Patents

Literature

95results about How to "Harmless treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

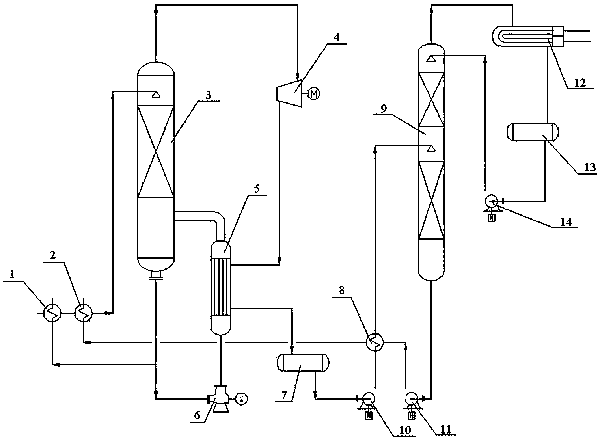

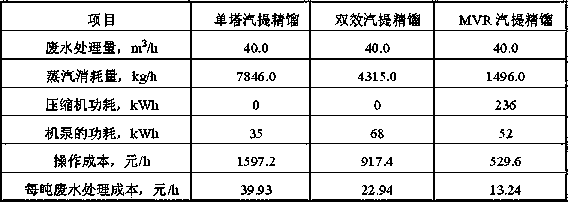

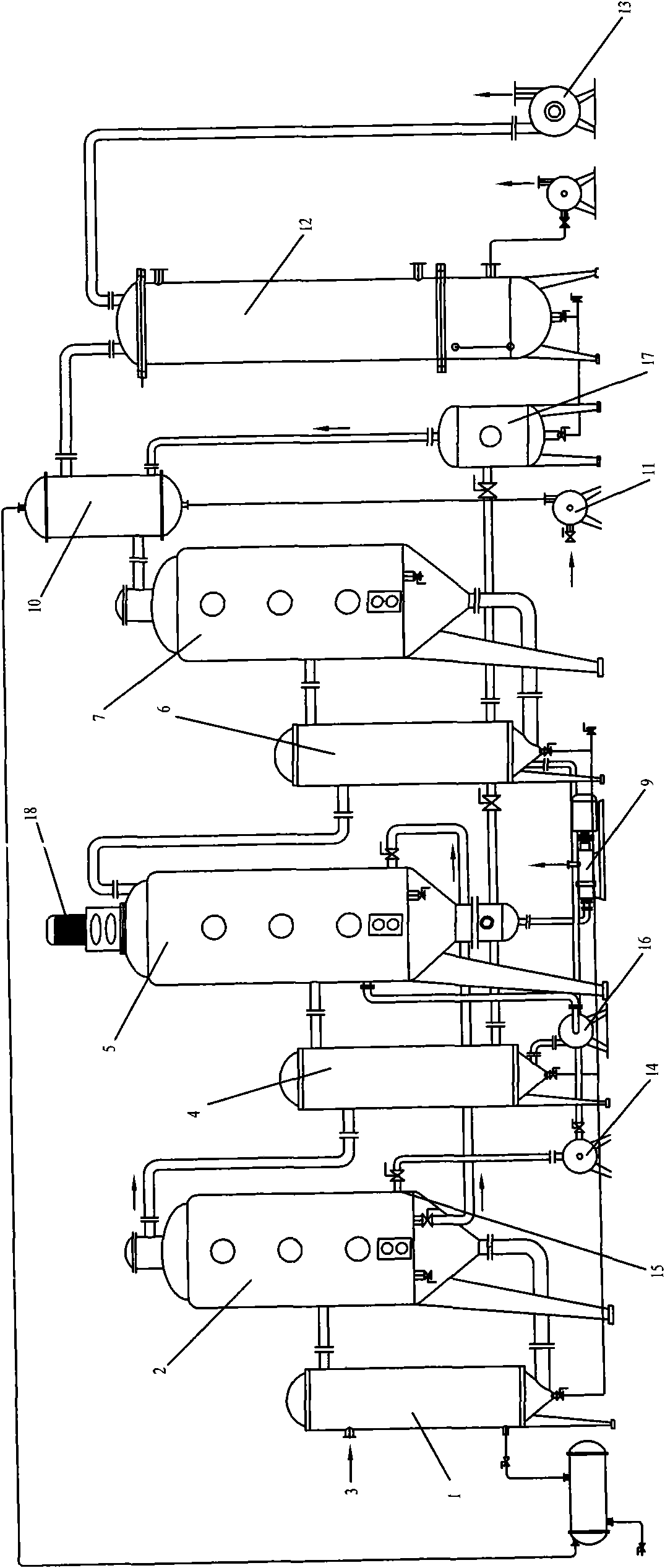

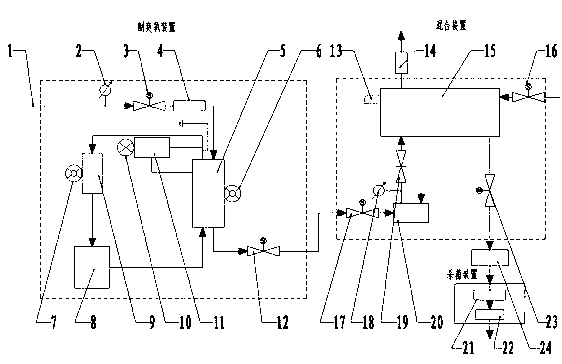

MVR (Mechanical Vapor Recompression) vapor-stripping deamination system and application method thereof

InactiveCN103408086AIncrease pressureIncrease temperatureWater/sewage treatment by degassingAmmonia preparation/separationAxial-flow pumpWater discharge

The invention relates to an MVR vapor-stripping deamination system. The MVR (Mechanical Vapor Recompression) vapor-stripping deamination system comprises a vapor-stripping deamination tower, an ammonia water rectification tower and a condenser, wherein a high-ammonia-nitrogen sewage input pipe, a vapor input pipe I, a post-deamination waste water discharge port and an ammonia-containing vapor discharge port I are arranged on the vapor-stripping deamination tower; the vapor-stripping deamination tower is connected with a reboiler; the high-ammonia-nitrogen sewage input pipe is connected with waste water feed preheaters (II and I); the post-deamination waste water discharge port is connected with the waste water feed preheater I and an axial flow pump respectively; the ammonia-containing vapor discharge port I is connected with the reboiler through a mechanical vapor compressor; the reboiler is connected with a dilute ammonia water storage tank connected with the ammonia water rectification tower; a discharge port, an ammonia-containing vapor discharge port II and a vapor input pipe are arranged on the ammonia water rectification tower; the discharge port is connected with a rectification tower kettle discharge pump and the waste water feed preheater II; the ammonia-containing vapor discharge port II is connected with the condenser; a strong ammonia water discharge port is connected with a strong ammonia water storage tank connected with the ammonia water rectification tower. Meanwhile, the invention further discloses an application method of the MVR vapor-stripping deamination system. The MVR vapor-stripping deamination system has the advantages of less investment, high feasibility and high comprehensive utilization ration.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

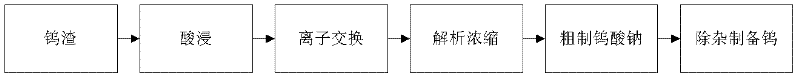

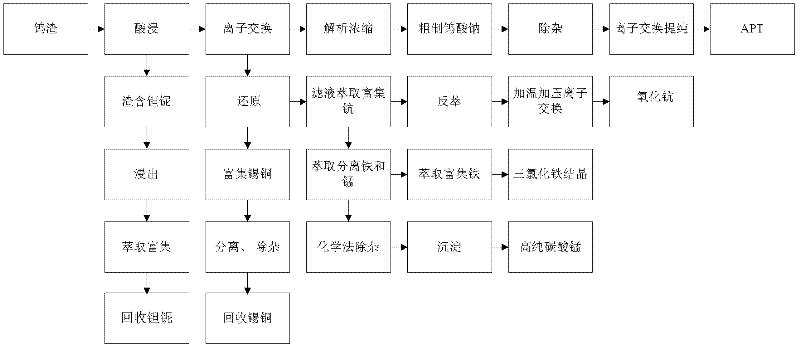

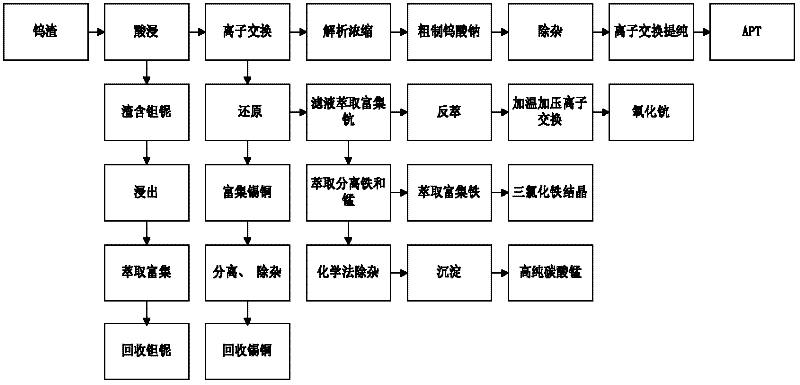

Tungsten slag treatment method

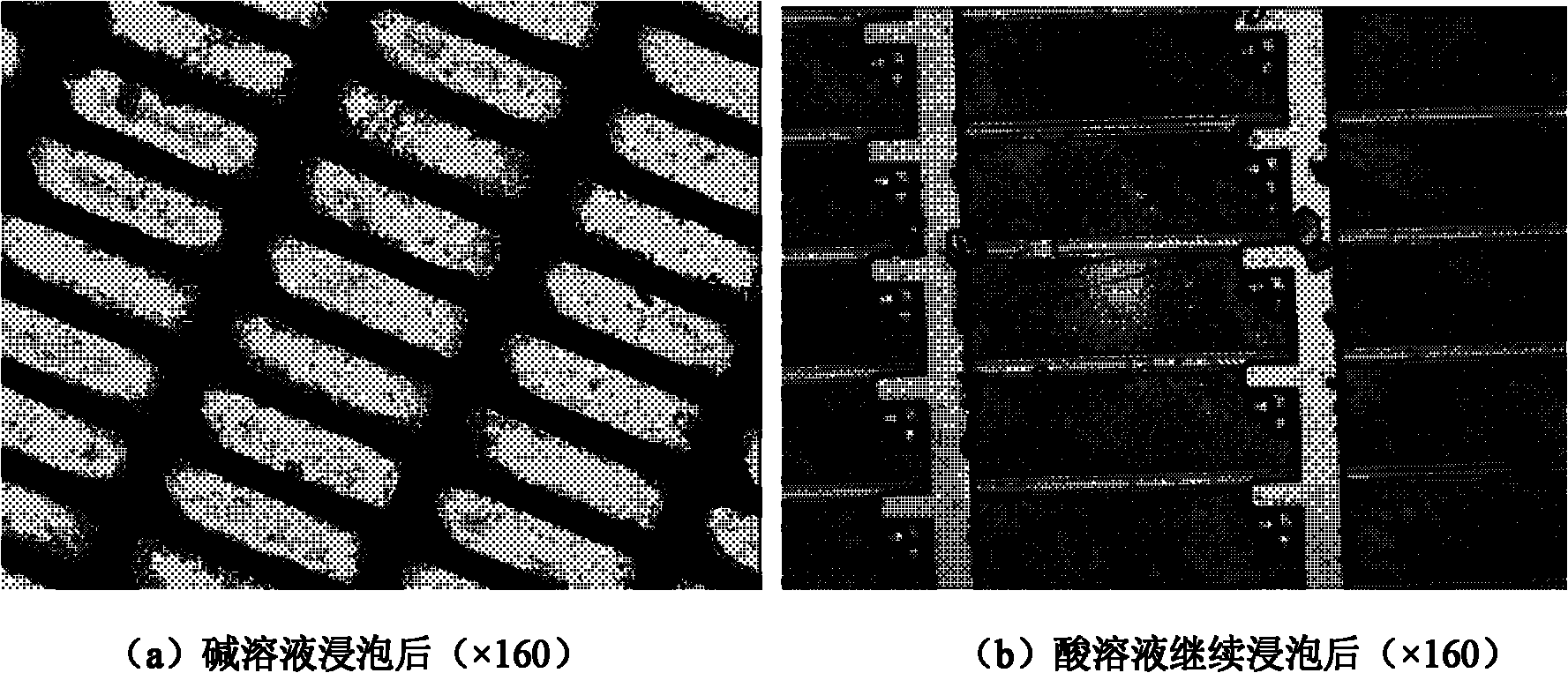

ActiveCN102212697ASolve the problem of secondary pollutionReduce recycling costsProcess efficiency improvementSlagFiltration

The invention discloses a tungsten slag treatment method. The tungsten slag treatment method comprises the following steps of: dissolving: mixing tungsten slag and 15 to 30 percent HCl solution of 50 to 65 DEG C, adding a tungsten stabilizing agent, and performing filtration after the reaction is finished to obtain acid solution; and reclaiming tungsten: adsorbing the tungsten in the acid solution by adopting weak alkali acrylic acid series anion exchange resin to obtain tail solution I, resolving the exchange resin by using sodium hydroxide solution to obtain sodium tungstate, and reclaimingthe tungsten from the sodium tungstate. By using the technical scheme, the tungsten slag is leached at a low temperature under normal pressure by adopting the HCl solution, and the tungsten is directly reclaimed by a one-step method under the acid condition; and the process is simple and low in reclamation cost.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

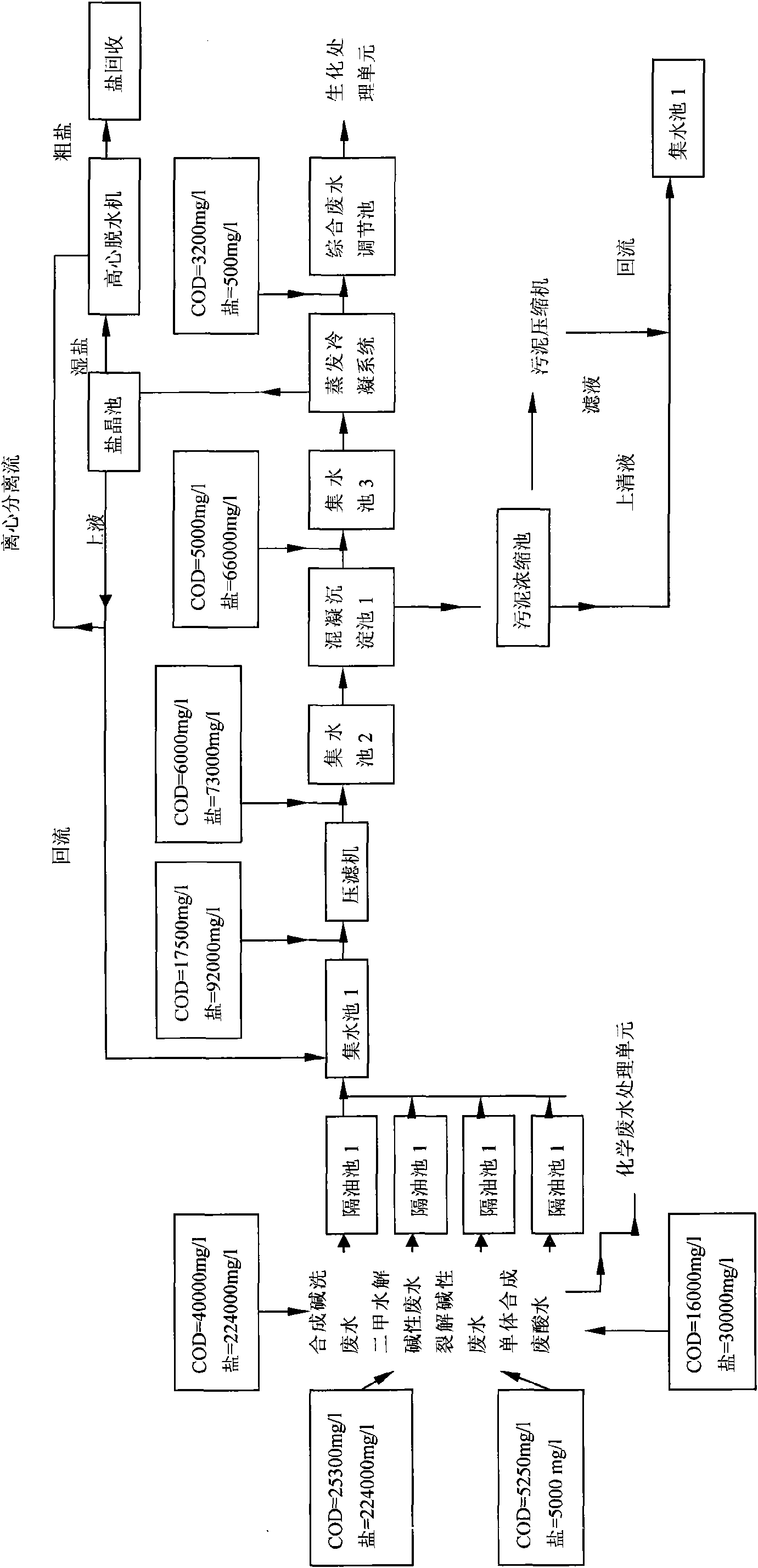

Method for treating waste water containing high concentration of organosilicon

ActiveCN101549938ALow costHarmless treatmentFatty/oily/floating substances removal devicesWater contaminantsHigh concentrationSludge

The invention provides a new method for treating waste water containing high concentration of organosilicon. The method comprises: solidifying the waste water containing high concentration of organosilicon; conditioning sludge characteristic to increasing the press filtering water penetration of the sludge, and performing solid-liquid separation; adding flocculating agent into the filtrate to remove the residual salts in the waste water; performing sludge-water separation to the flocculated filtrate, and pumping the obtained supernatant into a condenser to cause the volatile pollutants and waste water to separate from the waste water in gas mode; removing all the salts in the waste water to improve the biodegradability of the waste water, and create conditions for the subsequent low concentration waste water treatment. The invention provides a high efficient, energy saving technical approach with low cost to the treatment of waste water containing high concentration of organosilicon; can recover useful resources such as salts; has great application prospect.

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

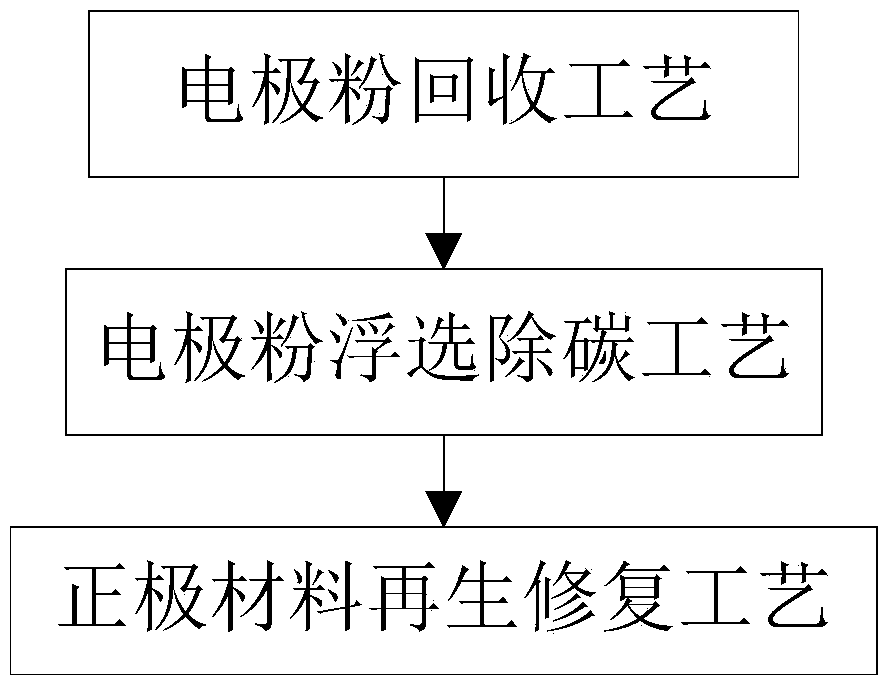

Recycling process of positive electrode materials of waste batteries

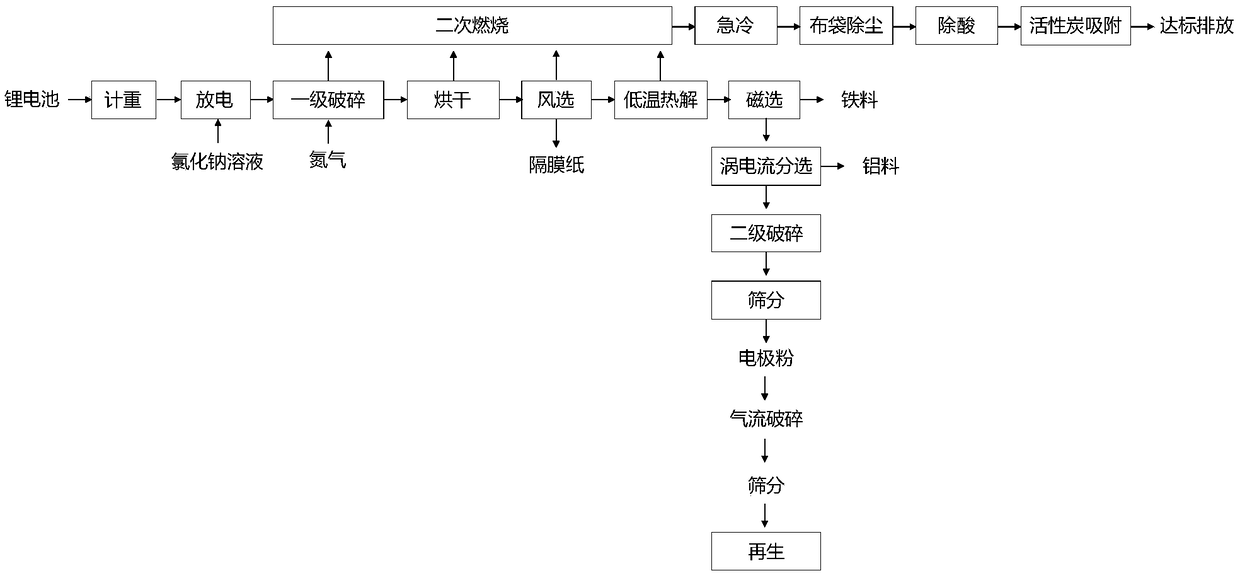

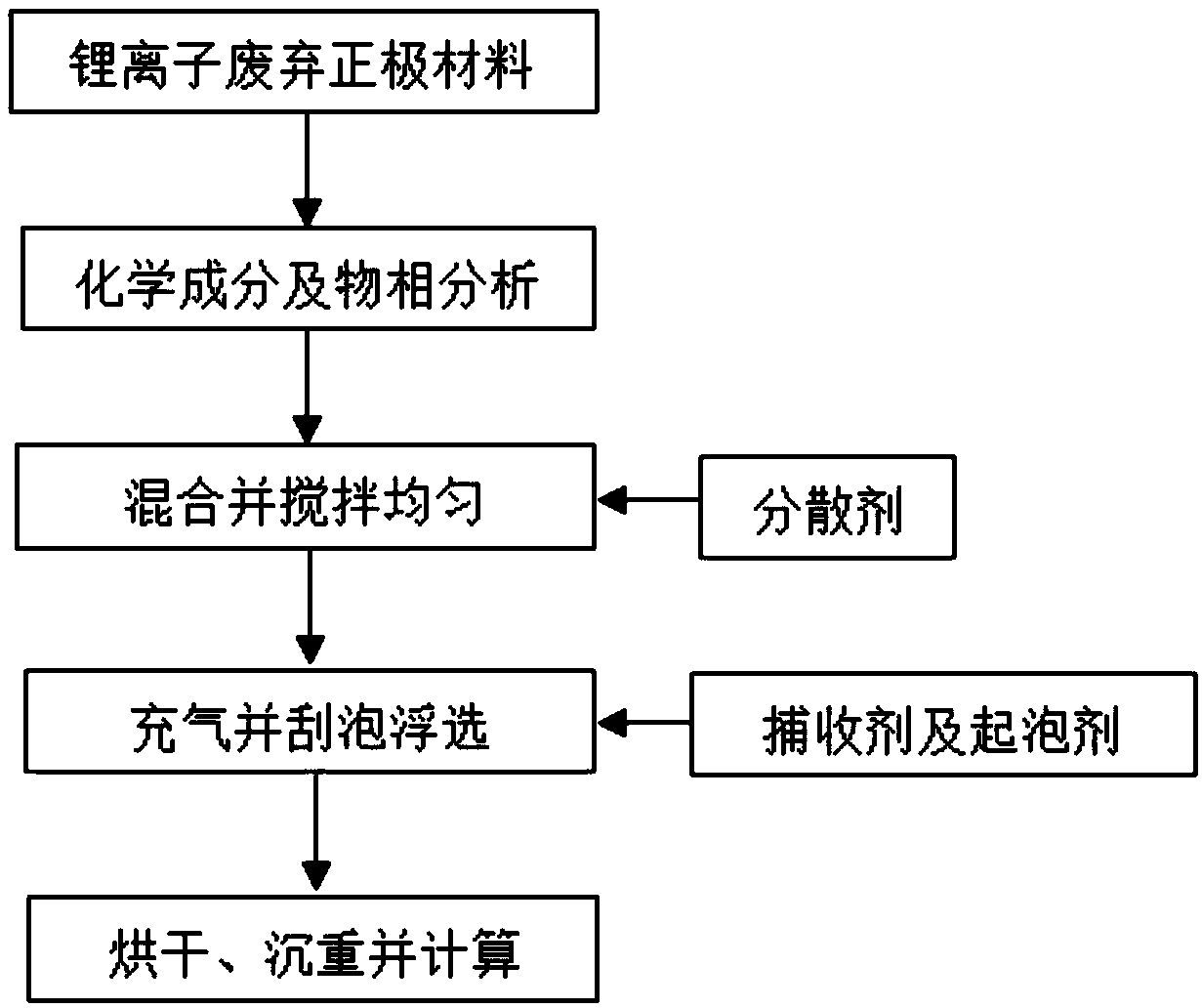

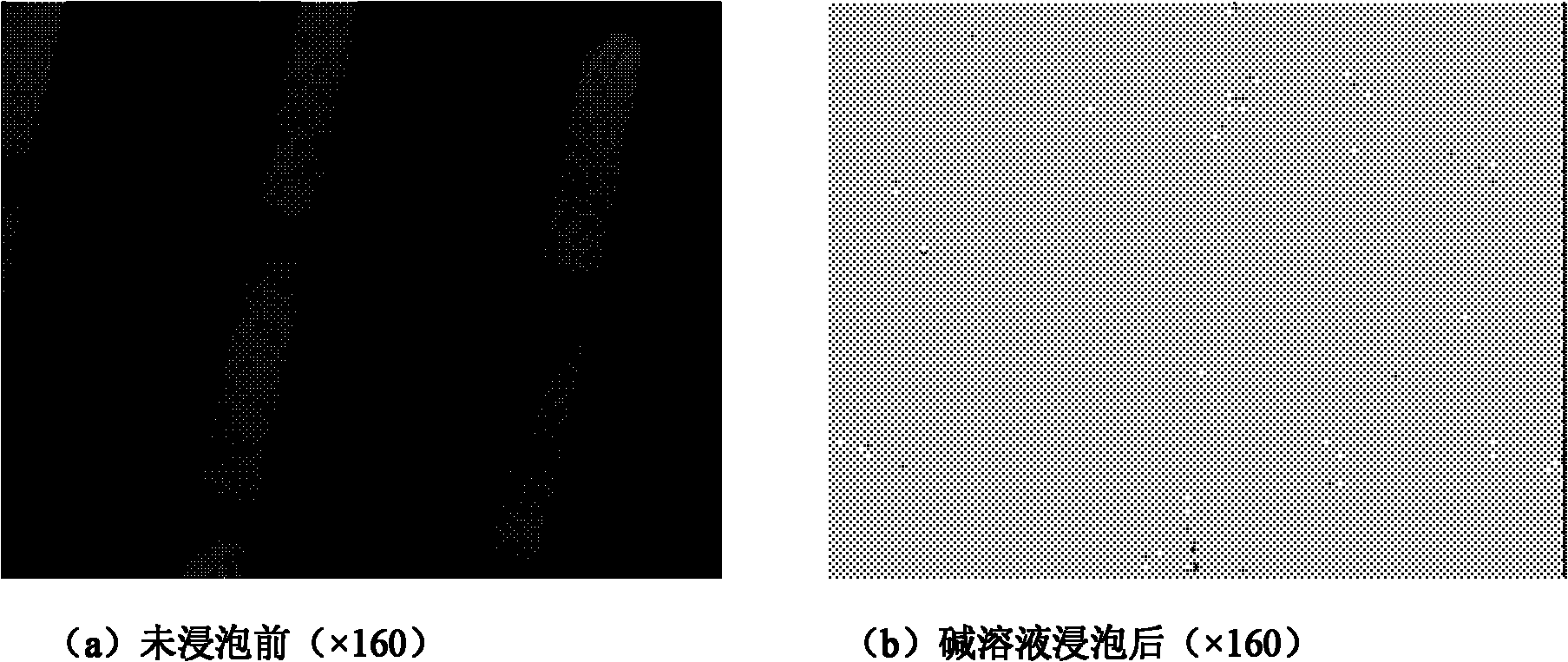

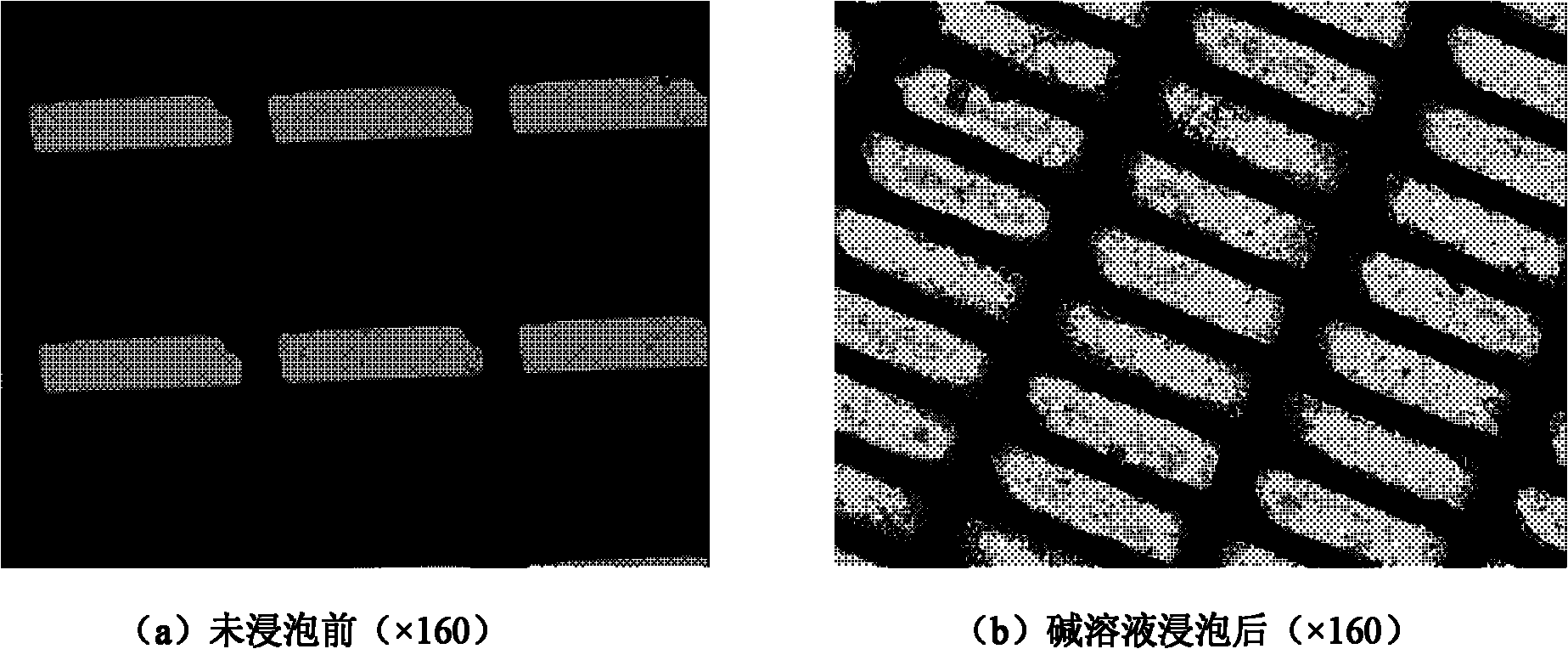

ActiveCN109326843ASimple recycling processHarmless treatmentWaste accumulators reclaimingFlotationEngineeringBiological activation

The invention discloses a recycling process of positive electrode materials of waste batteries. The recycling process includes the steps of completely discharging the waste lithium batteries, subjecting the waste lithium batteries to primary crushing under inert gas protection, removing diaphragm paper through air classification after crushing, performing low-temperature pyrolysis, respectively removing iron materials and aluminum materials through sorting, performing re-pulverization to obtain electrode powder, determining a flotation reagent system according to the phase composition of the electrode powder, performing flotation in a flotation tank, and filtering and drying products at the bottom of the flotation tank to obtain the positive electrode materials; according to the Li / M ratioof the positive electrode materials, calculating the lithium source powder to be added, and mixing water-soluble dispersants and the lithium source powder with water to form a mixed solution; addingthe positive electrode materials to be repaired into the mixed solution, performing cooking activation at a high temperature and under high pressure, continuing to dry the product under normal pressure to obtain uniform mixture powder, and calcining the mixture powder under an aerobic condition to obtain the regenerated and repaired lithium ion battery positive electrode materials. The recycling process has the advantages of low repair cost, high activity after repair, and higher promotion and application value.

Owner:荆门动力电池再生技术有限公司

Method for recovering glass substrates of liquid crystal display screen

InactiveCN102179397AAvoid secondary pollutionSave time and costSolid waste disposalLiquid-crystal displayWaste recovery

The invention relates to a waste recovery technology, in particular to a method for recovering glass substrates of a liquid crystal display screen, which comprises the following steps of: A, detaching; B, classifying; C, recovering a glass substrate containing a resin black matrix membrane; D, recovering a glass substrate containing a chromium black matrix membrane; and E, recovering a matrix-free glass substrate. By the method, innocent treatment of the glass substrates is realized, secondary pollution is avoided, different treatment methods for different types of glass substrates are provided, and time and cost are saved; and by the technical route, the glass substrates can be effectively recovered and are easily treated, and the method is suitable for industrialization.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

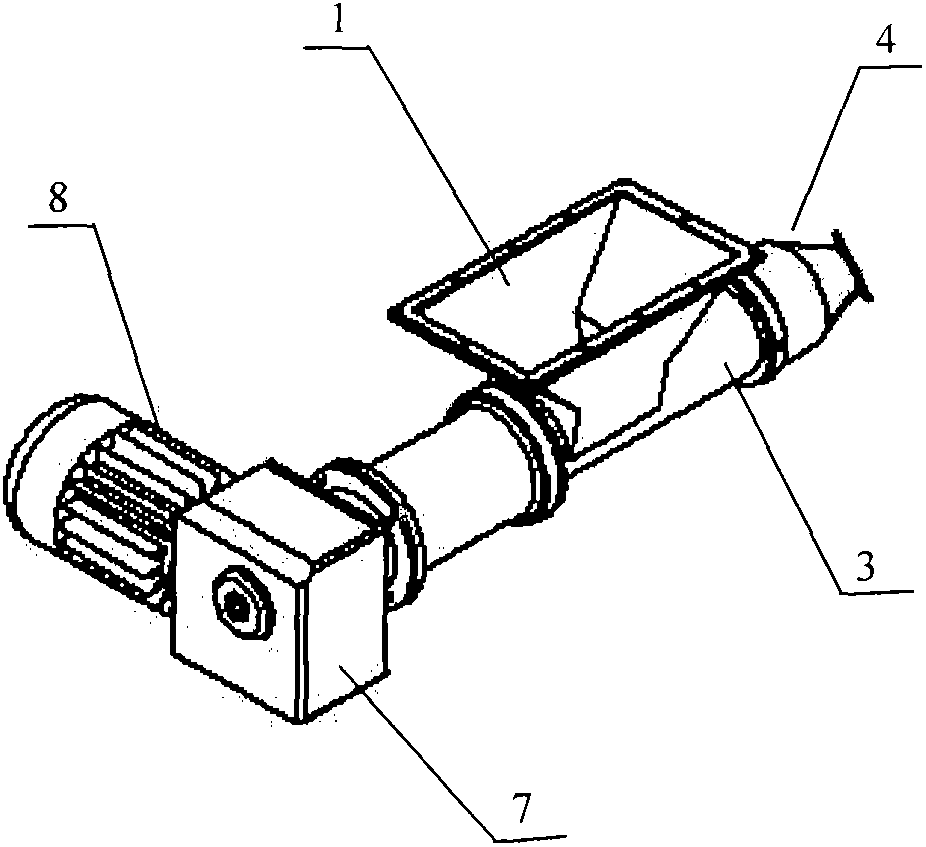

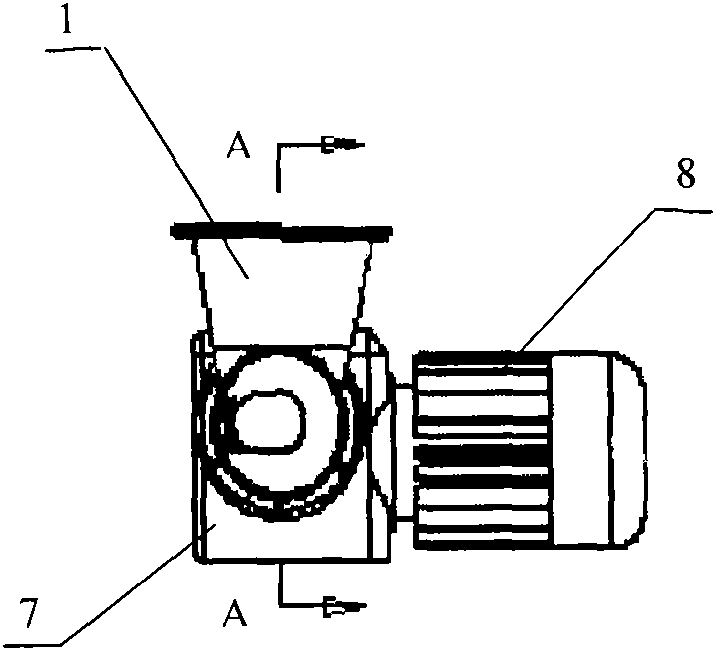

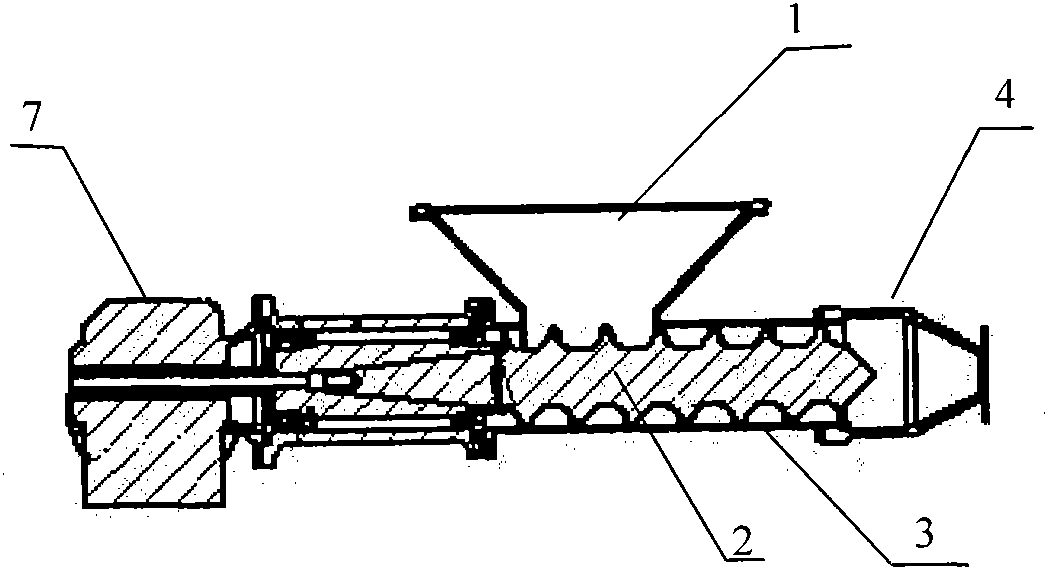

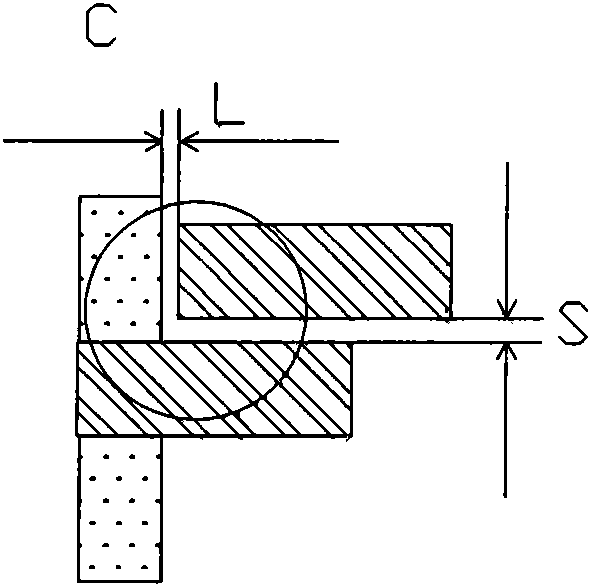

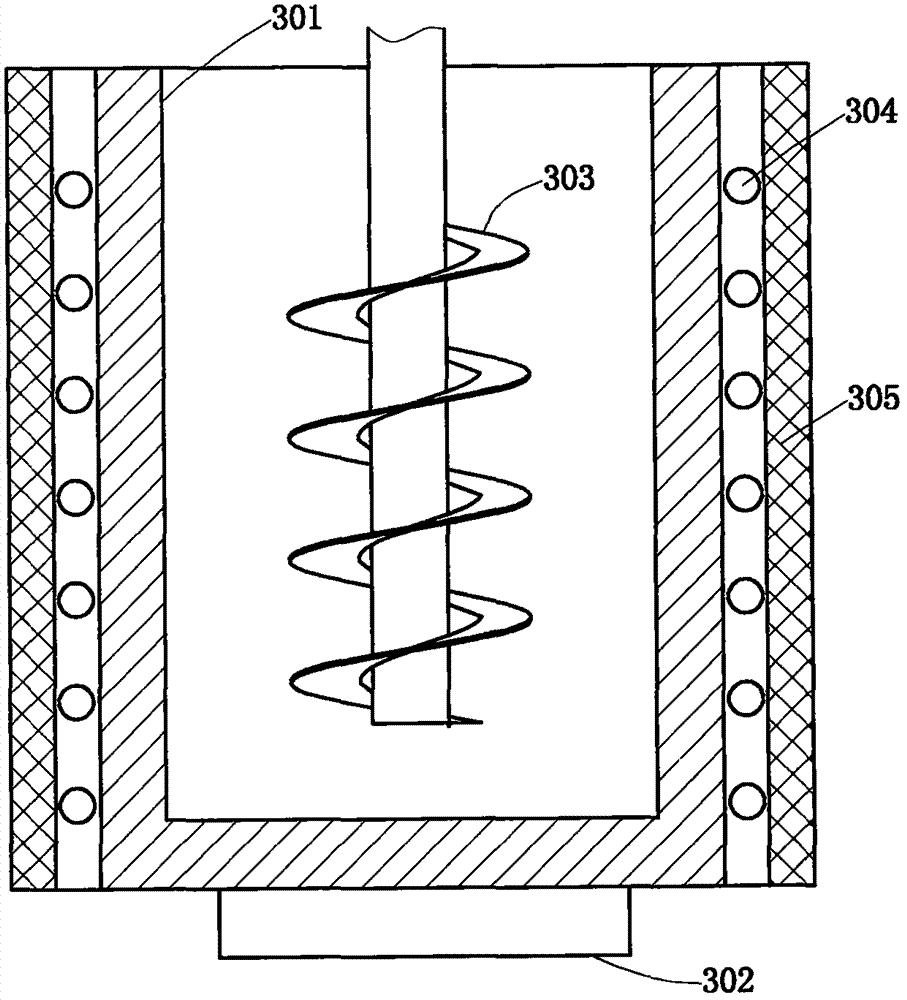

Squeezing device and squeezing machine

The invention relates to mechanical equipment, in particular to a squeezing device and a squeezing machine. The invention provides the squeezing device, which comprises a feed inlet, a screw, a material storage sleeve, a pressure cylinder and a taper cylinder, a screen and a discharge hole, wherein the screw is arranged in the material storage sleeve; the feed inlet is formed in the sleeve wall on the upper part of the material storage sleeve; one end of the material storage sleeve is fixed; and the other end of the material storage sleeve is connected with the pressure cylinder; one end of the screw is connected with the fixed end of the material storage sleeve; and the other end of the screw is suspended in the pressure cylinder; the cylindrical screen is arranged in the pressure cylinder; the two ends of the screen are connected with the material storage sleeve and the taper cylinder respectively; a liquid outlet is formed in the cylinder wall on the lower part of the pressure cylinder; and the discharge hole is formed in the taper cylinder. The invention also provides the squeezing machine, which comprises an electrical motor, a speed reducer, a rack and the squeezing device provided by the invention. By using the squeezing device and the squeezing machine provided by the invention, the squeezing processing of materials can be finished continuously and efficiently.

Owner:邢征

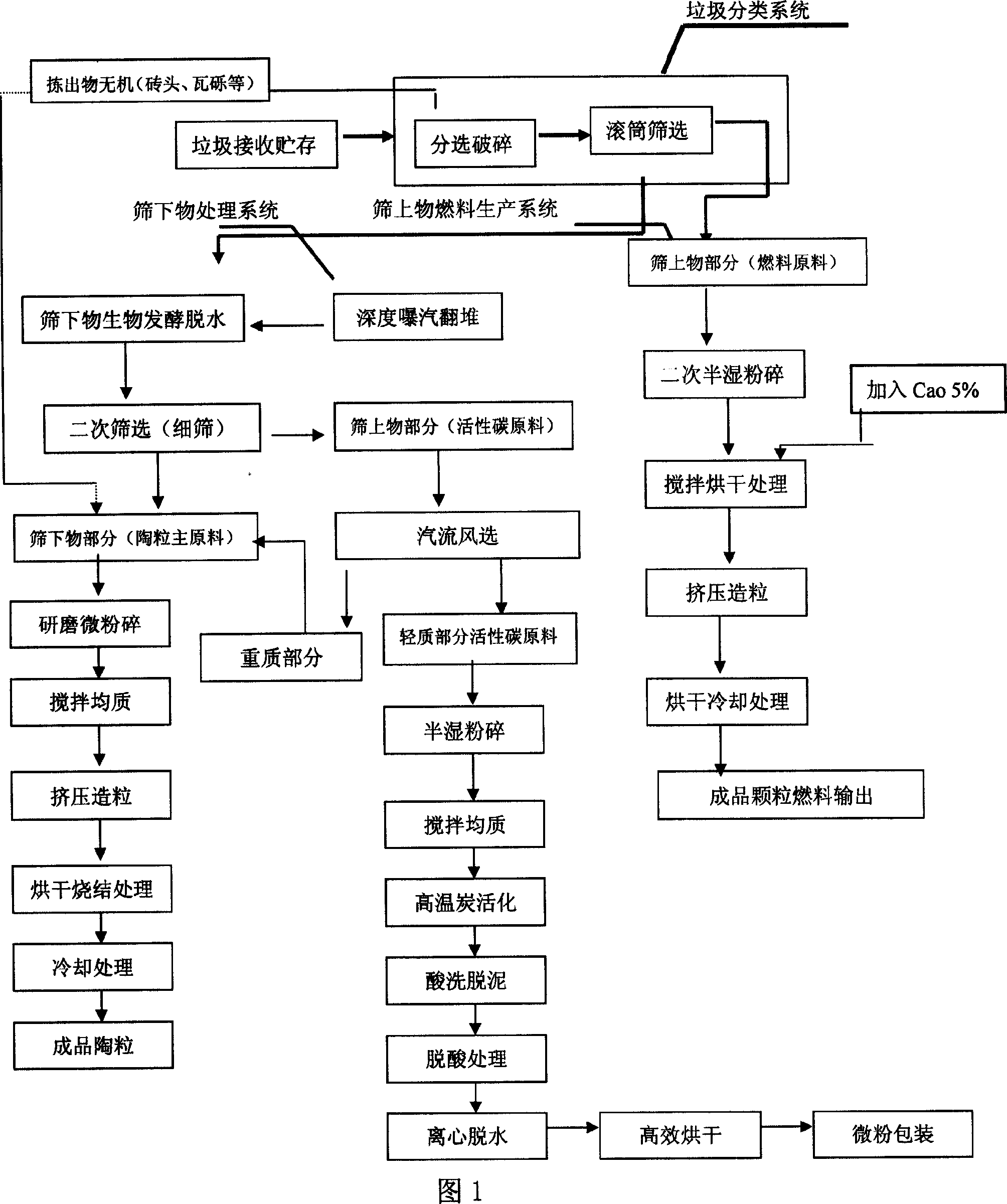

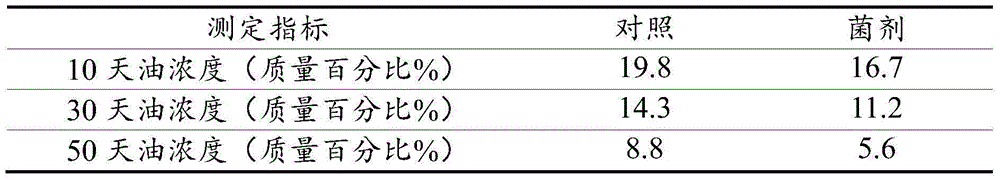

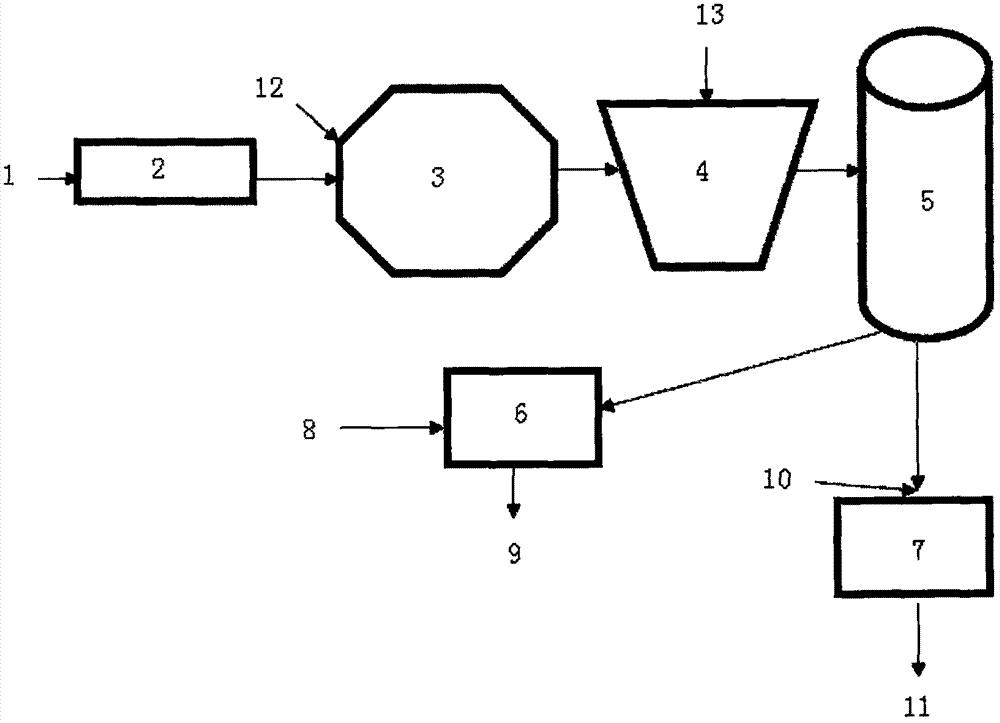

Method for one-step producing biomassfuel, biological haydite and active carbon using high wet mixed city garbage as raw material

InactiveCN1944602APerfect separation processHarmless treatmentBiofuelsSolid fuelsActivated carbonActive carbon

The process of producing biomass fuel, biological haydite and active carbon with city garbage with high water content as raw material includes the following steps: sorting and crushing garbage, drum screening, preparing biomass fuel, biologically fermenting and dewatering, preparing biological haydite and active carbon, etc. The present invention makes it possible to make best utilization of garbage resource.

Owner:雷丰源

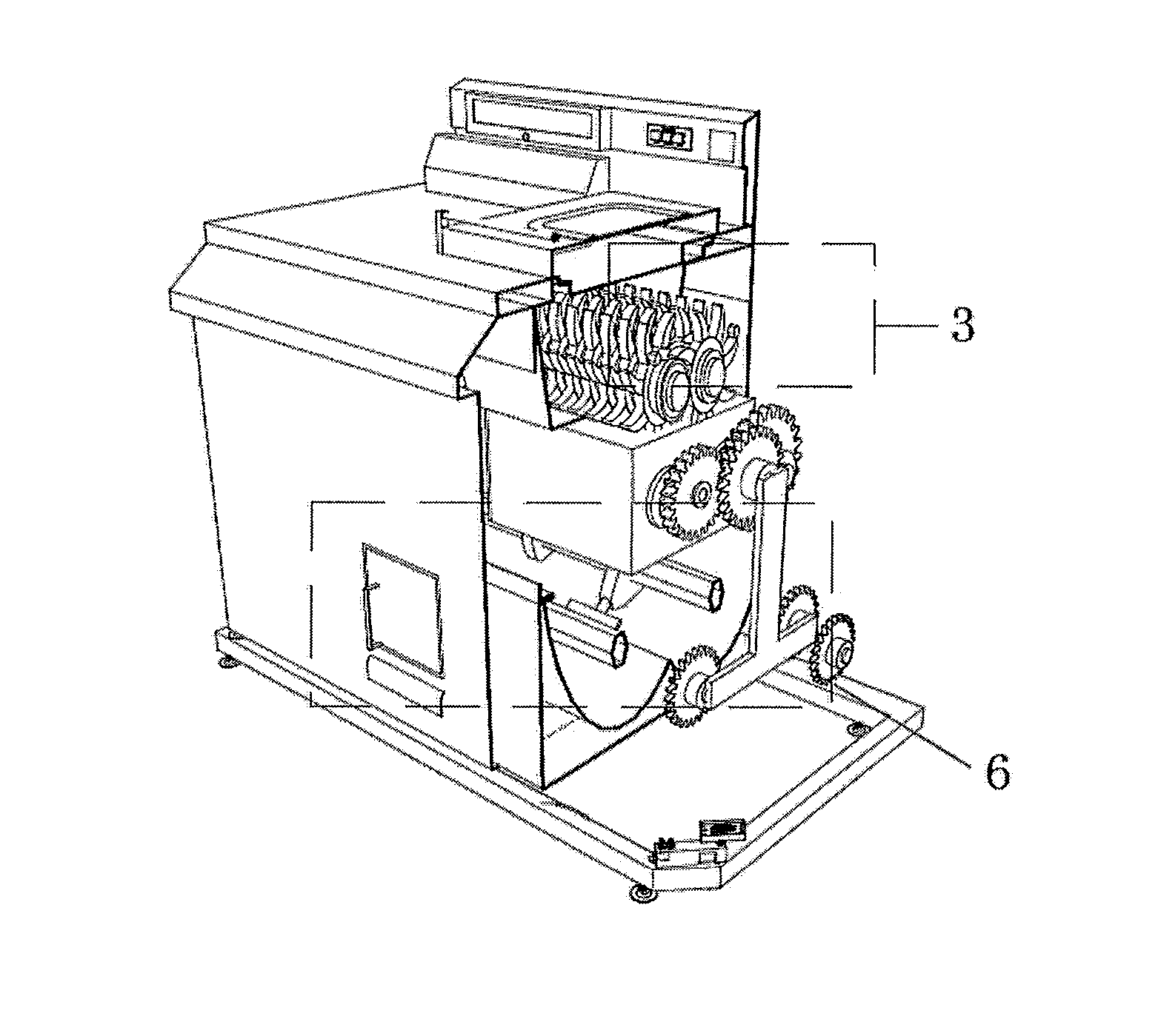

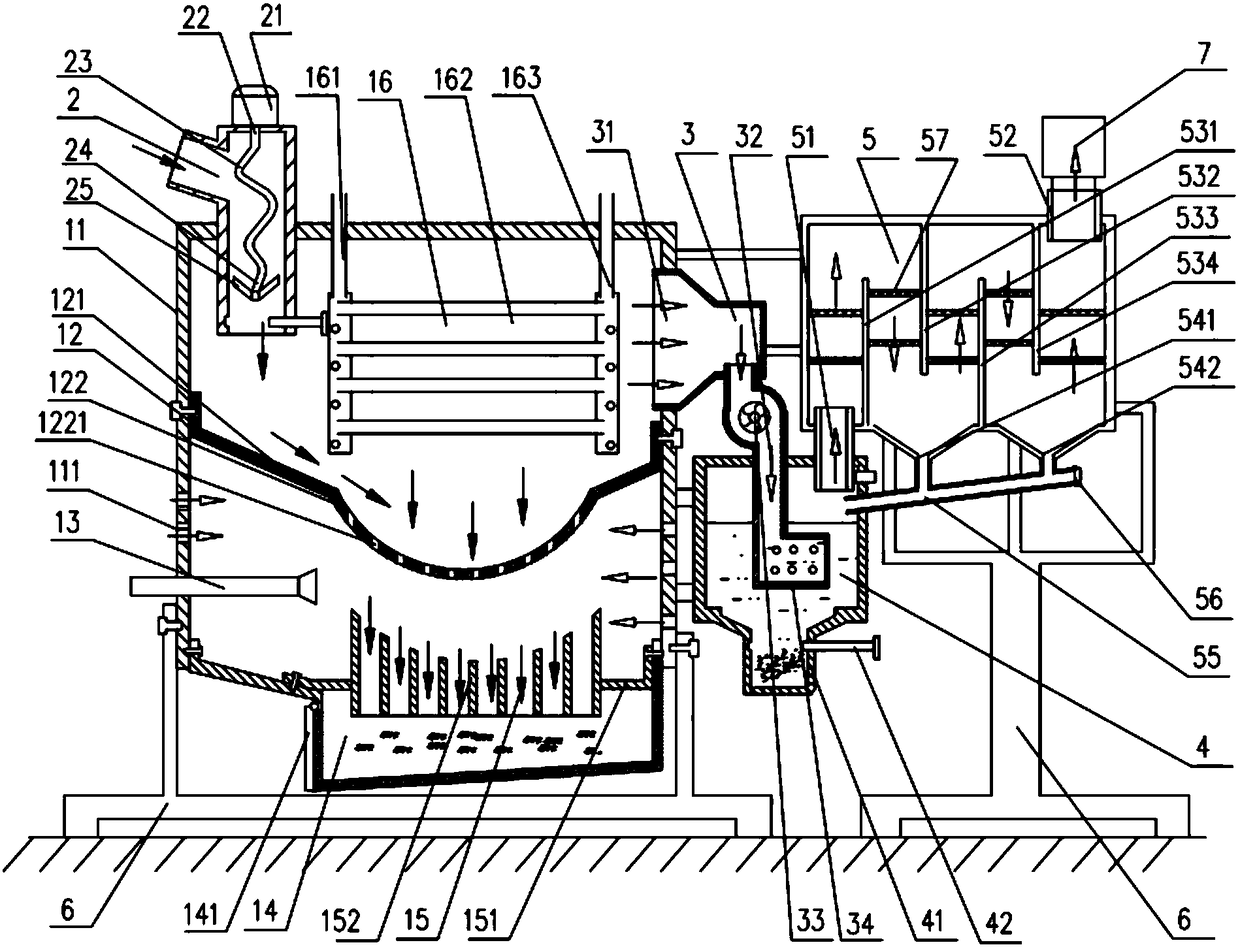

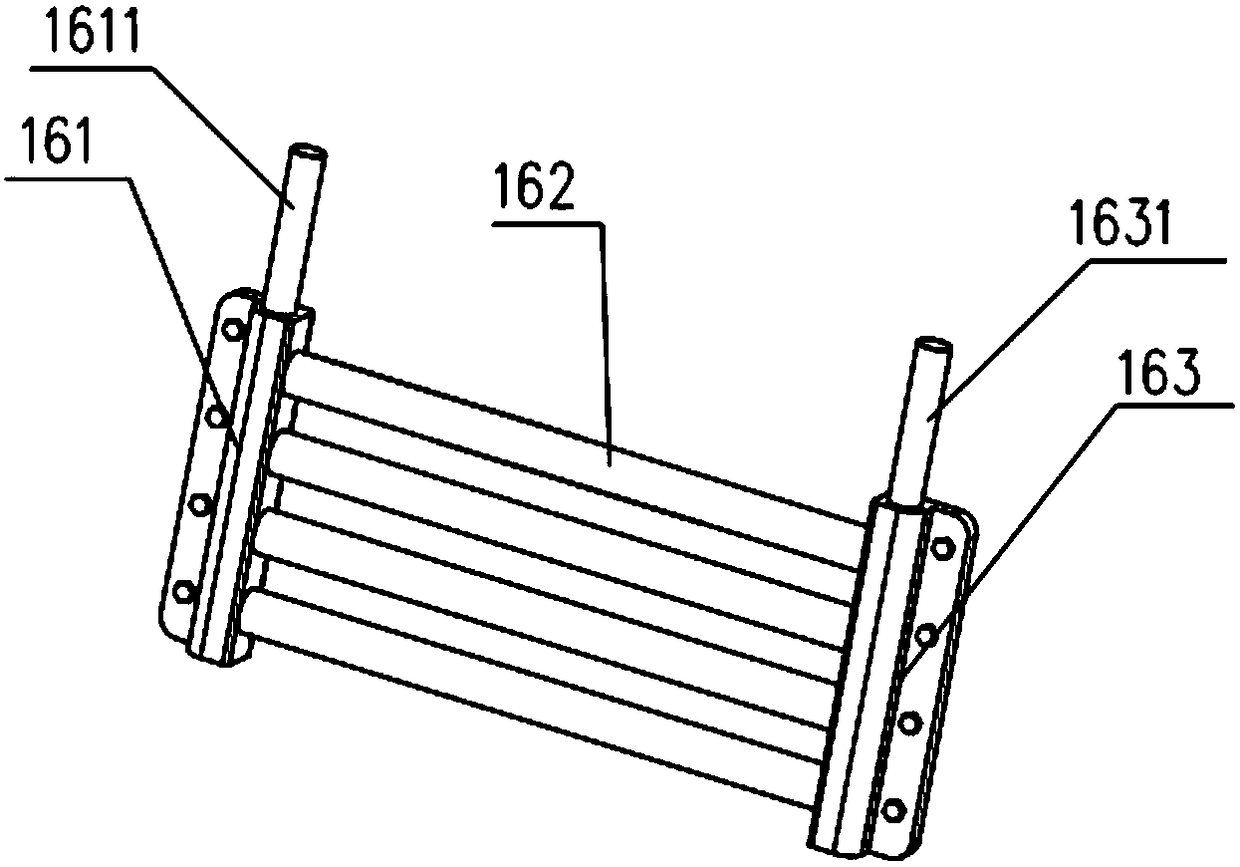

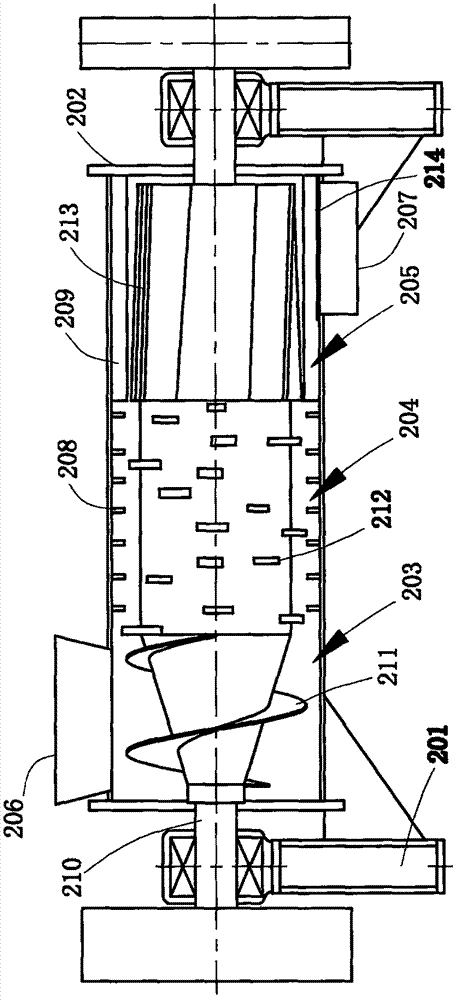

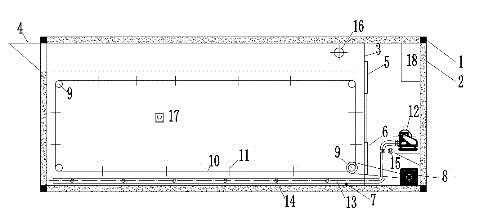

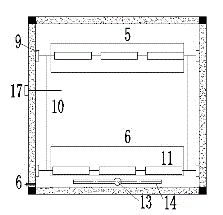

Kitchen Waste Disposal System

InactiveUS20140070037A1Promote growthImprove soil structureBio-organic fraction processingProductsGear grindingTreatment system

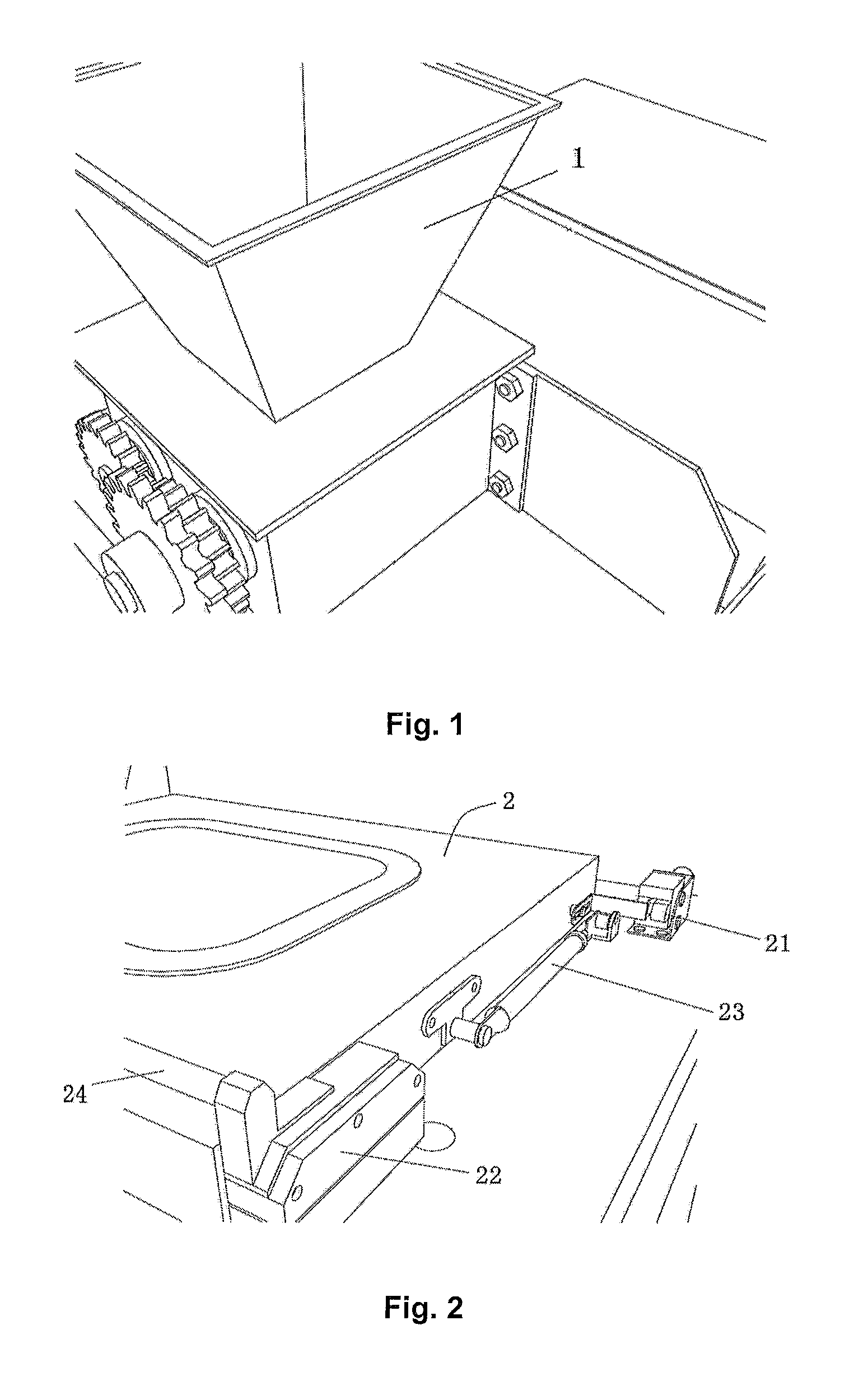

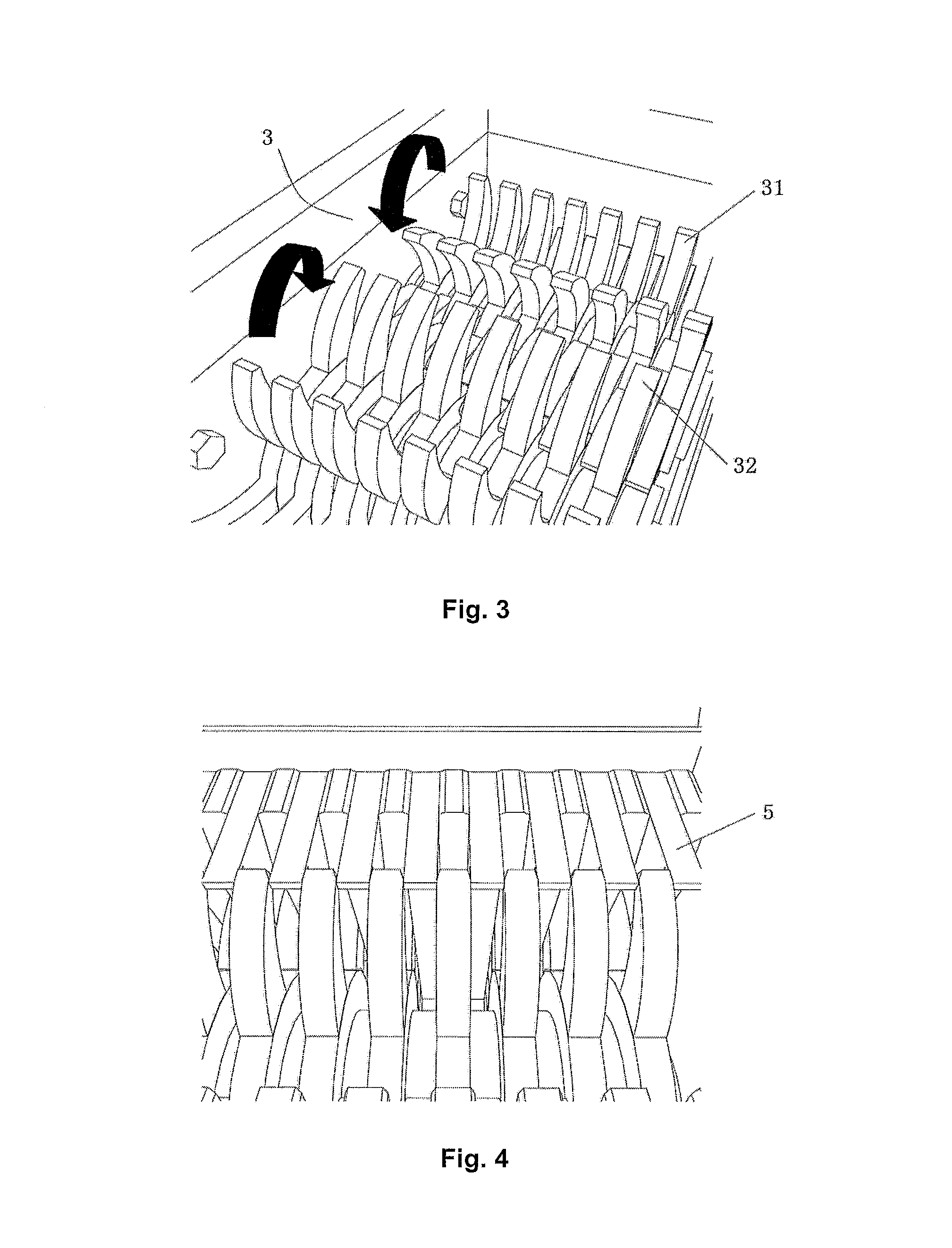

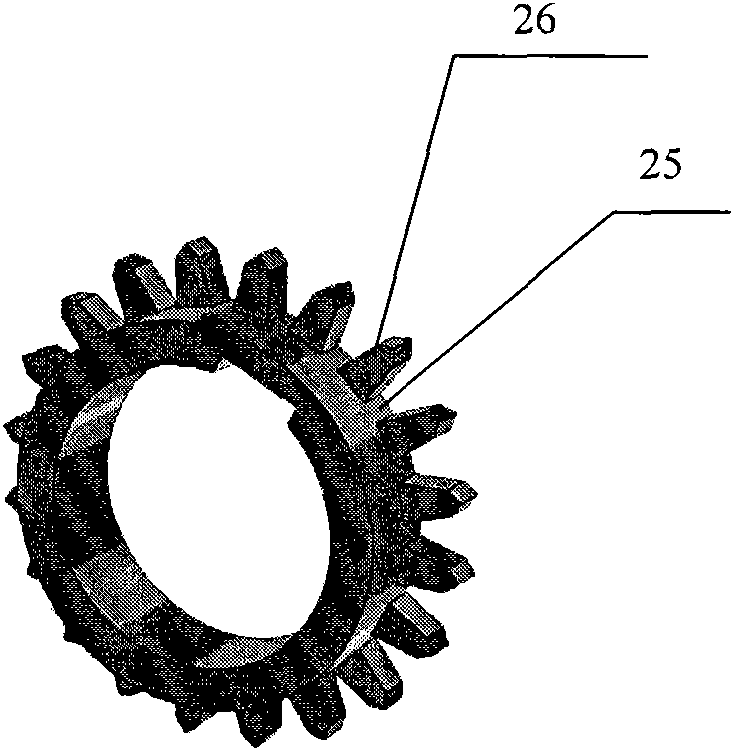

Disclosed is a kitchen waste disposal system which includes a residue feeding mechanism, a mechanical gear grinding mechanism and a paddle-type stirring mechanism. The residue feeding mechanism receives kitchen waste and leads the kitchen waste into a mechanical gear grinding zone in the disposal system. The mechanical gear grinding mechanism is provided with a double-shaft bi-directional gear grinding component. Two gear shafts are arranged in parallel and rotate in opposite directions. Each gear shaft is provided with first buckle gears and second buckle gears, and the first buckle gears and the second buckle gears are combined to crush the kitchen waste from the residue feeding mechanism. The paddle-type stirring mechanism comprises a W-shaped treatment groove and a paddle component in the middle of the treatment groove.

Owner:LEE MANBIU

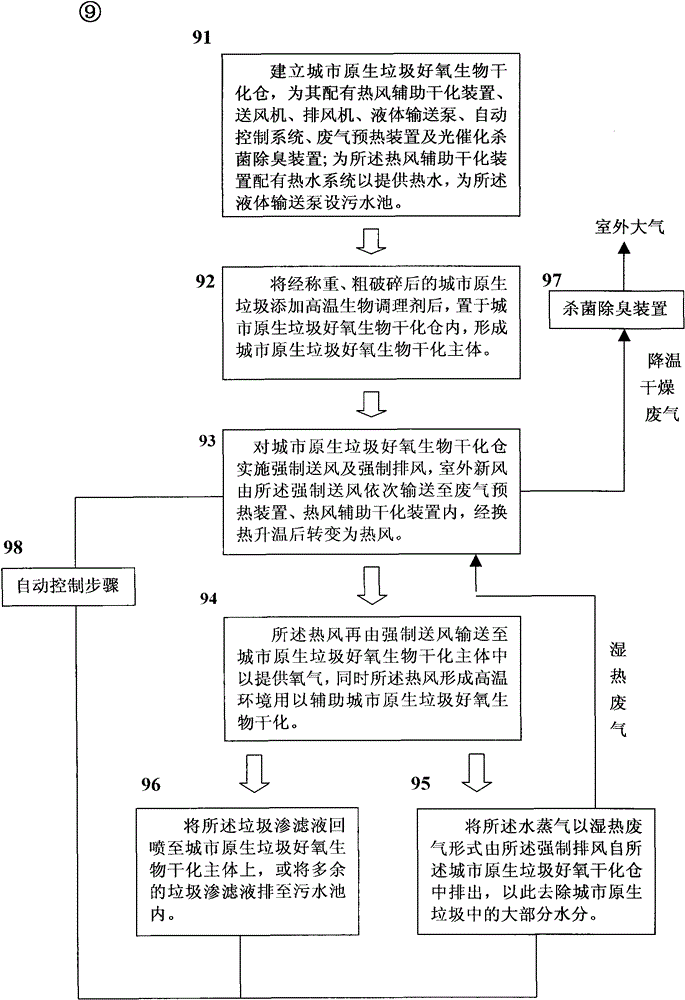

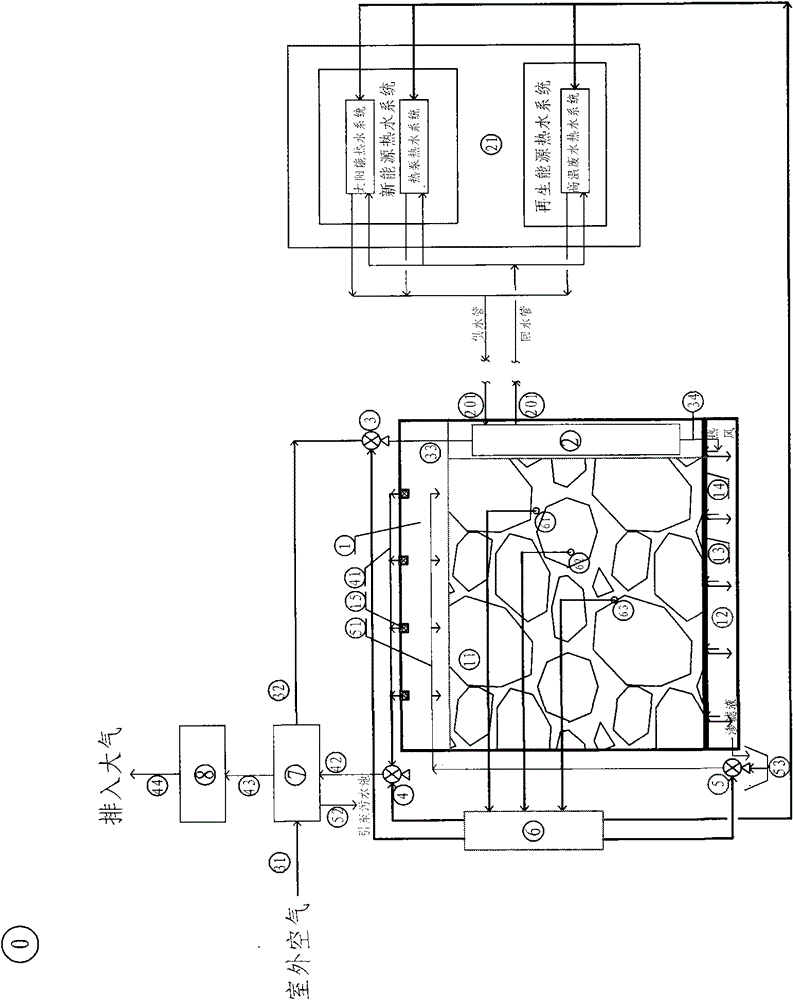

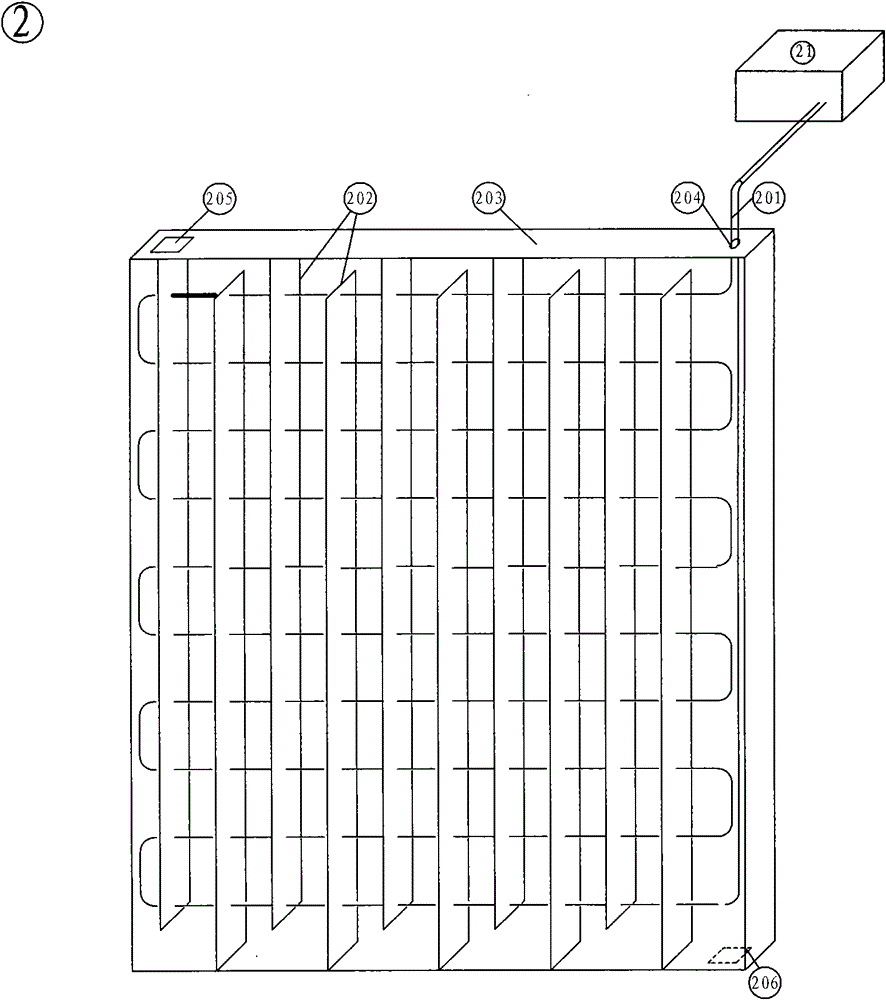

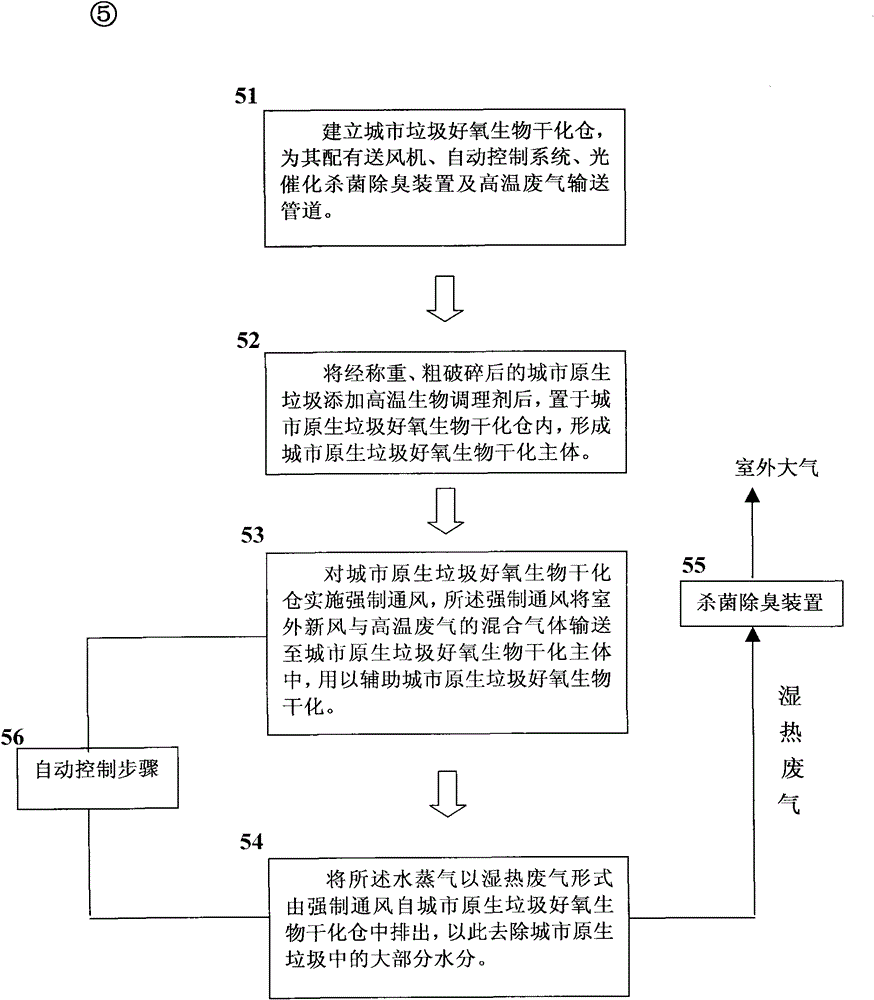

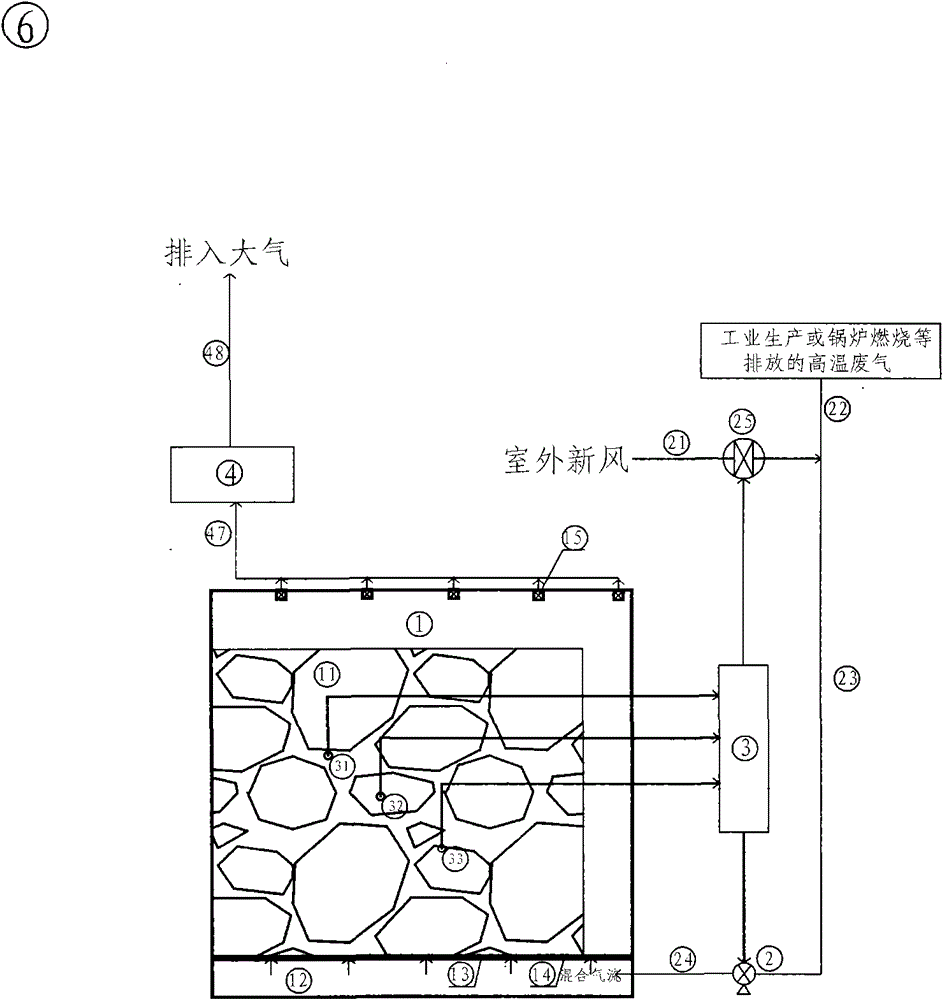

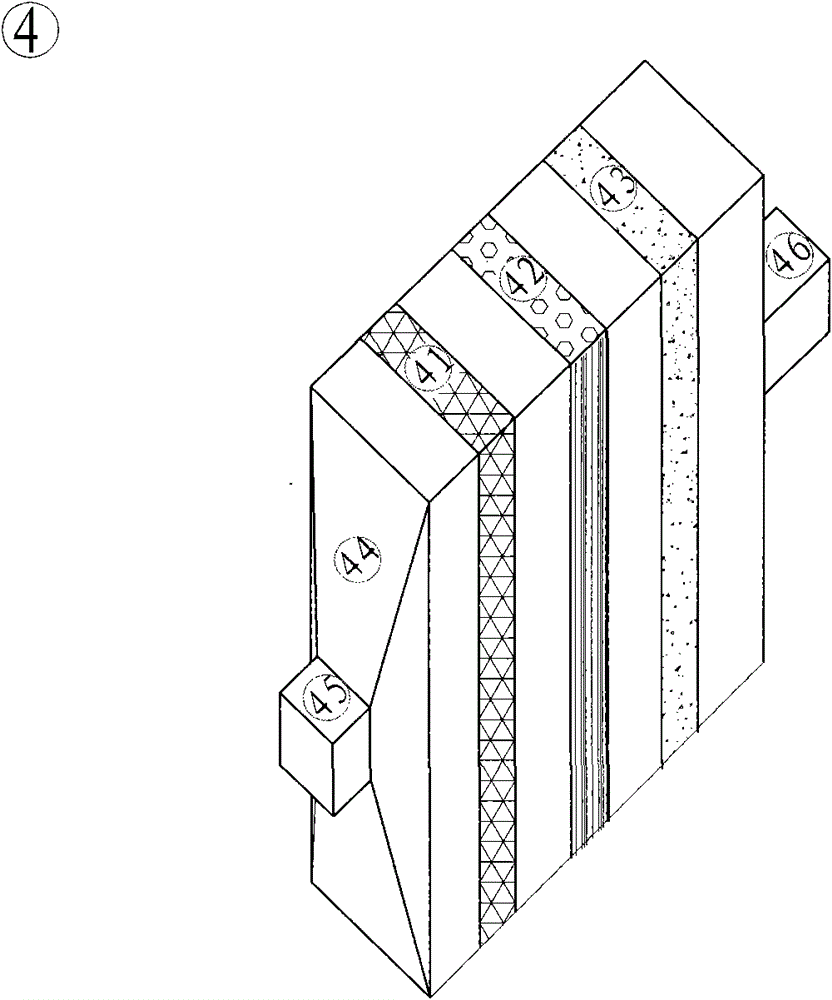

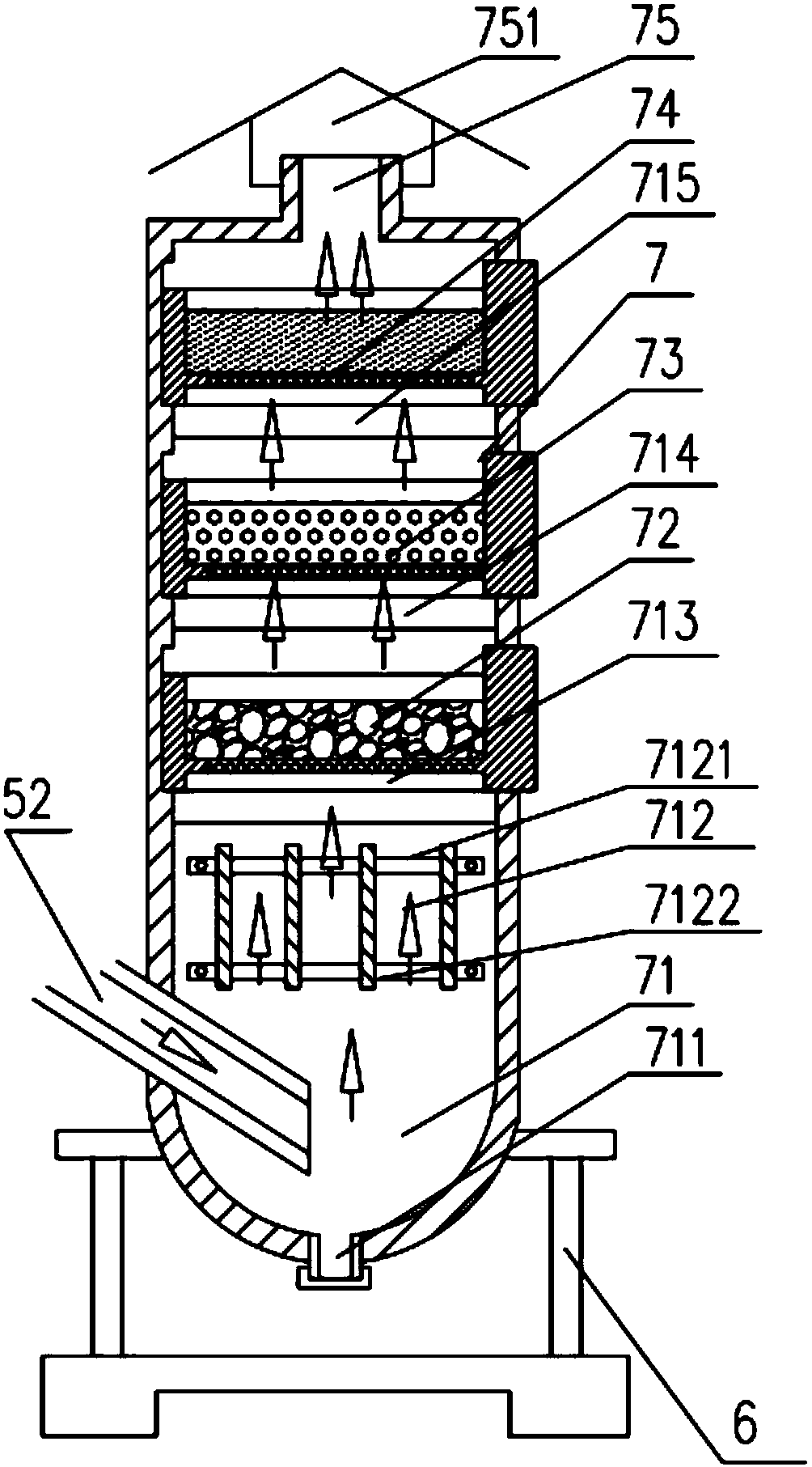

Method and system for drying aerobic organisms in urban raw garbage by aid of hot air

InactiveCN102716894AHigh degree of decompositionLarge amount of water evaporationSolid waste disposalAutomatic controlDecomposition

The invention provides a method and a system for drying aerobic organisms in urban raw garbage by the aid of hot air. Organic matters in the urban raw garbage are decomposed into moisture and other inorganic matters by the aerobic microorganisms in the urban raw garbage with high-temperature biological conditioners by the aid of oxygen provided by the hot air and a formed high-temperature environment, heat is released, most of the moisture is heated and evaporated into steam by the high-temperature environment and the heat, the steam is exhausted in a wet and hot waste gas form, garbage leachate is formed by an additional part of the moisture and drained, and the purpose of drying the aerobic organisms in the urban raw garbage is achieved. The system comprises an urban raw garbage aerobic organism drying bin, a hot-air auxiliary drying device, an air feeder, an exhaust fan, a liquid delivery pump and the like. The method and the system further can be optimized by means of automatic control, waste gas preheating, photocatalytic sterilization and deodorization and the like. The method and the system for drying the aerobic organisms by the aid of the hot air have the advantages that the decomposition degree of the organic matters in the urban raw garbage and moisture evaporation capacity are high, a drying process is short, a drying effect is obvious, and the garbage is treated in a harmless, reducing and stable manner.

Owner:SKYLINE DALIAN ENVIRONMENTAL HIGH TECH +1

Comprehensive utilization method of secondary aluminum ash

PendingCN112279283AHarmless treatmentEasy to recycleCalcium/strontium/barium fluoridesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSeed crystalOxide

The invention discloses a comprehensive utilization method of secondary aluminum ash, which comprises the following steps: crushing and grinding the secondary aluminum ash, uniformly mixing the crushed and ground aluminum ash with an additive, roasting, and recovering sintering gas; taking out a roasted clinker, cooling to room temperature, dissolving out by using dilute alkali liquor or water, carrying out solid-liquid separation to obtain a filtrate which is a sodium aluminate crude solution, adding calcium oxide, carrying out seed crystal decomposition and high-temperature calcination on asodium aluminate solution subjected to deep desilicication to obtain aluminum oxide, and returning insoluble filter residues which are fluorine-containing residues to an electrolytic cell for use; according to the method, aluminum oxide, nitride and fluoride in the aluminum ash are effectively separated, an aluminum oxide product is obtained, recycling of the nitride and the fluoride is achieved,and a new way for secondary comprehensive utilization of the aluminum ash is opened up.

Owner:KUNMING UNIV OF SCI & TECH

Method and system for drying high-temperature waste gas aerobe in urban raw refuse

InactiveCN102716895AHigh degree of decompositionHarmless treatmentSolid waste disposalAutomatic controlDecomposition

Owner:SKYLINE DALIAN ENVIRONMENTAL HIGH TECH +1

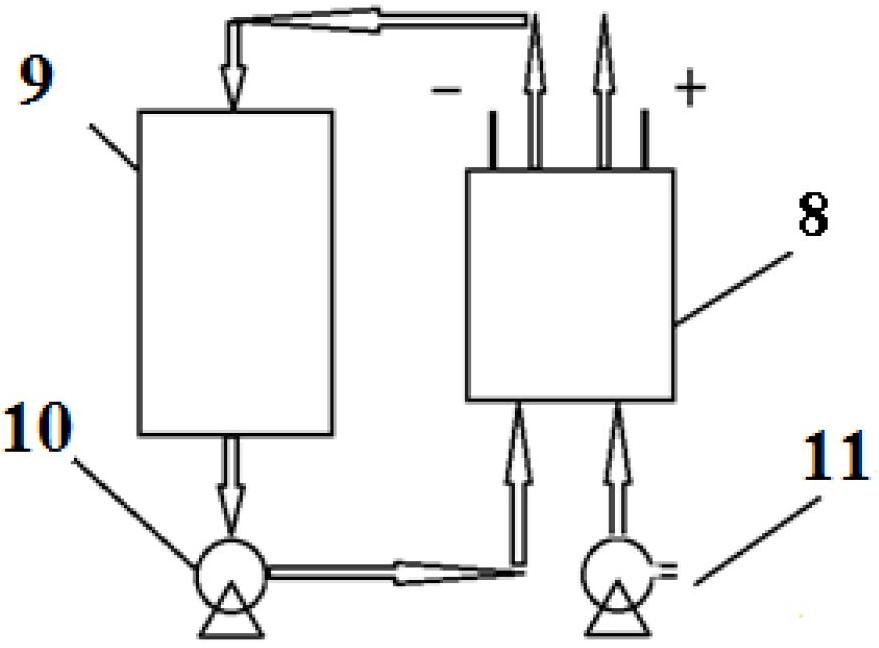

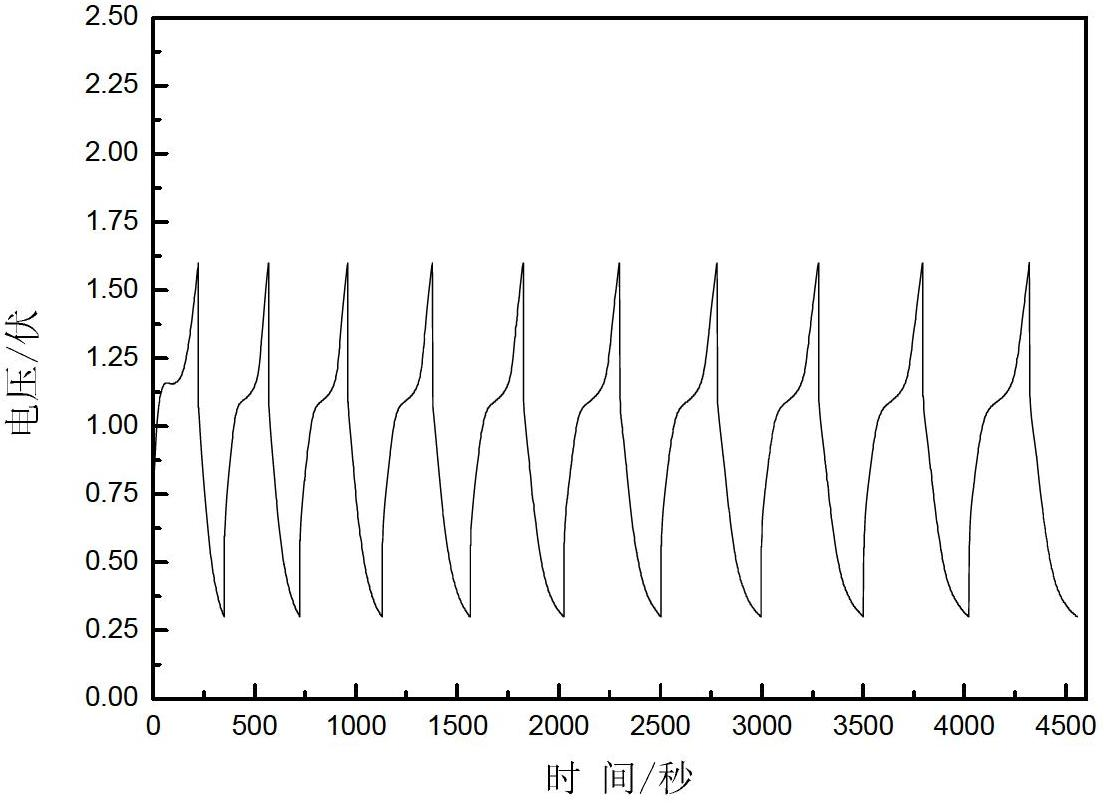

Air/vanadium redox flow battery

InactiveCN102694143AHigh capacity densityIncrease energy densityRegenerative fuel cellsActive material electrodesHigh energyLiquid storage tank

The invention discloses an air / vanadium redox flow battery, belonging to the technical field of power and energy storage. The cell of the air / vanadium redox flow battery is mainly composed of a positive pole, a negative pole and a negative pole liquid storage tank, wherein the positive pole and the negative pole are separated by a proton transfer film; the positive pole is a gas diffusion electrode and uses oxygen and water in air as active substances; the active substance of the negative pole is a vanadium-containing electrolyte, and is arranged in the negative pole liquid storage tank; the negative pole liquid storage tank, a liquid pump and the negative pole are connected through pipelines to form an electrolyte circulation loop; and a conductive buffer layer is arranged between the positive pole and a positive pole current collector. The air / vanadium redox flow battery has the advantages of easy scale-up implementation, long circulation life, simple structure, lower material price, high energy density, high power intensity and the like, does not generate any pollutant in the whole charging / discharging process, is suitable to be used as large-scale electric energy storage equipment in a wind or solar power generation system, and can be widely used in electric power, transportations and other industries.

Owner:TSINGHUA UNIV

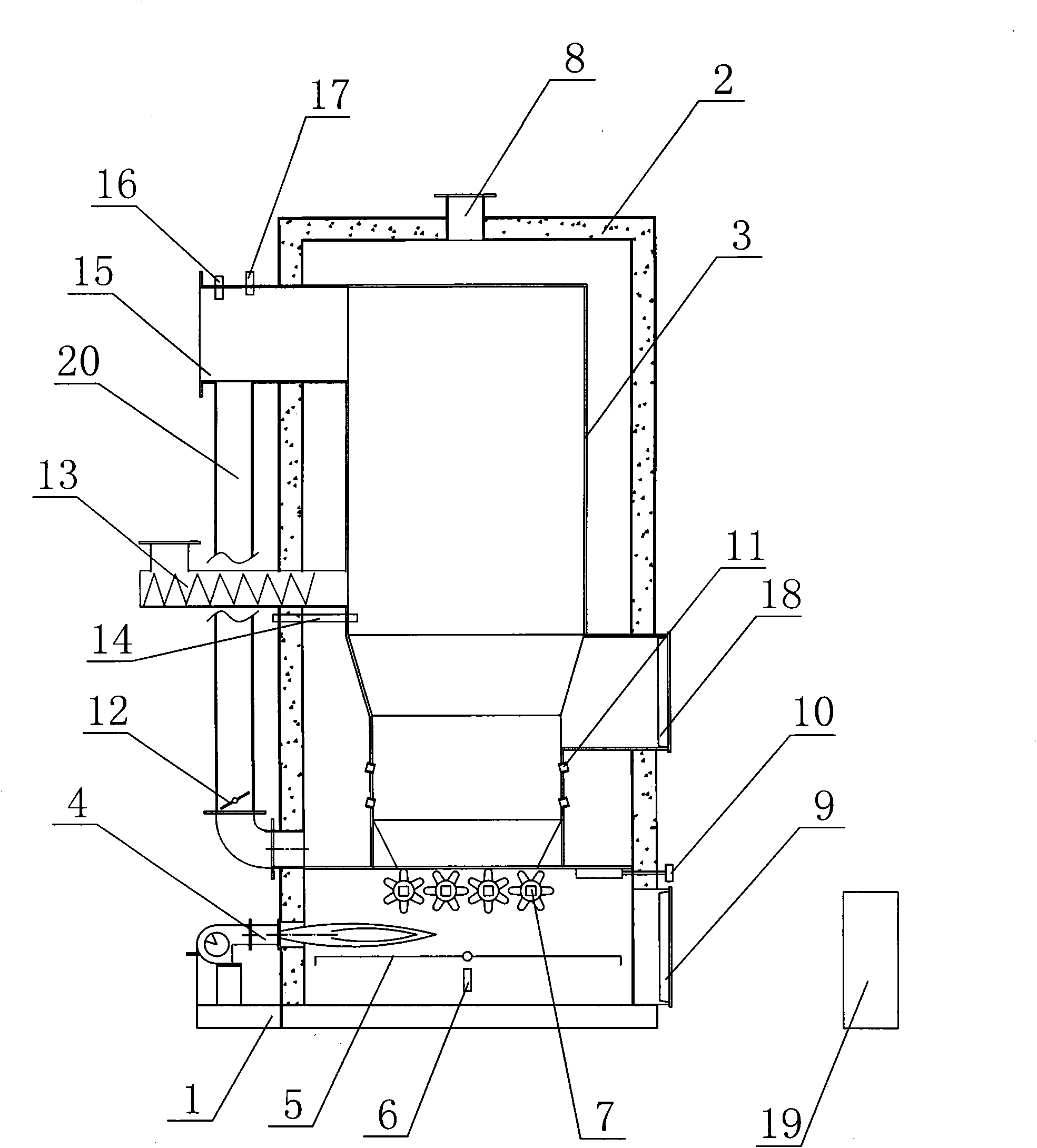

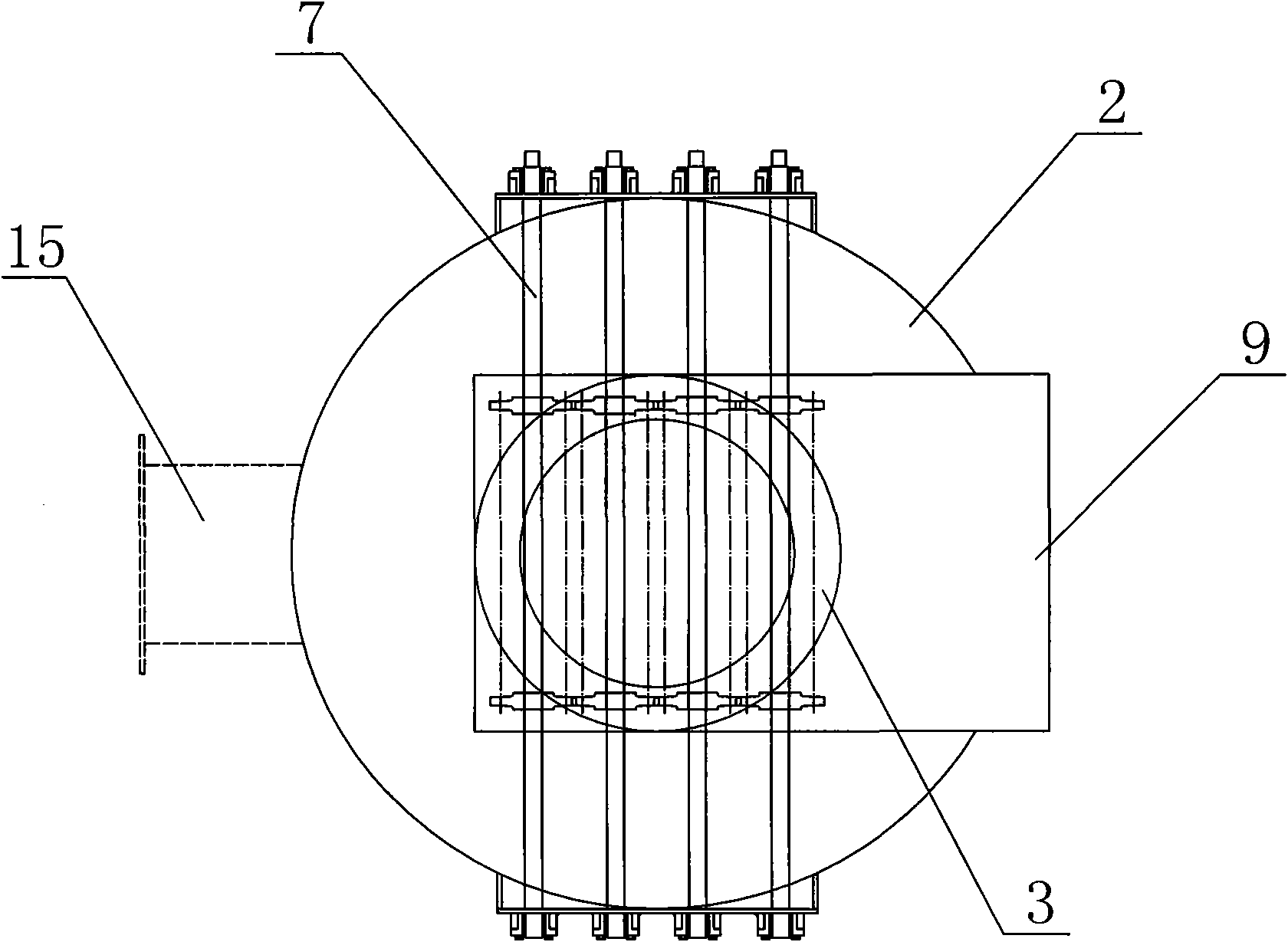

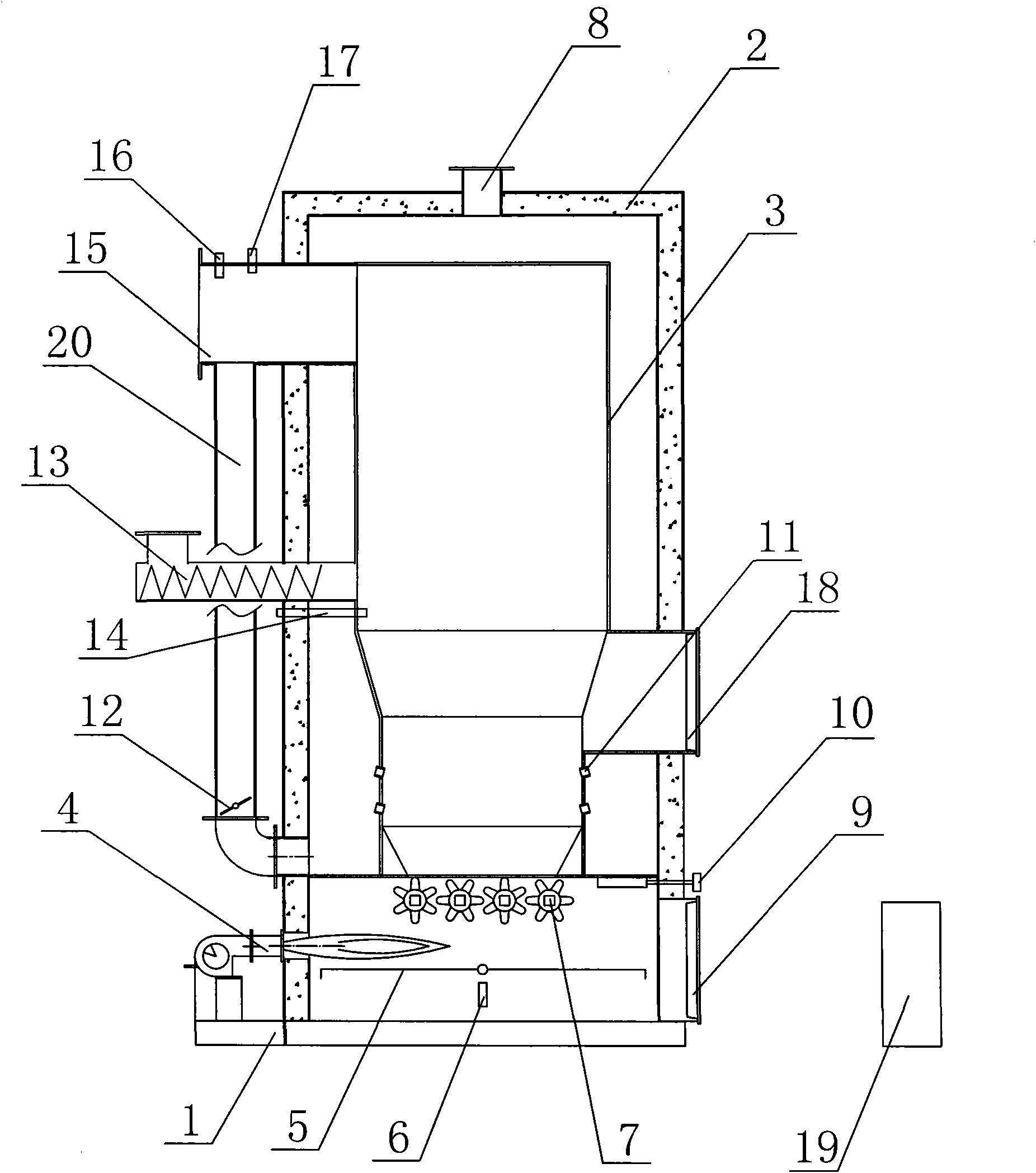

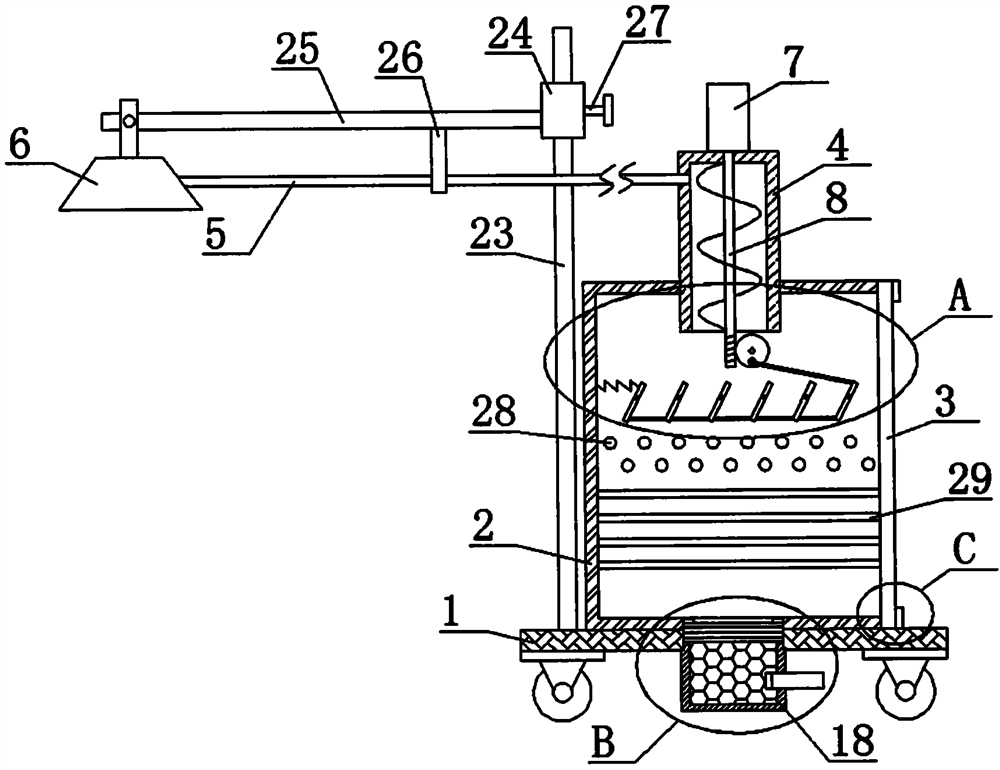

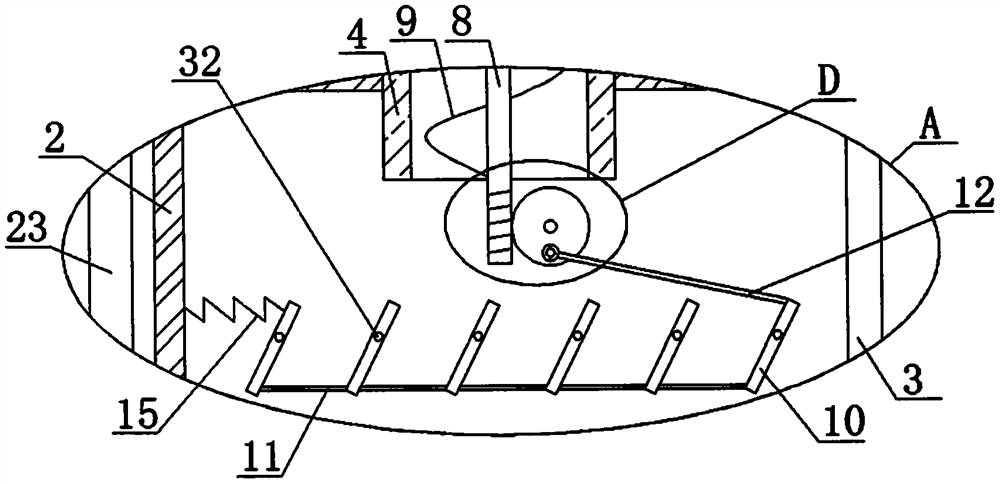

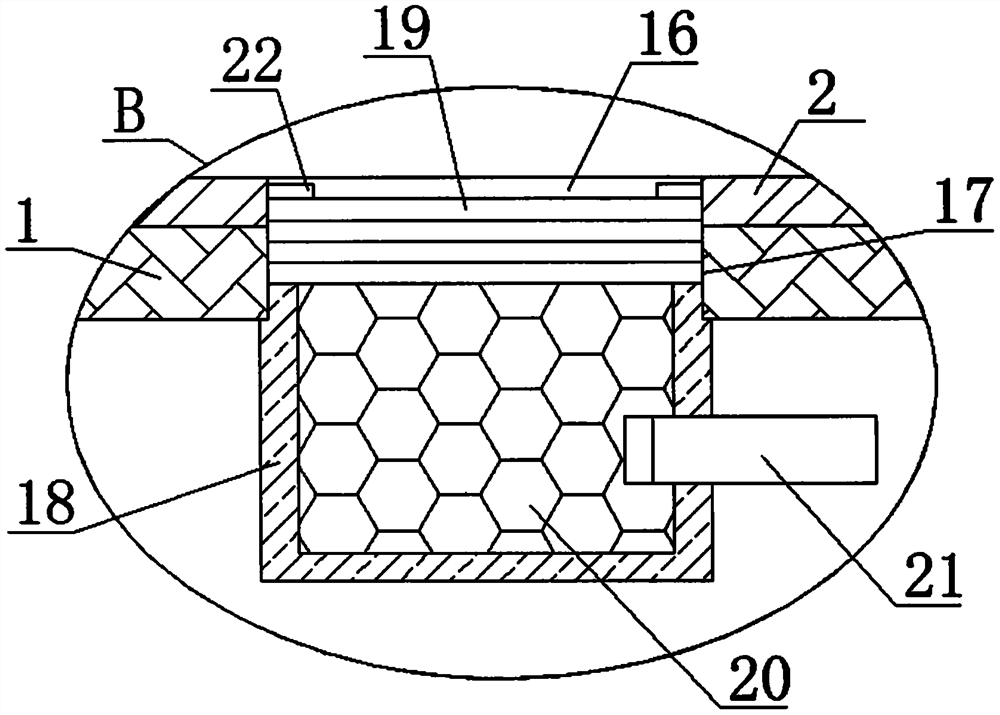

Intelligent sludge incinerator

InactiveCN101956987AIncineration stableHarmless treatmentIncinerator apparatusAutomatic controlCombustion

The invention discloses an intelligent sludge incinerator. The sludge incinerator comprises an outer furnace body, an inner furnace body, a base, an electrically driven automatic slag discharge grate, a screw feeder, an automatic slag discharge device, a diesel oil burner, a primary air inlet system, a secondary air inlet system and a controller, wherein the controller is used for controlling one or more temperature sensors arranged at a hearth, a smoke outlet and a primary inlet, an oxygen quantity sensor arranged at the smoke outlet and a weight sensor for automatic slag discharge. The intelligent sludge incinerator can realize reduction and harmlessness of sludge by adopting a bubbling suspension combustion method, and meanwhile realizes low discharge of pollutants; the combustion is stable by automatic control of parameters of primary and secondary air inlet, and the temperature in the incinerator is controlled at 850 to 950 DEG C all the time for combustion; and the sludge incinerator has high automation degree, saves labor, relieves labor intensity, realizes stable incineration of the sludge, obviously reduces the fault rate, and has low maintenance expense and humanized operation.

Owner:WUXI AMDI ENVIRONMENTAL PROTECTION TECH CO LTD

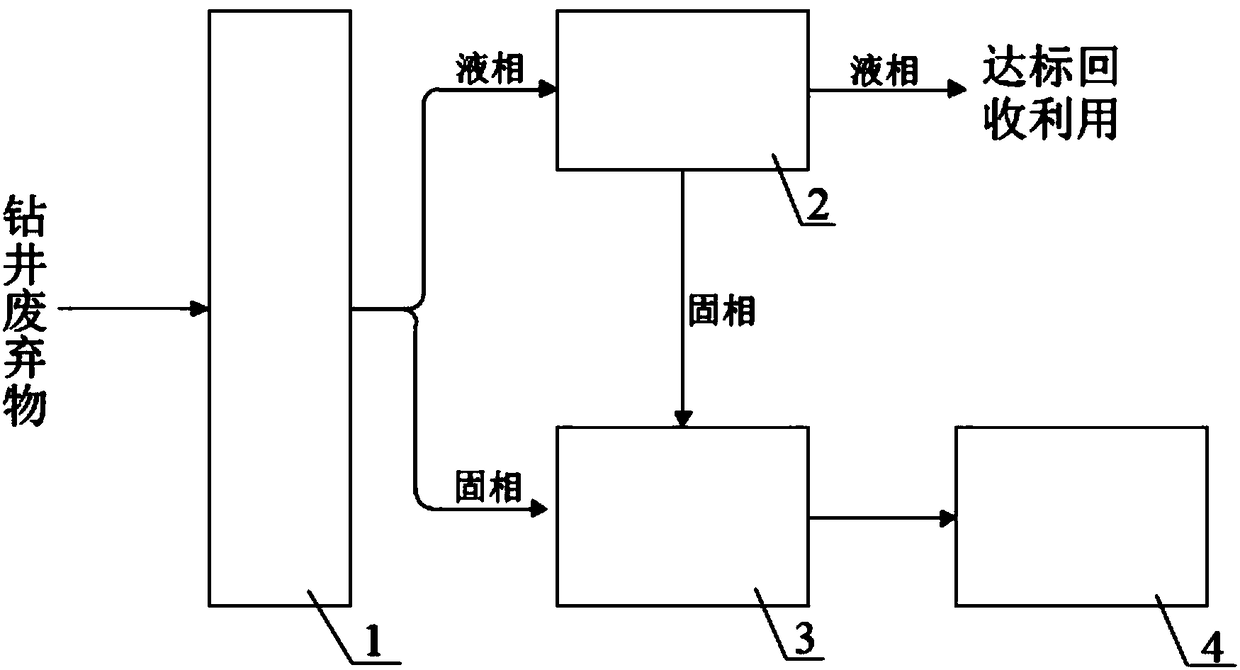

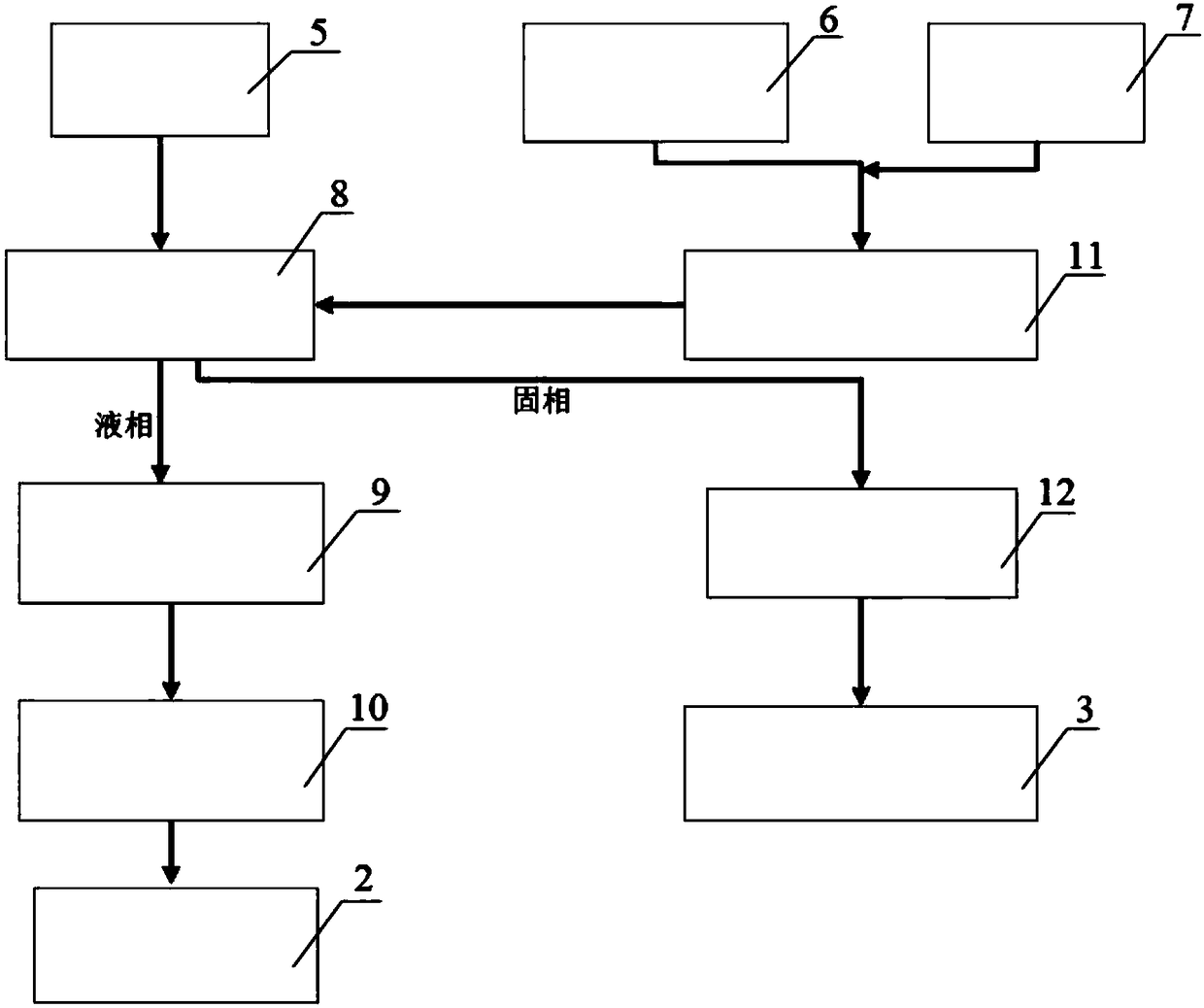

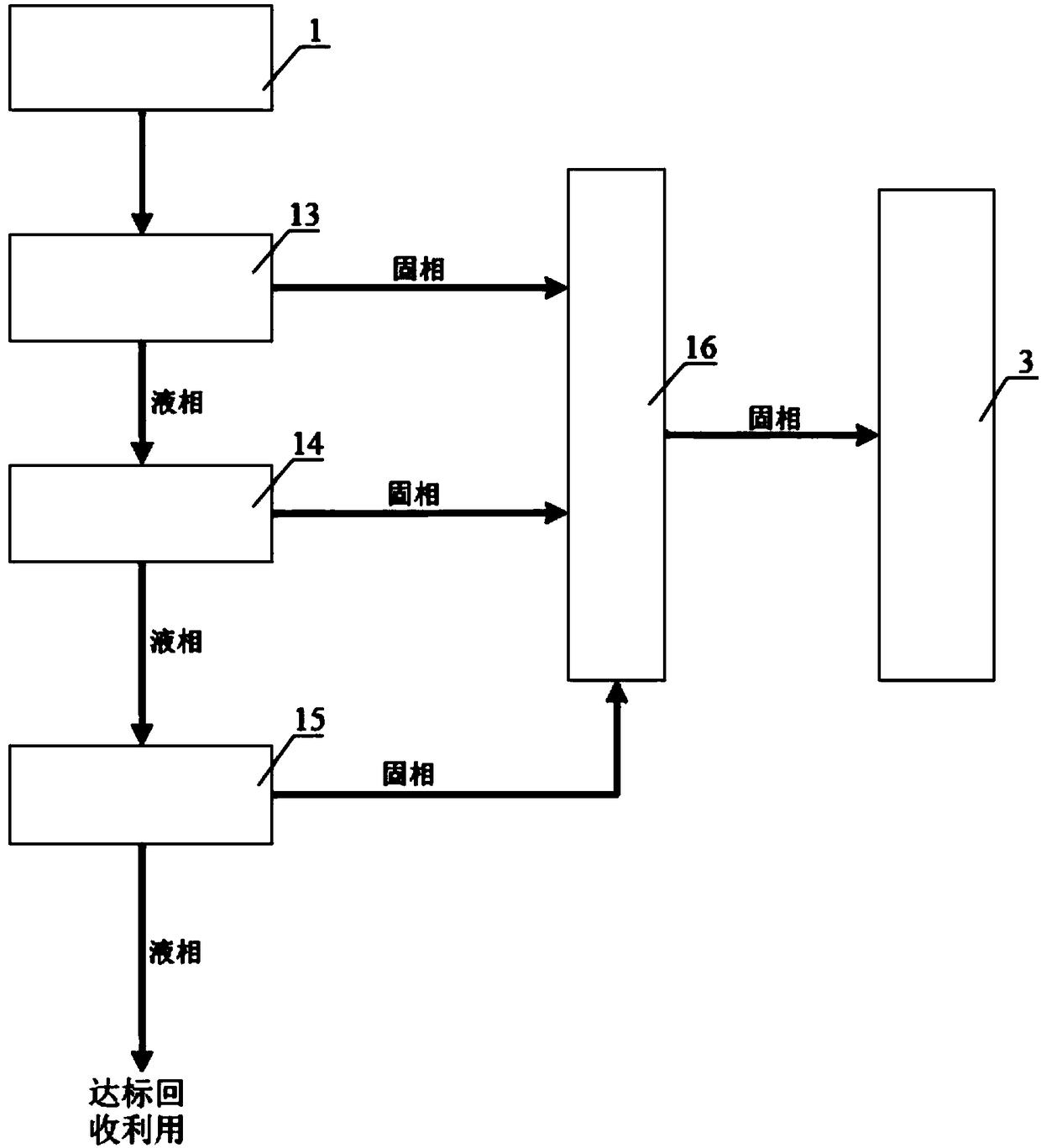

Water-based well drilling waste harmless treatment device and method, and application

The invention provides a water-based well drilling waste harmless treatment device and method, and application. The water-based well drilling waste harmless treatment device comprises a non-landing collecting unit, a liquid-phase regeneration treatment unit and a solid-phase harmless treatment unit, and the non-landing collecting unit communicates with the liquid-phase regeneration treatment unitand the solid-phase harmless treatment unit; and the liquid-phase regeneration treatment unit communicates with the solid-phase harmless treatment unit. According to the water-based well drilling waste harmless treatment device and method, the land cost and the treatment cost are saved, and the costs of well drilling waste harmless treatment, excavation of a landfill pool, seepage prevention and the like are saved; and indexes, such as pH, COD, color, petroleum type and the like, of a prepared base soil and burning-free building block leaching agent s after well drilling waste is subjected toharmless treatment reach the environmental protection requirement, the burning-free building blocks and the base soil reach the related building material standard, and regeneration and reuse and recycling of the well drilling waste are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

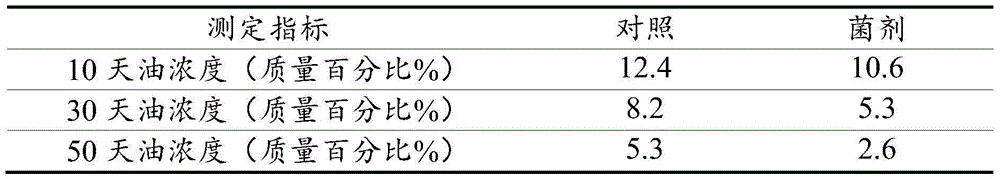

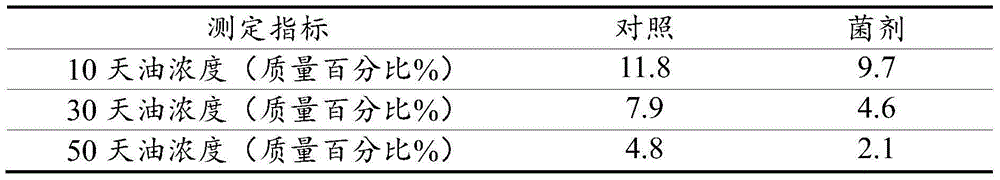

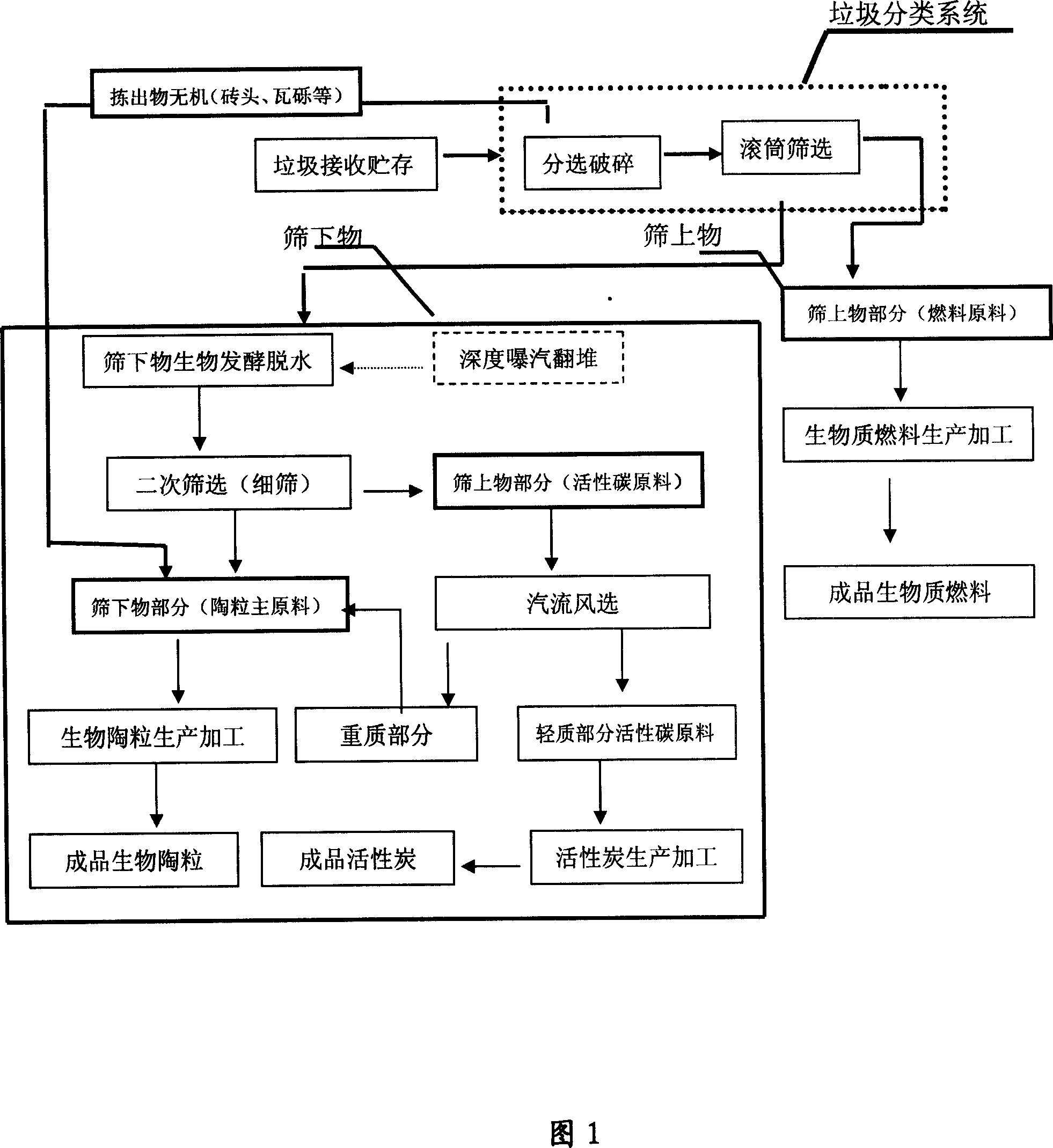

Microbial compound fungicide for treating oil base drilling cuttings as well as preparation method and application of microbial compound fungicide

ActiveCN104059867ALow costHarmless treatmentBacteriaMicroorganism based processesFungicideMicroorganism

The invention relates to a microbial compound fungicide for treating oil base drilling cuttings as well as a preparation method and application of the microbial compound fungicide. The compound fungicide comprises pseudomonas aeruginosa with a collection number of CGMCC NO:8983 and acinetobacter baumannii with the collection number of CGMCCNO:8984. The invention further discloses the preparation method of the microbial compound fungicide and application of the compound fungicide in treatment of oil base drilling cuttings. The preparation method includes preparation methods of liquid and solid fungicides.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S +1

Method of harmlessly treating electrolytic manganese residue percolate

InactiveCN106186455AWide variety of sourcesSimple technologyWater contaminantsTreatment involving filtrationElectrolysisManganese

The invention discloses a method of harmlessly treating electrolytic manganese residue percolate, characterized by comprising the steps of 1), percolating electrolytic manganese residue percolate collected in a residue storage to obtain clarified filtrate; 2), adding saturated clarified limewater in a container of the clarified filtrate, and adjusting pH of a solution to 7.0-8.0 to obtain mixture A; 3), adding sodium silicate powder into the mixture A, and stirring for 1-2 hours to obtain mixture B, wherein a weight-volume ratio (g:mL) of the sodium silicate to the clarified filtrate of step 1) ranges from 1:150 to 1:200; 4), adding sodium chloride crystal into mixture B, and stirring to obtain mixture C, wherein sodium chloride concentration in the mixture C ranges from 200 mg / L to 250 mg / L; 5), adding a positive plate and a negative plate into a container of the mixture C, loading an electric field, and stirring for 3-4 hours to obtain the electrolytic manganese residue percolate that is harmlessly treated, wherein voltage of the electric field is 10-20 V.

Owner:CHONGQING UNIV

Method for one step preparing biomass fuel raw material, biological haydite raw material and active carbon raw material using high wet mixed city garbage as raw material

InactiveCN1943888APerfect separation processHarmless treatmentGas current separationSolid waste disposalLitterEnvironmental engineering

The present invention is method of separating biomass fuel material, biological haydite material and active carbon material from wet mixed city refuse simultaneously. The method includes the steps of sorting and crushing refuse, drum screening, preparing biomass fuel material, biologically fermenting and dewatering, preparing biological haydite material, preparing active carbon material, etc. The present invention can make best utilization of refuse resource, reduce environmental pollution and power consumption and treat refuse in harmless mode.

Owner:广东利大德环保科技有限公司

Composite sludge deep dehydration conditioner as well as application and application method thereof

ActiveCN111484230AImprove settlement performanceImprove dehydration effectSludge treatment by oxidationWater treatment compoundsCationic polyelectrolytesProcess engineering

The invention relates to a composite sludge deep dehydration conditioner as well as an application and an application method thereof, which belong to the technical field of resource environment and sludge treatment. The conditioner is prepared from the following raw materials in percentage by mass: 1 to 2 percent of a strong oxidant, 19 to 40 percent of an inert substance and 59 to 80 percent of strong cationic polyelectrolyte. The compound sludge deep dehydration conditioner designed by the invention has the advantages of high conditioning speed, high sludge dehydration rate, small sludge increment, simplicity in operation, high sludge volume reduction rate and the like, so that the compound sludge deep dehydration conditioner can be widely applied to conditioning and enhanced deep dehydration of sludge.

Owner:山东益源环保科技有限公司

Method for comprehensively treating waste iron oxide desulfurizer and chromium slag

The invention discloses a method for comprehensively treating waste iron oxide desulfurizer and chromium slag so as to solve the problems that the conventional waste iron oxide desulfurizer contains FeS, the treating process is complex, the safety is low, the investment is high, the running expense is high and certain defects are existent in the conventional chromium salt detoxifying method. The method comprises two steps of pre-treating and mixing for reaction. According to the method, the two wastes are skillfully treated by each other and interact with each other to achieve the purpose of treating wastes with wastes; harmless treatment on the waste iron oxide desulfurizer and the chromium slag is effectively achieved while no other additive is used, so that the treatment cost is effectively reduced; the method is simple in process and convenient to operate, and has the characteristics of energy conservation, economy and environmental protection; the method is of important significance for solving the problem of the treatment of the waste iron oxide desulfurizer and the chromium slag, and especially can be used for effectively treating the chromium slag to effectively reduce harm of the chromium slag to the environment.

Owner:李平

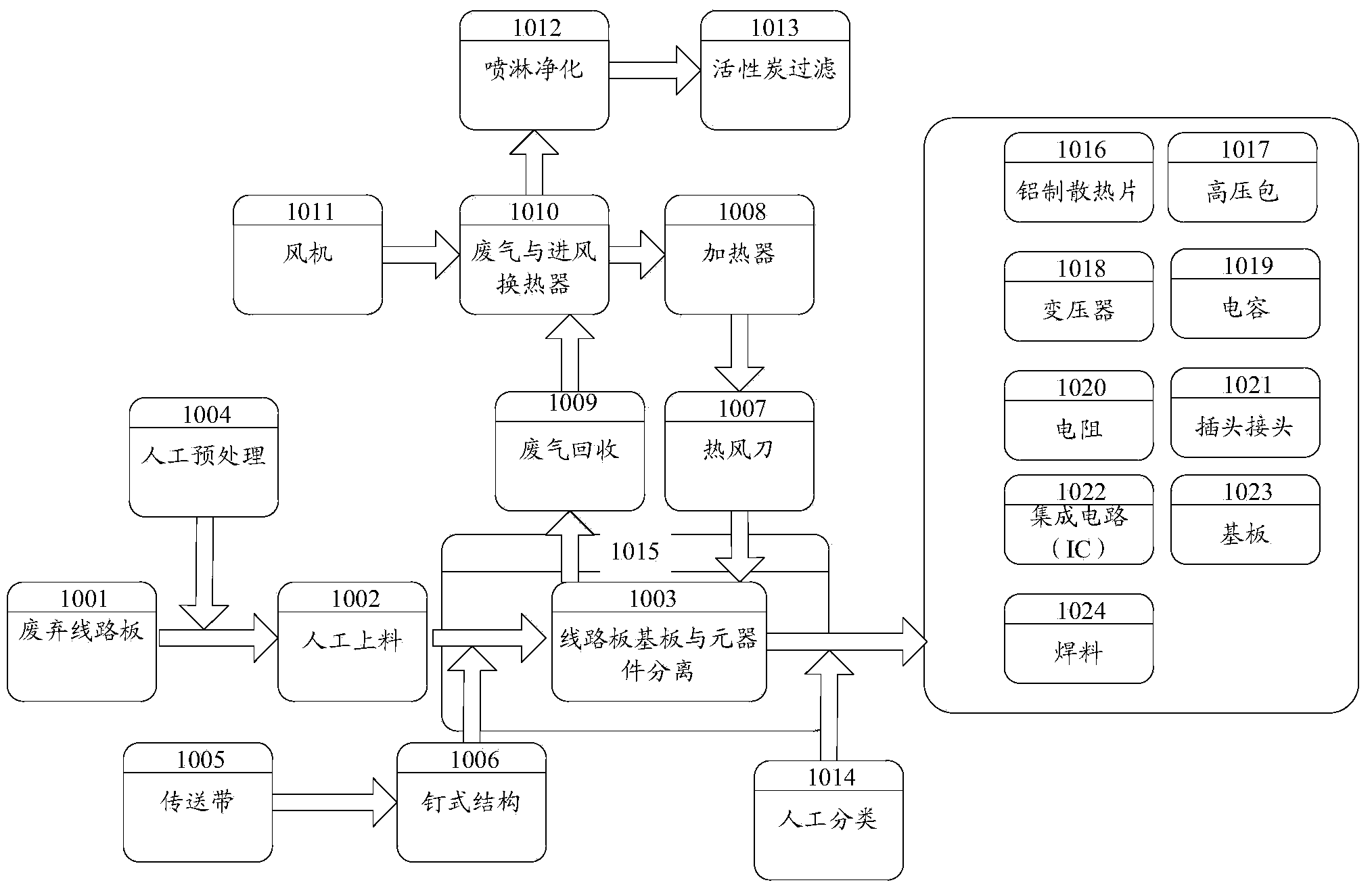

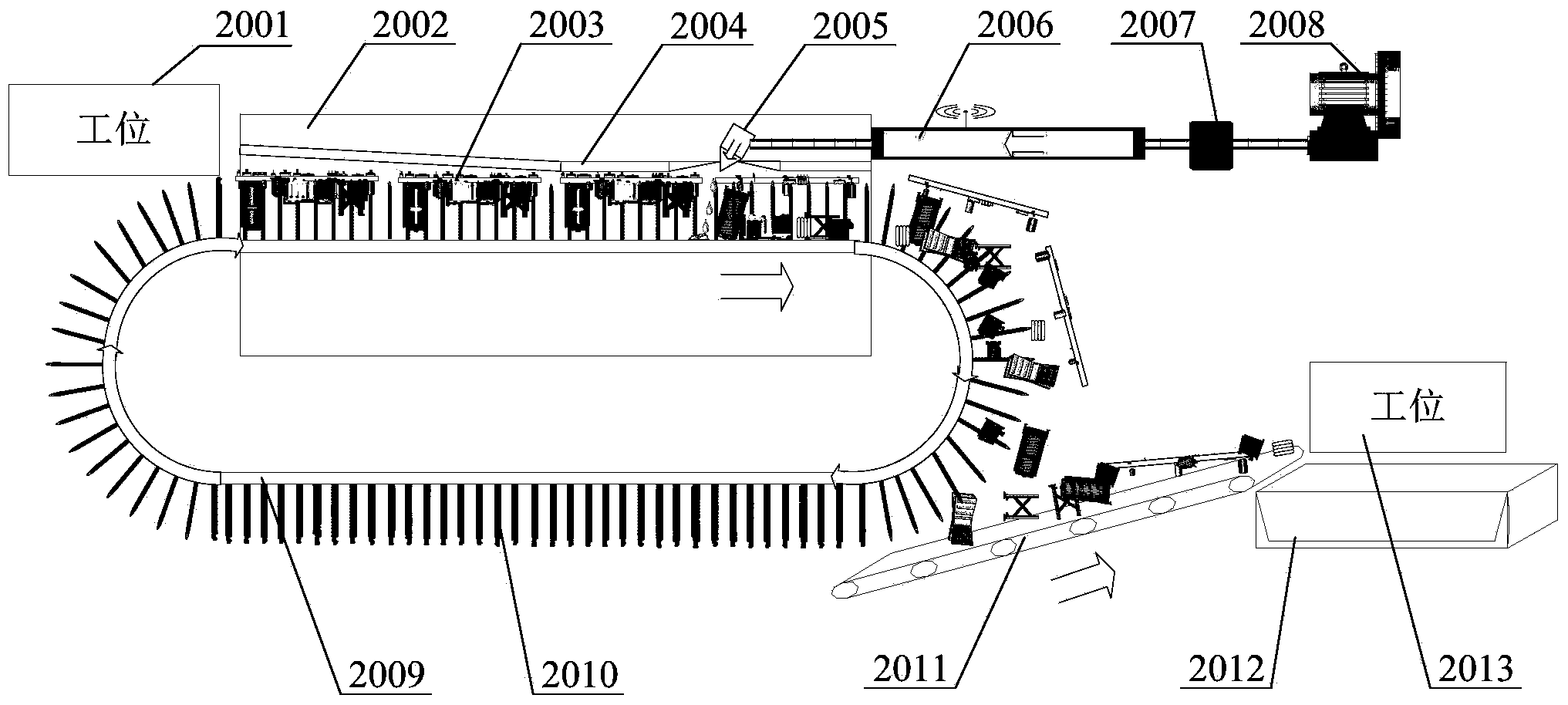

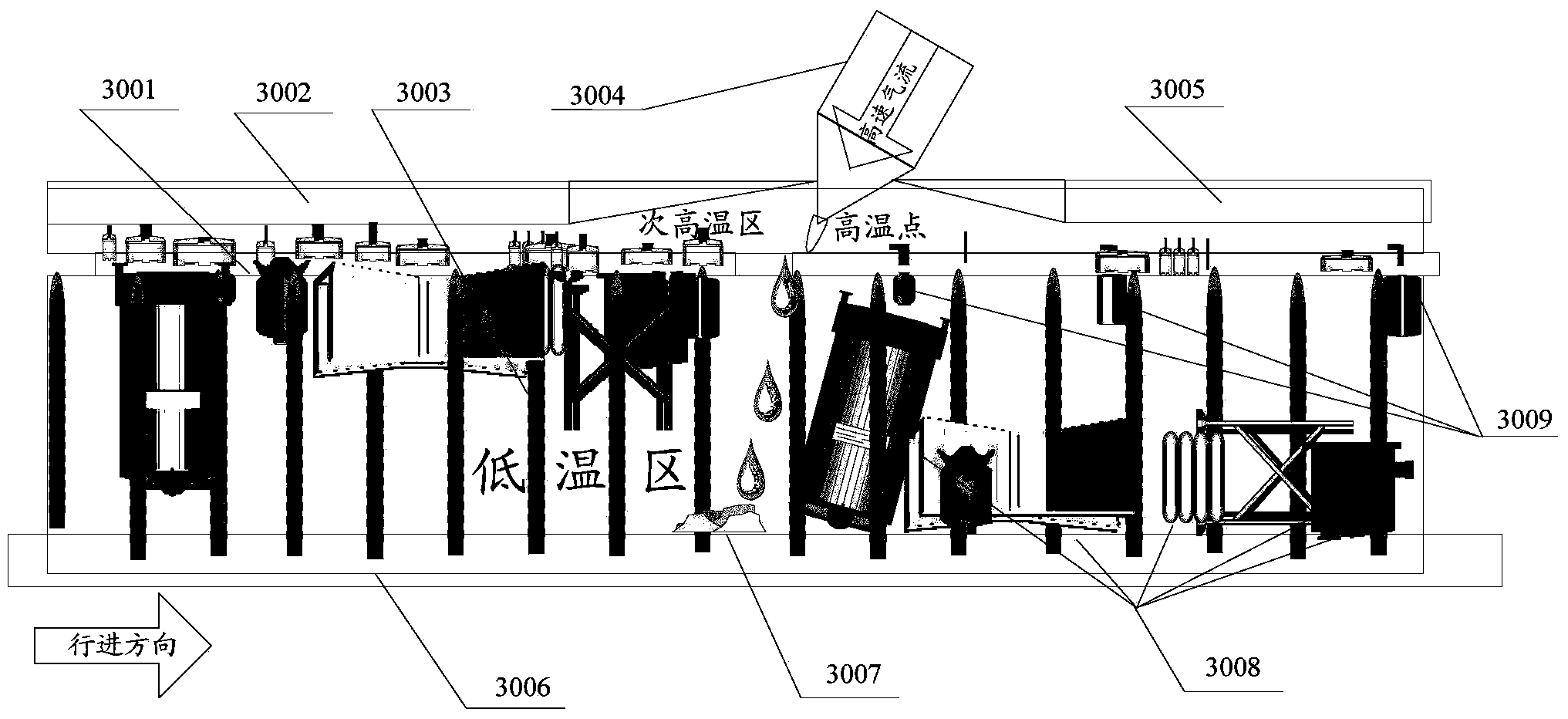

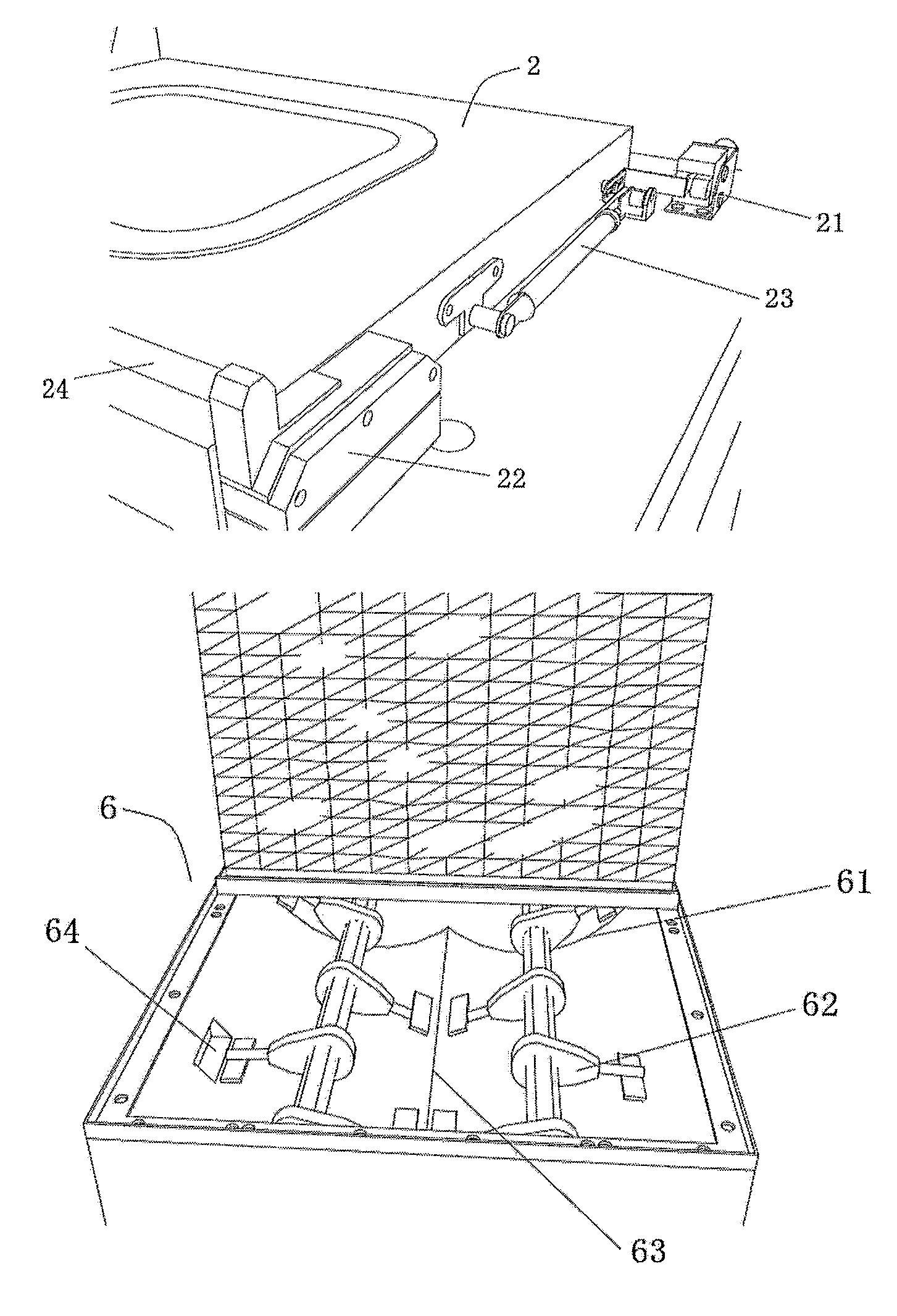

Method for utilizing high-pressure hot air to automatically separate waste circuit board elements

ActiveCN103480933AEasy to control temperaturePressure is easy to controlTransportation and packagingSoldering apparatusEngineeringSeparation pattern

The invention relates to a method for utilizing high-pressure hot air to automatically separate waste circuit board elements. The method includes using a screw structure to fix to-be-separated circuit boards on a conveying belt for conveying, and using high-pressure high-temperature air flow impact to separate substrates and the elements of the circuit boards, wherein high-pressure high-temperature air flows are blown out in a way like air knives or air knife slotting openings to remove soldering flux and force the elements to fall off. By the method, industrial application of the automatic waste circuit board element separation, harmless treatment is performed on toxic and harmful gases, the circuit boards are treated efficiently, a large amount of valuable elements are recycled losslessly, and recycling is possible.

Owner:伟翔环保科技发展(上海)有限公司

Kitchen waste disposal system

InactiveUS8919682B2Promote growthImprove soil structureProductsBio-organic fraction processingGear grindingEngineering

Disclosed is a kitchen waste disposal system which includes a residue feeding mechanism, a mechanical gear grinding mechanism and a paddle-type stirring mechanism. The residue feeding mechanism receives kitchen waste and leads the kitchen waste into a mechanical gear grinding zone in the disposal system. The mechanical gear grinding mechanism is provided with a double-shaft bi-directional gear grinding component. Two gear shafts are arranged in parallel and rotate in opposite directions. Each gear shaft is provided with first buckle gears and second buckle gears, and the first buckle gears and the second buckle gears are combined to crush the kitchen waste from the residue feeding mechanism. The paddle-type stirring mechanism comprises a W-shaped treatment groove and a paddle component in the middle of the treatment groove.

Owner:LEE MANBIU

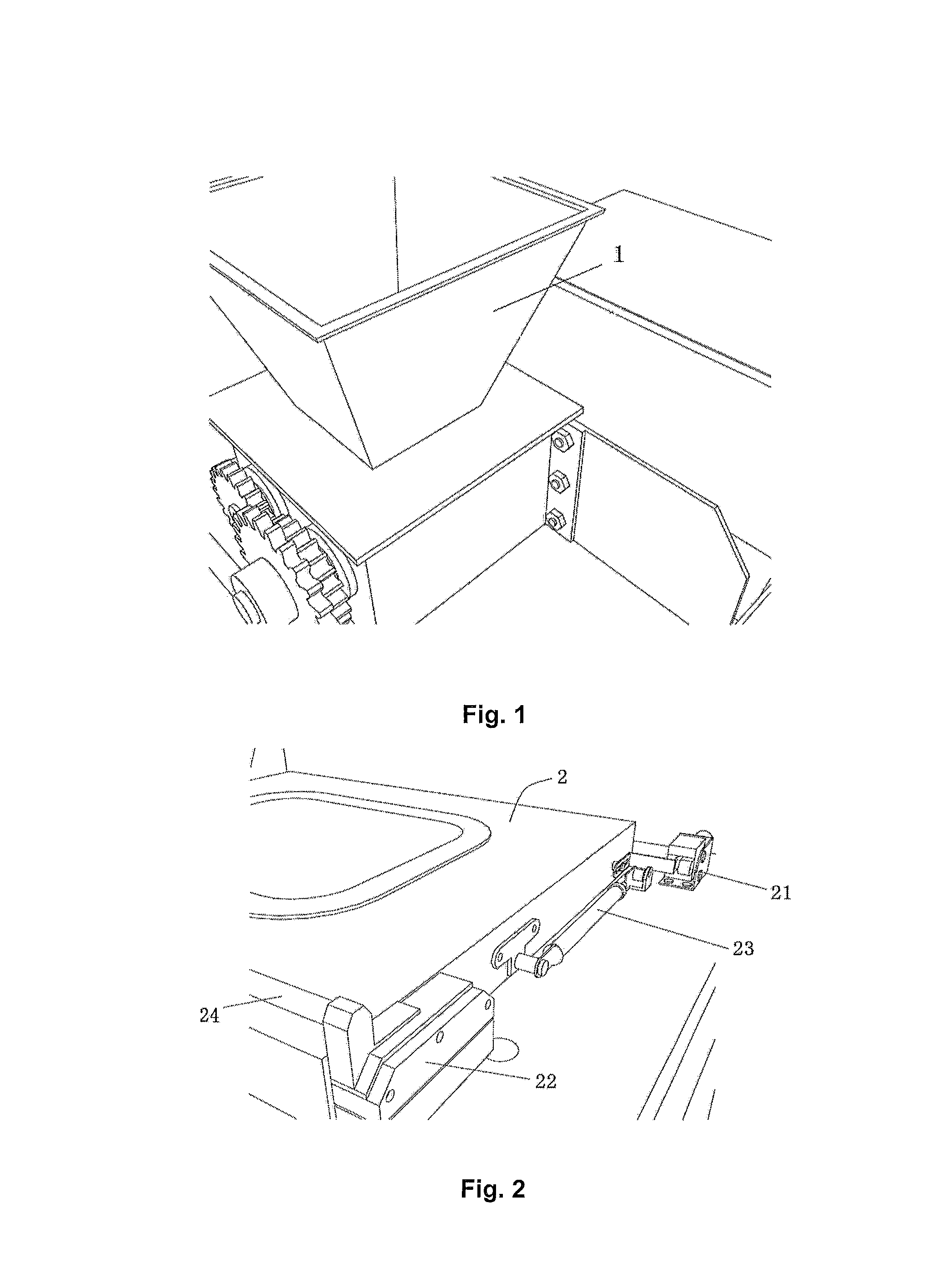

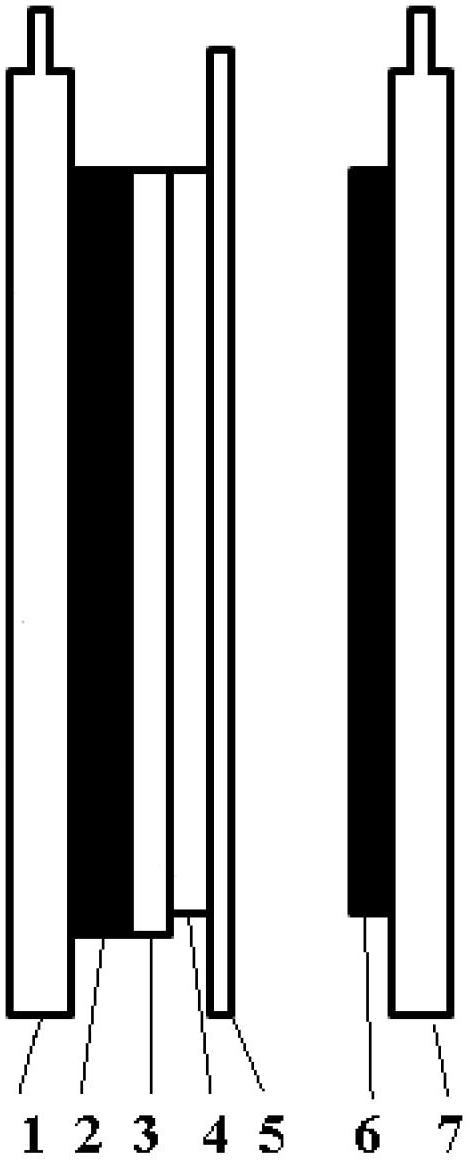

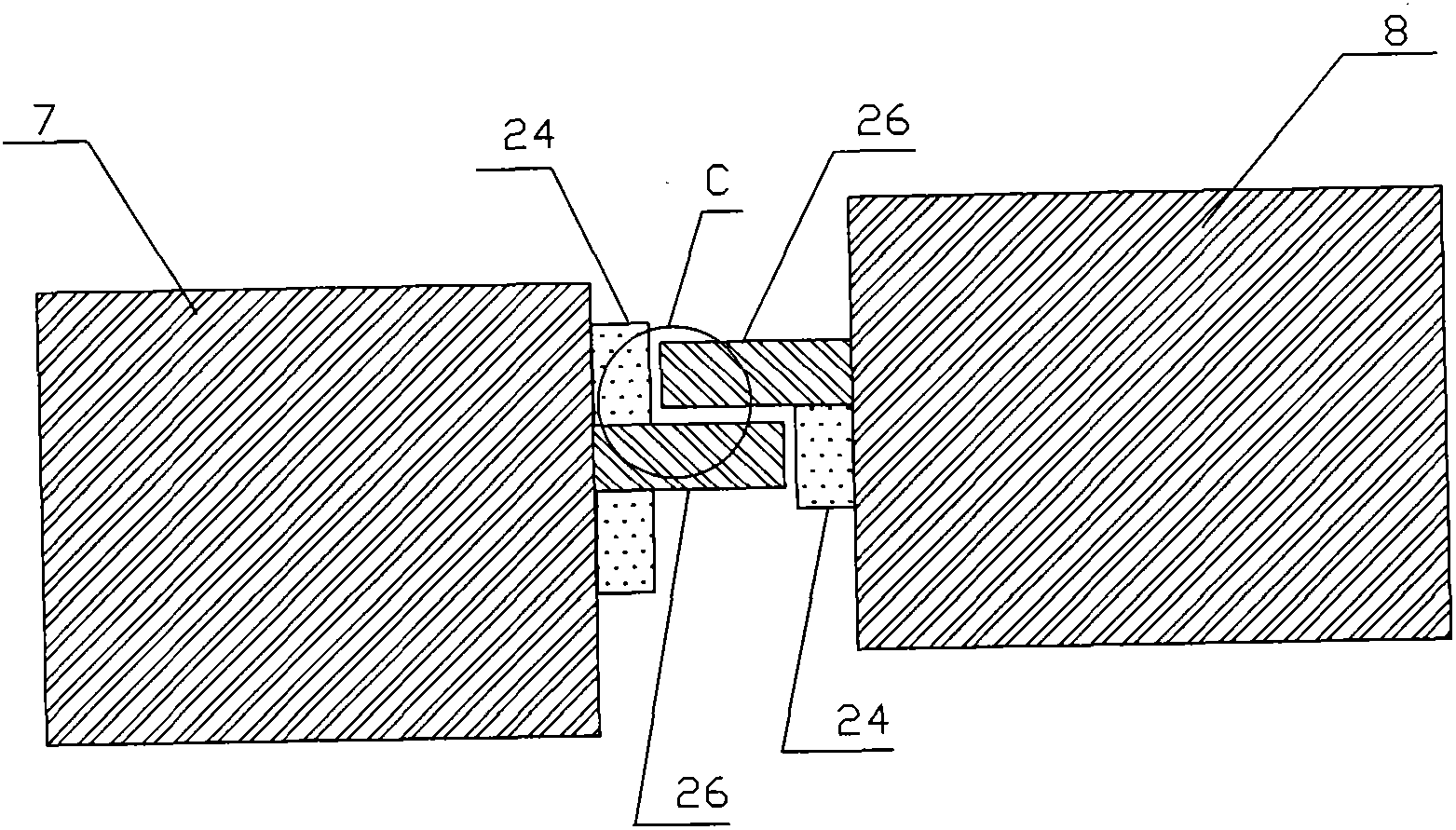

Grinding gear, grinding device and grinder

The invention belongs to the mechanical field and relates to a grinding or crushing device, in particular to a grinding gear, a grinding device and a grinder. The end part of the teeth on the existing grinding gear is generally a plane or cambered surface which is not good for grinding materials. In order to solve the defect of the prior art, the invention provides a grinding gear which comprises a gear ring, wherein gear teeth are arranged on the gear ring, and the top end of each gear tooth is of a sharp blade shape. The grinding gear can effectively stab or puncture and shear materials. The invention also provides a grinding device which comprises the grinding gear. The invention also provides a grinder which comprises the grinding device. Through the grinding gear, grinding device and grinder provided by the invention, the materials can be effectively ground.

Owner:邢征

Closed harmless treatment device for medical waste

InactiveCN108405564AImprove mixing efficiencyImprove the mixing effectSolid waste disposalCombustion chamberCooling chamber

The invention discloses a closed harmless treatment device for medical waste. The closed harmless treatment device comprises a feeding device, a combustion chamber, a gas collecting device, a gas washing chamber and a cooling chamber; the feeding device is arranged on the left side of the upper portion of the combustion chamber, and the gas collecting device is connected to the upper portion of the right side wall of the combustion chamber; a combustion grid mesh comprises a combustion round pit and material sliding inclined panels arranged on the two sides of the combustion round pit, and thecombustion round pit is provided with a plurality of openings; a fuel gas pipe is arranged on the portion, located under the combustion grid mesh, of the left side wall of an outer wall in a penetrating mode; an igniter is arranged under the combustion round pit; and an alkaline solution is stored in the gas washing chamber, the cooling chamber is located over the gas washing chamber, air in thegas washing chamber enters the cooling chamber through a second connecting pipe, and a metal cooling mesh is arranged between every two adjacent partition plates in the cooling chamber as well as between each adjacent partition plate and the corresponding side wall of the cooling chamber. According to the closed harmless treatment device for the medical waste, exhaust gas generated after medical waste incineration can be purified through the gas washing chamber and the cooling chamber, and polluting exhaust gas emission is reduced. The closed harmless treatment device for the medical waste issuitable for being widely applied to harmless treatment of the medical waste.

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

Gas disinfection device for preventing infection

PendingCN112057662AReasonable designHarmless treatmentDeodrantsRadiationEngineeringEnvironmental geology

The invention belongs to the technical field of medical treatment and epidemic prevention equipment and particularly relates to a gas disinfection device for preventing infection. In view of problemsof the existing gas disinfection equipment that gas cannot be in full contact with a disinfection mechanism, a minority of gas cannot disinfect thoroughly, and the efficiency of disinfection is low, ascheme is proposed at present as follows: the gas disinfection device comprises a base, wherein a box body with an open side is mounted at the top of the base, a box cover is arranged at one side ofthe box body, a sleeve with a closed top is welded to the top of the box body, the bottom of the sleeve communicates with the interior of the box body, the outer side of the sleeve is connected with one side of a gas inlet pipe, the other end of the gas inlet pipe extends to the outer side of the sleeve and is connected with a gas collection hood, and a motor is mounted at the top of the sleeve. The gas disinfection device is reasonable in design, gas exhaled from a sufferer can be effectively collected and uniformly blown into the box body, the gas can be thoroughly heated, microbes such as bacteria in the gas are killed, and innocent treatment on the gas exhaled from the sufferer is achieved so as to prevent the other people from being infected.

Owner:青岛市第六人民医院

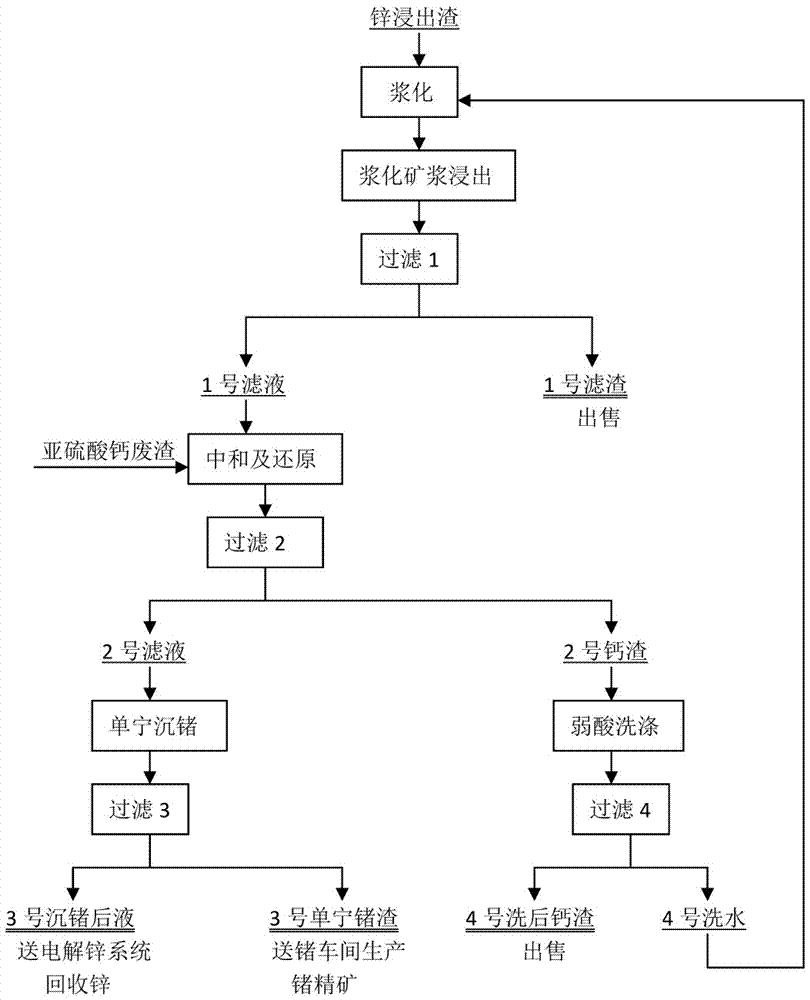

Comprehensive treatment method for zinc hydrometallurgy high-germanium raw material and calcium sulfite residues

ActiveCN106884095AImprove environmental benefitsAchieve restorationProcess efficiency improvementAcid washingHydrometallurgy

The invention discloses a comprehensive treatment method for a zinc hydrometallurgy high-content germanium raw material and calcium sulfite residues. The method comprises the following steps that 1), pulpifying of zinc leaching residues is performed; 2), pulpified ore pulp leaching is performed; 3), neutralization and reduction are performed; 4), calcium residue weak acid washing is performed; and 5), tannic germanium precipitation is performed. According to the comprehensive treatment method, when germanium is directly recycled in the zinc hydrometallurgy process, the simple and convenient method is adopted, the calcium sulfite residues generated when sulfur dioxide is absorbed through a double-alkali method during volatilization of a rotary kiln are comprehensively treated, and a marketable calcium sulfite industrial raw material is obtained; and recycling of resources is achieved, the environmental protection risk is eliminated, the production cost is saved, and meanwhile it is effectively guaranteed that the germanium is smoothly recycled from the zinc hydrometallurgy high-germanium raw material.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

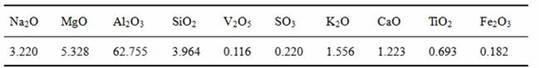

Harmless treatment process of electrolytic aluminium scum

ActiveCN109530387AHarmless treatmentWell mixedTransportation and packagingSolid waste disposalDecompositionDust particles

The invention discloses a harmless treatment process of electrolytic aluminium scum and belongs to the technical field of solid waste cyclic utilization in the aluminium electrolysis industry. The harmless treatment process comprises the following steps: aluminium scum after crushing and impurity removal, a catalyst (mixture of nitrate of potash and sodium chloride) and a reactant (mixture of positive cryolite and metallurgical-grade aluminium oxide) are uniformly mixed, and in a combustion furnace, nitrate of potash generates decomposition when burns at 600-760 DEG C to generate combustion-supporting gas namely oxygen so as to enable carbon in the aluminium scum to fully burn; sodium chloride has an accelerating and catalytic action on decomposition of ammonium nitrate category substances; and the metallurgical-grade aluminium oxide can effectively adsorb melted sub cryolite and fluoride salt. With adoption of the harmless treatment process, in burnt aluminium scum residual ash, the carbon content is 3%, and regeneration electrolyte is obtained through molecular ratio adjustment; in burnt exhaust gas, content of fluoride salt is less than 3mg / m3, content of dust particle is less than 20mg / m3, and the burnt aluminium scum residual ash can be directly discharged to the atmosphere after being connected into an aluminium electrolysis exhaust gas purifying system through purification, so that the harmless treatment purpose of electrolytic aluminium scum is realized.

Owner:GANSU DONGXING ALUMINUM

Method for preparing fertilizer by jointly treating agricultural waste with ultrasonic wave and alkali

InactiveCN107344880AGood technical effectImprove performanceBio-organic fraction processingOrganic fertiliser apparatusChemistryAgriculture

The invention relates to a method for preparing fertilizer by jointly treating agricultural waste with an ultrasonic wave and an alkali. The method comprises the following steps of S1, providing a fertilizer preparation device; S2, obtaining a waste organic matter; S3, obtaining a pretreated material; S4, carrying out solid-liquid separation, and obtaining liquid and a solid; S5, obtaining concentrated liquid fertilizer; S6, obtaining organic fertilizer. According to the method, through the unique fertilizer preparation device and unique process steps and the parameter selection of the preparation method, multiple excellent effects can be consequently obtained through a synergic effect; the concentrated liquid fertilizer and the organic fertilizer with excellent effects can be obtained; consequently, the method has favorable application prospect and industrialized production potential in the field of utilization of agricultural waste resources.

Owner:江苏绿方园生物科技有限公司 +2

Excrement sterilizer

InactiveCN103223186ADisinfection dynamicsSterilization InstantMedical waste disposalOzone generatorLine tubing

The invention discloses an excrement sterilizer which is composed of an ozone generator, a mixing unit, a sterilization device and their pipelines. Oxygen is used as a gas source; ozone is produced by the use of the ozone generator; ozone is used as a sterilization source; high-density ozone water is prepared by a gas-liquid mixing pump; and agitation is performed in the sterilization device so as to sterilize the excrement. Thus, the purpose of dynamic and concurrent sterilization of excrement is realized.

Owner:HUNAN YUECI GAOXIN TECH

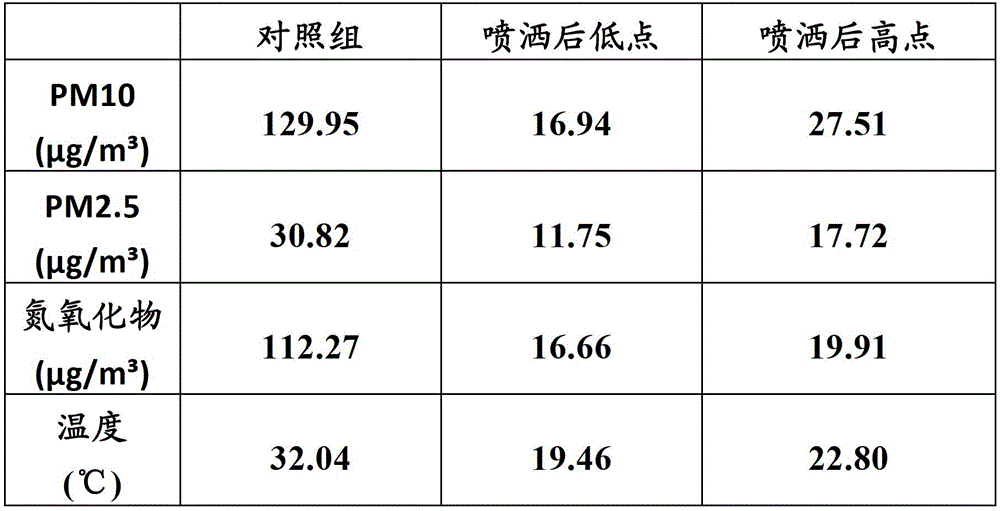

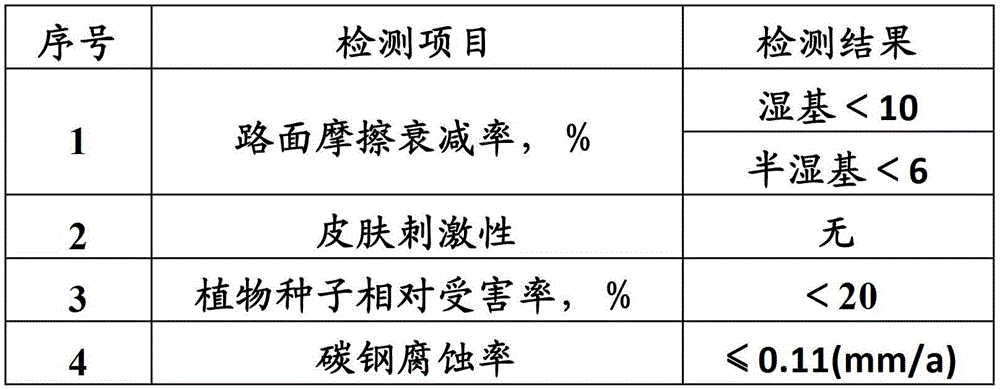

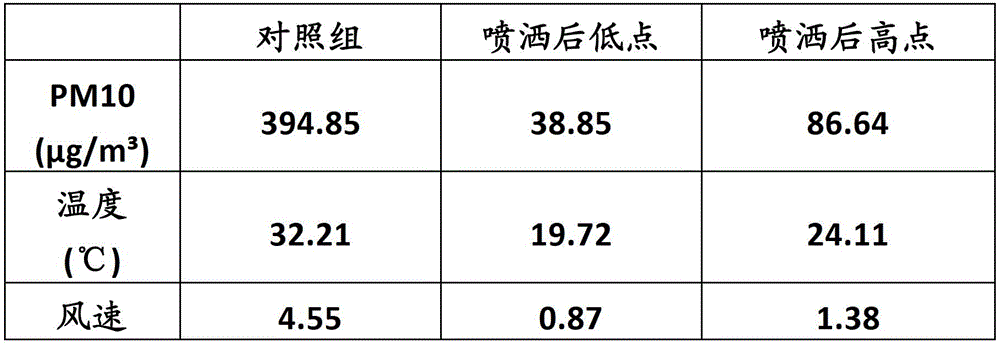

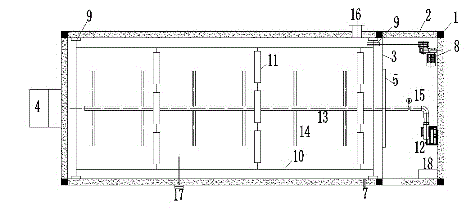

Road dust suppressant for controlling inhalable particulate matter in near-surface air and preparation method thereof

ActiveCN104073222BReduce concentrationWeak corrosiveOther chemical processesDispersed particle separationHazardous substanceAlkylphenol

The invention relates to a road dust suppressant for controlling the inhalable particles in near-surface air and a preparation method thereof. The road dust suppressant comprises the following components in parts by weight: 100-150 parts of calcium magnesium acetate, 0.04-0.2 part of dust suppression aid and 300-1,800 parts of water, wherein the calcium magnesium acetate comprises 0.1-0.9 part of calcium acetate and 0.1-0.9 part of magnesium acetate; and the dust suppression aid is one of surfactants including sodium lauryl sulfate, alkylphenol polyoxyethylene ether TX-10, wetting agent X-405, sodium dodecyl benzene sulfonate, Tween and Span or a mixture of more than one of the surfactants. The road dust suppressant provided by the invention can effectively reduce the inhalable particles and harmful substances such as nitrogen oxides and sulfides on the road, and has the characteristics of environmental friendliness, low corrosion to vehicles and pavement, long-lasting effect and the like.

Owner:北京首创大气环境科技股份有限公司

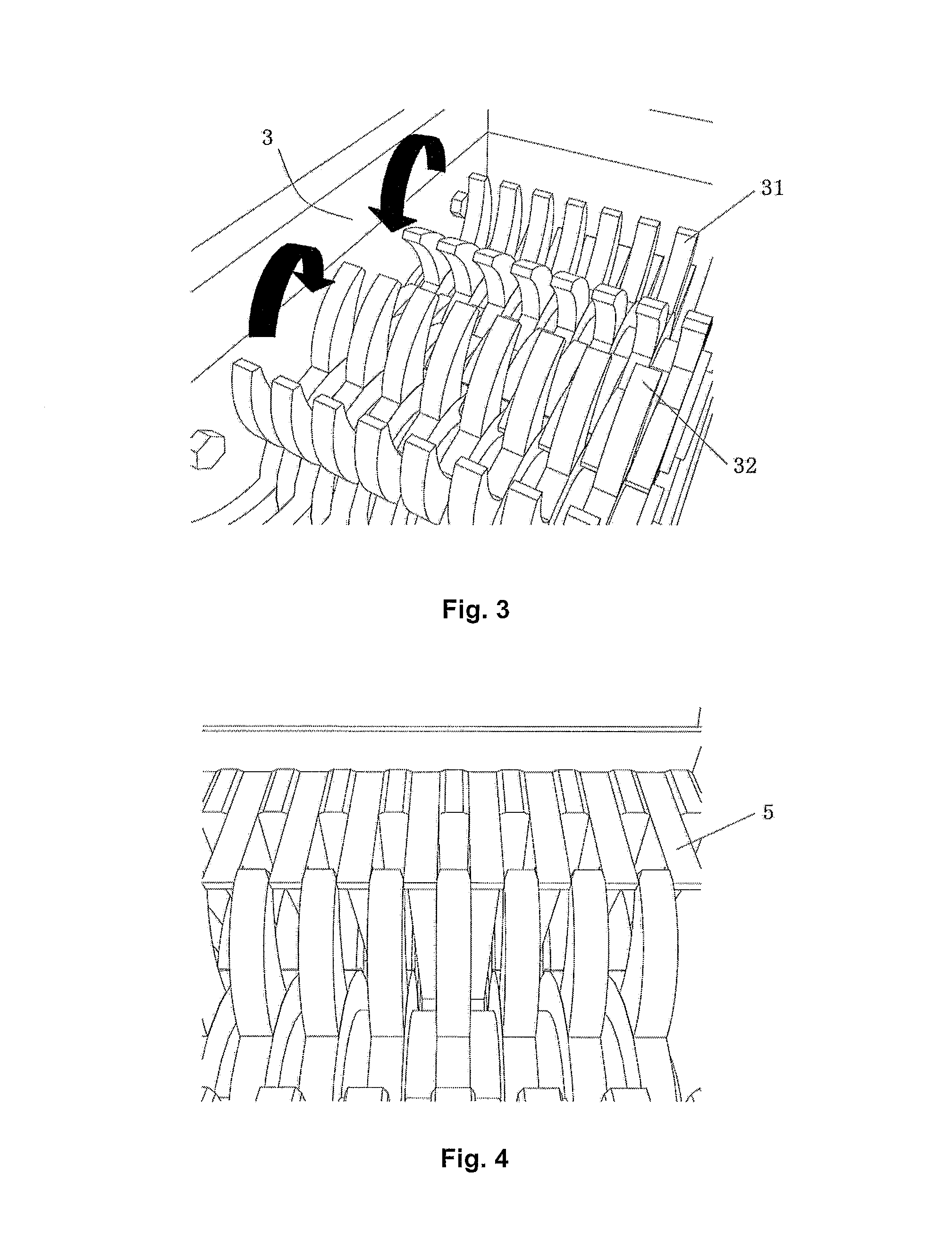

Aerobic fermentation device and method for organic waste

InactiveCN106140776AAchieve continuous accessAchieving processing powerSolid waste disposalGear wheelExhaust fumes

The invention discloses an aerobic fermentation device and method for organic waste, and belongs to the field of waste treatment. The aerobic fermentation device comprises a box body, a chained turning-throwing device, an air supply system and a monitoring system, wherein according to functions, the box body is divided by a partition plate into a fermentation zone and an operation zone; a heat preservation layer, a feeding port, a discharging valve plate, an exhaust vent and a waste liquid port are arranged in the box body; the chained turning-throwing device comprises a driving motor, a movable gear group, a chain and scraping plates; turning, throwing, feeding and discharging of a material in the box body can be achieved; the air supply system comprises a draught fan, a control valve, a main pipe, branch pipes and a waste gas pipe; the monitoring system comprises a monitoring instrument and a control unit; and the control unit is used for controlling material feeding and discharging, running of the air supply system and other processes by monitoring and analyzing data fed back by the monitoring instrument. By adoption of the aerobic fermentation device, continuous feeding, continuous discharging, uniform mixing of the material, air supply as required and the reduction of odor emission can be achieved; the fermentation efficiency is improved and the fermentation period is shortened; and eventually, harmless and recycling treatment of the organic waste can be achieved.

Owner:IMP ENVIRONMENT SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com