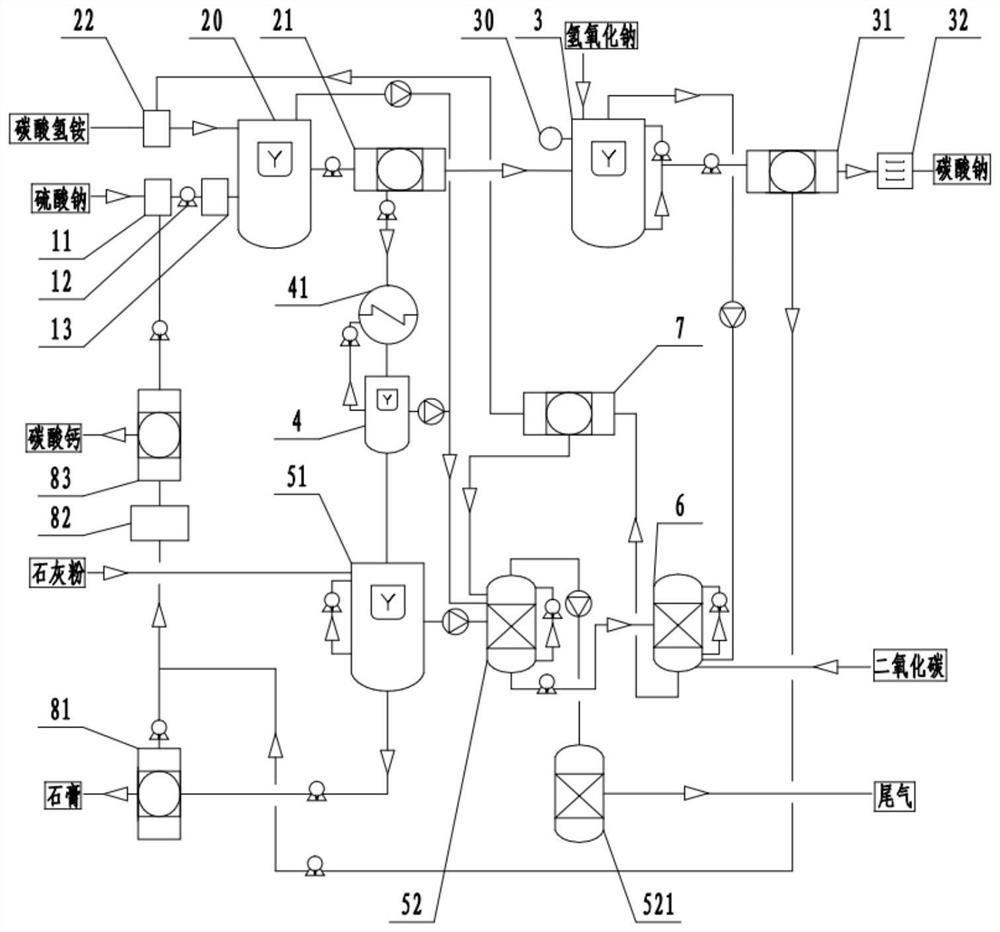

[0035] The technical scheme of the present invention combines the metathesis reaction of sodium sulfate and ammonium bicarbonate and the wet decomposition process of sodium bicarbonate to prepare soda ash, and the ammonia gas (gas I) and carbon dioxide (gas II) produced by the process are synthesized into hydrogen carbonate through the ammonia distillation process and carbonization process Ammonium, the synthesized ammonium bicarbonate can be reacted with sodium sulfate again to prepare soda ash. Reaction raw materials according to figure 1 The process shown in the reaction, while preparing soda ash and by-product gypsum, recycles the gas generated in the process, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com