Method for preparing high-quality and odorless regenerated rubber

A reclaimed rubber, high-quality technology, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve the problems affecting the quality of reclaimed rubber, difficult to completely remove iron powder, large iron powder content, etc., to solve the secondary pollution. Problems, small wear, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 tread rubber powder

[0039] The method includes the steps of separating the waste tires into rings, cutting into strips, cutting into blocks and then crushing and magnetic separation. The separation of the rings, cutting into strips and cutting into blocks are all existing processes, and the size of the rubber after cutting into blocks is about 40mm*40mm.

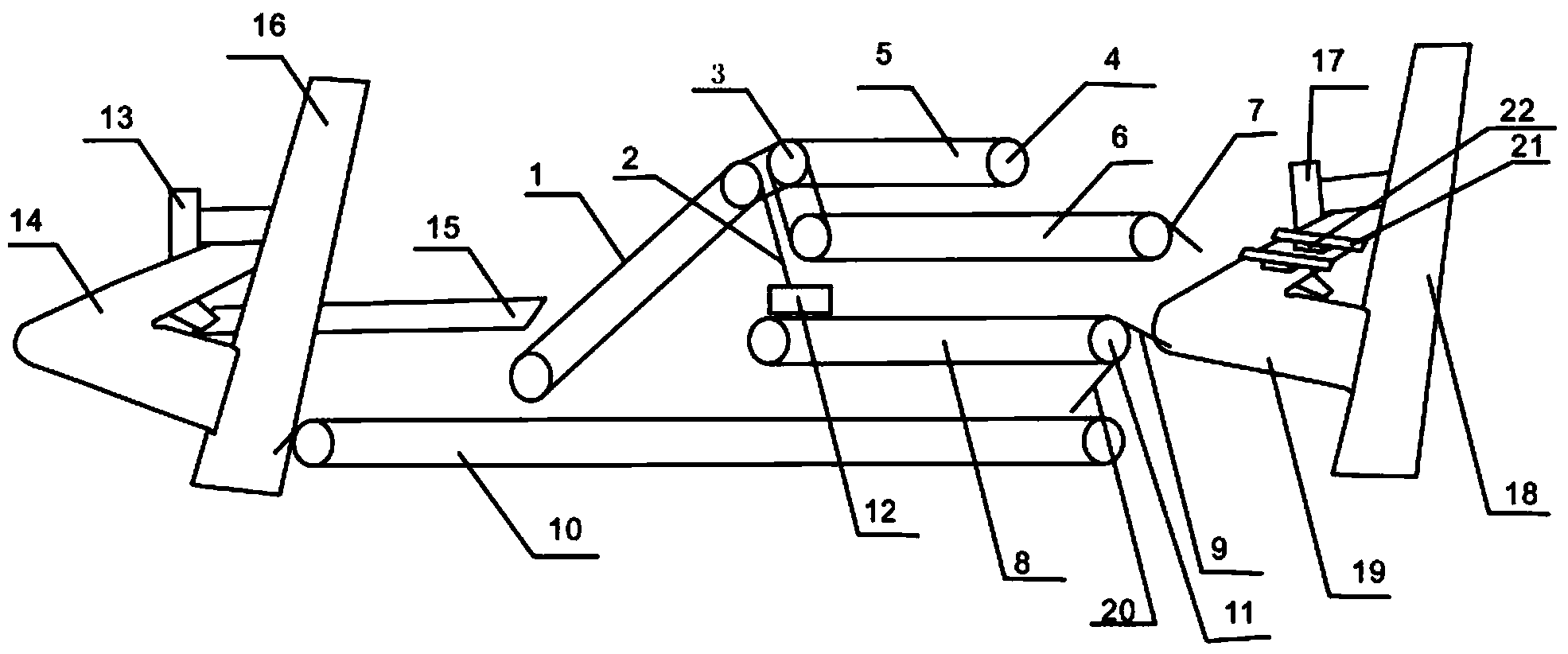

[0040] The equipment used in crushing and magnetic separation consists of a mixture conveyor belt 1, a rubber particle hopper 2, the first full magnetic drum 3, a driven drum 4, a steel wire separation conveyor belt 5, a steel wire recovery conveyor belt 6, a steel wire hopper 7, and rubber particle conveyor Belt 8, rubber discharge hopper 9, circulating conveyor belt 10, second full magnetic drum 11, baffle plate 12, rubber coarse crushing machine 13, first, vibrating screen 14, first conveyor belt 15, recycling conveyor belt 16, tire Flour rubber powder pulverizer 17, the second con...

Embodiment 2

[0051] The 30-32 mesh tread rubber powder obtained in Example 1 is used as a raw material, and is produced through chemical desulfurization, rubber mixing, and molding processes.

[0052] In the chemical desulfurization process, add tread rubber powder and additive formula: according to parts by weight, 1200 parts of tread rubber powder, 120 parts of vegetable oil asphalt, 4804 parts of reclaimed rubber desulfurization activator, 10 parts of baking soda, 100 parts of water share.

[0053] Add tread rubber powder, vegetable oil asphalt, activator, baking soda and water into the desulfurization tank, stir the material continuously, and heat up to 280°C at the same time. When the pressure reaches 2.8MPa, the reaction time is about 2h, stop heating , after standing for 5 minutes, exhaust and release the pressure to complete the desulfurization operation. After rough refining, scraping and refining in the rubber mixer, the product is formed by molding.

[0054] The obtained produ...

Embodiment 3

[0057] The 30-32 mesh tread rubber powder obtained in Example 1 is used as a raw material, and is produced through chemical desulfurization, rubber mixing, and molding processes.

[0058] In the chemical desulfurization process, add tread rubber powder and additives to the formula: in parts by weight, 1800 parts of tread rubber powder, 180 parts of vegetable oil asphalt, 5106 parts of reclaimed rubber desulfurization activator, 25 parts of soda, 350 parts of water .

[0059] Put tread rubber powder, vegetable oil asphalt, activator, soda and water into the desulfurization tank, stir the materials continuously, and heat up to 270°C at the same time. When the pressure reaches 2.0MPa, the reaction time is about 2h, stop heating, After standing still for 10 minutes, exhaust and release the pressure to discharge the material to complete the desulfurization operation. After rough refining, scraping and refining in the rubber mixer, the product is formed by molding.

[0060] The ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com