Aerated concrete debris-based masonry mortar for thermal-insulation masonry and preparation method thereof

A technology of aerated concrete and masonry mortar, which is applied in the field of masonry mortar for thermal insulation masonry and its preparation, can solve the problems of poor thermal insulation performance, reduced thermal insulation performance of self-insulating masonry or wall, large thermal conductivity, etc. The effect of sufficient raw materials, saving money and energy consumption, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

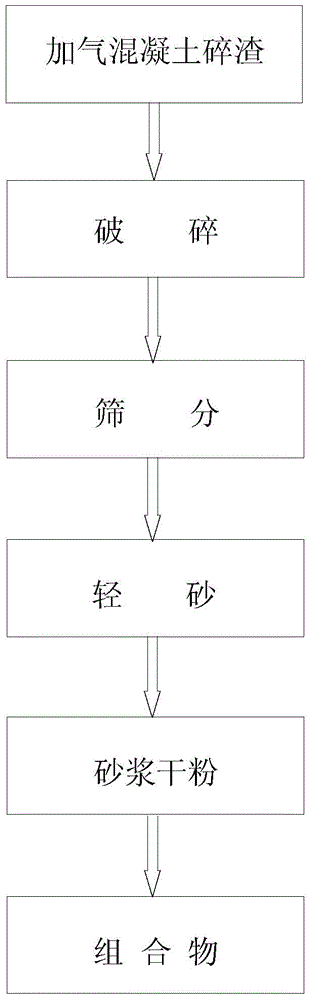

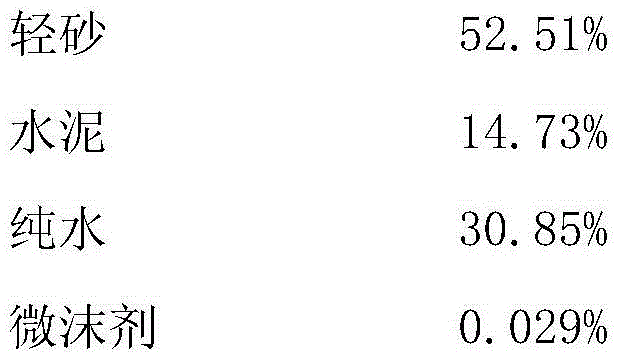

[0047] combine figure 1 And Table 1, Table 2, a kind of masonry mortar for thermal insulation masonry based on aerated concrete slag, with aerated concrete slag and waste as the base material, the components of the insulation mortar strength grade made of M5 and The weight percentage is:

[0048] Light sand: 52.51%, cement: 14.73%, pure water: 30.85%, microfoam: 0.029%;

[0049] The operation steps are as follows:

[0050] ⑴. Ordinary aerated concrete slag and waste materials according to the above weight percentages are used as base materials for later use;

[0051] (2) Use crocodile crusher or other crushing equipment to crush the above spare base materials;

[0052] ⑶. The above spare base materials are crushed and then sieved to obtain a particle size of 0-2.5mm, a fineness modulus of 3.0, and a bulk density of 680-710kg / m 3 of light sand;

[0053] ⑷. According to the content of the above components, dry mix light sand and cement to make dry mortar powder;

[0054] ⑸...

Embodiment 2

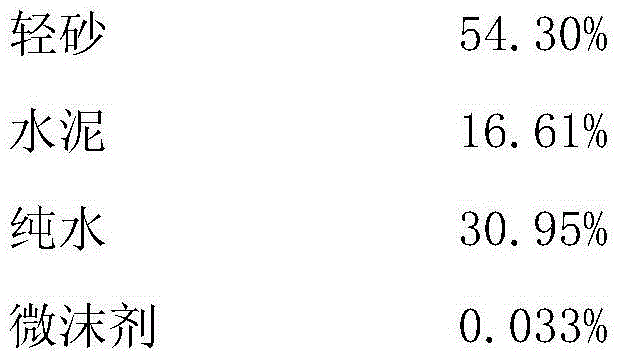

[0059] combine figure 1 And Table 1, Table 2, a kind of masonry mortar for thermal insulation masonry based on aerated concrete slag, with aerated concrete slag and waste as base material, each group of insulation mortar strength grades made of M7.5 Points and weight percentages are:

[0060] Light sand: 54.30%, cement: 16.61%, pure water: 30.95%, microfoam: 0.033%;

[0061] The operation steps are as follows:

[0062] ⑴. Ordinary aerated concrete slag and waste materials according to the above weight percentages are used as base materials for later use;

[0063] (2) Use crocodile crusher or other crushing equipment to crush the above spare base materials;

[0064] ⑶. The above spare base materials are crushed and then sieved to obtain a particle size of 0-2.5mm, a fineness modulus of 3.0, and a bulk density of 680-710kg / m 3 of light sand;

[0065] ⑷. According to the content of the above components, dry mix light sand and cement to make dry mortar powder;

[0066] ⑸. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com