Water-based well drilling waste harmless treatment device and method, and application

A technology for harmless treatment and drilling waste, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc. It can solve the problems of not being broad-spectrum, increasing costs, wasting resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

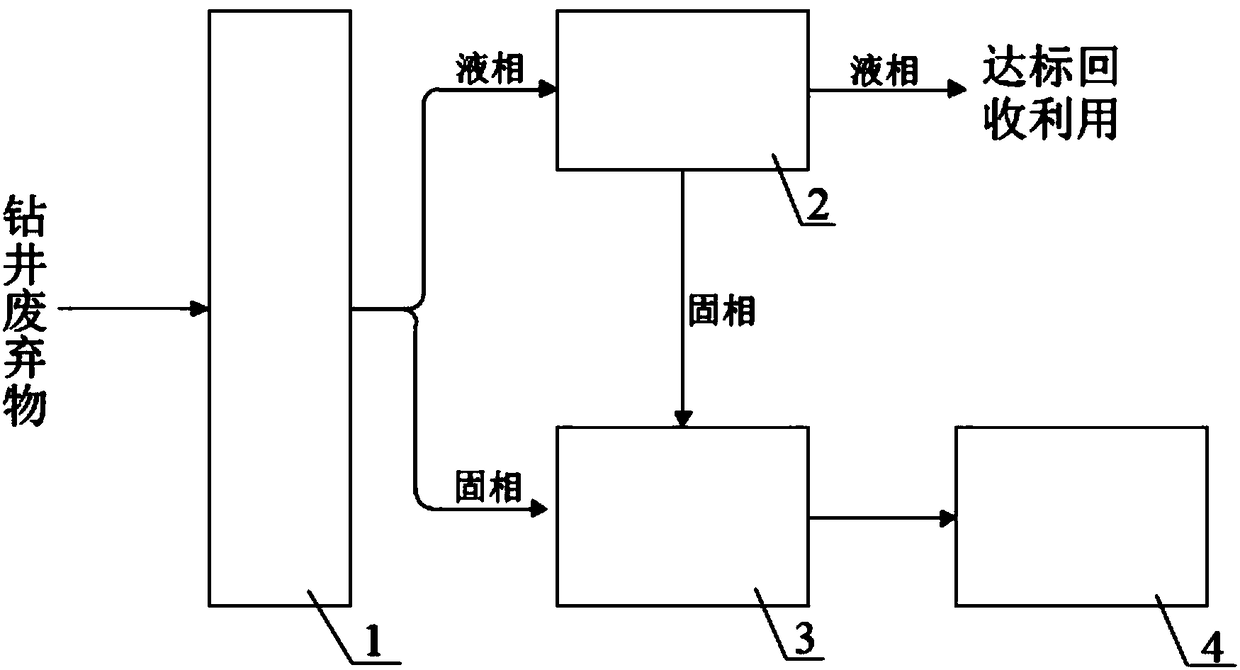

[0063] This embodiment provides a water-based drilling waste harmless treatment device, such as figure 1 As shown, the water-based drilling waste harmless treatment device includes a non-falling collection unit 1, a liquid phase regeneration treatment unit 2, a solid phase harmless treatment unit 3 and a solid phase recycling unit 4;

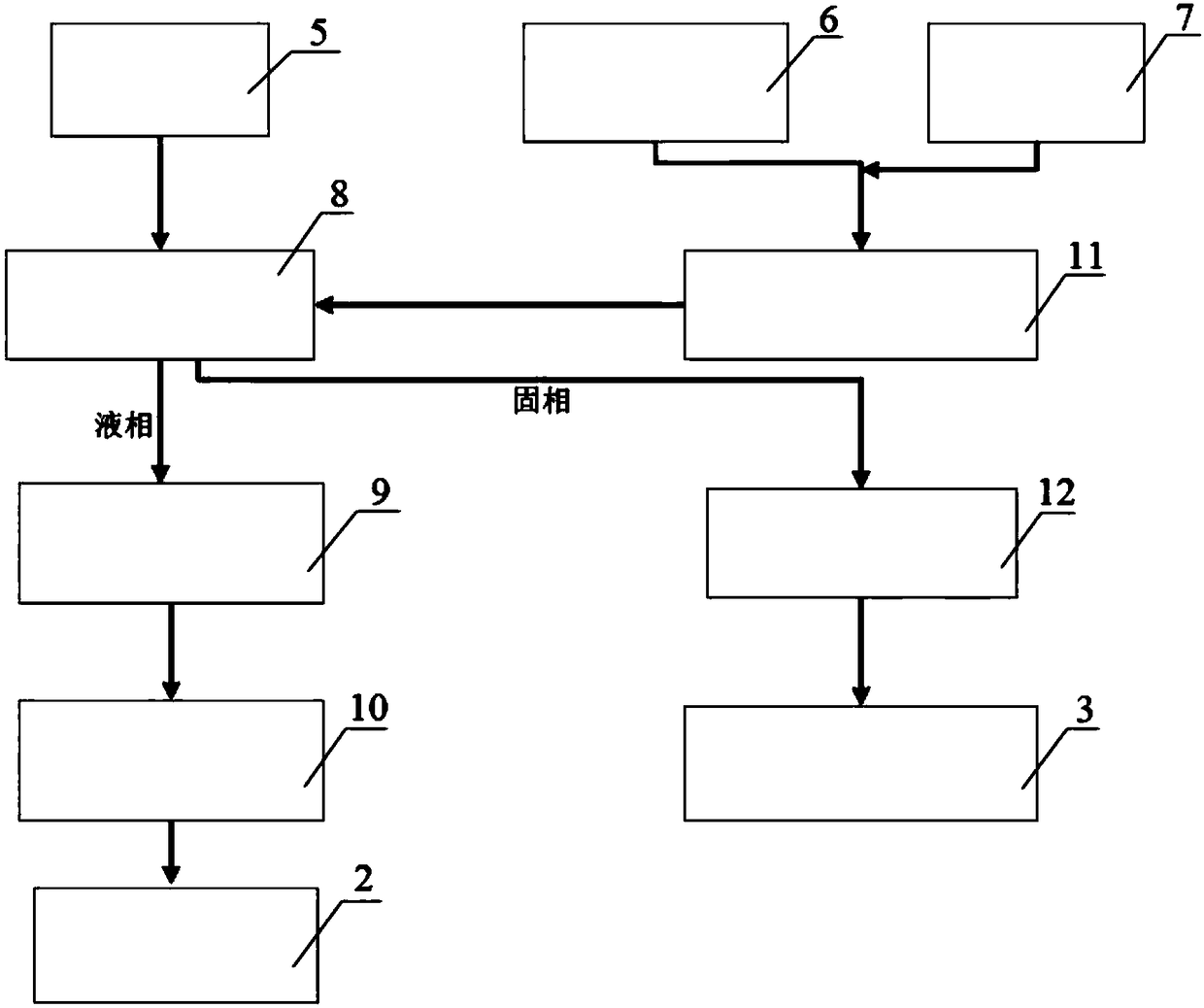

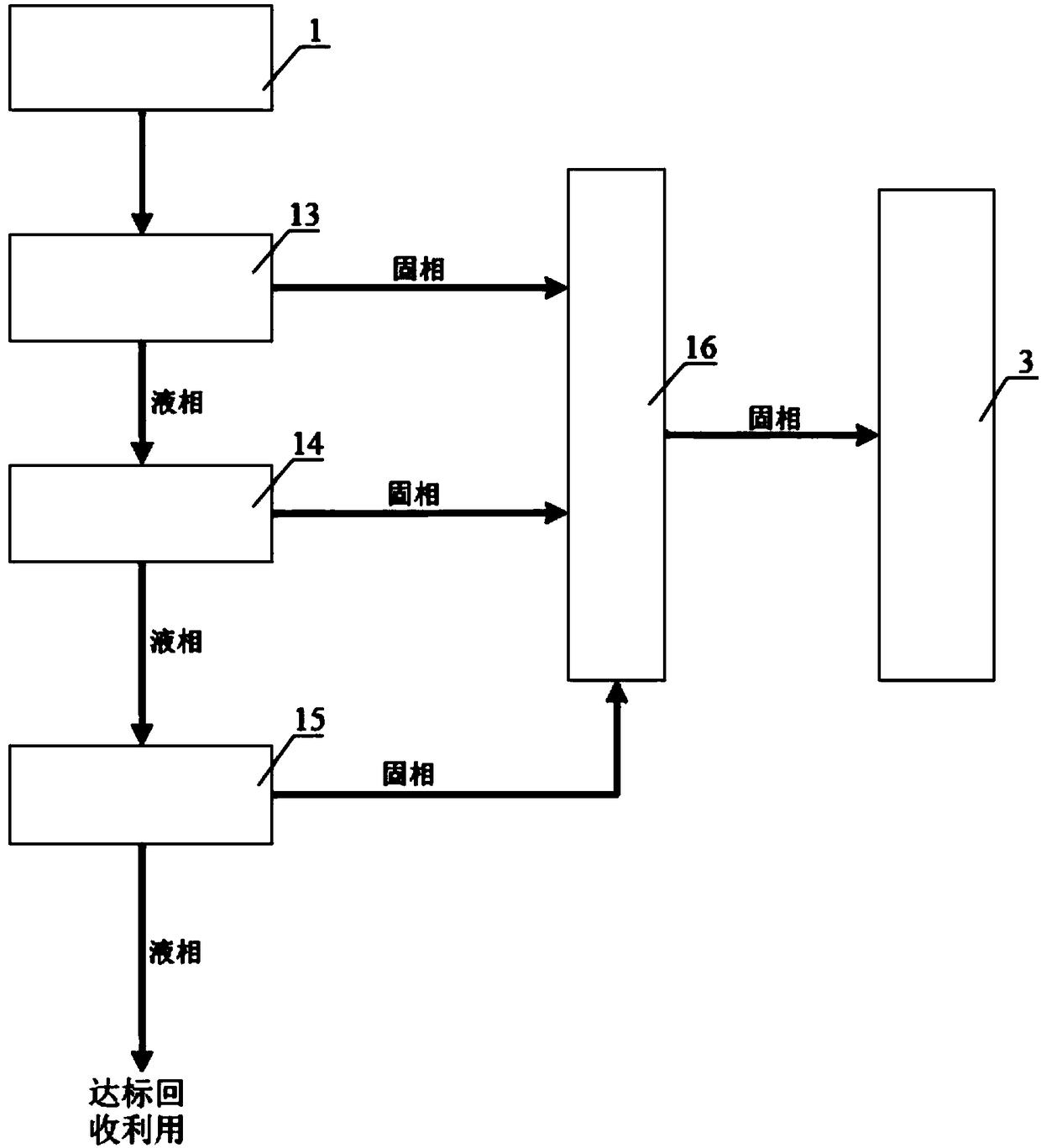

[0064] like figure 2 As shown, the non-falling collection unit 1 includes a double helix collection skid 8 , a solid phase plunger pump 12 , a screw receiving conveyor 11 and a drilling solids control vibrating screen 5 . like image 3 As shown, the liquid-phase regeneration treatment unit 2 includes a high-G vibrating screen 13, a frequency conversion centrifuge 14, an electrochemical processor 15 and a Pumai pump 16; Figure 4 The shown solid phase harmless treatment unit 4 includes a primary weighing and mixing screw machine 17 , a secondary mixing screw machine 18 and a harmless treatment agent dosing device 19 .

[0065] A first mortar ...

Embodiment 2

[0071] This embodiment also provides a water-based drilling waste harmless treatment process, which uses the water-based drilling waste harmless treatment device provided in Example 1 to treat a conventional natural gas well polymer system drilling waste, including the following step:

[0072] The drilling waste discharged from the drilling solid control vibrating screen 5 falls into the double-helix collection skid 8 through the chute, and the drill cuttings discharged from the centrifuge 7 of the drilling team are received by the spiral receiving conveyor 11 and then sent to the double-helix collection skid 8. After preliminary solid-liquid separation in the cache, the upper layer of liquid phase drilling waste (liquid content greater than 60%) is pumped into the high G vibrating screen 13 through the first mortar pump 9, and the pumping speed is controlled by the flow meter 10, and the lower layer of solid phase drilling waste The waste (with a liquid content less than 60%)...

Embodiment 3

[0076] This implementation provides a water-based drilling waste harmless treatment process, which uses the water-based drilling waste harmless treatment device provided in Example 1 to treat a shale gas well KCl-polymer system drilling waste, including the following step:

[0077] The drilling waste discharged from the drilling solid control vibrating screen 5 falls into the double-helix collection skid 8 through the chute, and the drill cuttings discharged from the centrifuge 7 of the drilling team are received by the spiral receiving conveyor 11 and then sent to the double-helix collection skid 8. After preliminary solid-liquid separation in the cache, the upper layer of liquid phase drilling waste (liquid content greater than 60%) is pumped into the high G vibrating screen 13 through the first mortar pump 9, and the pumping speed is controlled by the flow meter 10, and the lower layer of solid phase drilling waste The waste (with a liquid content less than 60%) is transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com