Blowing-free demolding machine for colloidal gloves

A technology for gloves and degassing, applied in coatings, household appliances, household components, etc., can solve the problems of increased production costs, inability to achieve full demoulding, noise pollution, etc., to improve environmental protection standards and avoid unmolded gloves. Existence and guarantee the effect of normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

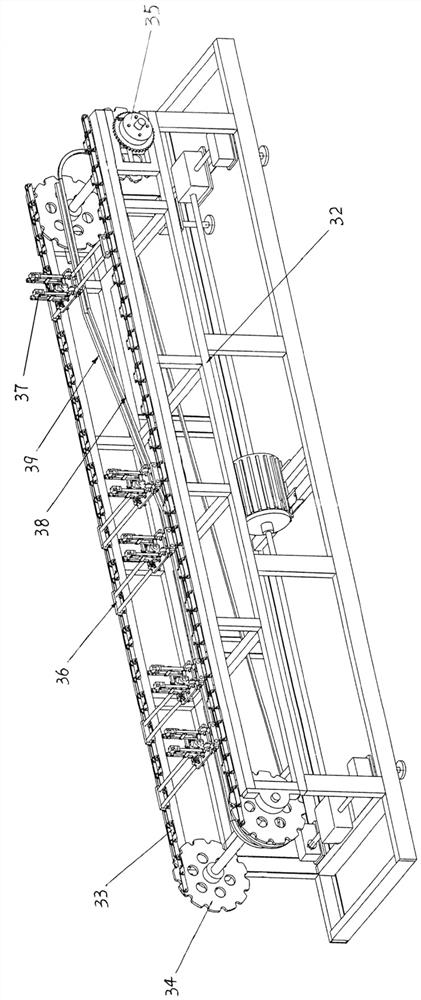

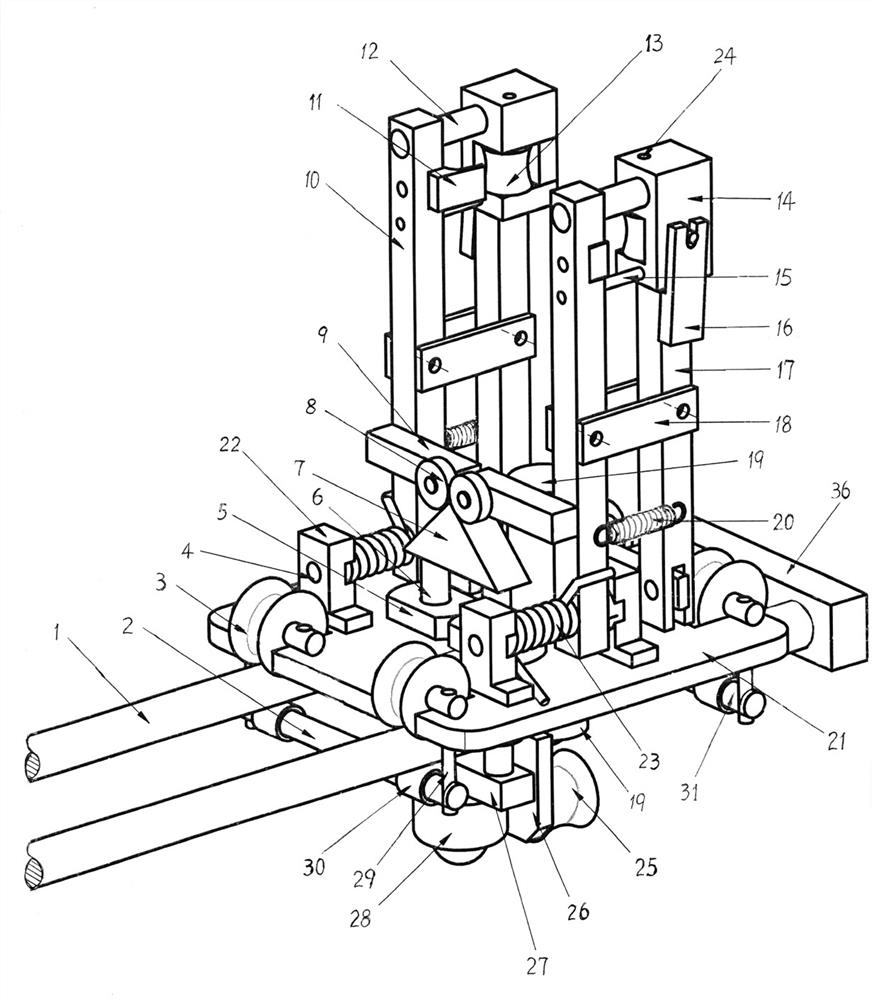

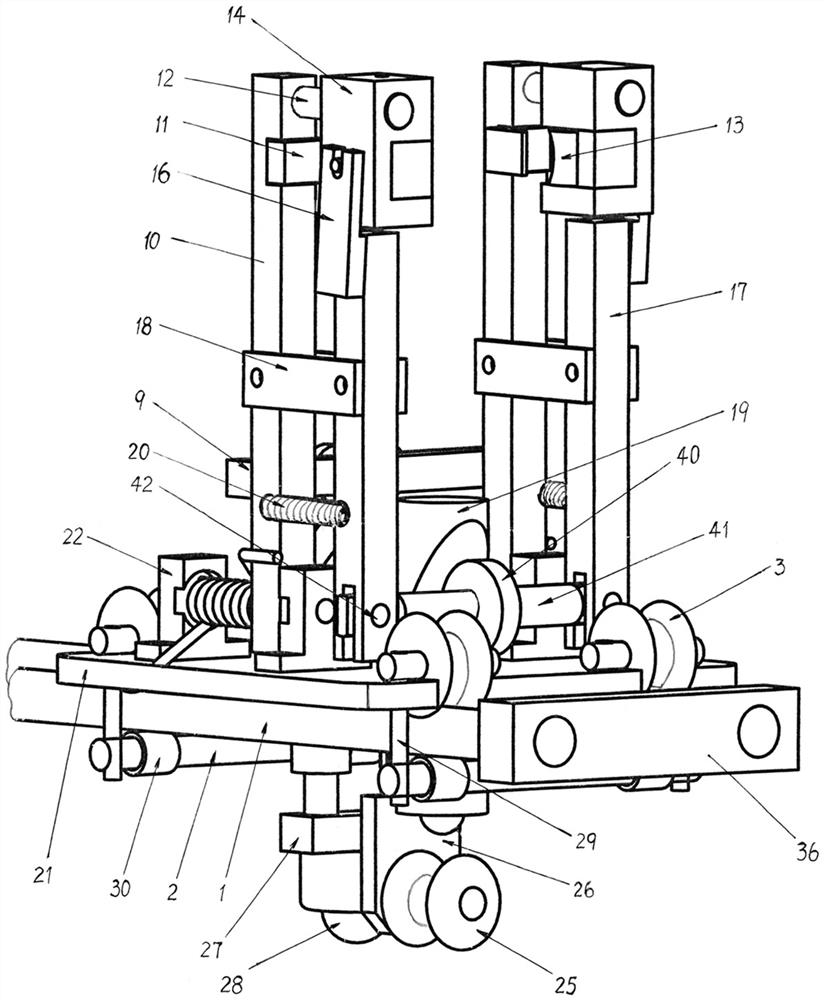

[0031] like figure 1 As shown in the present invention, the rubber glove blow-free mold release machine is provided with two sets of annular synchronous chains 33 on the body 32, which are driven by the sprocket 34 to rotate. The main drive chain on the glove production line is connected to the synchronous adjustment wheel 35 of the stripping machine, and the synchronous adjustment wheel 35 drives the sprocket 34 and the chain 33 to realize the synchronous operation of the stripping machine and the glove production line. Several traveling frames 36 are bridged on the two sets of synchronizing chains 33 , and a set of demoulding manipulators 37 are arranged on each traveling frame, and the demoulding manipulators 37 can move back and forth on the traveling frames 36 . Two guide rails are also provided on the body 32, one of which is a first guide rail 38 arranged in a ring shape to control the front and rear movement of the demoulding manipulator on the walking frame 36; The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com