A kind of trapezoidal nitrogen blowing nitrogen control method

A trapezoidal, nitrogen technology, applied in the field of metallurgy, can solve the problems of unfavorable production continuity and high efficiency, secondary pollution of molten steel, etc., and achieve the effect of reducing production costs, reducing smelting costs, and solving precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

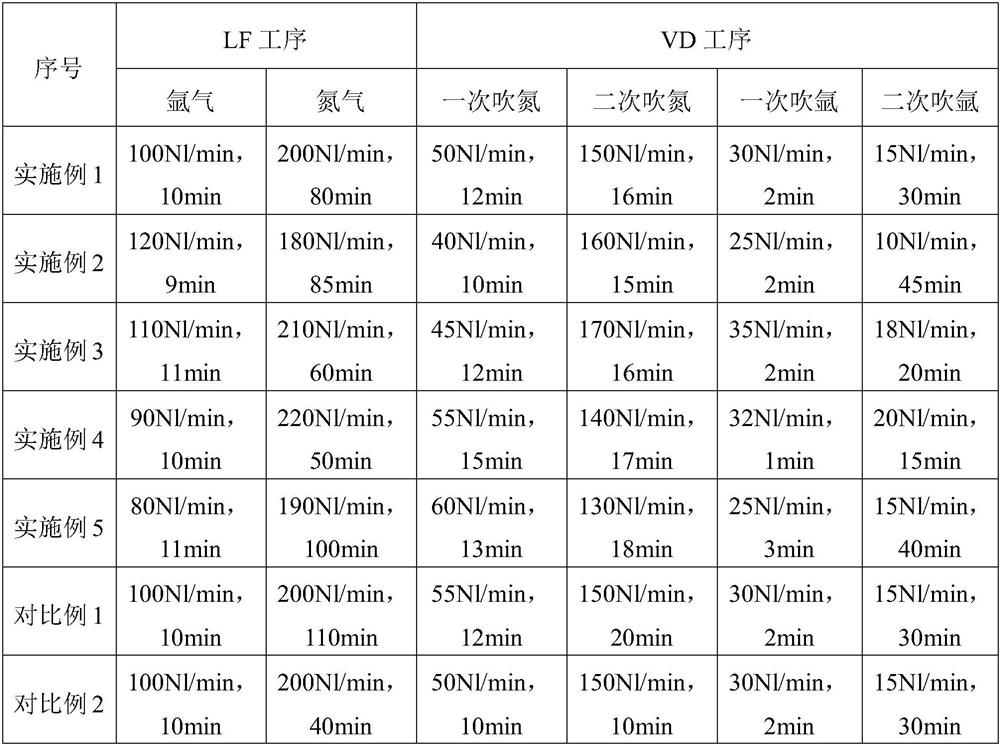

[0019] In this embodiment, the steel grade C38N2 is taken as an example. The target element content of the steel grade is as follows: the nitrogen content is 140 ppm, the hydrogen content is below 2.0 ppm, and the oxygen content is below 10 ppm.

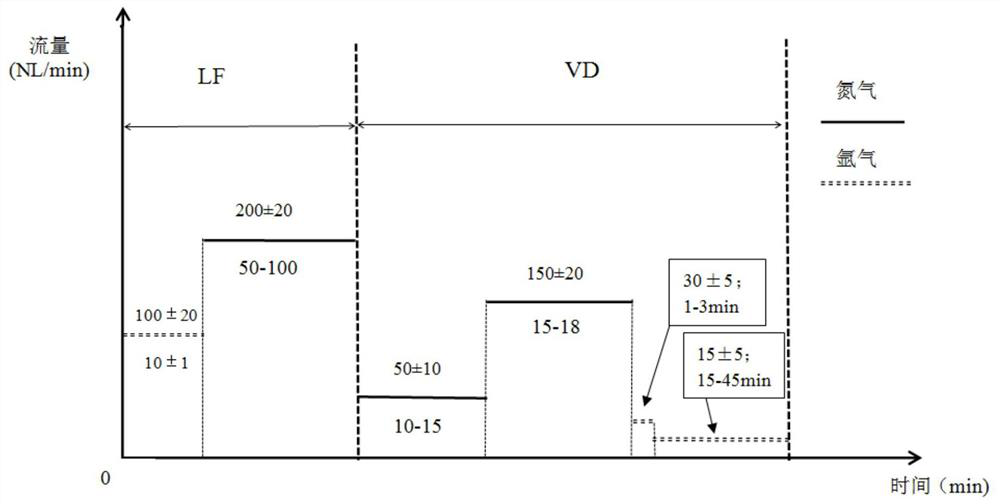

[0020] The trapezoidal nitrogen blowing and nitrogen control method of the present invention is used for production. The process implementation is divided into two processes, which need to be completed in sequence. The process control schematic diagram is as follows figure 1 shown; among them, figure 1 The meanings of the two data in each section of the blowing segment are the blowing flow rate and the blowing time. The data in the upper row of each segment represents the blowing flow rate, and the data in the next row represents the blowing time.

[0021] Among them, there is no fixed requirement before the molten steel enters the LF process. According to the end point of the electric furnace and the waiting time for smelting, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com