DC composite tower sulfur dioxide treatment system

A sulfur dioxide and treatment system technology, applied in the direction of gas treatment, combustion product treatment, combined devices, etc., can solve the problems that the reaction tower cannot operate, affects the desulfurization efficiency of the desulfurization tower, and is easy to block the screen holes, etc., to achieve enhanced operation reliability, The effect of saving investment costs and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

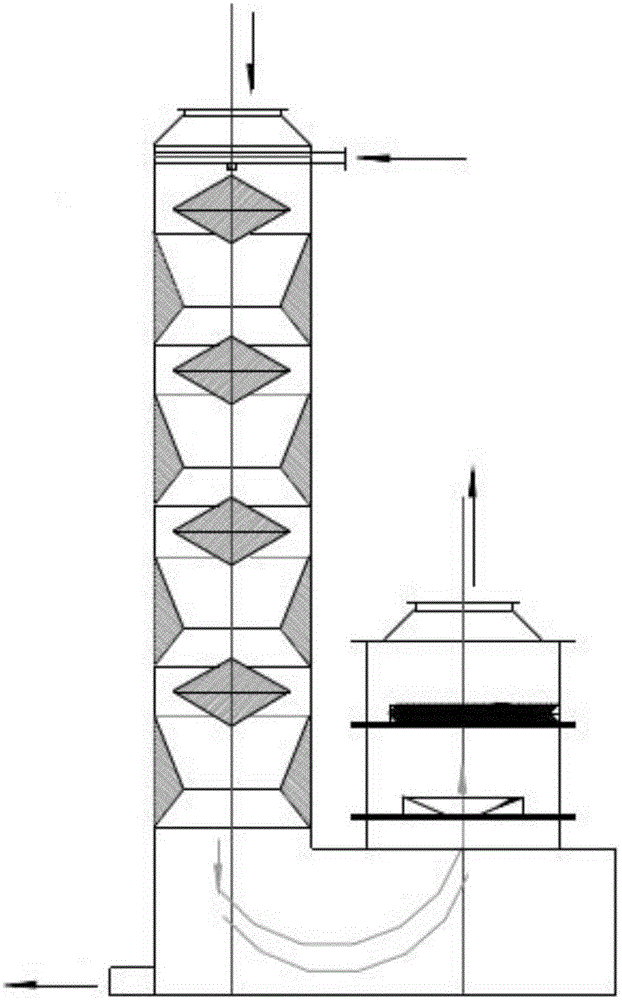

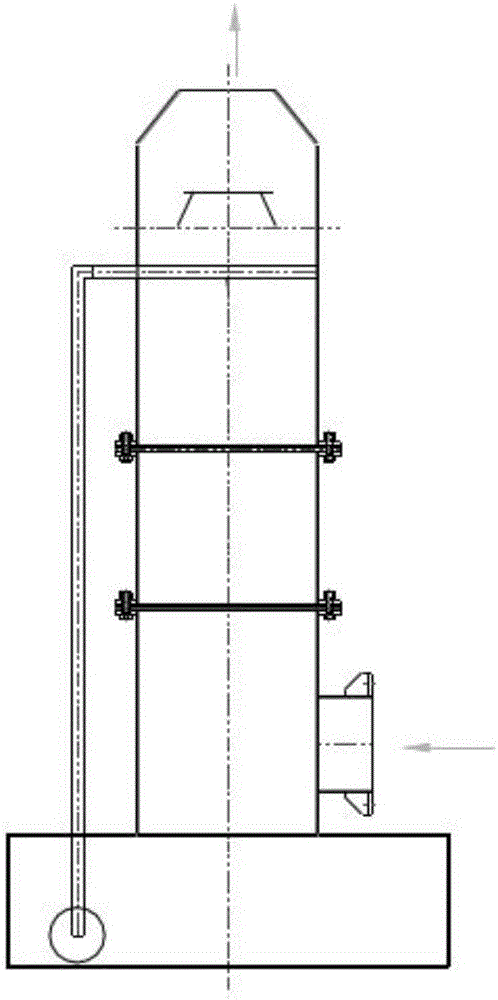

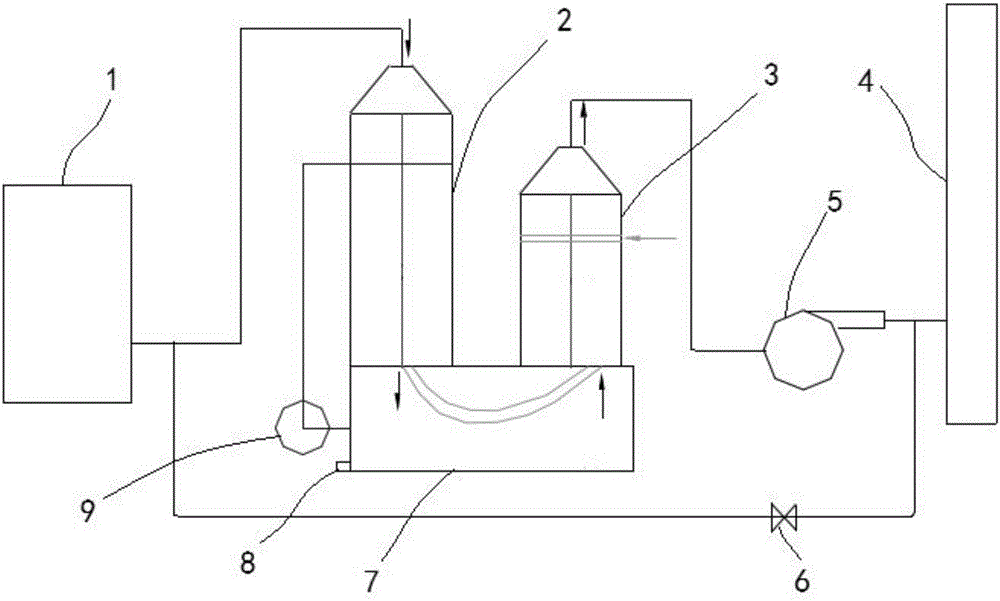

[0016] A kind of DC composite tower sulfur dioxide treatment system, such as image 3 As shown, it includes a DS multiphase desulfurization tower 2 and a CST through-flow plate tower 3; the top of the DS multiphase desulfurization tower 2 is connected to the boiler 1 through a pipeline, and the lower end of the DS multiphase desulfurization tower 2 is set on the sedimentation tank 7 and communicated with it;

[0017] The lower end of the CST through-flow plate tower 3 is set on the sedimentation tank 7 and communicated with it; the top of the CST through-flow plate tower 3 is connected to the induced draft fan 5 through a pipeline, and the induced draft fan 5 is connected to the chimney 4 through a pipeline;

[0018] The lower part of the sedimentation tank 7 is provided with a sewage outlet 8; the middle part of the sedimentation tank 7 is connected to the upper part of the DS multiphase desulfurization tower 2 through a circulation pump 9;

[0019] On the pipeline between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com