Stripping method for cathode material and current collector of waste ternary power lithium battery

A positive electrode material and meta-power technology, applied in the field of resource regeneration, to achieve the effects of easy industrialization and automatic operation, low operating cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Cut the fully discharged ternary power battery by cold cutting, collect battery poles, shells, etc. for recycling, and manually separate the positive and negative electrodes and plastic diaphragms from the removed batteries;

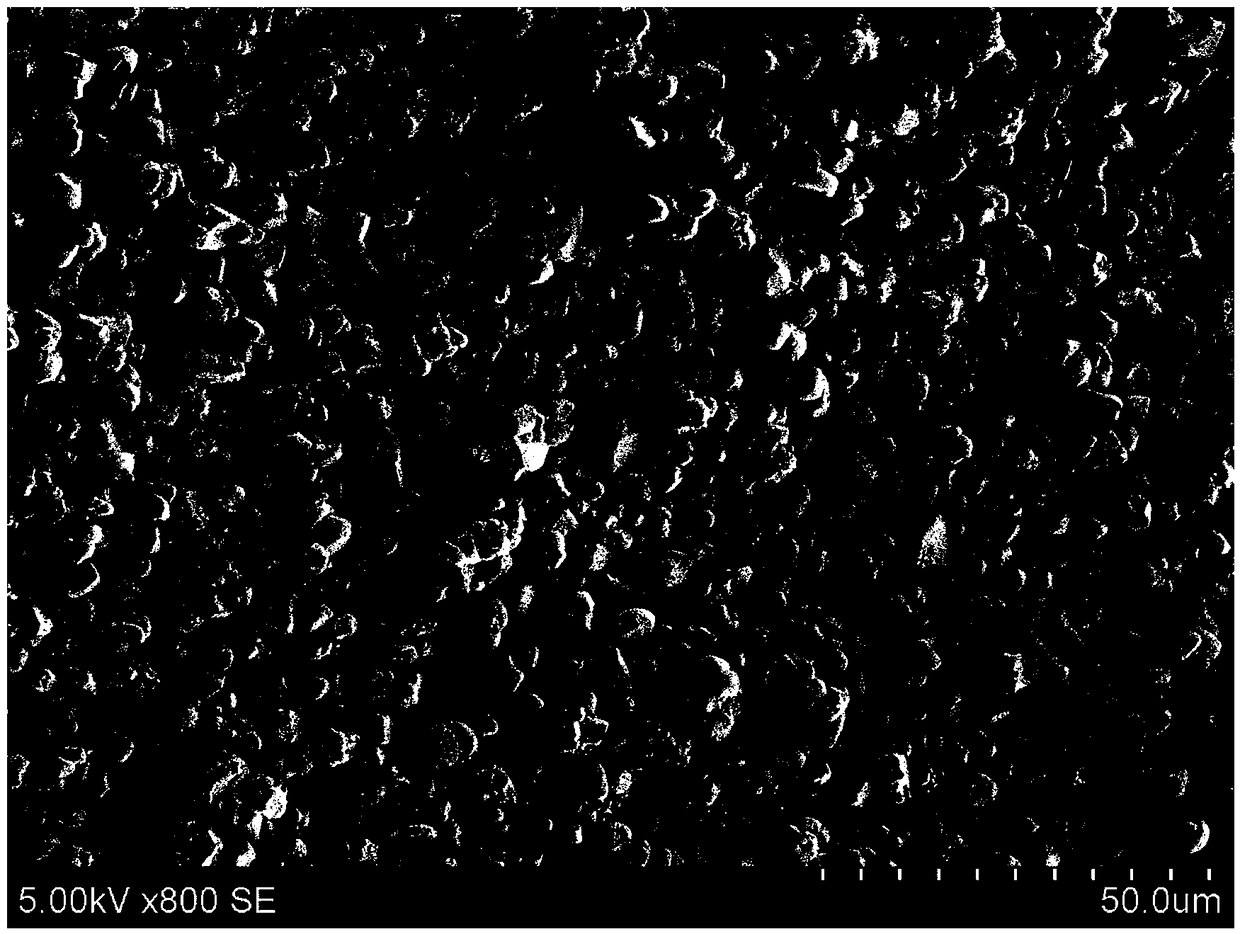

[0058] (2) Cut the positive electrode sheet into a strip shape of 69mm×45mm (1 / 4 of the electrode sheet), put it in an oven, raise the temperature to 450°C at a rate of 3°C / min, keep it warm for 1.5 hours, and cool it down to room temperature naturally. Shaking the positive electrode sheet, the positive electrode material on the current collector hardly fell off.

[0059] (3) Put the insulated positive electrode sheet into deionized water at room temperature for 10 seconds with an ultrasonic cleaning frequency of 60KHz and a power of 1.5Kw, and the positive electrode material will completely fall off from the aluminum foil of the current collector.

[0060] (4) The positive electrode material is suction-filtered and then dried in a blast oven ...

Embodiment 2

[0063] (1) Cut the fully discharged ternary power battery by cold cutting, collect battery poles, shells, etc. for recycling, and manually separate the positive and negative electrodes and plastic diaphragms from the removed cells;

[0064] (2) Cut the positive electrode sheet into a rectangle of 90mm×46mm (1 / 3 of the electrode sheet), put it in an oven, raise the temperature to 500°C at a rate of 4°C / min, keep it warm for 2 hours, cool it down to room temperature naturally, and shake the positive electrode There is a very small amount of powder shedding from the positive electrode material on the current collector, which can basically be ignored.

[0065] (3) Put the insulated positive electrode sheet into deionized water at room temperature and ultrasonically clean it at a frequency of 60KHz and a power of 1.5Kw for 20 seconds, and the positive electrode material will completely fall off from the aluminum foil of the current collector.

[0066] (4) The positive electrode mat...

Embodiment 3

[0069] (1) Cut the fully discharged ternary power battery by cold cutting, collect battery poles, shells, etc. for recycling, and manually separate the positive and negative electrodes and plastic diaphragms from the removed cells;

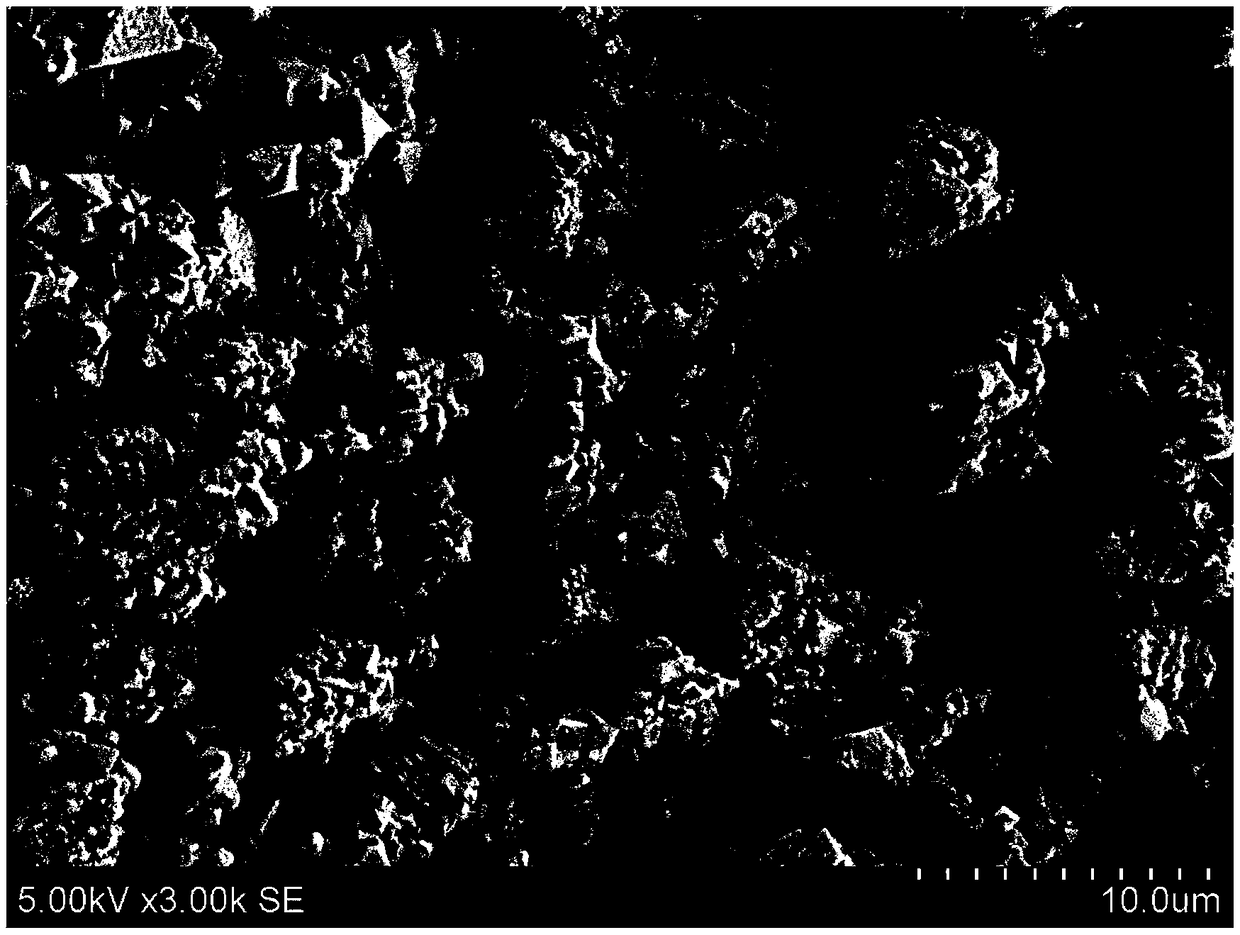

[0070] (2) Put the positive electrode sheet 138mm×90mm (complete electrode sheet) into the oven, raise the temperature to 550°C at a rate of 5°C / min, keep it warm for 2.5 hours, cool down to room temperature naturally, shake the positive electrode sheet, and the positive electrode material will be released from the current collector There is a small amount of powder falling off, and the average quality of the material that falls off from each pole piece accounts for 5.25% of the quality of the material collected by ultrasound.

[0071] (3) Put the insulated positive electrode sheet into deionized water at room temperature and ultrasonically clean it at a frequency of 60KHz and a power of 1.5Kw for 30 seconds, and the positive electrode material wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com