Alkyl ester method glyphosate solvent recovery system and process based on three-stage condensation

A technology of alkyl ester method and recovery system, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of poor intrinsic safety, large logistics load, and low energy consumption of phase transition, and avoid the Large logistics load, reduced steam consumption, and improved intrinsic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

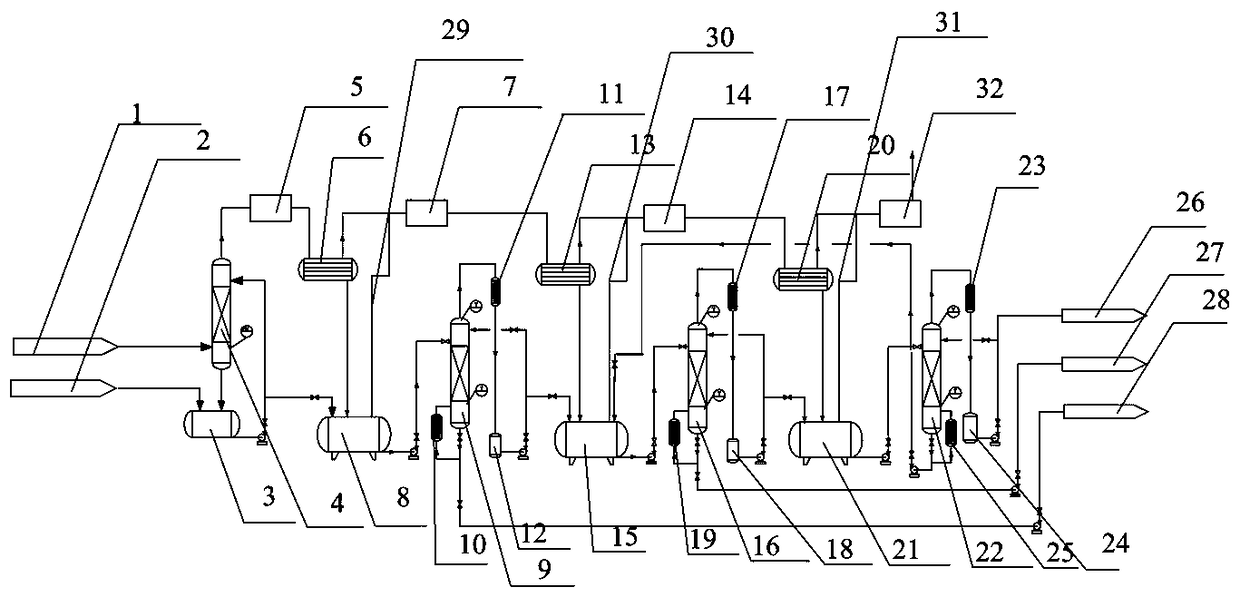

[0047] A three-stage condensation-based alkyl ester method glyphosate solvent recovery system, including a primary tail gas condenser 6, an aqueous solution collection tank 8, a primary rectification tower 9, a secondary tail gas condenser 13, and a methanol solution collection tank 15 , two-stage rectification tower 16, three-stage tail gas condenser 20, methylal solution collection tank 21, three-stage rectification tower 22, the glyphosate hydrolysis tail gas pretreatment system produced by the alkyl ester method passes through the first-stage tail gas condenser 6 is connected with the aqueous solution collection tank 8, the aqueous solution collection tank 8 is connected with the primary rectification tower 9, the primary rectification tower 9 is connected with the methanol solution collection tank 15 through the pipeline, and the bottom of the primary rectification tower 9 is connected to the decontamination station 28 ;

[0048] The primary exhaust gas condenser 6 is con...

Embodiment 2

[0067] A kind of alkyl ester method based on above-mentioned system produces glyphosate solvent recovery process, and its concrete steps are as follows:

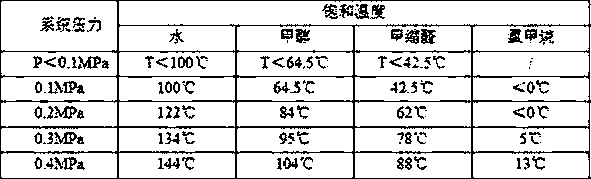

[0068] The mixture of hydrogen chloride, methyl chloride, methanol, methylal, and water vapor from the glyphosate hydrolysis station enters the tail gas neutralization tower together with liquid caustic soda and neutralizes to a pH of 7-14, removes the acidic components in the tail gas, and then The first, second, and third stage condensers carry out pressure control, staged condensation and separation, and the condensate goes to the aqueous solution collection tank, methanol solution collection tank, and methylal solution collection tank respectively; the aqueous solution collection tank, methanol solution collection tank, and methylal solution The aqueous solution, methanol solution, and methylal solution in the collection tank are decompressed and then rectified and purified; the non-condensable gas is sent to the methyl c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com