Pollution-free oil-containing mud cleaning treatment method and treatment system thereof

A purification treatment and pollution-free technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of increased operating costs, long process flow, separation of oil and fine mud, etc., and achieves simple and loose implementation conditions, The effect of simple processing flow and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

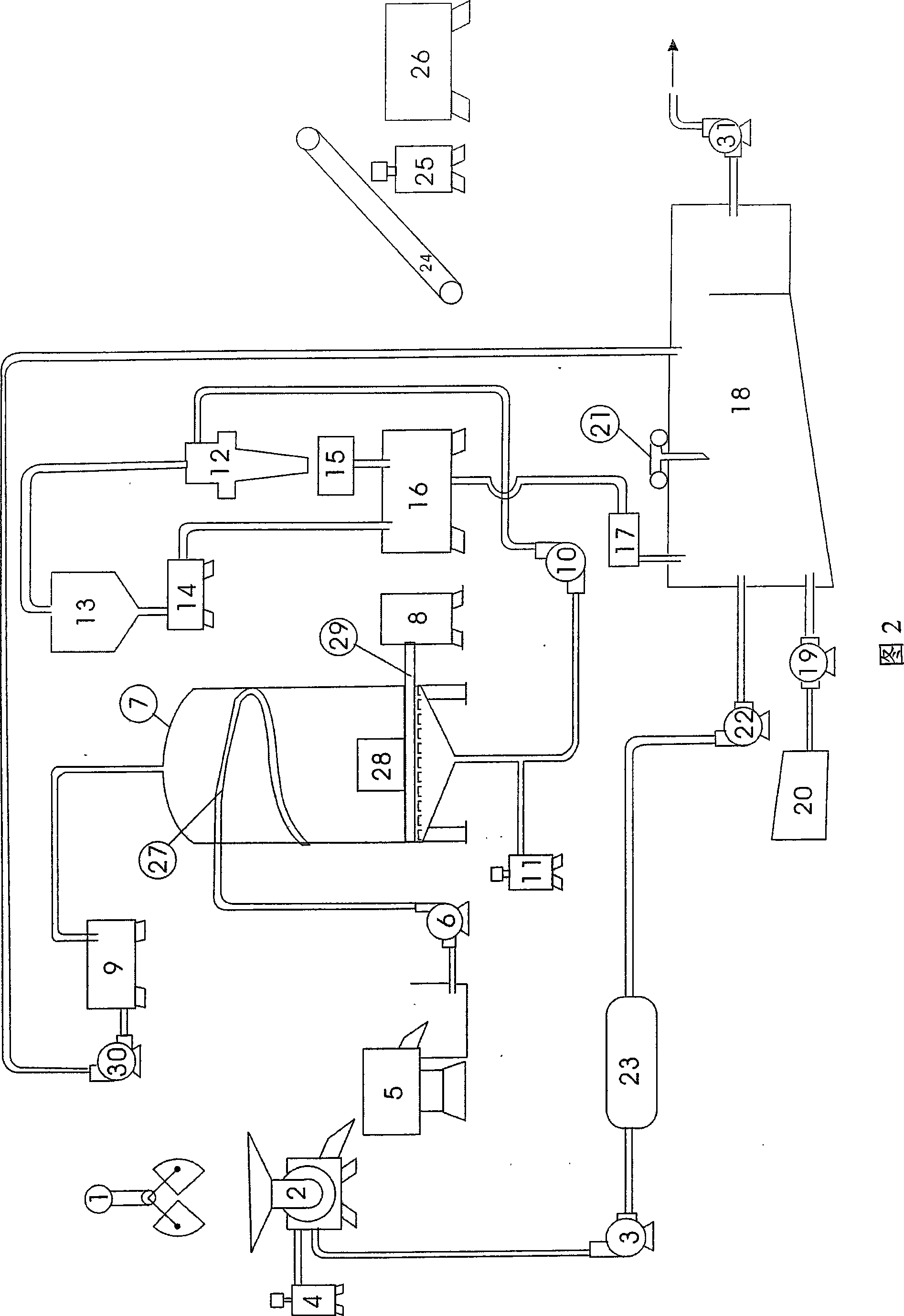

[0033] Below in conjunction with accompanying drawing and preferred embodiment, the specific implementation mode, structure, feature provided according to the present invention are described in detail as follows:

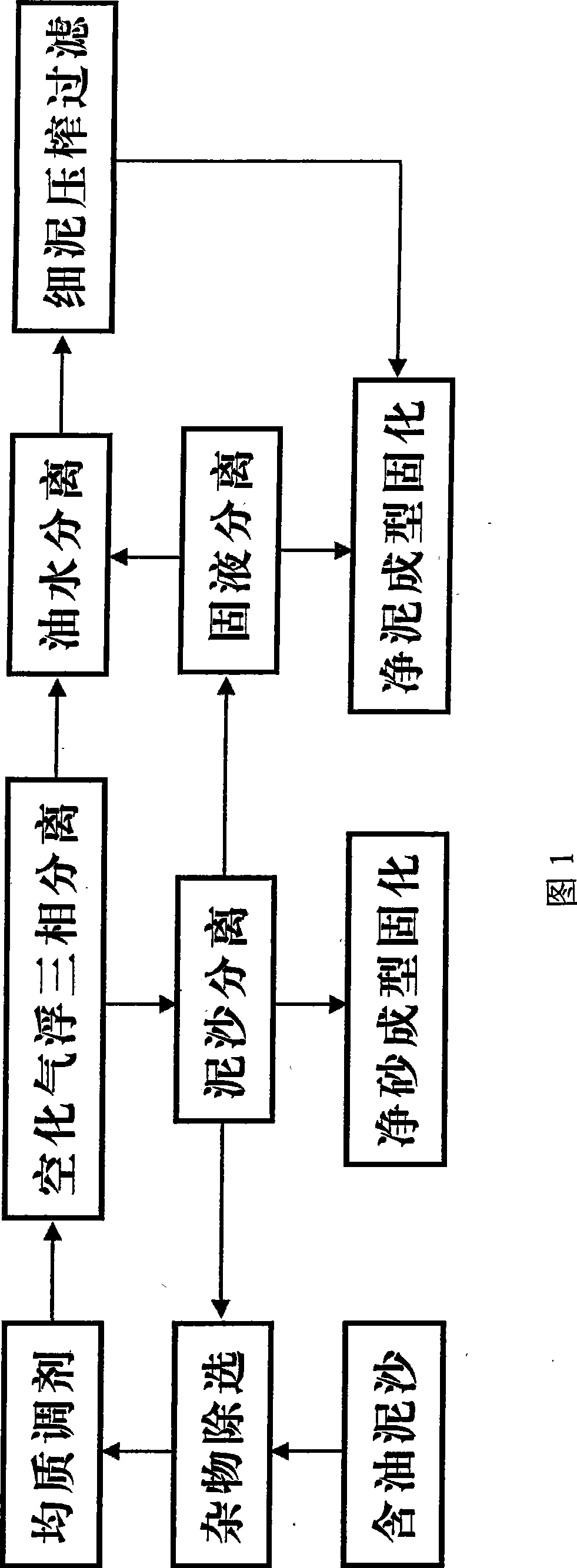

[0034] As shown in Figure 1, a pollution-free oily sediment purification treatment method, which separates and purifies oily sediment deposits, the implementation steps are as follows:

[0035] (1) Use the debris removal machine to sort and screen the debris in the oily sediment, and use a mechanical feeding device to evenly send the oily sediment into the debris removal machine and pour hot water and polymer into the oily sediment Separation demulsifier, the polymer separation demulsifier can be one of dodecylbenzenesulfonic acid, alkylphenol polyoxyethylene ether phosphate, petroleum sulfonate, sodium hydroxide, sodium tripolyphosphate and other agents Or more than one type; the temperature of hot water is 40-95 °C, or add steam, the temperature of which is to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com