Method for treating waste water and waste liquor in titanium tetrachloride industrial production process

A treatment method and industrial production technology, applied in natural water treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems such as damaged equipment, waste of valuable components, and environmental pollution, so as to reduce environmental pollution and improve Environmental protection standards, the effect of improving the production and operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

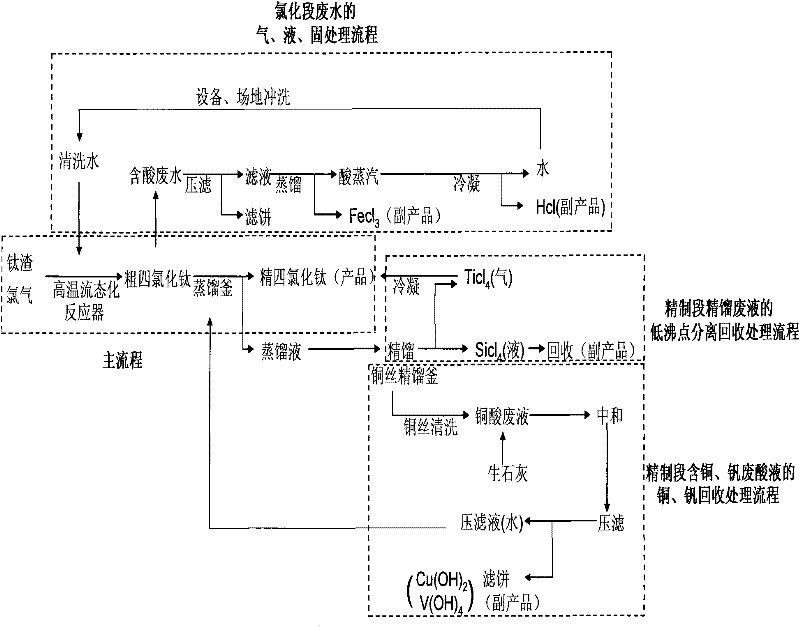

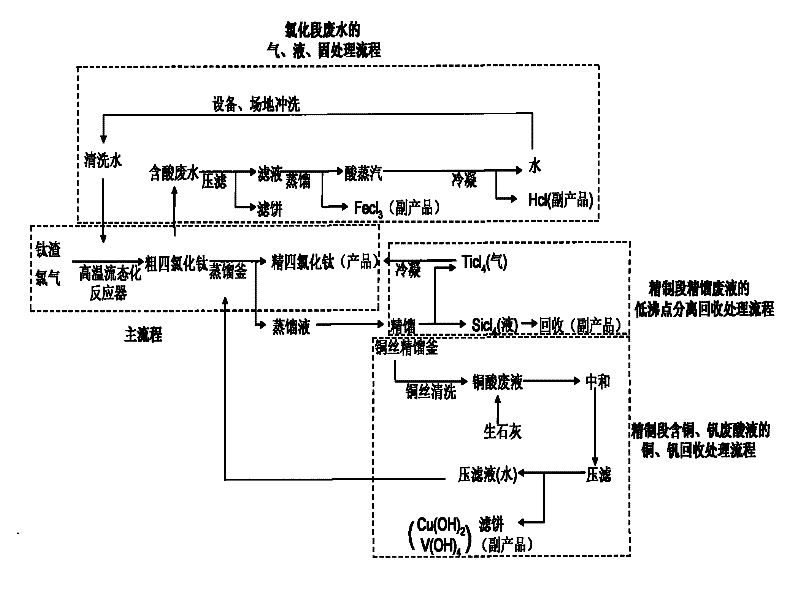

[0028] 1. Gas, liquid and solid treatment process of wastewater in the chlorination section

[0029] Regularly detect the concentration of wastewater in the wastewater collection tank. When the concentration reaches 18°-20°Be, pump it into the plate and frame filter press to filter through the acid pump. After filtering, the filtrate is discharged into the wastewater treatment tank, and stop when the flow rate of the filtrate is slow. Filtrate, clean the filter cake between the plates and frames, collect and bag the filter cake (reuse). From the treatment pool, the filtrate is continuously added to the distillation kettle by the acid pump, and at the same time, the distillation kettle is continuously heated by heat conduction oil to heat the wastewater in the kettle to boiling (105°C), and the wastewater is continuously evaporated, and the evaporated acid gas is buffered The sub-cylinder enters the water condenser to condense, and the condensate after water cooling is pure hyd...

Embodiment 2

[0035] 1. Gas, liquid and solid treatment process of wastewater in the chlorination section

[0036] With embodiment 1.

[0037] 2. Low boiling point separation and recovery treatment process of rectification waste liquid in the refining section

[0038] Pump the rectification waste liquid from the acid to the high-level temporary storage tank, adjust the flow rate, continuously flow the rectification waste liquid from the temporary storage tank into the rectification kettle, control the temperature of the rectification kettle at 128°C, and put TiCl 4 with SiCl 4 and other low-boiling point impurities, the separated refined TiCl 4 Send it to the condenser for cooling, and then enter the refining storage tank after cooling, and the residual liquid in the rectifying kettle (mainly containing SiCl 4 ) for recycling (by-product).

[0039]3. Copper and vanadium recovery and treatment process of waste acid solution containing copper and vanadium in the refining section

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com