Method for treating silt, sludge and/or nocuous hurtful solid waste by employing biological cured protease and use of product thereof

A technology of solid waste and protease, which is applied to the field of use of the obtained products of the treatment method, can solve the problems of secondary pollution, threat to the ecological environment, and large amount of waste, and achieve strong pressure resistance and the effect of solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

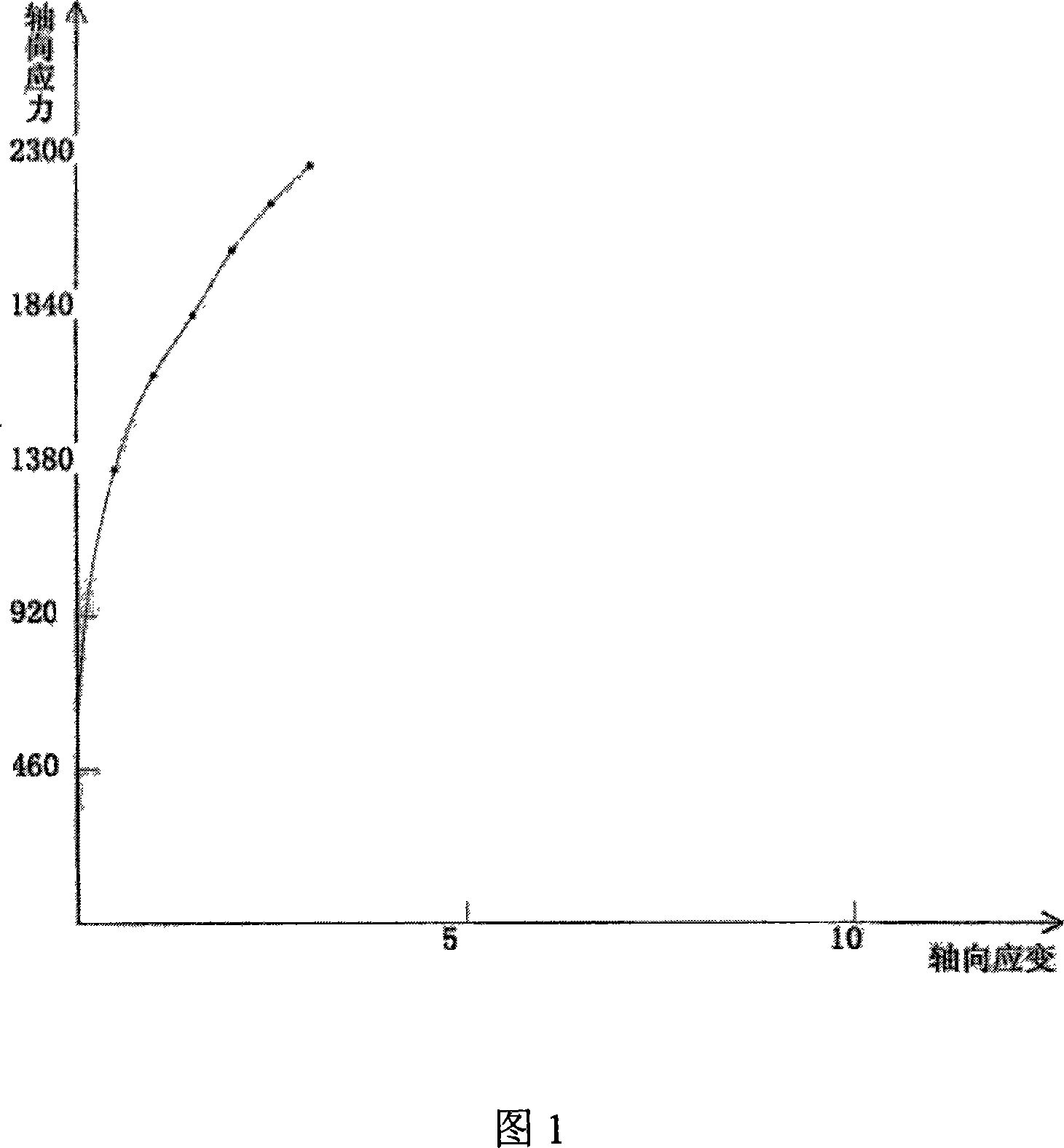

[0041] Wuxi pure 100% Taihu Lake silt, controlled water drying, so that the water content is dried to about 10%; prepare 2 mold volumes of sludge material (the mold is calculated as 15cm×15cm×15cm), here use 0.1ml of biological solidification Protease stock solution (produced by American Aizyson Joate New Technology Co., Ltd., the same below) + 50 milliliters of water is made into a dilution of biological immobilized protease (1:500); then this dilution is stirred into the above-mentioned In the silt, and evenly stir it into "enzyme silt mixture" (hereinafter referred to as "enzyme silt mixture"); and adjust this "enzyme silt mixture" to the optimum water content (if it is too wet, cool After drying and drying, if it is too dry, add water (choose according to the actual situation), make the module according to the "mud cake geotechnical characteristics test" method, and the anti-leakage rate of the test is: -8 ; The "unconfined strength" test for 7 days of natural air drying is...

Embodiment 2

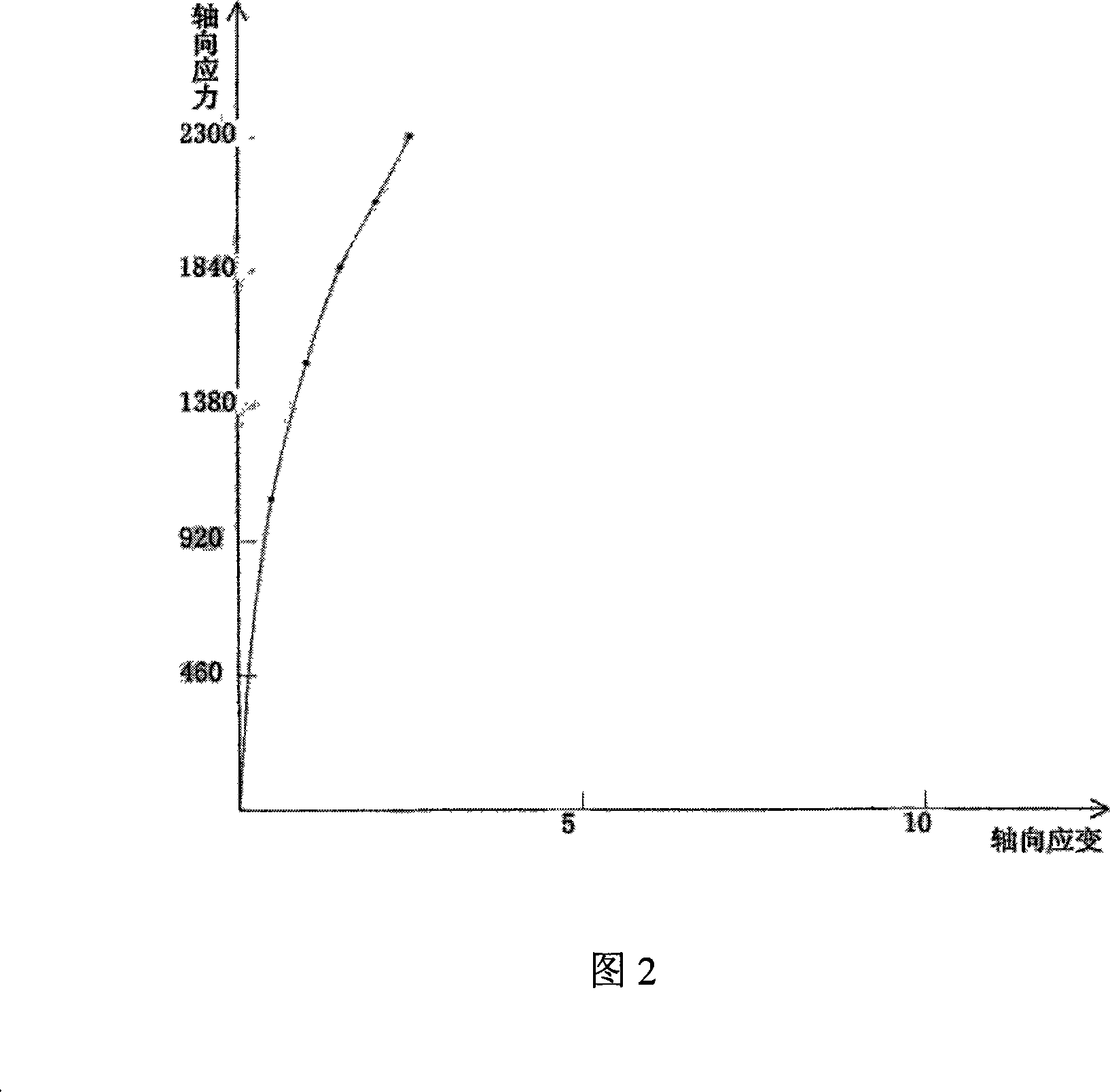

[0070] 90% of Wuxi Taihu silt, 10% of industrial sludge treated by the sewage plant, controlled water drying, so that the water content is dried to about 10%, and they are evenly mixed; prepare silt and sludge materials with the size of 2 molds Quantity (the mold is counted by 15cm * 15cm * 15cm), here, 0.1 milliliter of biological solidified protease stock solution+50 milliliters of water is made into the dilution (1:500) of biological solidified protease with biological solidified protease; Stir into the above-mentioned silt and sludge, and evenly stir with it to form "enzyme silt, sewage mixture" (hereinafter referred to as "enzyme silt, sewage mixture"); and this "enzyme silt, sewage mixture" "After adjusting to the optimum water content (cooling, drying or adding water - choose according to the actual situation), the module is made according to the mode of the "mud cake geotechnical characteristics test" method, and the anti-leakage rate of the test is: -8 ; The "unconfin...

Embodiment 3

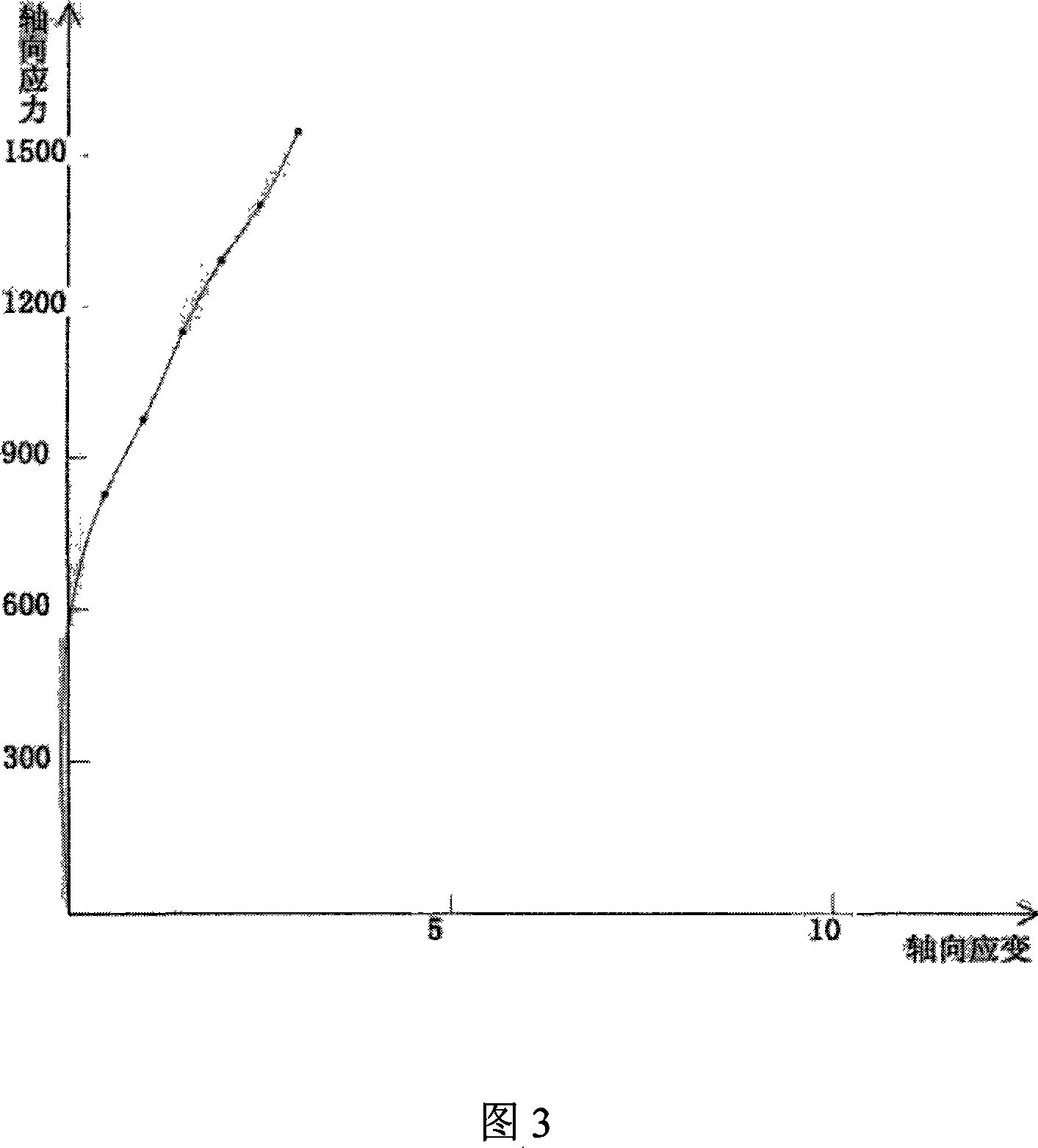

[0098] 90% of Wuxi Taihu Lake sludge is crushed into 10% of batteries with a particle size of 0.5-2.5cm, controlled water drying, so that the water content is dried to about 10%, and they are evenly mixed; prepare silt and sewage with the size of 2 molds The amount of mud (the mold is temporarily calculated by 15cm × 15cm × 15cm), here use 0.1 milliliter of biological immobilized protease stock solution+50 milliliters of water to make the dilution of biological immobilized protease (1:500); The diluted liquid material is stirred into the above-mentioned silt and sludge, and evenly stirred with it to form "enzyme sludge, battery mixture" (hereinafter referred to as "enzyme sludge, battery mixture"); and this "enzyme sludge, battery mixture" "After adjusting to the optimum water content (cooling, drying or adding water - choose according to the actual situation), the module is made according to the mode of the "mud cake geotechnical characteristics test" method, and the anti-leak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com