Patents

Literature

38results about How to "Improve environmental standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

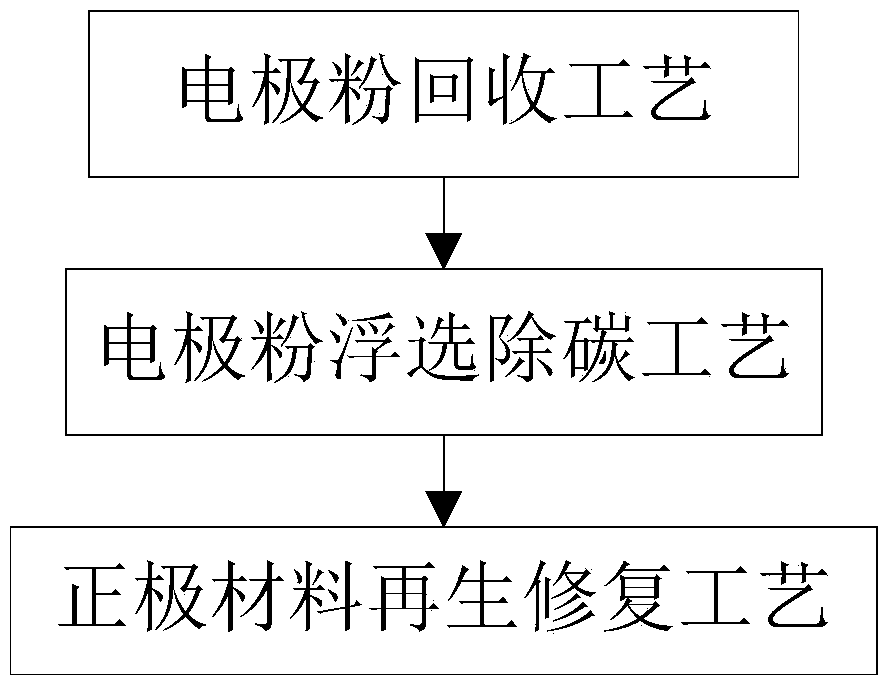

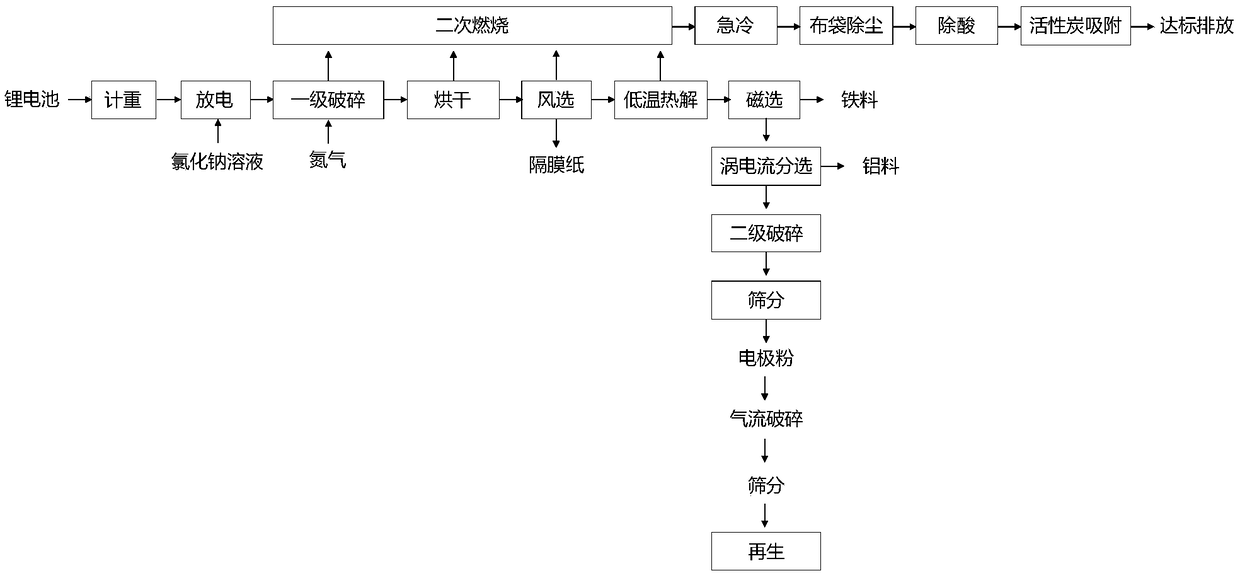

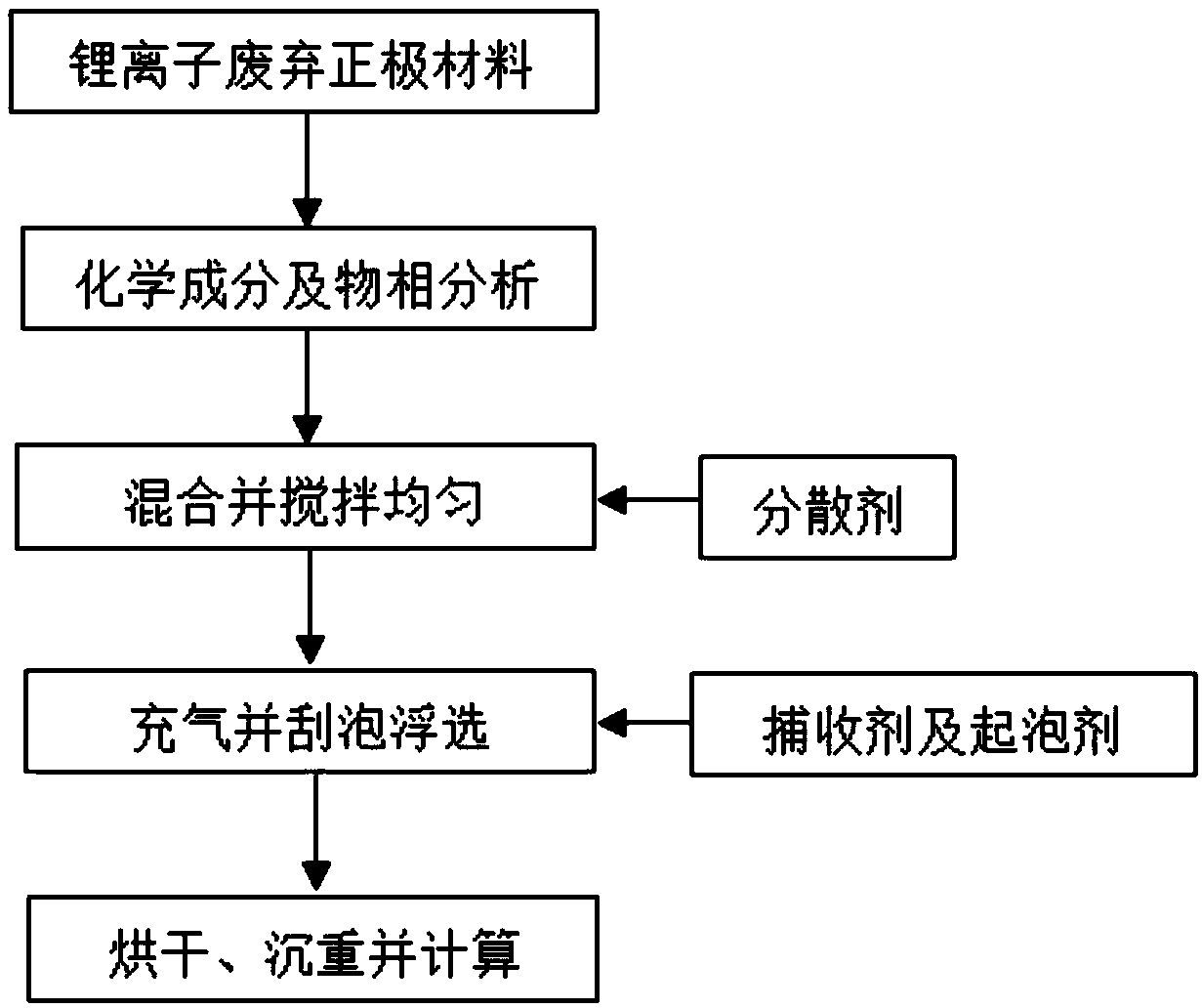

Recycling process of positive electrode materials of waste batteries

ActiveCN109326843ASimple recycling processHarmless treatmentWaste accumulators reclaimingFlotationEngineeringBiological activation

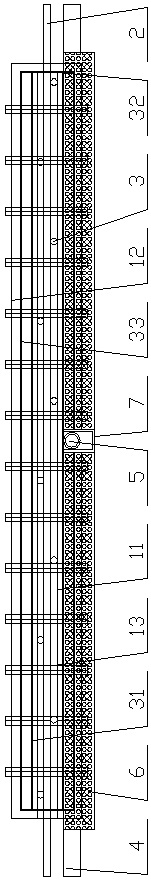

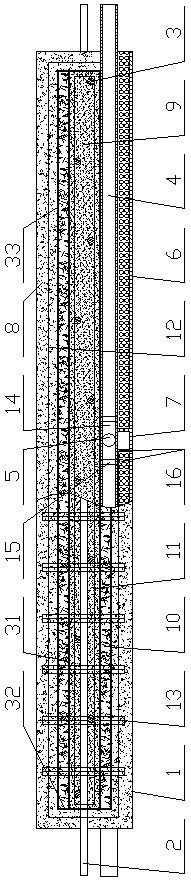

The invention discloses a recycling process of positive electrode materials of waste batteries. The recycling process includes the steps of completely discharging the waste lithium batteries, subjecting the waste lithium batteries to primary crushing under inert gas protection, removing diaphragm paper through air classification after crushing, performing low-temperature pyrolysis, respectively removing iron materials and aluminum materials through sorting, performing re-pulverization to obtain electrode powder, determining a flotation reagent system according to the phase composition of the electrode powder, performing flotation in a flotation tank, and filtering and drying products at the bottom of the flotation tank to obtain the positive electrode materials; according to the Li / M ratioof the positive electrode materials, calculating the lithium source powder to be added, and mixing water-soluble dispersants and the lithium source powder with water to form a mixed solution; addingthe positive electrode materials to be repaired into the mixed solution, performing cooking activation at a high temperature and under high pressure, continuing to dry the product under normal pressure to obtain uniform mixture powder, and calcining the mixture powder under an aerobic condition to obtain the regenerated and repaired lithium ion battery positive electrode materials. The recycling process has the advantages of low repair cost, high activity after repair, and higher promotion and application value.

Owner:荆门动力电池再生技术有限公司

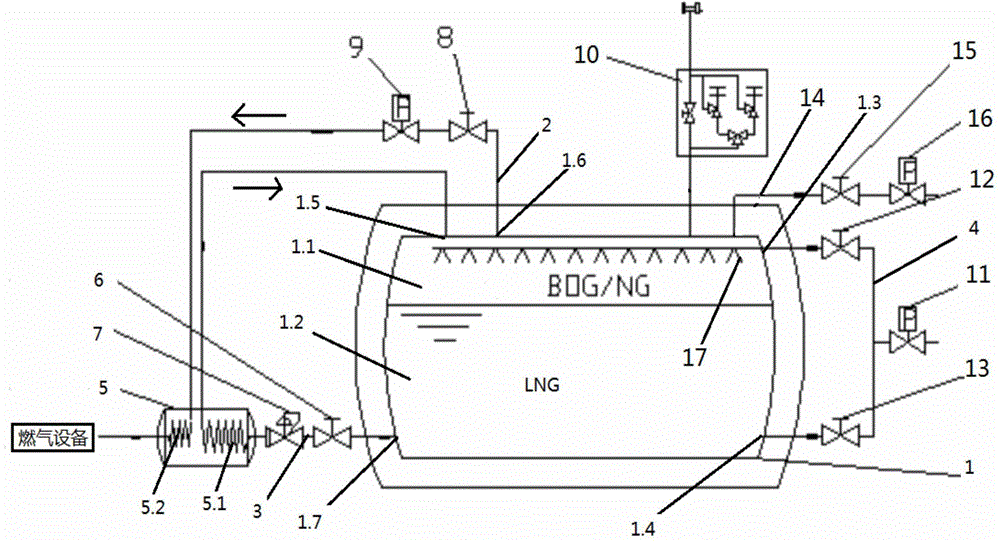

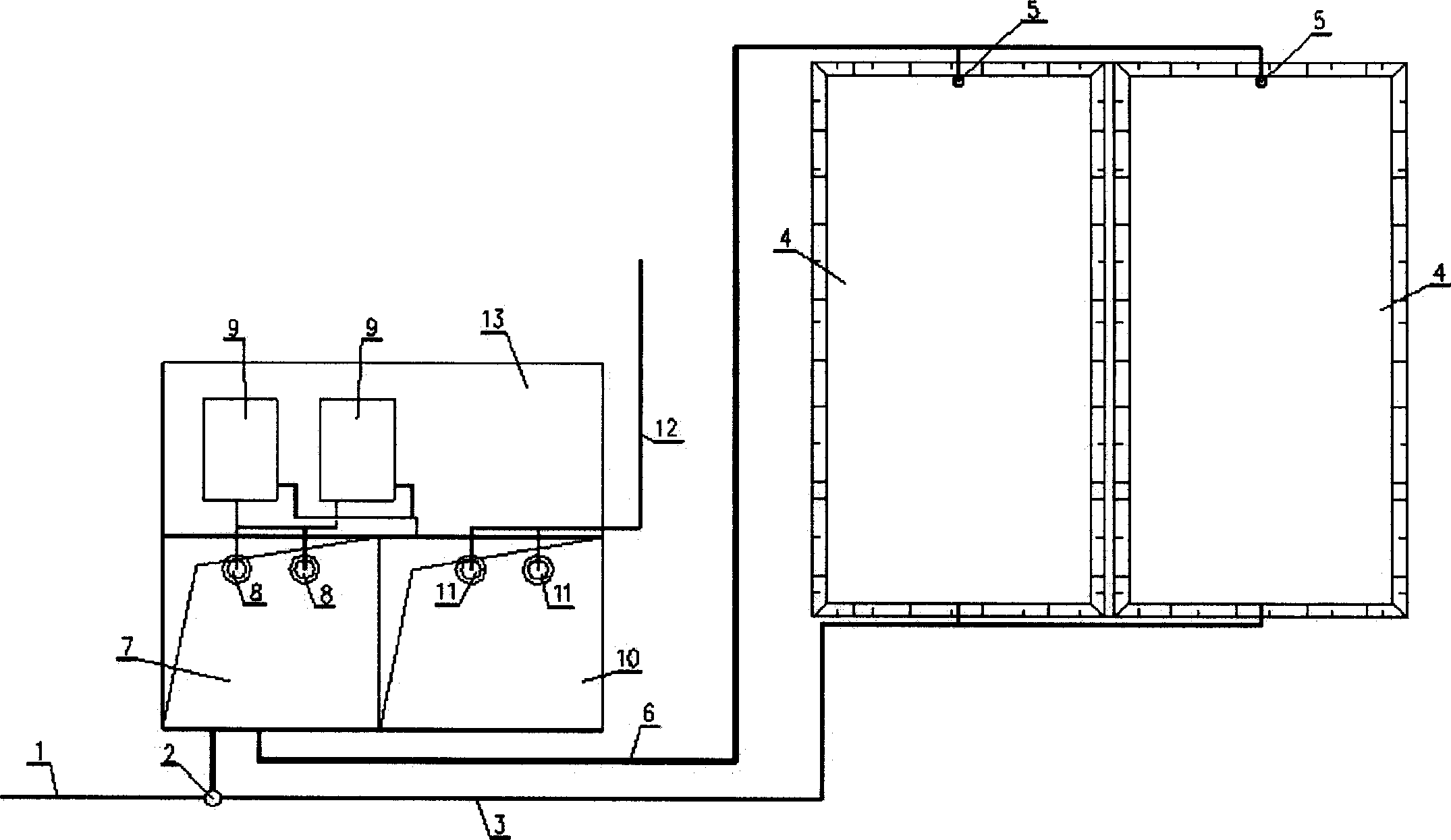

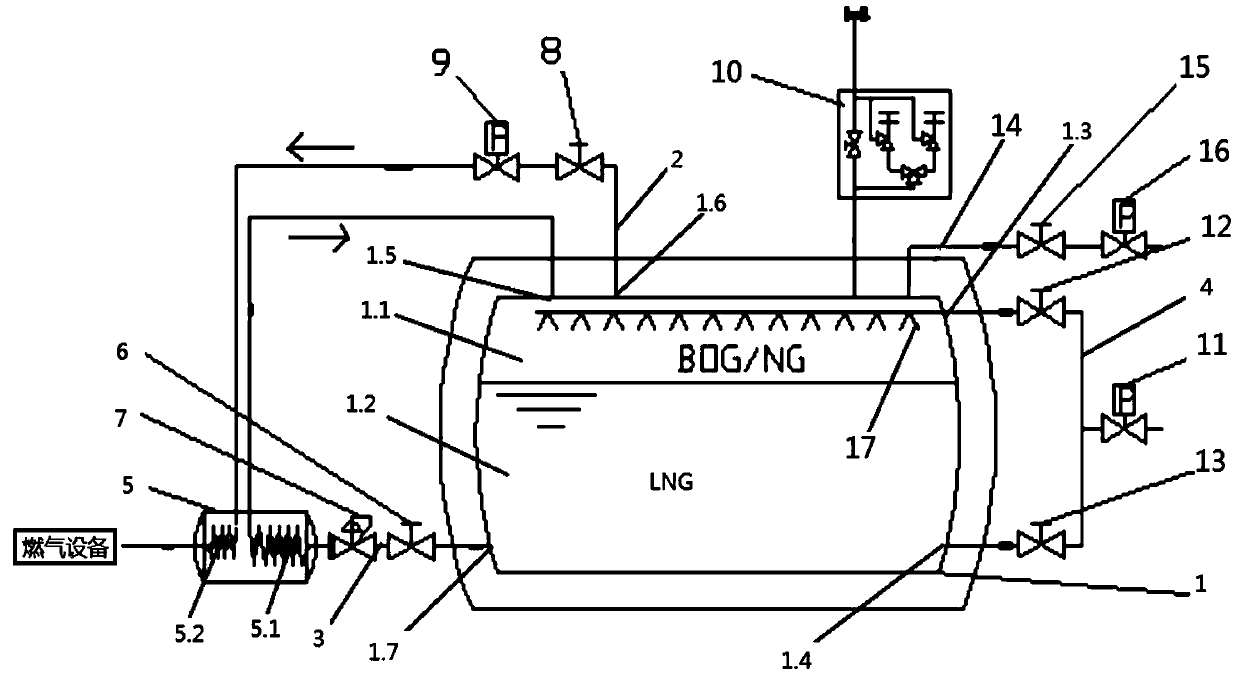

LNG (liquefied natural gas) fuel supply method and device utilizing BOG (boil-off gas) preferentially

ActiveCN104791602AAvoid problems such as easy freezingEasy to controlPressure vesselsContainer discharging from pressure vesselsPlate heat exchangerProcess engineering

The invention relates to an LNG (liquefied natural gas) fuel supply method and device utilizing BOG (boil-off gas) preferentially and solves problems that the reliability is poor, equipment is easily frozen and cannot work during starting and the fuel utilization rate is low in existing LNG gas fuel supply. According to the technical scheme, the LNG fuel supply device comprises an LNG storage tank, wherein a liquid outlet in the bottom of the LNG storage tank is connected with a gasifier through a pressurization pipe; the gasifier comprises a fuel heat exchanger and a self-pressurization heat exchanger; the pressurization pipe is connected with a gas inlet in the top of the LNG storage tank through the self-pressurization heat exchanger of the gasifier; a gas outlet in the top of the LNG storage tank is connected with gas equipment through a gas supply pipe and the fuel heat exchanger. The LNG fuel supply device is simple in structure, simple and convenient to operate, small in volume, high in reliability, good in safety, low in equipment investment and running cost, high in fuel utilization rate and environment-friendly.

Owner:WUHAN JIAOSHENG NEW ENERGY ENG

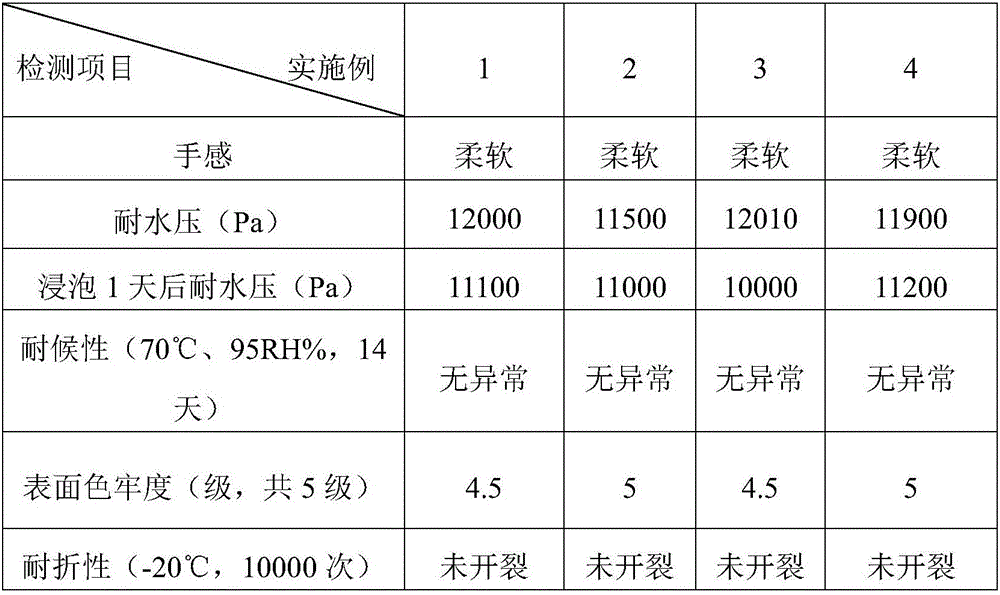

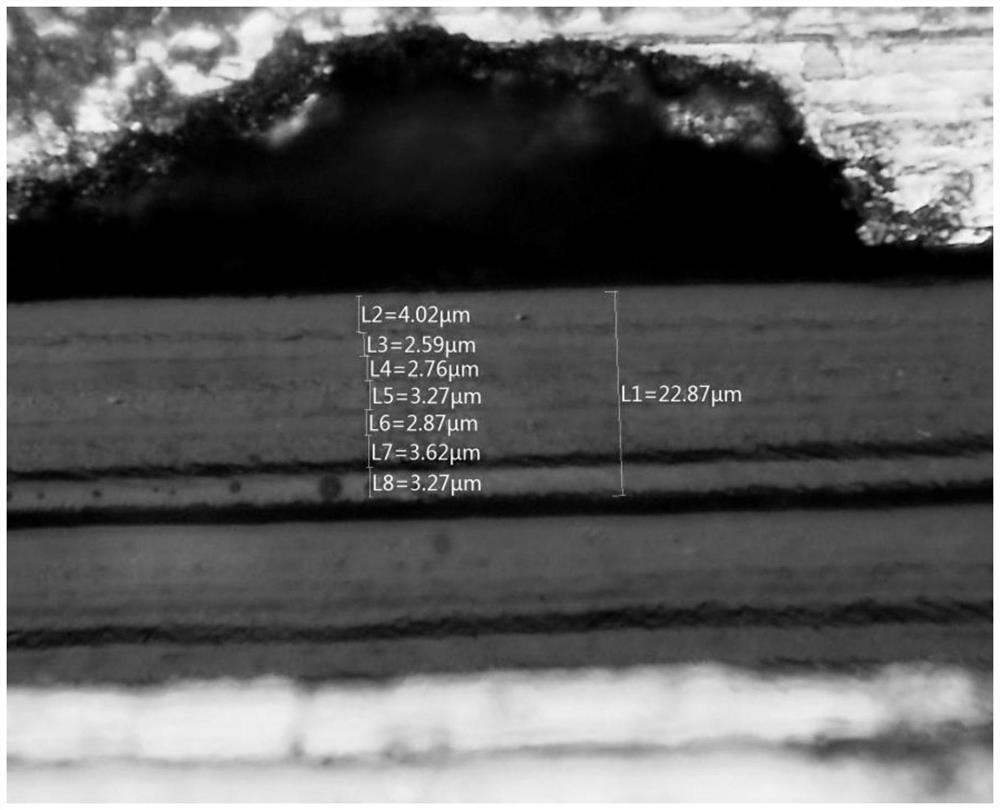

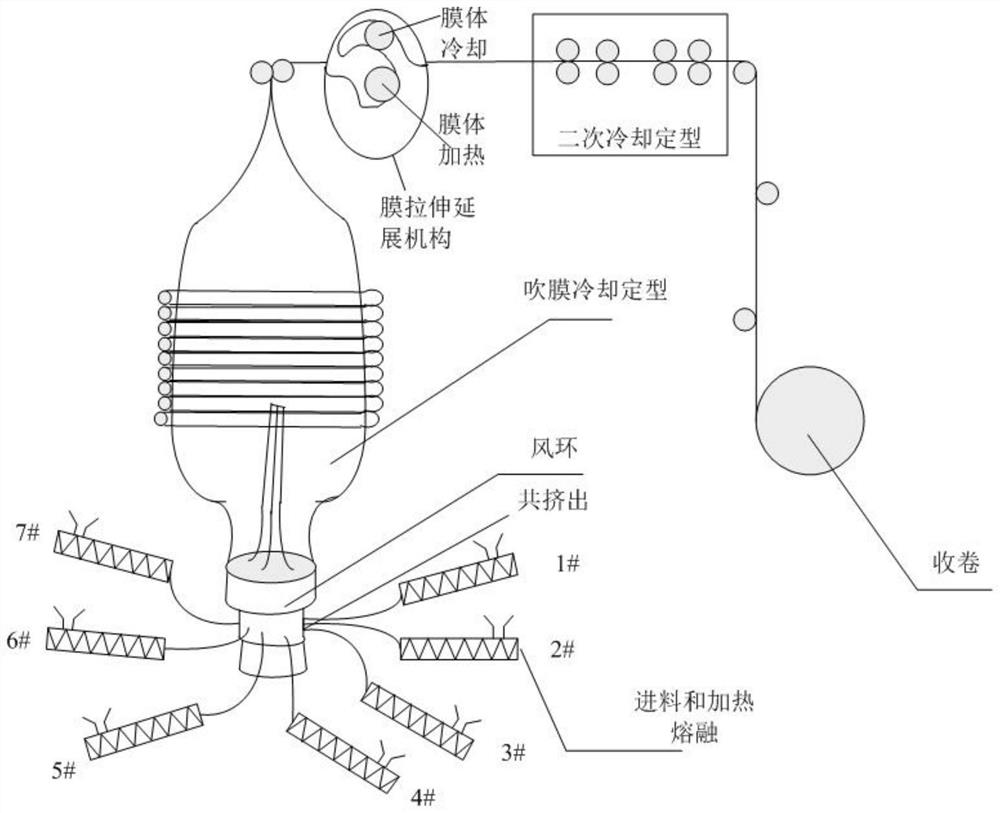

Water-based dry method foaming raincoat leather and preparation method thereof

InactiveCN106012564AImprove environmental standardsStop air bubblesTextiles and paperDefoaming AgentsChemistry

The invention provides water-based dry method foaming raincoat leather and a preparation method thereof. A water-based thickening agent, a defoaming agent, a flatting agent and other preparations are added into waterborne polyurethane resin, slurry on the surface layer, the middle layer, and the foaming layer and the bottom layer of waterborne polyurethane resin slurry is prepared through mixing and vacuum defoaming; through a dry method film moving processing method, release paper is firstly coated with the surface layer, the surface layer is coated with the middle layer after being dried and cooled, the middle layer is coated with the foaming layer after being dried and cooled, and the foaming layer is coated with the bottom layer after being dried and cooled; after low-temperature drying, base cloth is attached at high temperature, drying, curing and cooling are carried out, the release paper is stripped, split rolling and surface aftertreatment are carried out, and the water-based dry method foaming raincoat is obtained. The obtained water-based dry method foaming raincoat has good washing and water pressure resistance, and the water pressure resistance is still 10,000 MPa or above after washing; the water-based dry method foaming raincoat leather is soft in hand feeling, resistant to wrinkles, high in real leather sense, good in breathability and high in washing and water pressure resistance and completely meets the needs of the market for raincoat leather.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

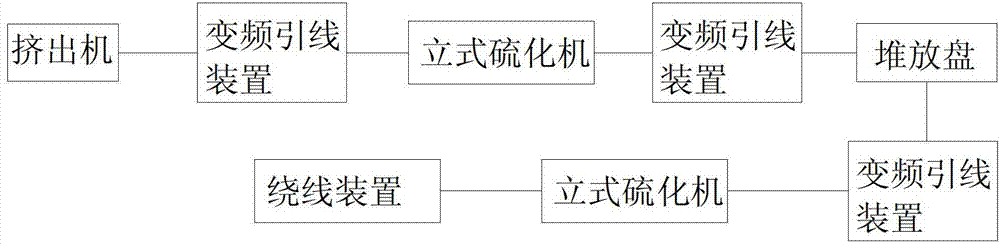

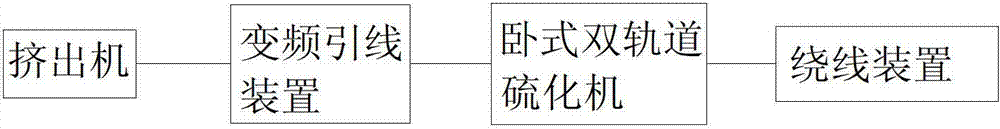

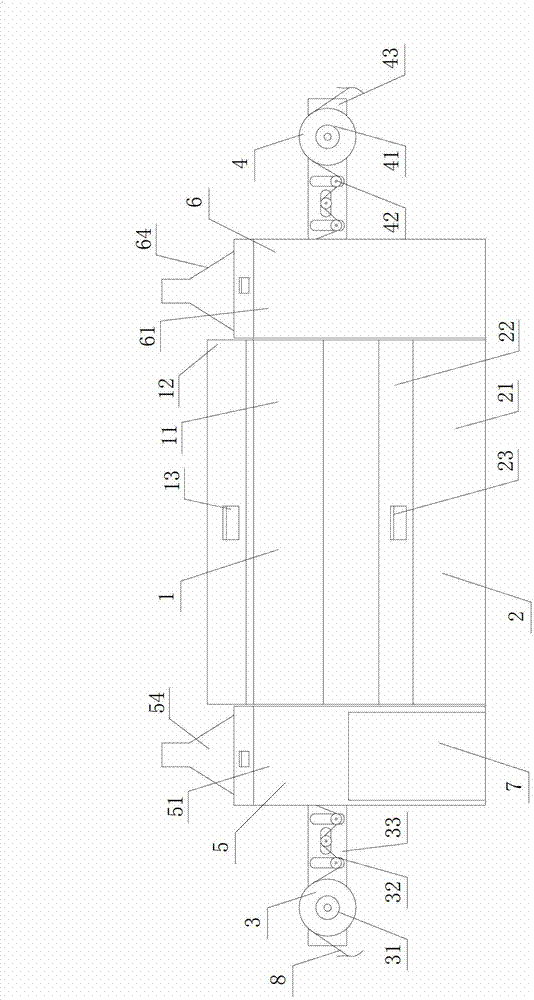

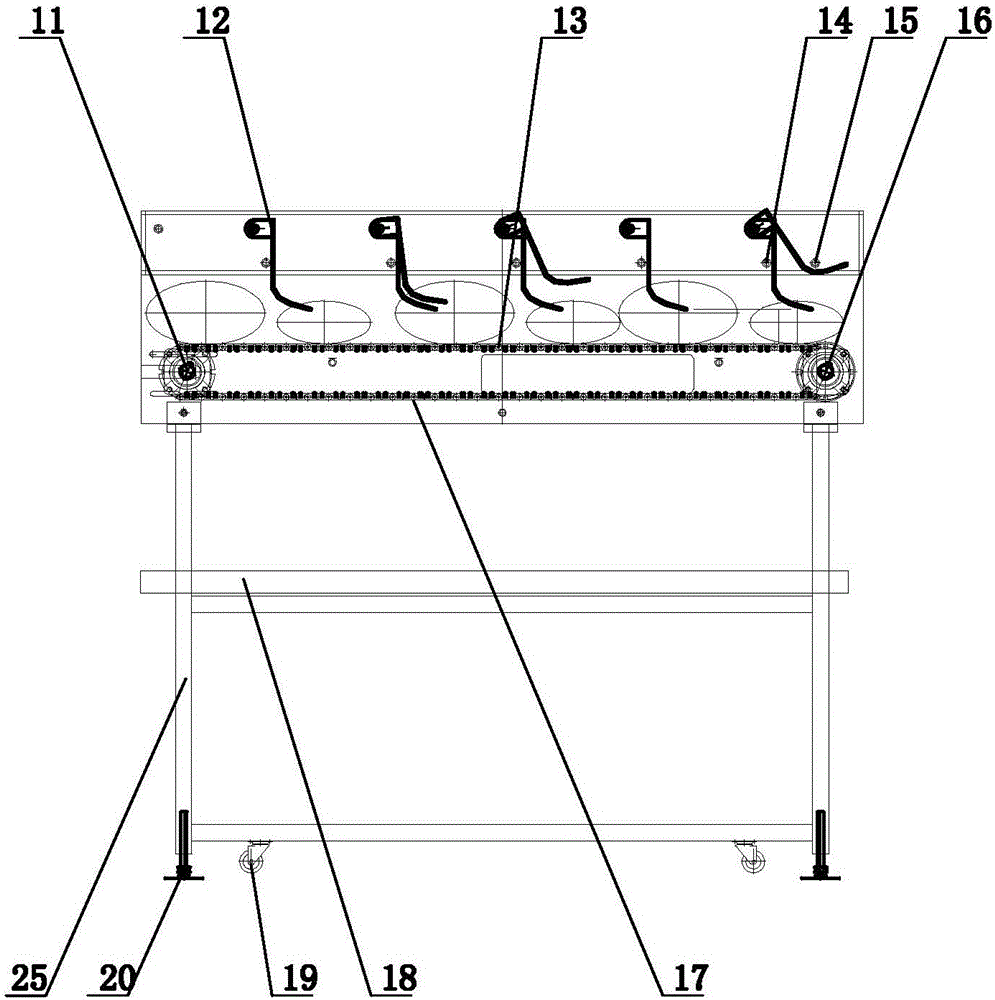

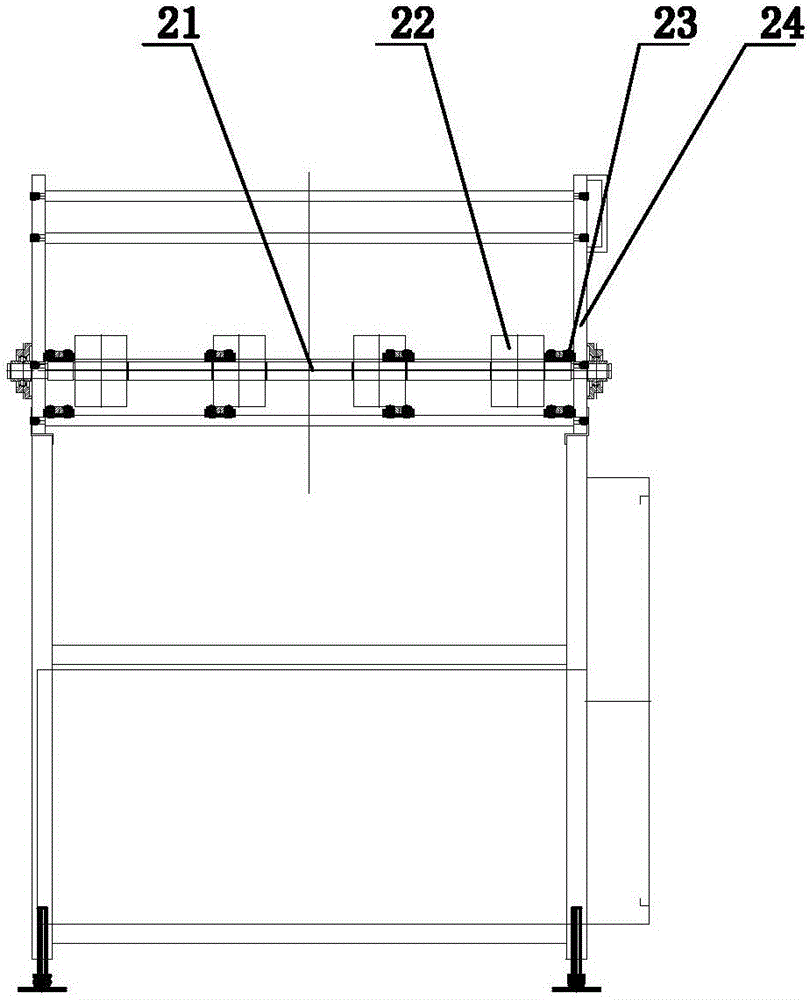

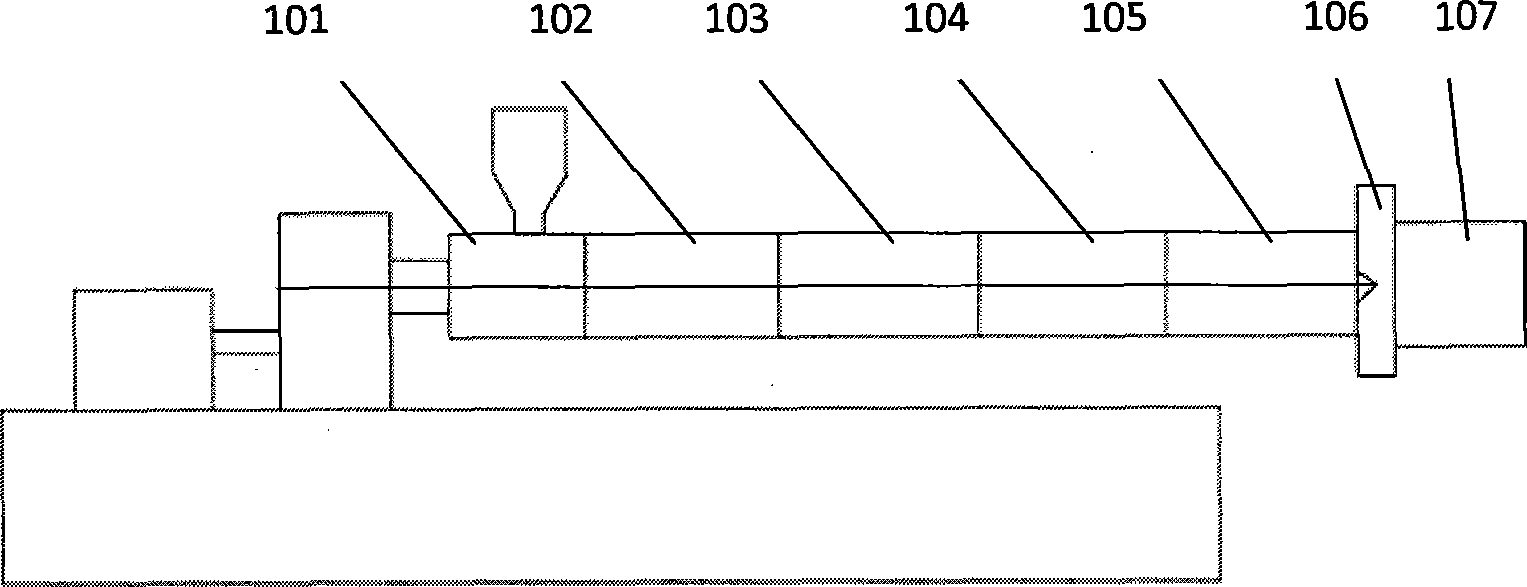

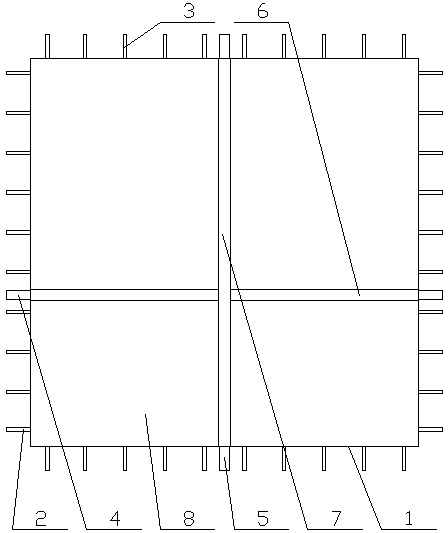

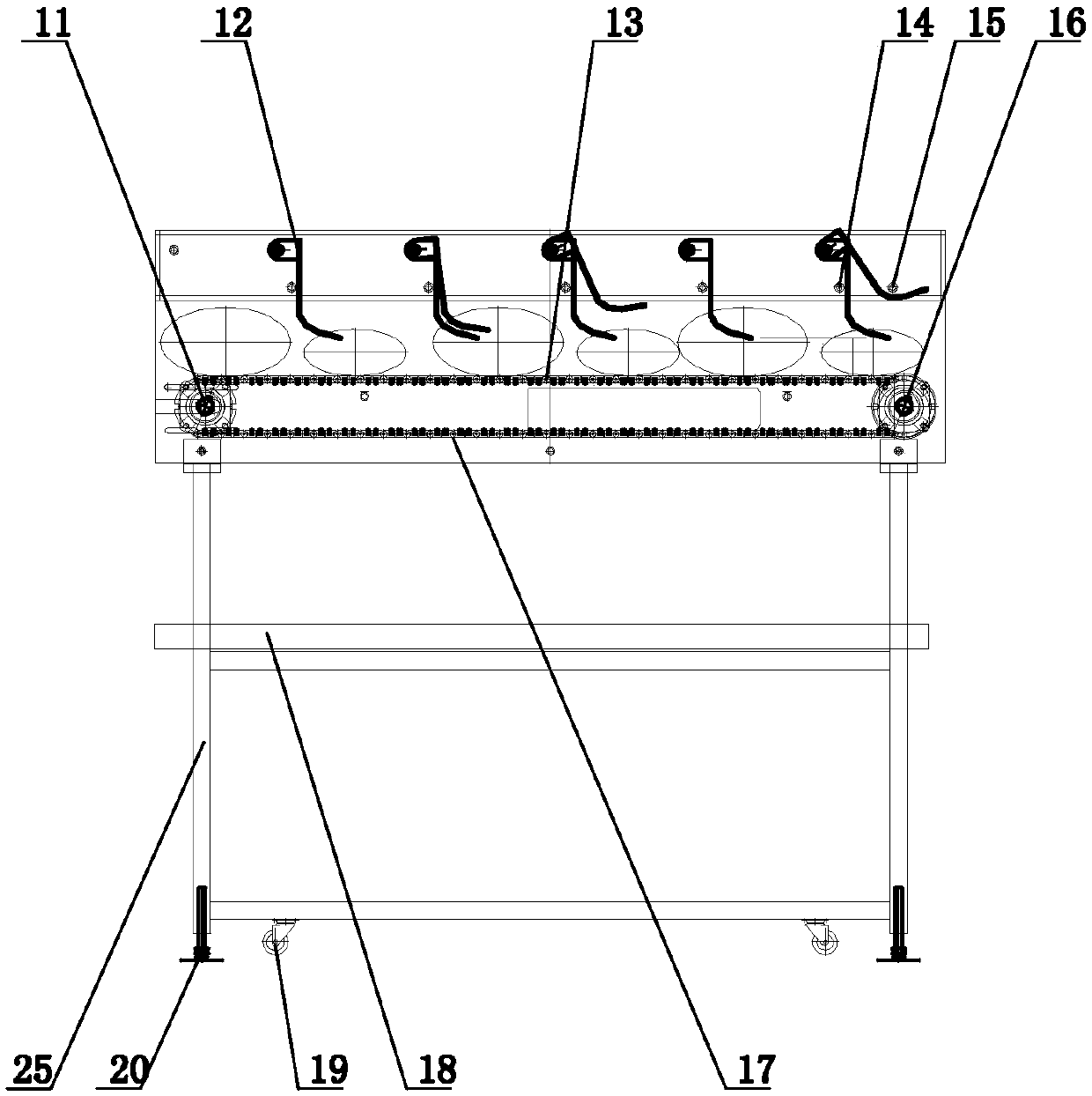

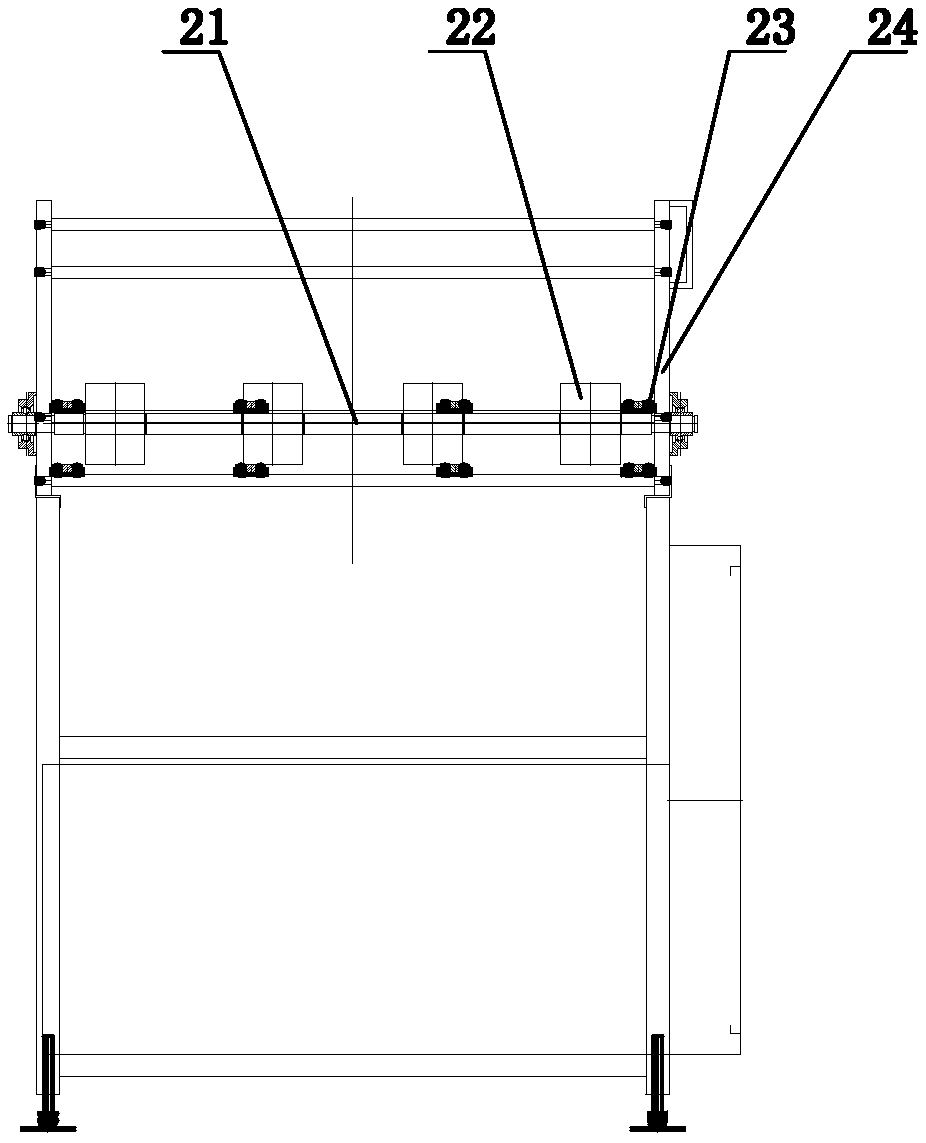

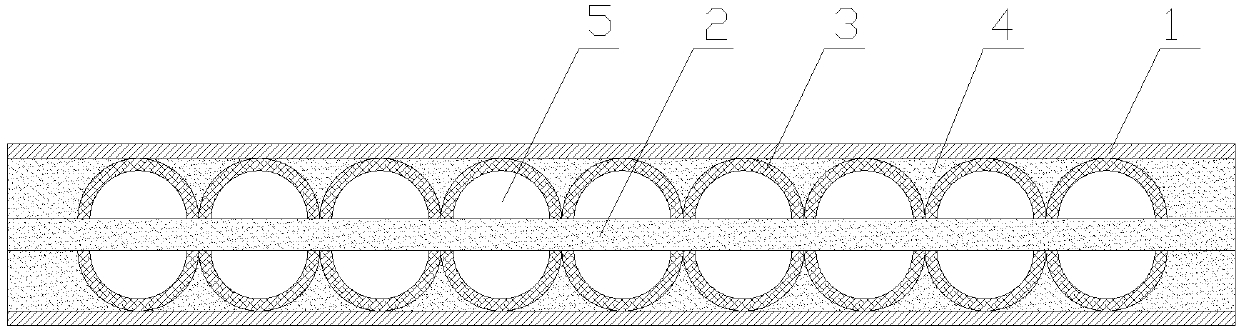

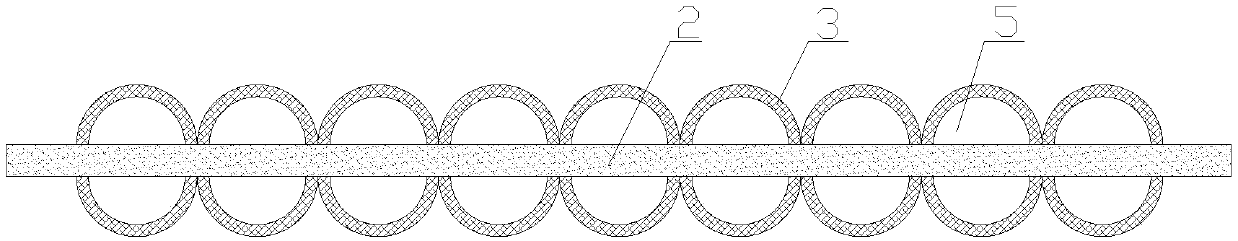

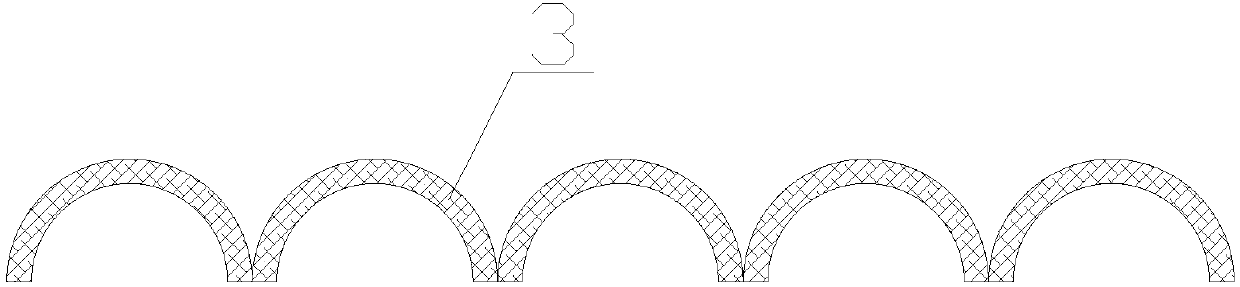

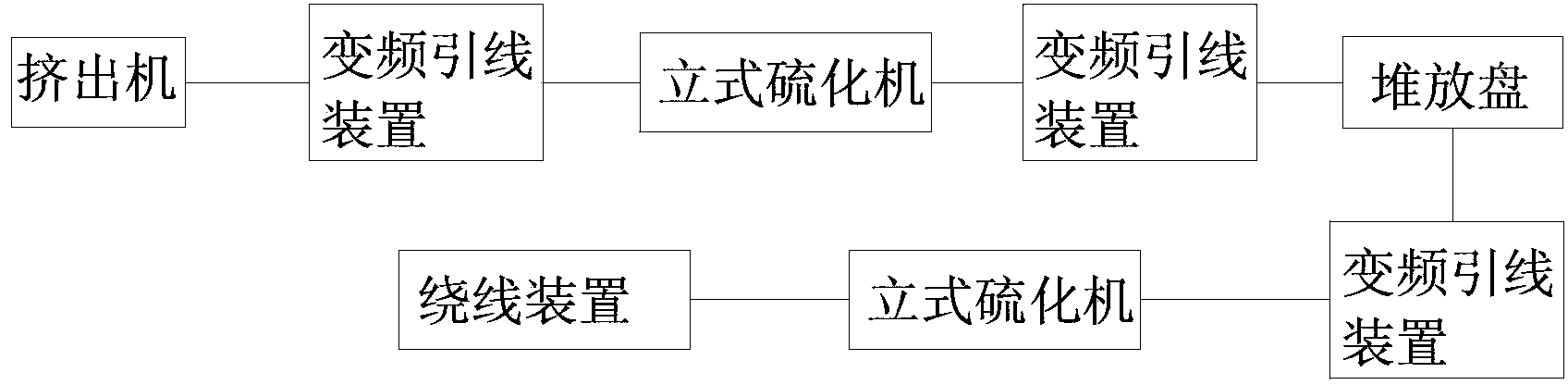

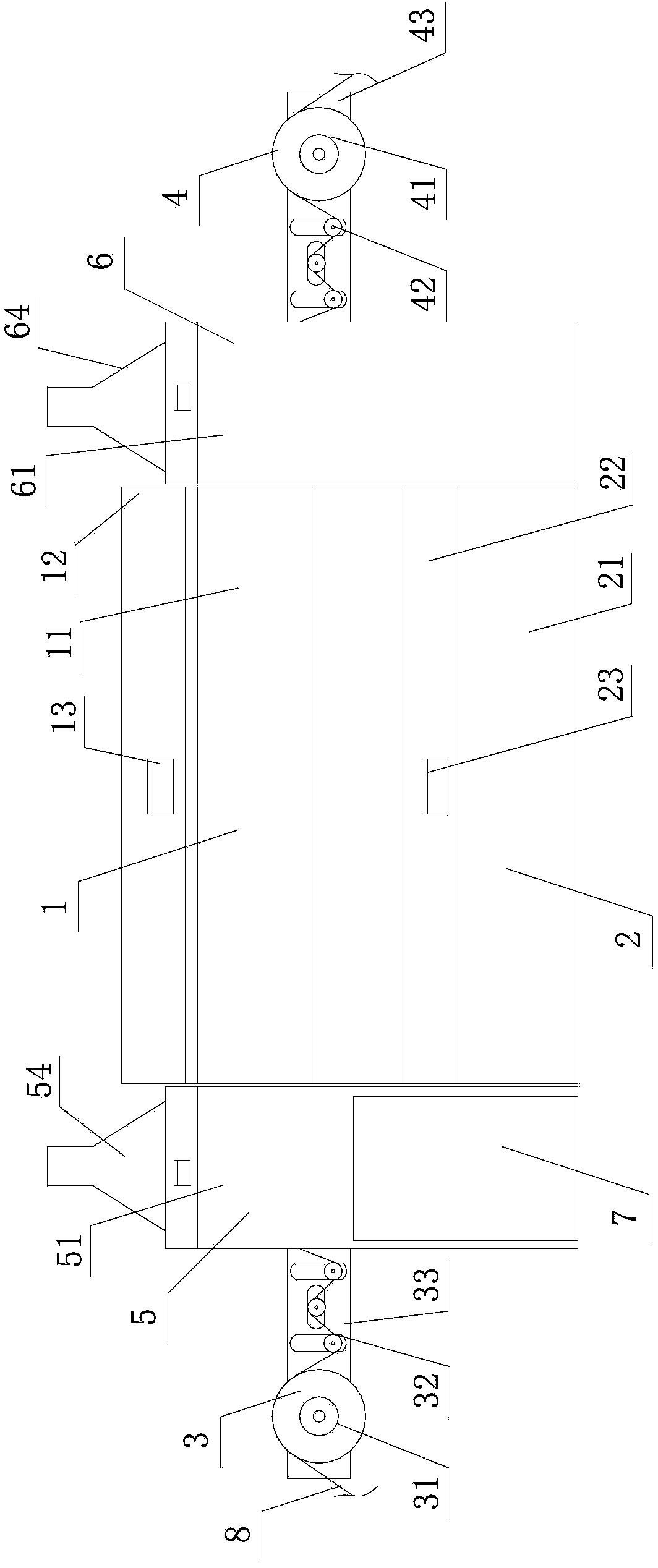

Silicone tube production line and process

The invention discloses a silicone tube production line which comprises an extruder, a variable-frequency wire leading device, a horizontal double-track vulcanizing machine and an automatic wire winding device which are arranged in sequence. The horizontal double-track vulcanizing machine comprises an upper vulcanizing box and a lower vulcanizing box which are communicated with each other up and down and used for vulcanizing a silicone tube; and two sides of the horizontal double-track vulcanizing machine are both provided with a transmission device which is used for making the silicone tube do circular motion in the upper vulcanizing box and the lower vulcanizing box. The silicone tube production line has the advantages of simple structure, convenience of operation, low production cost, low equipment cost and high security, occupies less floor area and can be used for vulcanizing the silicone tube for many times so that the produced silicone tube has good quality and wide range of application and can be used for the medical products and the food-grade products which can be in direct contact with the human body.

Owner:DONGGUAN SUNTRACK WIRE

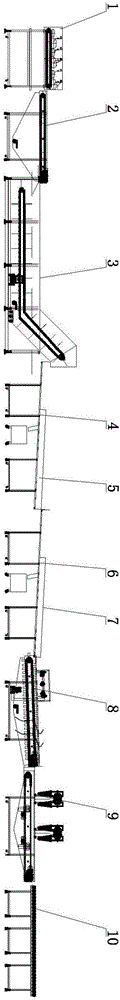

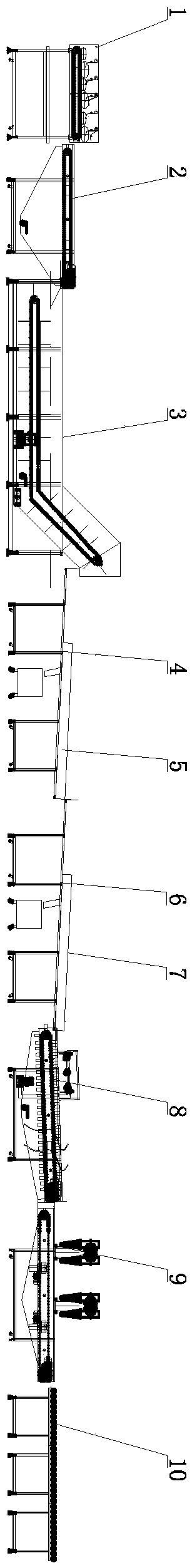

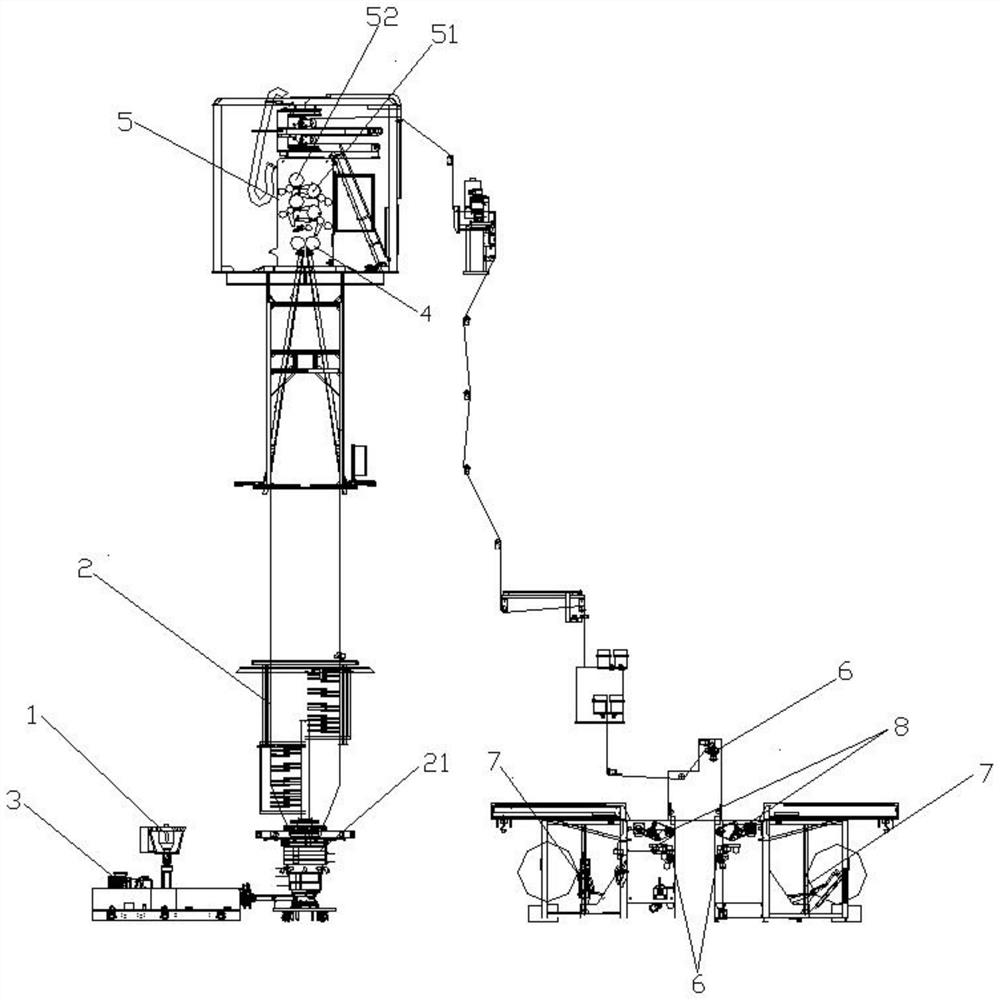

Salmon automatic processing line and automatic processing method

ActiveCN106035601AAvoid manual transport transfer processIncrease productivityFish work-tablesWater treatment systemEnvironmental standard

The invention relates to a salmon automatic processing line and automatic processing method and belongs to the field of fish processing lines; fish processing steps are subdivided, workers at each position only perform one fixing operation, platforms are connected through a conveyer belt, a manual conveying process is avoided, time differences for handling each step are created for the workers at each position, each station is enabled for continuous production so that production efficiency is greatly improved, the workers at each station repeat only the single work so that working speed is effectively increased, each of a gill-binding conveyer belt, a bloodletting apparatus, a dirt suction platform, a flushing platform, a ripping platform and a hemal gland scraping platform is provided with a dirt collection system so that dirt is collected centrally at its place of origin and is finally gathered to a fully-closed sewage treatment system for central treatment, and therefore, operations at each station are green and environmental standards for production are greatly increased.

Owner:新疆额河生态养殖科技有限公司 +1

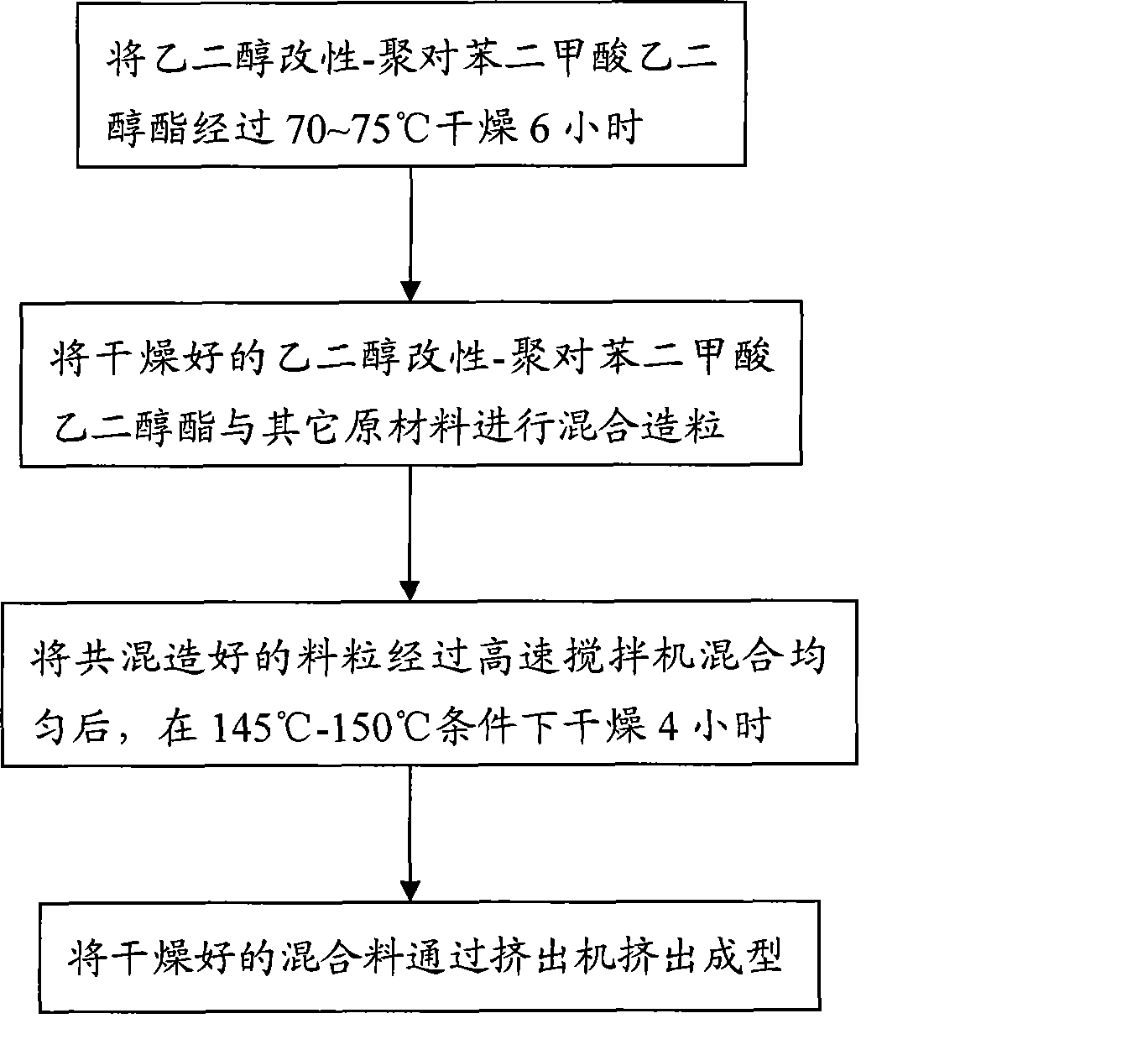

Flame-retardant environment friendly PET thermal shrinkage material and preparation thereof

ActiveCN101475733AImprove fire and flame retardant performanceImprove securityPhosphateEnvironmental standard

The invention relates to a flame retardant and environment-friendly PET heat-shrinkable material and a method for preparing the same. The flame retardant and environment-friendly PET heat-shrinkable material comprises 40 to 60 percent of PETP, 15 to 30 percent of PETG, 5 to 8 percent of poly terephthalic acid succinimide ester, 1 to 2 percent of thermoplastic elastomers, 10 to 20 percent of phosphate flame retardant and 0.01 to 0.05 percent of lubricant. The method comprises the following steps: 1, pre-drying raw materials; 2, blending the materials and pelletizing; 3, blending material and drying; and 4, extruding to mold. The method is simple in technology, the flame retardant and environment-friendly PET heat-shrinkable material has better fireproof flame retardant property than the prior PET heat-shrinkable material, and all the environmental standards are higher than the prior PET heat-shrinkable material.

Owner:CYG CHANGTONG NEW MATERIAL

Recovering and utilizing device for rain in factory area

InactiveCN1821496AImprove environmental standardsNo disasterGeneral water supply conservationWater supply tanksRainwater harvestingEngineering

Owner:GUIYANG AL-MG DESIGN & RES INST

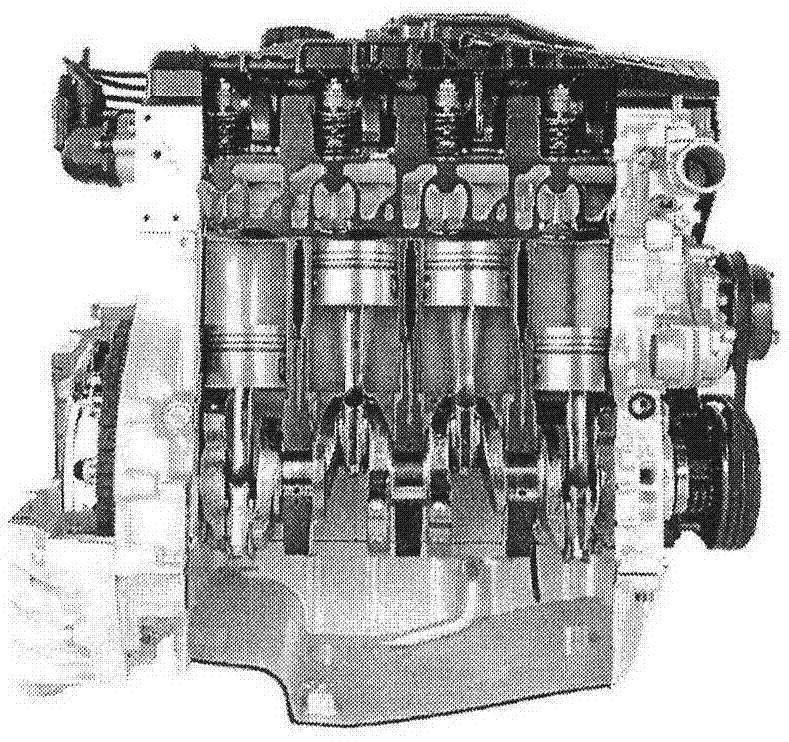

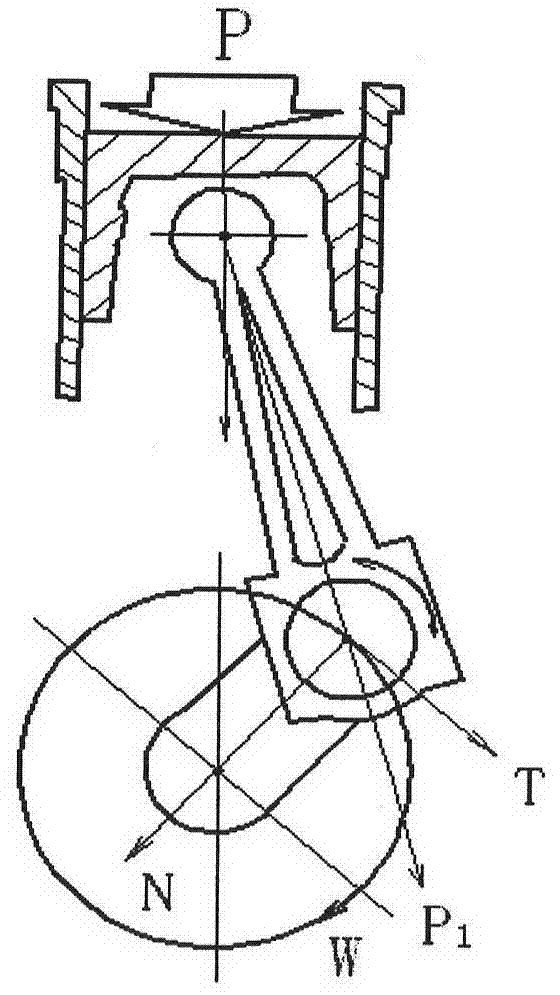

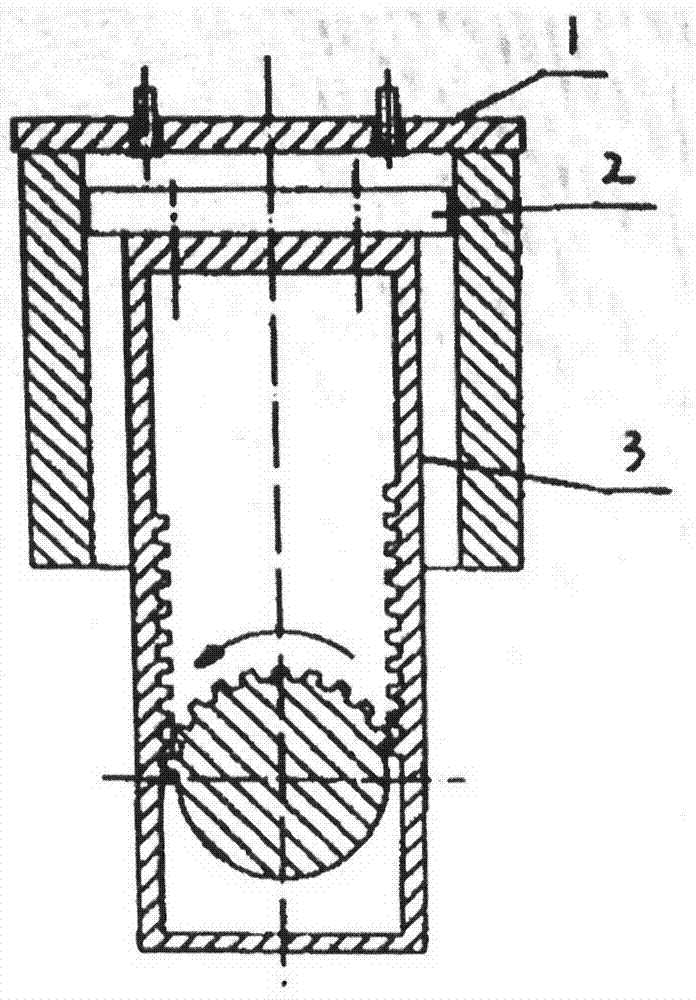

Piston type straight shaft internal combustion engine

InactiveCN104500222AStable contact curveAvoid collisionMachines/enginesExternal combustion engineInternal combustion engine

The invention relates to a piston type straight shaft internal combustion engine which consists of a double-half-wheel union straight shaft double-rail tooth frame and a tooth framework, wherein a fan-shaped gear on a double-half-wheel union straight shaft can rotate in a rack rail of the double-rail tooth frame; a two-tooth special-shaped wheel on the double-half-wheel union straight shaft can rotate in a tooth groove rail of the double-rail tooth frame; the fan-shaped gear and the two-tooth special-shaped wheel are respectively and alternately in contact with a rack and a tooth groove in the double-rail tooth frame during rotation, so that stable contact operation at five interruption points with irregular shapes is finished during rotation, and nearly 90-degree moment meshing between the rack in the double-rail tooth frame and the fan-shaped gear on the double-half-wheel union straight shaft is realized; therefore, almost 90 percent of huge explosive force of fuel oil of the internal combustion engine is output by doing useful work, and the output efficiency of the internal combustion engine is greatly improved. On the basis of the existing internal combustion engine, the double-half-wheel straight shaft and a case of the tooth frame and the tooth framework are only changed, the improving cost is low, the whole structure is firm, the parts are simple, robust and firm in structure, and operation is reasonable.

Owner:郝凤成

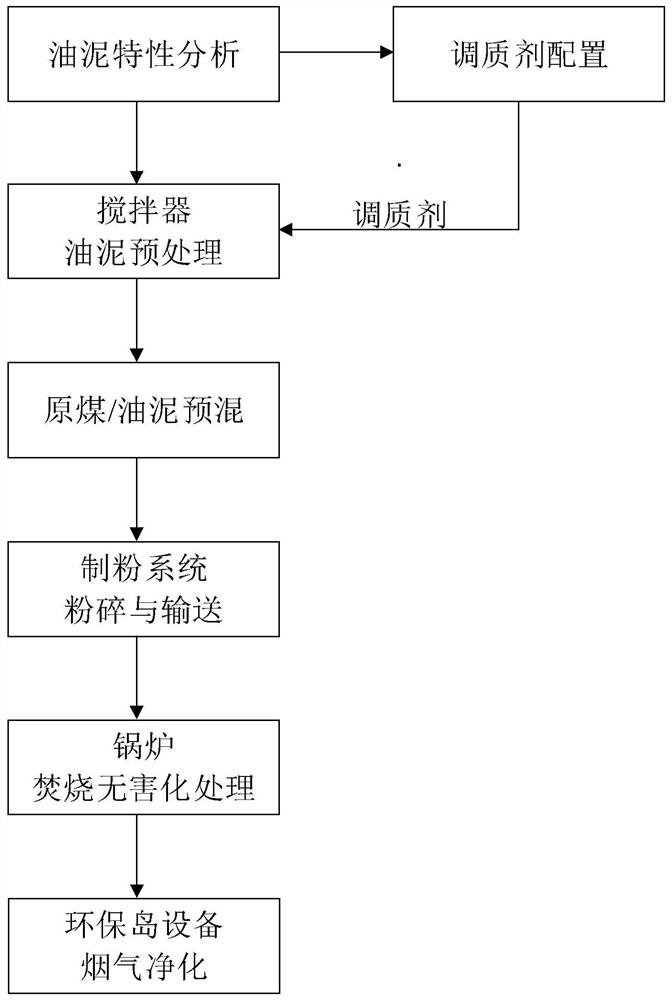

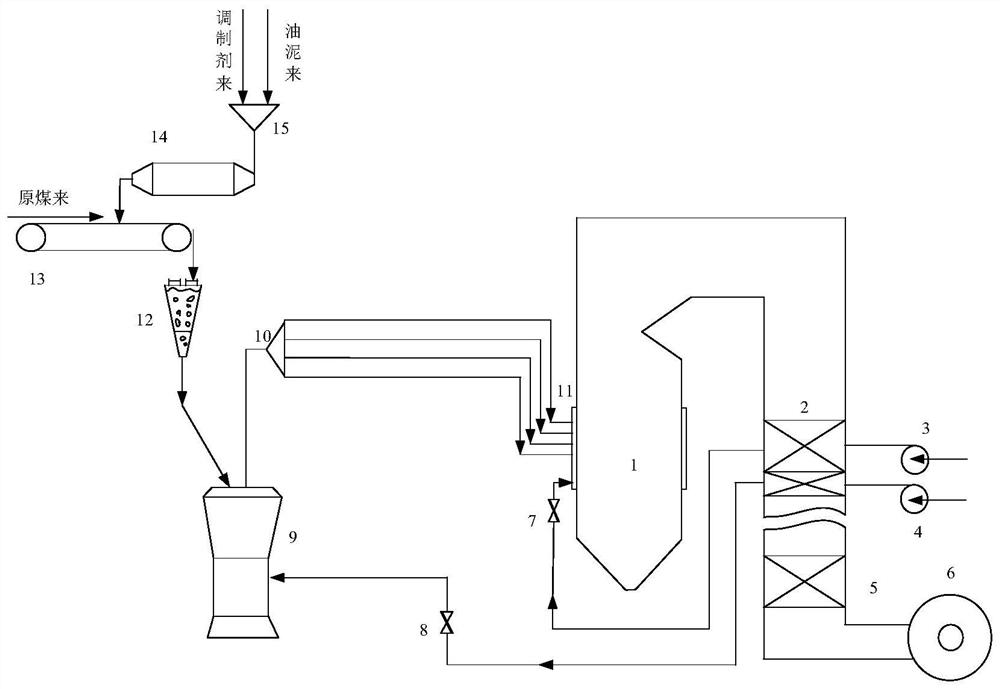

System and method for incinerating oil sludge by utilizing pulverized coal fired boiler of power station

PendingCN113819469ASimple systemReduce construction costsRotary stirring mixersIndirect carbon-dioxide mitigationProcess engineeringPower station

The invention discloses a system and method for incinerating oil sludge by utilizing a pulverized coal fired boiler of a power station. The system comprises a boiler, an air preheater, an air feeder, a primary air fan, a flue gas purification device, a coal mill, a separator, a combustion system, a coal bunker, a coal conveying belt, a spiral stirrer and a mixer feed port, According to the method, under the condition that a middle oil sludge incineration device is not arranged, oil sludge is subjected to certain pretreatment and then directly mixed with raw coal, the mixture is smashed through an existing coal pulverizing system of the boiler and conveyed into a hearth of the boiler to be incinerated, and then purification is conducted through an existing flue gas purification device of the boiler, so that the utilization and harmless treatment of the oil sludge are realized.

Owner:XIAN THERMAL POWER RES INST CO LTD

LNG gas fuel gas supply method and device for bog priority utilization

ActiveCN104791602BAvoid problems such as easy freezingEasy to controlPressure vesselsContainer discharging from pressure vesselsProcess engineeringGas supply

The invention relates to an LNG (liquefied natural gas) fuel supply method and device utilizing BOG (boil-off gas) preferentially and solves problems that the reliability is poor, equipment is easily frozen and cannot work during starting and the fuel utilization rate is low in existing LNG gas fuel supply. According to the technical scheme, the LNG fuel supply device comprises an LNG storage tank, wherein a liquid outlet in the bottom of the LNG storage tank is connected with a gasifier through a pressurization pipe; the gasifier comprises a fuel heat exchanger and a self-pressurization heat exchanger; the pressurization pipe is connected with a gas inlet in the top of the LNG storage tank through the self-pressurization heat exchanger of the gasifier; a gas outlet in the top of the LNG storage tank is connected with gas equipment through a gas supply pipe and the fuel heat exchanger. The LNG fuel supply device is simple in structure, simple and convenient to operate, small in volume, high in reliability, good in safety, low in equipment investment and running cost, high in fuel utilization rate and environment-friendly.

Owner:WUHAN JIAOSHENG NEW ENERGY ENG

Poly-generation combined-type fuel comprising branches of fast-growing forests, coal and natural gas

The invention discloses a poly-generation combined-type fuel adopting the poly-generation combined-type combustion of the branches of fast-growing trees, coal and natural gas for power generation. The poly-generation combined-type fuel mainly comprises the branches of the fast-growing trees, the coal and / or the natural gas. The invention adopts the method that scattered residues such as the branches of the fast-growing trees are converted into biological oils or compressed wood particles to facilitate transportation and storage; a 'hot air-cold air wind generation' five-generation diversified combined-type flexible raw material power plant is built to ensure national energy security according to the raw material supply condition; and zero-paint waste oil coating, zero-aldehyde plastic and the like are utilized to process 'trunks' into high-grade 'environment-friendly furniture of low-income housing', wherein the environment-friendly furniture can meet super-high environment-friendly standards and smell natural costus root. Therefore, the invention fundamentally solves the bottleneck problem that the straw resource is disperse and limited by seasons in the large-scale application of biomass raw materials.

Owner:窦观一

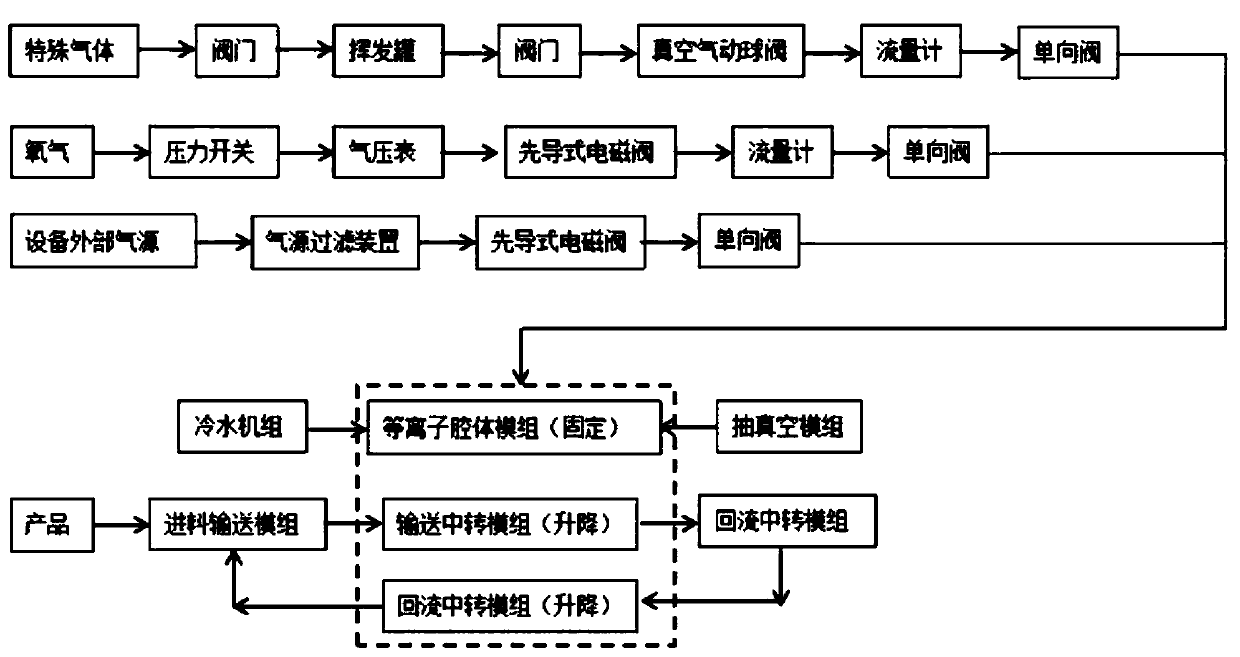

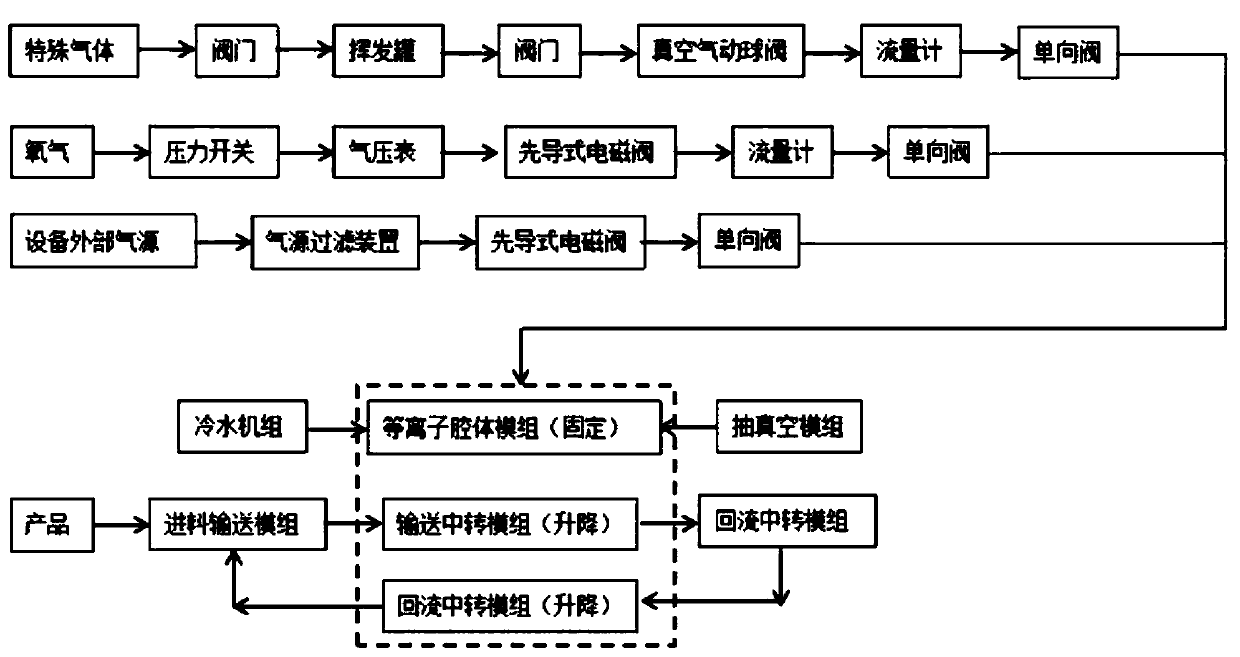

Shoe material surface plasma processing machine

PendingCN109968697AAdhesivelyEasy to handleDomestic articlesCleaning processes and apparatusVacuum pumpingMonitoring system

The invention discloses a shoe material surface plasma processing machine. The shoe material surface plasma processing machine comprises an upper computer, a monitoring system, a reaction gas controlsystem and a plasma excitation system, wherein the plasma excitation system comprises a plasma cavity module, a transport and transfer module and a backflow transfer module, a water chilling unit provides cold water for the plasma cavity module, a vacuum pumping module is mounted on one side of the plasma cavity module, and to-be-washed objects are arranged in the plasma cavity module and vacuatedthrough the vacuum pumping module. According to the shoe surface plasma processing machine, a low temperature plasma surface treatment technology replaces the working procedure that treating water isfirstly coated, and then a shoe material is glued in an existing shoe making process, the purposes that the effect of shoe material surface treatment is better, bonding is firmer, and the productionefficiency is improved are achieved, meanwhile the cost is saved, damages on worker health of gas sent out of the treating water can be eliminated, harmful gas emission is reduced, environmental protection level of shoe manufacturing enterprises is improved, the product quality is improved, and the shoe material surface plasma processing machine has the characteristics that the processing efficiency is high, operation is convenient, and the cost is low.

Owner:深圳市东信高科自动化设备有限公司

Splicing type construction method of wall

ActiveCN114809373AImprove construction efficiencyShorten construction timeDischarging arrangementWallsArchitectural engineeringFixed Beam

The invention discloses a splicing type construction method of a wall body. The splicing type construction method comprises the following steps that column bodies on the two sides of the wall body are fixed to the tops of corresponding column bodies below the wall body; when the distance between the two column bodies is smaller than or equal to one meter, the two column bodies are fixedly connected through transverse ribs; when the distance between the two column bodies is larger than one meter, the tops of the adjacent lower-layer beam bodies and the two column bodies are spliced and fixed through connecting pieces and at least one prefabricated wallboard horizontal pre-tightening tie bar or vertical pre-tightening tie bar; a fixed beam body is placed on the top between the two column bodies in the extending direction of the wall body; when the distance between the two column bodies is smaller than or equal to one meter, the screw rods at the bottoms of the beam bodies are fixedly connected with the screw rods at the tops of the adjacent lower-layer beam bodies through vertical ribs; cast-in-place concrete C is conducted on the wall defined by the column bodies and the beam bodies and the area located outside the prefabricated wall panel; and after the cast-in-place concrete C is solidified, wall building and forming are completed. According to the splicing type construction method of the wall, the building construction efficiency can be improved, the wall is firm and stable, the integration effect is good, and the good anti-seismic effect is achieved.

Owner:CHINA CIVIL ENG CONSTR CORP +2

Salmon automatic processing production line and automatic processing method

ActiveCN106035601BAvoid manual transport transfer processIncrease productivityFish work-tablesProduction lineWater treatment system

Owner:新疆额河生态养殖科技有限公司 +1

Buffer filling agent applied to interior of corrugated layer of high-strength corrugated board

InactiveCN107858858ALow costEasy to storeNon-macromolecular organic additionReinforcing agents additionCardboardFiber

The invention provides a buffer filling agent applied to the interior of a corrugated layer of a high-strength corrugated paper board, and relates to the technical field of manufacturing and processing of paper boards. The buffer filling agent is prepared from: 80-100 parts of ABS plastic particles, 1-1.5 parts of lapis stone powder, 1-2 parts of a halogen-free flame-retardant synergist, 1.5-3 parts of ethylene propylene rubber, 0.2-1 part of lubricant, 0.1-0.5 part of an antioxidant, 1-2 parts of an initiator, 0.2-0.4 part of graphite lubricant, 5-10 parts of polypropylene staple fiber, 0.5-1part of dimethyl silicone oil, 5-8 parts of perchloroethylene, 1.5-3 parts of sodium silicate, 1-2 parts of a stiffening agent, 0.5-1 part of talc, 0.5-1 part of surfactant and 3-5 parts of cryolitepowder. A reinforcing effect on corrugated paper can be achieved by the buffer filling agent, a buffering effect can be provided, space inside the corrugated paper can be dehumidified, and the utilization effect of the dehumidified corrugated paper is more obvious.

Owner:舒城宏峰纸板有限公司

A fluorescent anti-counterfeiting ink for UV curing offset printing

The present invention discloses an ultraviolet light curing offset printing fluorescent anti-counterfeiting ink, which comprises, by weight, 40-60% of a polyester acrylate resin, 5-15% of a propoxylate neopentylene glycol diacrylate ester monomer, 15-25% of a luorescent anti-counterfeiting pigment, 5-15% of a filler, 1-2% of an auxiliary agent, and 8-12% of a photoinitiator. According to the present invention, when the prepared single-component ultraviolet light curing offset printing fluorescent anti-counterfeiting ink is used, no solvent exists, and no toxic gas is discharged, such that the advantages of environmental protection and no pollution are provided; and after the curing, different color patterns are displayed along with the irradiation with different anti-counterfeiting lamps, the coloring is good, the mobility is good, and the requirements of the anti-counterfeiting ink can be met.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

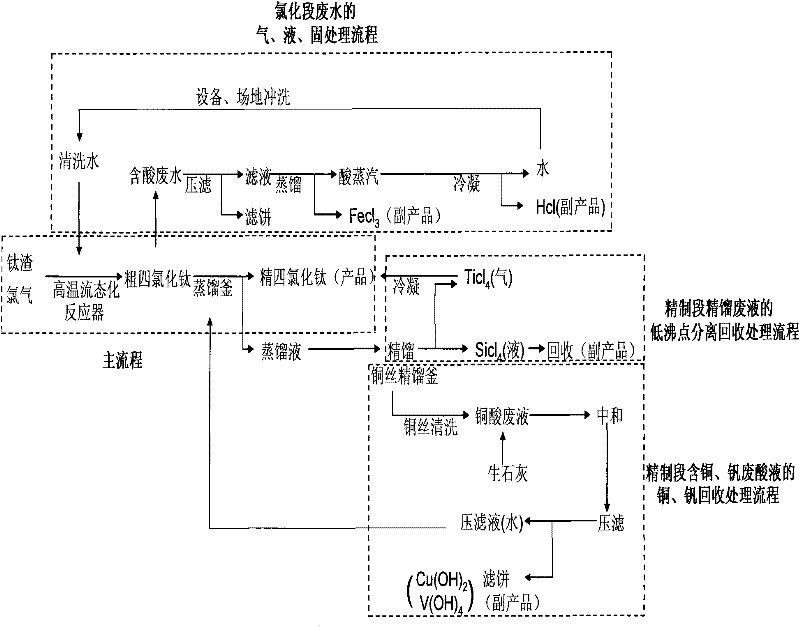

Method for treating waste water and waste liquor in titanium tetrachloride industrial production process

ActiveCN101921035BSolve industry challenges that are fully handledSolve industry problemsChlorine/hydrogen-chloride purificationMultistage water/sewage treatmentSolution treatmentTetrachloride

The invention discloses a method for treating waste water and waste liquor in a titanium tetrachloride industrial production process, which comprises a chlorination-stage waste water treatment method, a refining-stage rectification waste liquor treatment method and a refining-stage copper-vanadium containing waste acid solution treatment method, and is characterized in that the chlorination-stagewaste water treatment method is a gasification, liquidation and solidification treatment method for chlorination-stage waste water; the refining-stage rectification waste liquor treatment method is alow boiling point separating and recycling treatment method for refining-stage rectification waste liquor; and refining-stage copper-vanadium containing waste acid solution treatment method is a copper and vanadium recycling treatment method for refining-stage copper-vanadium containing a waste acid solution. The invention solves the industry problem of completely treating the waste water and thewaste liquor which are produced in the whole titanium tetrachloride production process, and has obvious effects of improving environmental protection standards, lessening environmental pollution, improving production operating environment, turning waste materials into things of value and finally reaching standard emission.

Owner:河北欧克新型材料股份有限公司

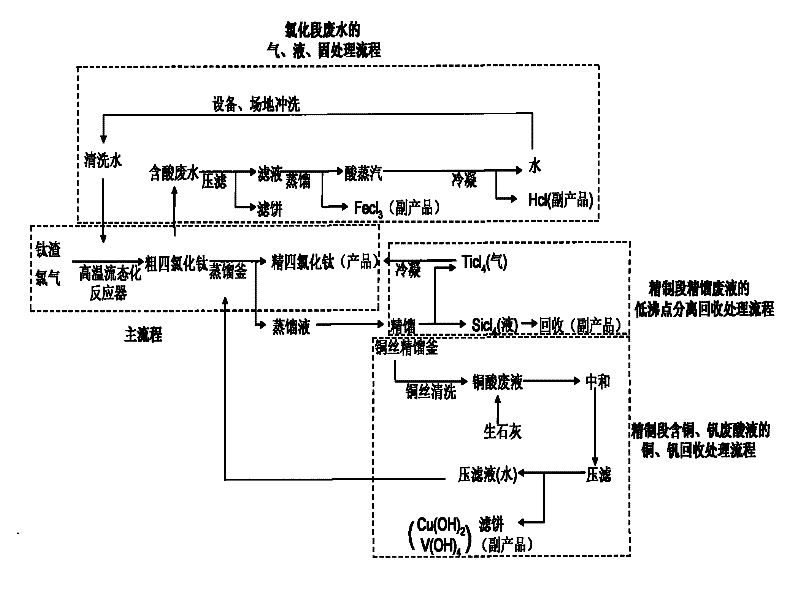

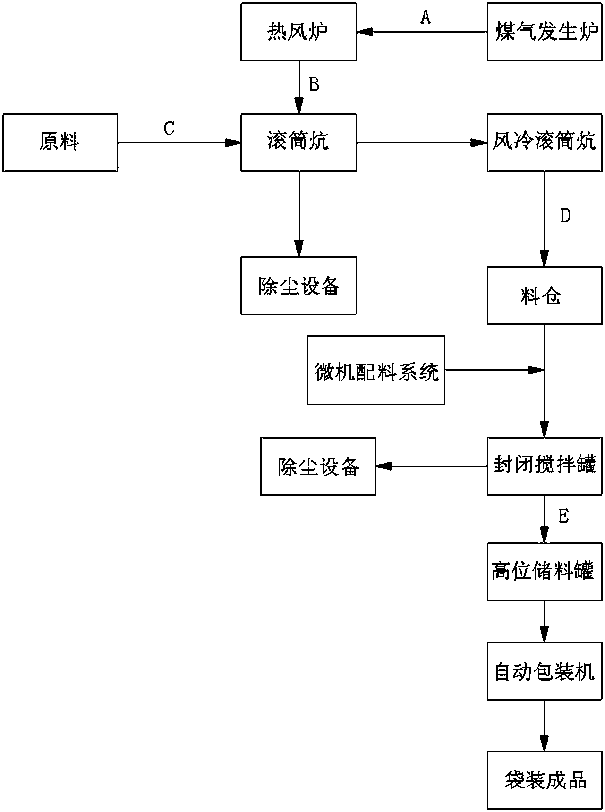

A kind of production technology of ladle drainage agent

ActiveCN104557090BReduce in quantityImprove product qualityMelt-holding vesselsProduction lineHot blast

The invention provides a process for producing a steel ladle drainage agent and belongs to the technical field of metal smelting. The process comprises the following steps: combusting gas provided by a gas generator in a hot blast heater to serve as a heat source, drying various raw materials in a roller flue, performing air cooling, conveying the materials into a corresponding storage bin, automatically blanking and adding carbon according to the formula ratio, uniformly mixing in a closed stirring tank, automatically packaging, and warehousing. According to the overall process, a full-automatic production line is adopted, the stable product quality is guaranteed, the number of operating personnel is reduced, the manual cost is reduced, and the influence of human factors on the product quality is greatly reduced. Meanwhile, dust removal equipment is arranged in the link that dust is easily generated in the roller flue and the closed stirring tank, so that the generated dust is collected and removed, the dust pollution is reduced, the environmental protection standard is improved, and clean and high-efficiency production is realized.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

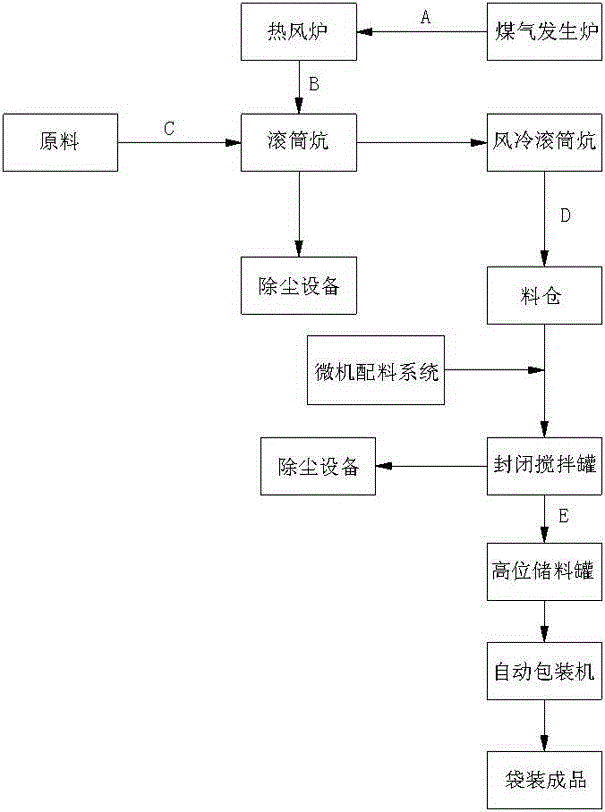

Method for dissolving Bayer process red mud

ActiveCN102757060BMeet industrial requirementsReduce sodiumCalcium/strontium/barium carbonatesSludge treatmentCalcium silicateAluminium hydroxide

The invention discloses a method for dissolving red mud. The method comprises the following specific steps of: mixing Bayer process red mud with white lime in the mass ratio of 1:(0.3-0.9); stirring at the temperature of 80-140 DEG C for reacting for 1-15 hours for calcifying, transforming and dealkalizing; mixing calcified, deformed and dealkalized Bayer process red mud with clear water or a low-concentration sodium aluminate solution in an enclosed container; introducing CO2 into the container to obtain calcified slag containing calcium silicate, calcium carbonate and aluminum hydroxide serving as main components; and extracting aluminum hydroxide from the calcified slag by using a sodium hydroxide solution or an aluminum hydroxide solution. In the method disclosed by the invention, the structure and composition of red mud are changed by adopting calcification transformation and pressurizing calcification transformation methods, so that dealkalization and extraction of aluminum can be realized; and iron is extracted properly, so that the structure and the composition of red mud can meet the requirements of cement production, and the aim of dissolving red mud on a large scale at low cost is fulfilled.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

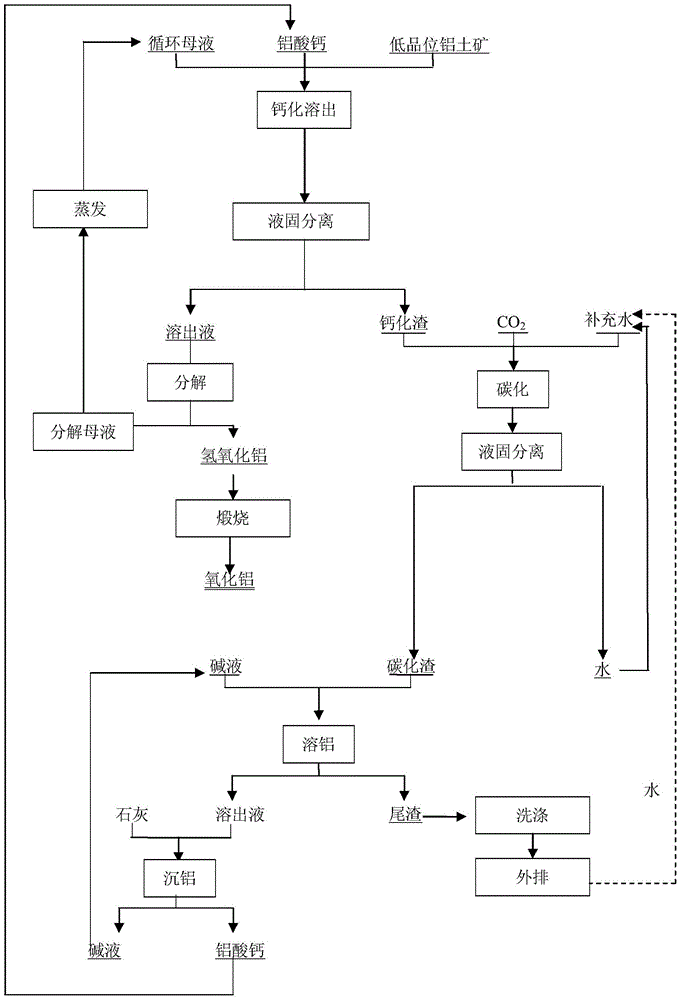

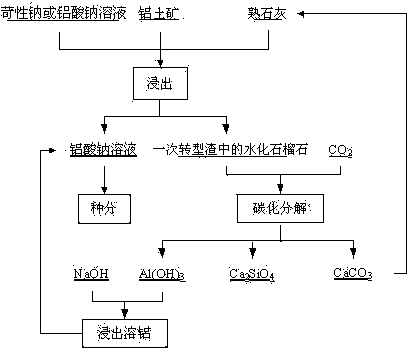

A method of calcification-carbonization processing of low-grade aluminum-containing raw materials and aluminum circulation

ActiveCN103964478BEfficient use ofCalcification transformation achievedAluminium oxides/hydroxidesFiltrationAdditive ingredient

The invention relates to the field of aluminiferous raw material utilization, in particular to a calcification-carbonization method for treating a low-middle grade aluminiferous raw material and aluminum cycle. The calcification-carbonization method comprises the following steps: carrying out calcification transformation dissolving reaction of low-middle grade bauxite or other aluminiferous materials in a dissolving liquid of 100g / L to 280g / L to obtain calcification residues; carrying out carbonization reaction on the calcification residues to obtain carbonization residues; dissolving out the aluminiferous phase of the calcification transformation residues by adopting a sodium hydroxide solution of 40g / L to 120g / L; adding calcic materials into the dissolved liquid obtained in the dissolving process of the phase to obtain a calcium aluminate precipitate; in addition, alkali liquor is returned to the dissolving process and can be recycled after filtration, and the calcium aluminate precipitate is returned to the calcification transformation dissolving process as an ingredient of calcium source or replaces lime in a production process adopting Bayer process. According to the invention, obtained tailings can be used in the cement industry, so that the recycling efficiency of alumina in the aluminiferous raw material is improved, the harmless utilization of the tailings is realized and a large quantity of CO2 can be absorbed during the production process at the same time. Therefore, the calcification-carbonization method is an environment-friendly method for alumina production.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

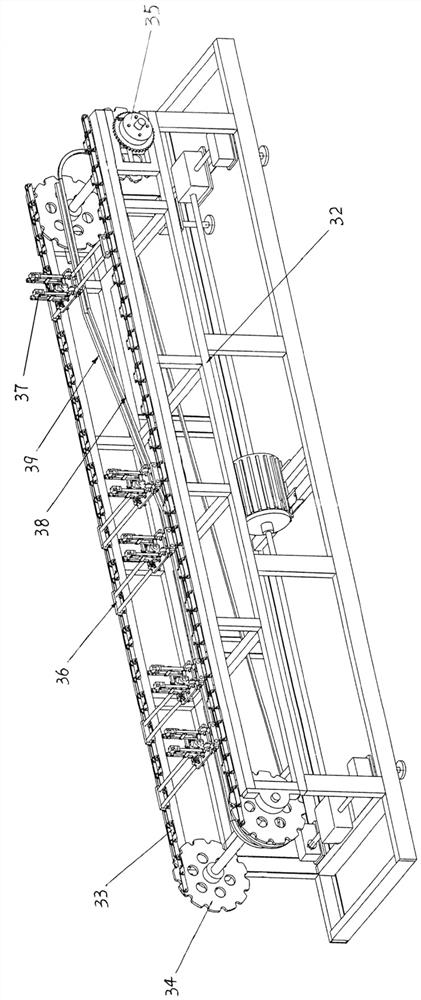

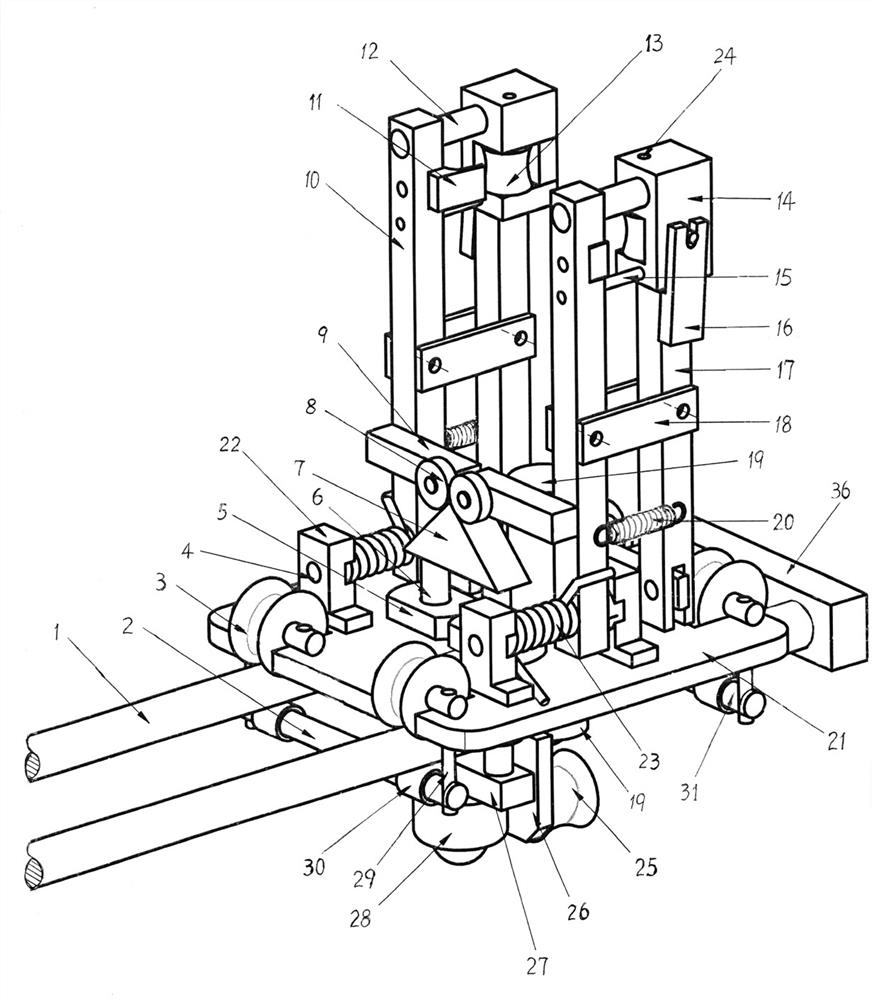

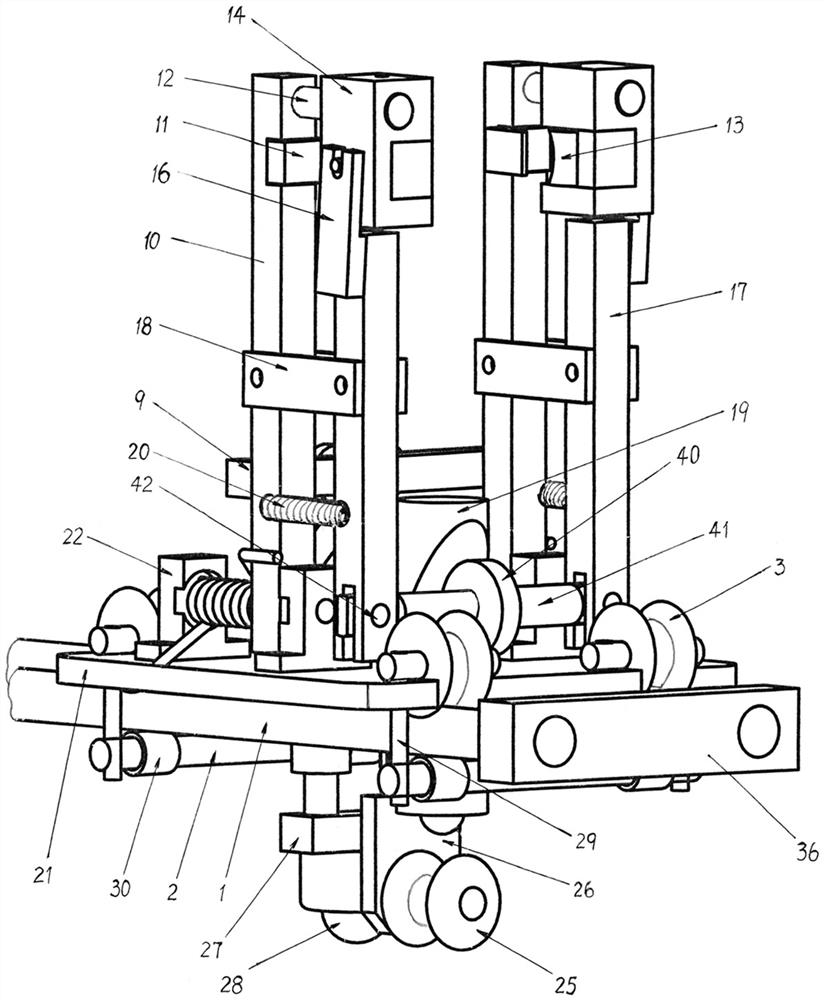

Blowing-free demolding machine for colloidal gloves

The invention relates to a blowing-free demolding machine for rubber gloves, which is structurally characterized in that synchronous chains are arranged on a machine body, a plurality of walking racks are bridged on the two groups of synchronous chains, a set of demolding manipulator is arranged on each walking rack, and the demolding manipulators reciprocate on the walking racks. The demolding manipulator is composed of a bottom plate, a glove wrist clamping and expanding mechanism, a manipulator pushing mechanism, a wrist opening flanging clamping mechanism, a sliding block push-pull mechanism and the like, wherein the glove wrist clamping and expanding mechanism, the manipulator pushing mechanism, the wrist opening flanging clamping mechanism and the sliding block push-pull mechanism are arranged on the bottom plate. Two guide rails are arranged on the machine body, and one guide rail is used for controlling the demolding manipulator to move back and forth on the walking rack; and the other one is used for controlling the glove demoulding action of the demoulding manipulator. According to the demolding machine, gloves on a production line are demolded in a pure mechanical mode, an air blowing process is omitted, energy consumption and production cost are reduced, high-decibel noise pollution is avoided, and the demolding machine is beneficial to the environment and the body health of production workers.

Owner:石家庄启腾机械制造有限公司

Method for producing aluminum oxide based on calcification-carbonization transformation

ActiveCN102757073BAchieve full calcification transitionReduce production energy consumptionCalcium/strontium/barium carbonatesAlkaline-earth metal silicatesCalcium silicateSlag

The invention belongs to the field of production of aluminum oxide, and particularly relates to a method for producing aluminum oxidizing based on calcification-carbonization transformation. The method comprises the following steps of: performing a calcification transformation reaction on white lime and middle and low-grade alumyte serving as a raw material in a caustic alkali solution of 1400-260g / L to obtain primarily-transformed slag; intruding CO2 into the primarily-transformed slag in clear water or a low-concentration sodium aluminum solution under an enclosed condition for carbonating obtain the secondarily-transformed slag; and dissolving the secondarily-transformed slag out by adopting a sodium hydroxide solution of 30-120g / L or a sodium aluminate solution of a corresponding concentration at the temperature of 40-100 DEG C to obtain novel structure slag which takes calcium silicate and calcium carbonate as main components and of which the aluminum to silicon ratio is 0.0-0.4, wherein the soda content can be lowered below 0.5 percent, and the comprehensive yield of aluminum oxide in a mineral raw material can be up to 90-100 percent. Due to the adoption of the method, the novel structural slag can be completely taken as a raw material in the cement industry, the problem of environmental pollution such as red mud space occupation and the like is solved completely, and a large amount of CO2 can be absorbed simultaneously in a production process; and the method is an environment-friendly and economical aluminum oxide production method.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

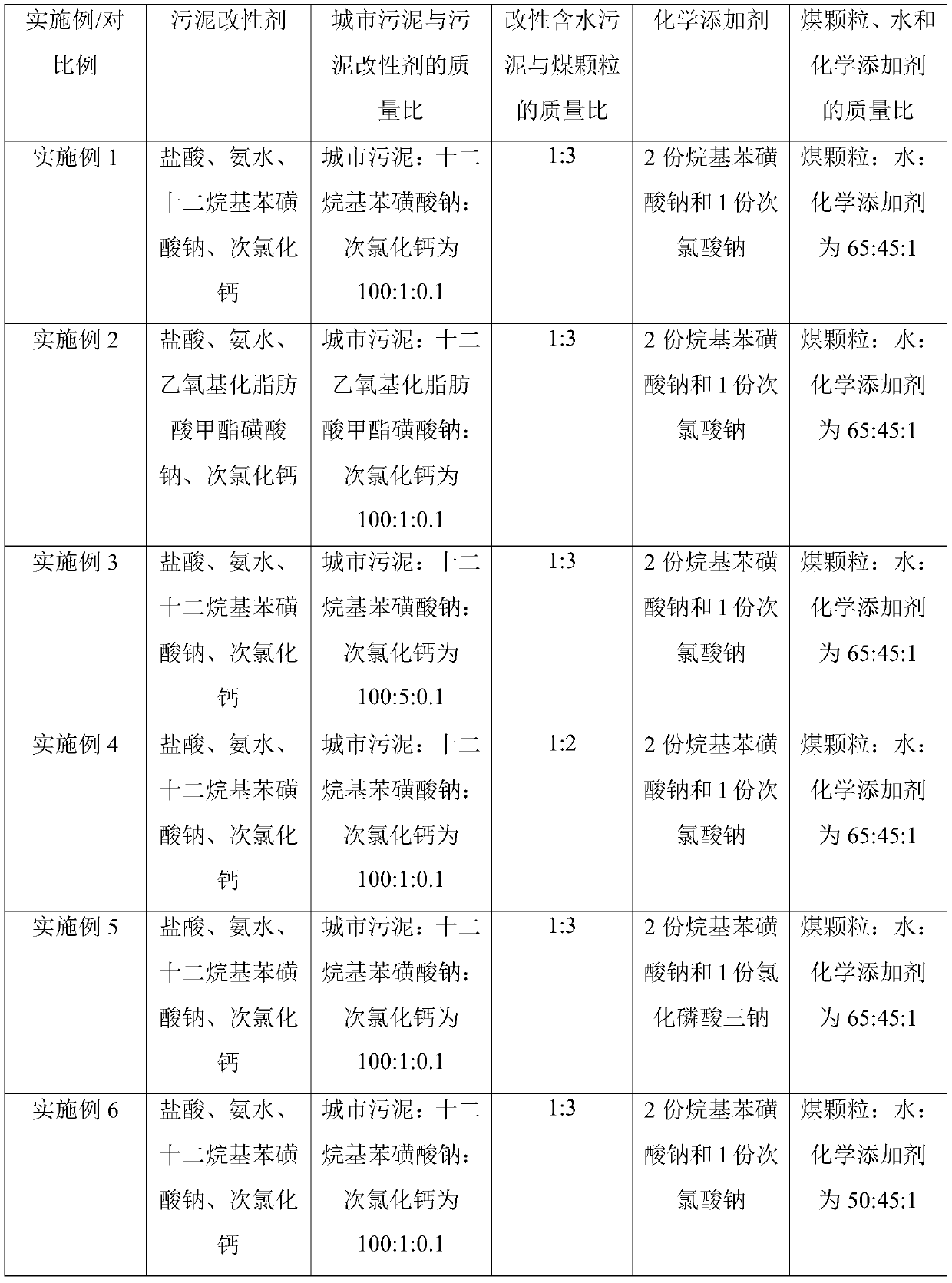

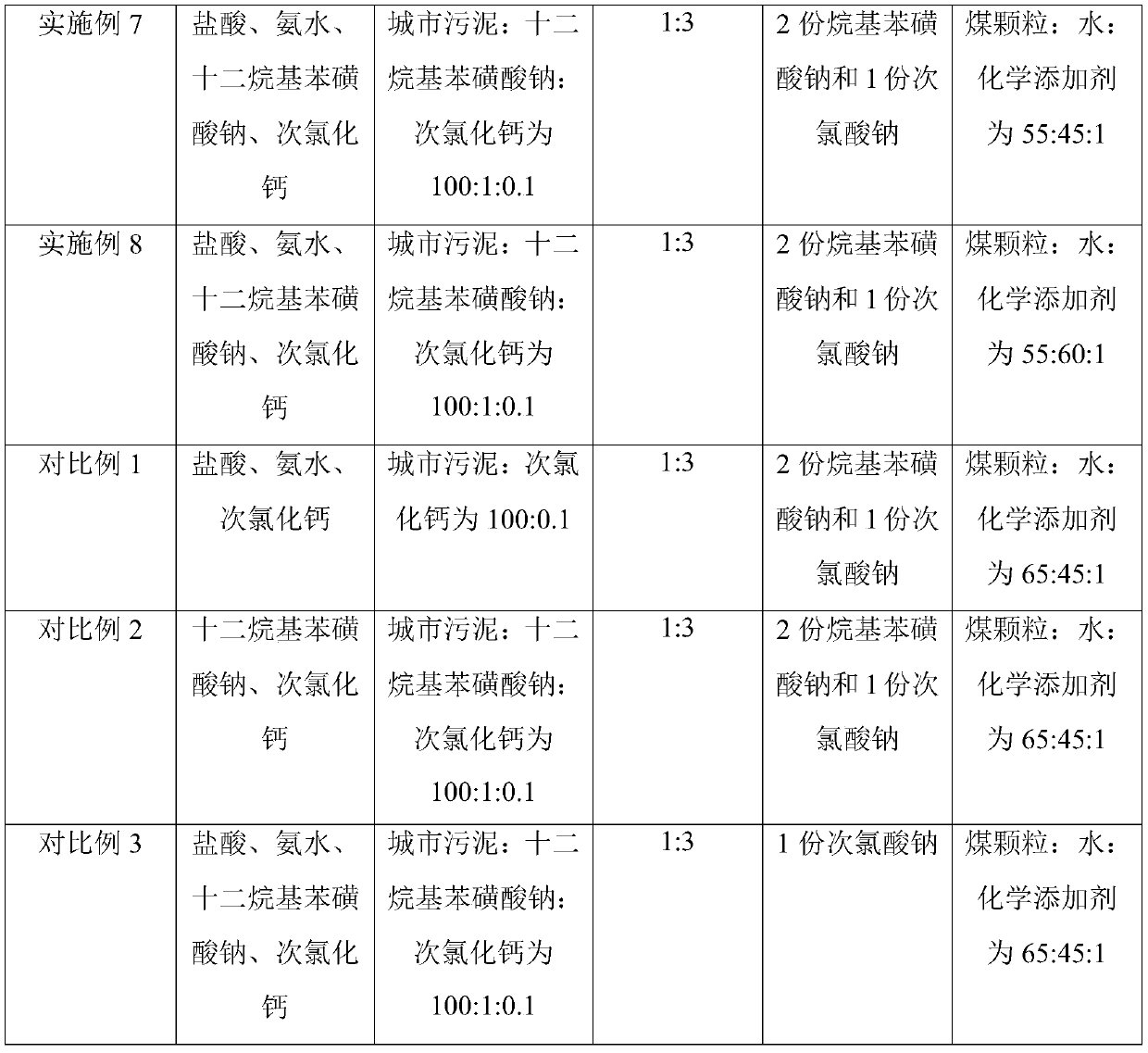

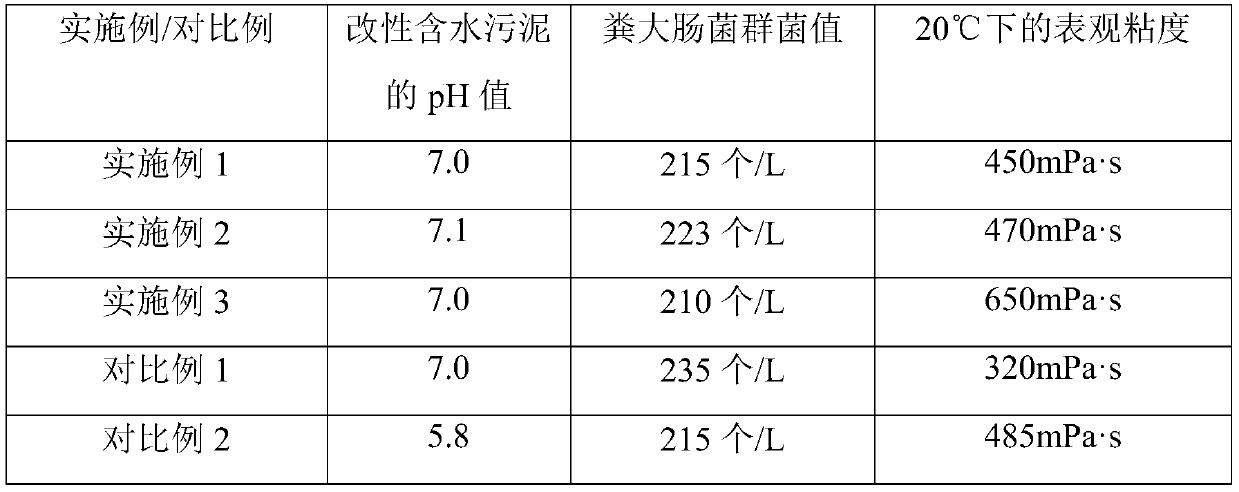

Preparation method of combustible mud from urban sludge and firecoal

InactiveCN110628480AImprove environmental standardsCause secondary pollutionSludge treatmentBiofuelsSludgeResource utilization

The invention provides a preparation method of combustible mud from urban sludge and firecoal. The preparation method comprises the following steps: (1) mixing the urban sludge with a sludge modifier,and performing shearing stirring so as to obtain modified aqueous sludge; and (2) mixing the modified aqueous sludge with coal particles, and performing ball milling so as to obtain the combustible mud. Closed pipeline transportation is adopted during preparation and transportation, no wastewater or waste gas isgenerated, zero emission is achieved during production, and no secondary pollution toair, soil and groundwater is caused, so that the environmental-protection standards during sludge treatment are improved completely, and resource utilization is achieved; and when the preparation method is compared with a traditional drying treatment mode, no pressure filtration, drying and stirring are needed, and the combustible mud has no generation of hard precipitates and good fluidity afterstorage is performed for 90 days, and is suitable for screw pumping.

Owner:宋合富

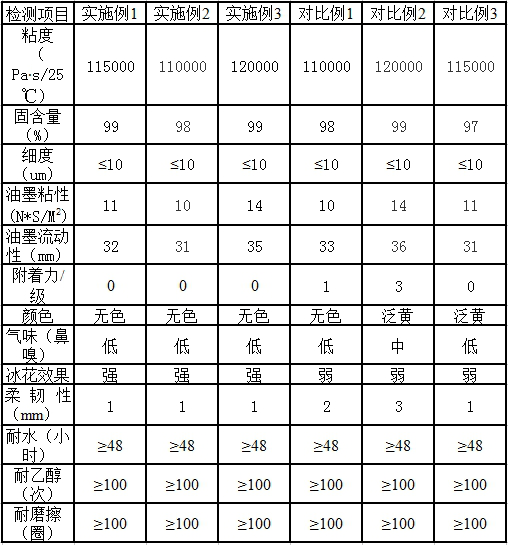

Ultraviolet curing offset printing ice flower effect ink and its preparation method and application

The invention relates to the field of polymer materials, and discloses a UV-curable offset printing ice flower effect ink, which comprises the following components in mass percentage: polyester acrylate resin 40-60%; dipentaerythritol hexaacrylate 5-15%; filler 20-35% %; photoinitiator combination 6‑10%; auxiliary agent 1‑3%. The invention also discloses the preparation method and application of the ink. The UV-curable offset printing ink provided by the invention has no solvent and low odor, and has better appearance effect after printing and curing.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

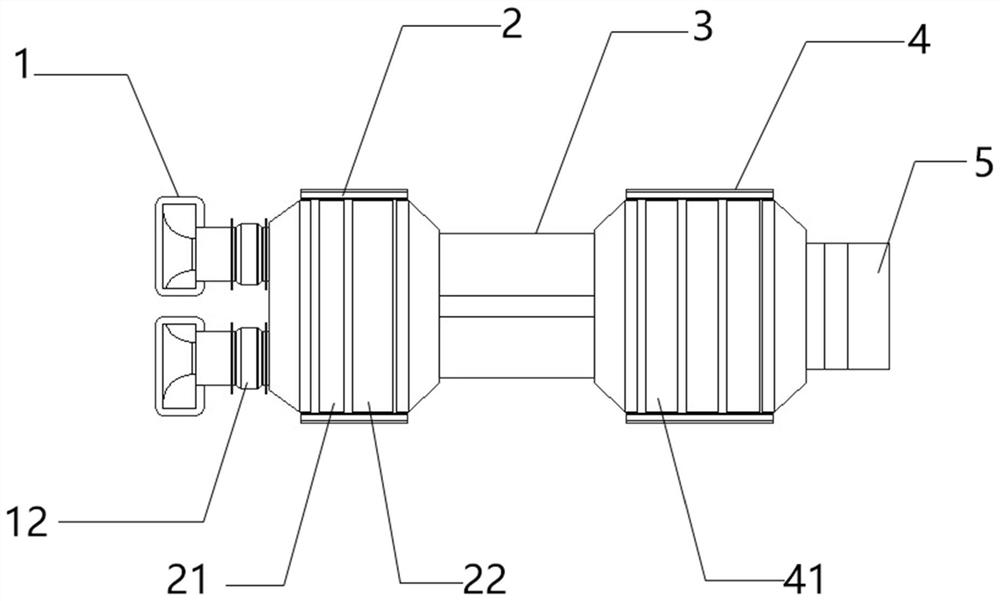

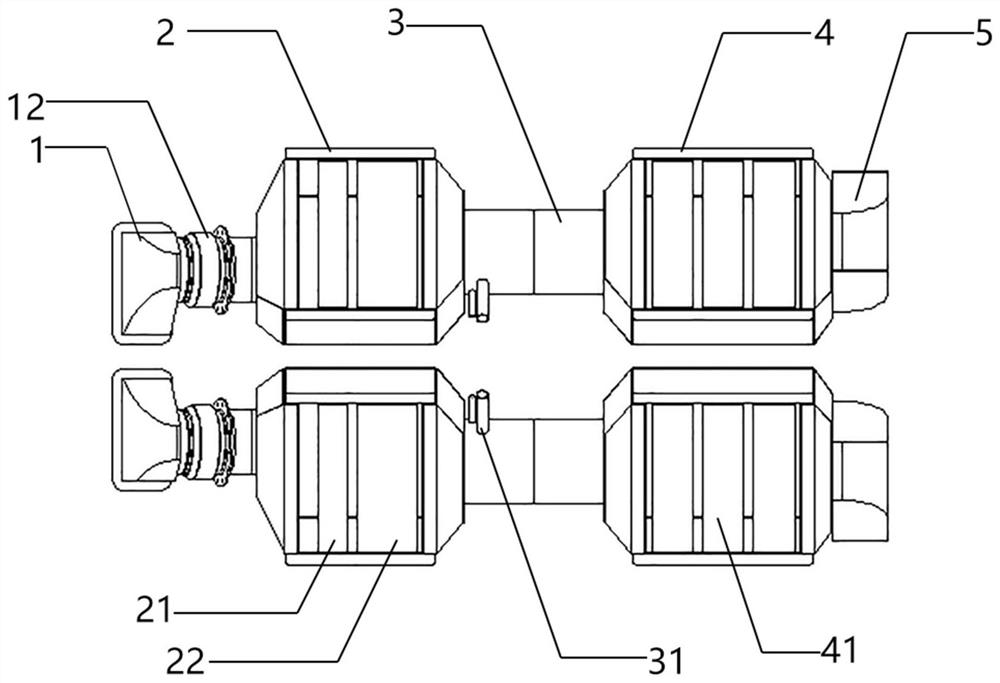

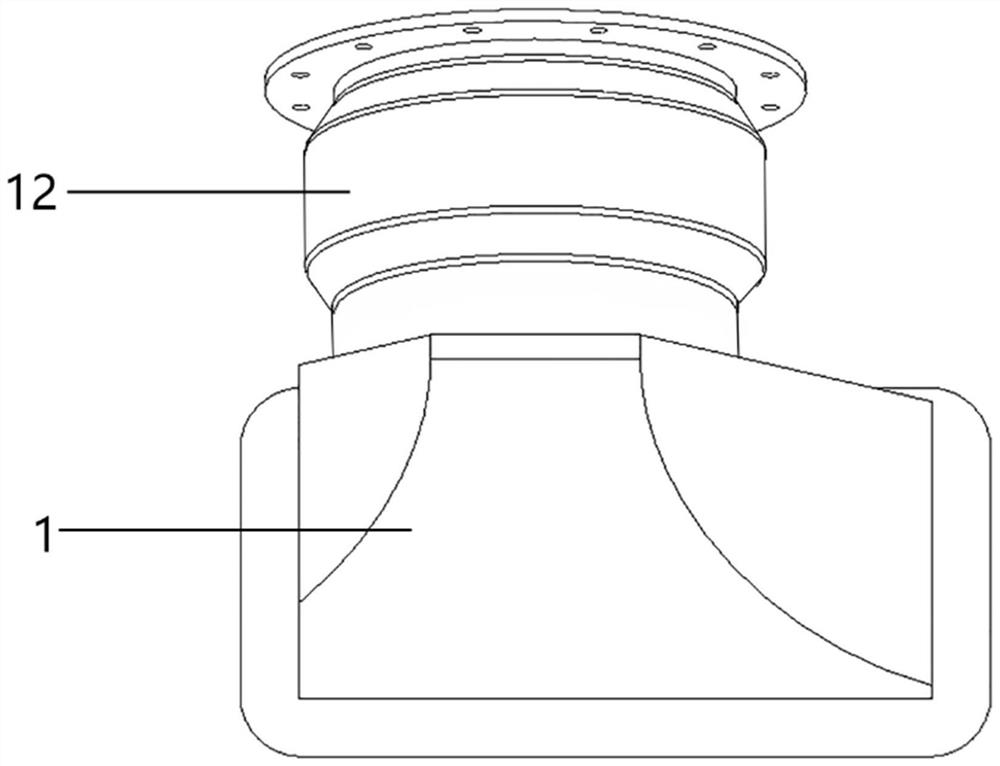

Tail gas purification system for fuel train

PendingCN114017164APrevent or treat minor blockagesImprove environmental standardsInternal combustion piston enginesExhaust apparatusOxygen contaminationCatalytic oxidation

The invention provides a tail gas purification system for a fuel train. The tail gas purification system is characterized by comprising a gas inlet unit, a catalytic oxidation filter unit, a urea mixing cavity, a catalytic reduction unit and a gas exhaust unit, wherein the gas inlet unit is directly connected with an exhaust port of an engine, tail gas exhausted from the exhaust port of the engine sequentially passes through the gas inlet unit, the catalytic oxidation filtering unit, the urea mixing cavity and the catalytic reduction unit and is finally exhausted from the exhaust port, the catalytic oxidation filtering unit comprises a DOC carrier (a diesel catalytic oxidizer) and a DPF carrier (a diesel particulate filter), and the catalytic reduction unit comprises an SCR carrier (a selective catalytic reduction unit). According to the invention, the SCR carrier is added to treat nitrogen and oxygen pollutants, so purified engine tail gas reaches a higher environmental protection standard; and the DOC carrier, the DPF carrier and the SCR carrier can be conveniently detached, replaced and maintained, so the service life of the whole purification system is guaranteed.

Owner:无锡市隆盛轨道科技有限公司

A kind of production process of drainage agent

The invention provides a production technology for a drainage agent and belongs to the technical field of metal smelting. Gas provided by a gas generator is combusted in a hot blast stove to serve as a heat source, and various raw materials are dried in a heatable roller brick bed firstly; then the raw materials are cooled through air cooling and conveyed into corresponding bins, automatic discharging and carbon adding are conducted according to the ratio of a formula, and even stirring is conducted in a closed stirring tank; and then automatic packaging is conducted, and warehousing is conducted. A full-automatic production line is adopted for the integral technology, stability of the product quality is ensured, in addition, the number of working personnel is reduced, and the labor cost is reduced; and meanwhile, the influences of human factors on the product quality are also greatly reduced, dust removing devices are arranged for links where dust is liable to be generated on the heatable roller brick bed and the sealed stirring tank so that generated dust can be collected and removed, dust pollution is reduced, the environment-friendly standard is improved, and clean and efficient production is achieved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

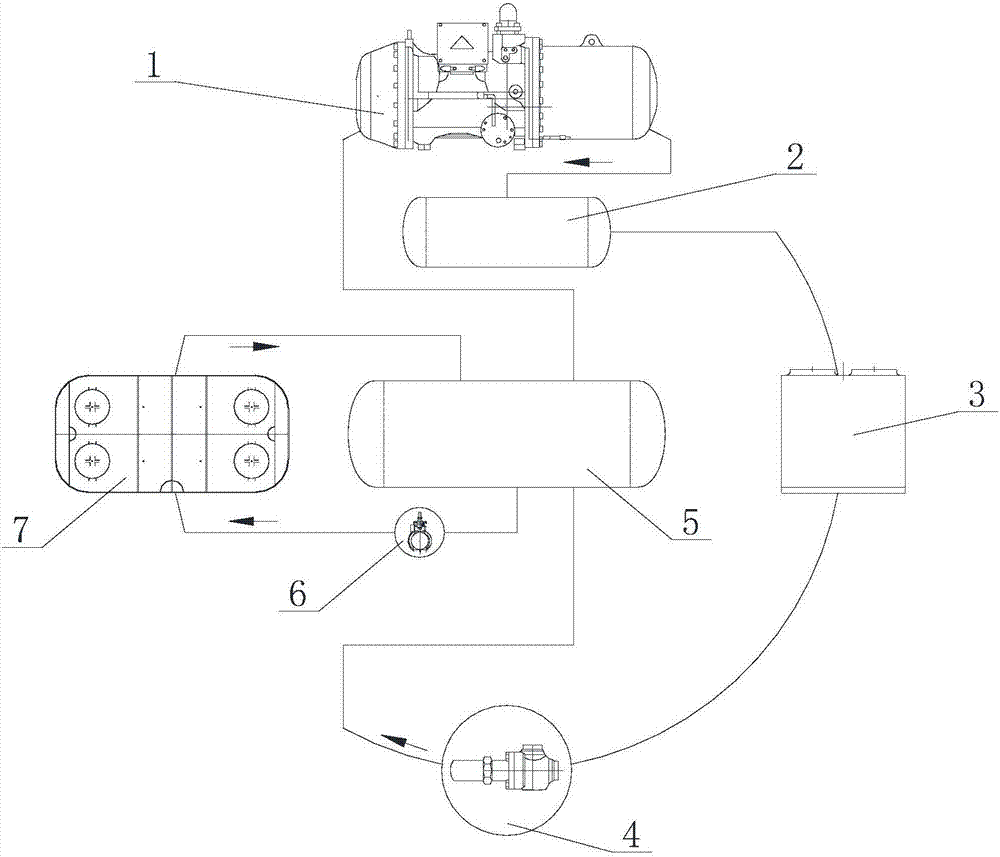

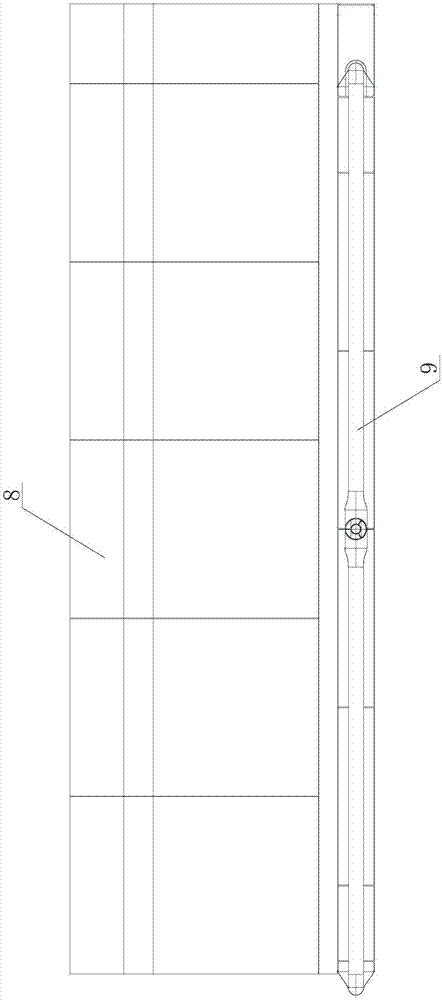

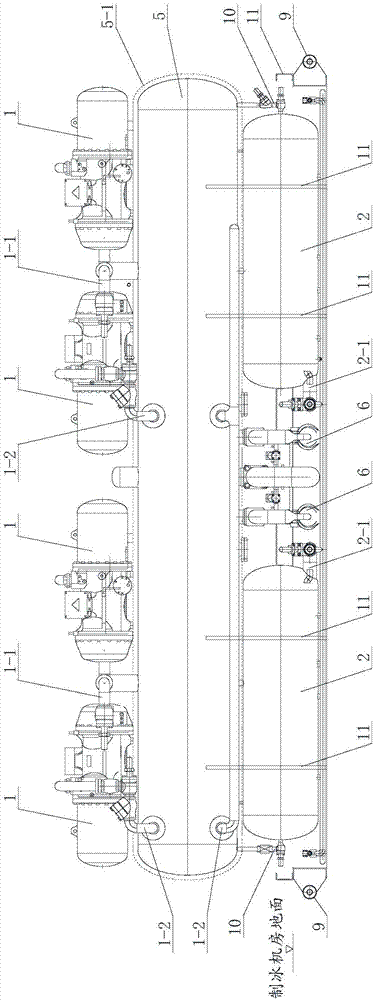

Environment-friendly ice making integrated machine

PendingCN107131685AReduce volumeOptimizing Structural RelationshipsCompressorMechanical apparatusUnit sizeSpatial structure

The invention discloses an environment-friendly ice making integrated machine. The technical problems that an ice making machine is large in size, complicated in structure and inconvenient to transport, install and use in the prior art are solved. The environment-friendly ice making integrated machine comprises a compressor, an oil separator and a low-pressure circulating tank. The compressor, the oil separator and the low-pressure circulating tank are connected in sequence through a refrigerant transporting pipeline. The oil separator is located in the lower layer. The low-pressure circulating tank is located in the middle layer. The compressor is located in the upper layer. According to the environment-friendly ice making integrated machine, the structural relationship between the devices is fully optimized; the main devices are combined together; the unit space is fully utilized; the structure is compact; the unit size is reduced; and the environment-friendly ice making integrated machine is convenient to transport, install and use.

Owner:魏一伦

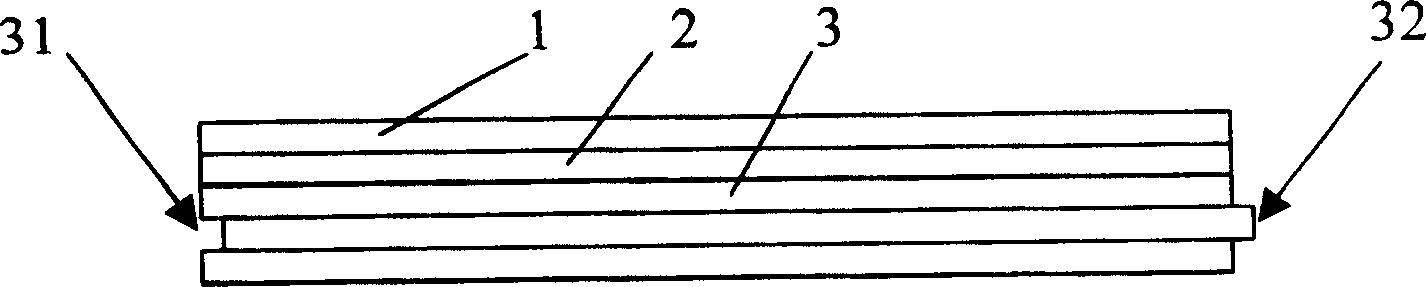

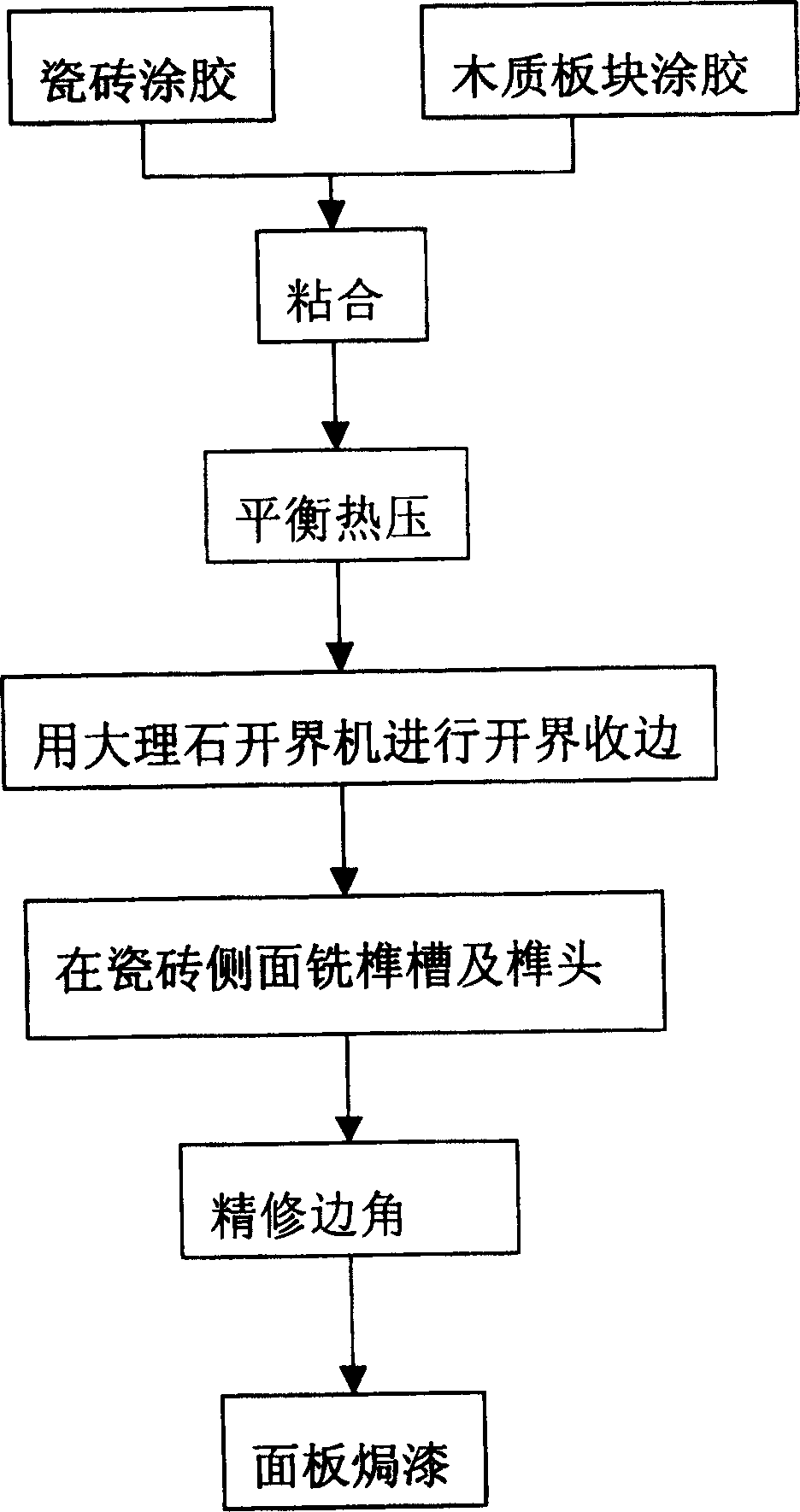

Composite floorboard and fabrication method

A composite floor, comprising a ceramic tile substrate, the upper surface of the ceramic tile substrate is bonded with a wooden panel layer by strong glue, and there are tenons and / or tenons extending along the length direction of its side surface around the ceramic tile substrate. The present invention also provides a method for producing the novel composite floor, which comprises the following steps in sequence: applying adhesive to the wooden boards and tiles, bonding the wooden boards to the tiles, performing balanced hot pressing on the bonded boards, using The marble opening machine is used to open the edge, mill the mortise and tenon on the side of the tile, refine the corner, and paint the panel. This new type of composite floor has strong waterproof, moisture-proof, deformation-proof, and heat-preservation performances, and has low noise, low cost, and convenient construction. It is especially suitable for the first floor and has very good social and economic benefits.

Owner:黄坤岳

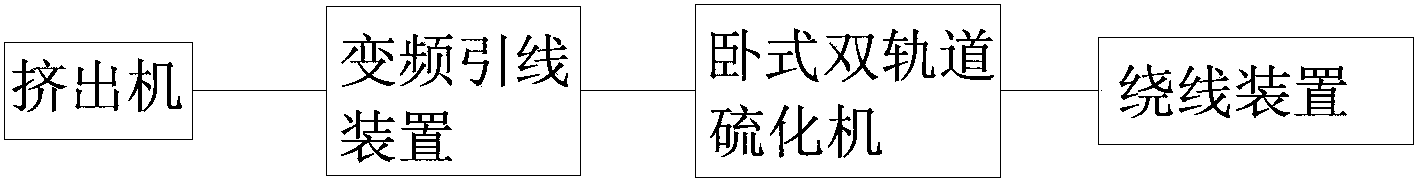

Silicone tube production line and process

The invention discloses a silicone tube production line which comprises an extruder, a variable-frequency wire leading device, a horizontal double-track vulcanizing machine and an automatic wire winding device which are arranged in sequence. The horizontal double-track vulcanizing machine comprises an upper vulcanizing box and a lower vulcanizing box which are communicated with each other up and down and used for vulcanizing a silicone tube; and two sides of the horizontal double-track vulcanizing machine are both provided with a transmission device which is used for making the silicone tube do circular motion in the upper vulcanizing box and the lower vulcanizing box. The silicone tube production line has the advantages of simple structure, convenience of operation, low production cost, low equipment cost and high security, occupies less floor area and can be used for vulcanizing the silicone tube for many times so that the produced silicone tube has good quality and wide range of application and can be used for the medical products and the food-grade products which can be in direct contact with the human body.

Owner:DONGGUAN SUNTRACK WIRE

Completely recoverable barrier PE membrane material as well as preparation method and application thereof

Owner:GUANGDONG FORETURE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com