Device for automatically detecting electric detonators and rejecting waste electric detonators

A technology for rejecting waste and automatic detection, applied in sorting and other directions, can solve problems such as safety hazards, equipment that cannot meet the requirements of modern production enterprises, and cannot form assembly line operations, etc., to achieve stable operation, compact structure, and small floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

[0014] preferred embodiment

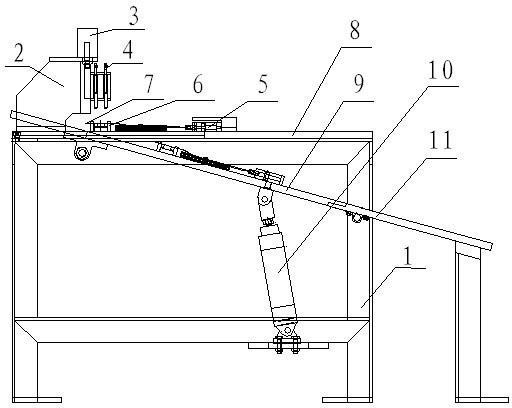

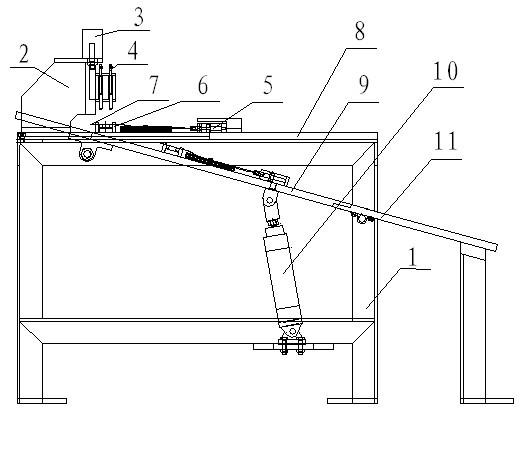

[0015] Such as figure 1 The shown electric detonator automatic detection and rejection device is installed on the support 1 as a whole, the top of the support 1 is the detection table 2, and the detection control device 4 is installed on the side of the detection table 2 supported by the support frame 3, and the detection control device 4 is provided below. As for the detection column 5 , when the detection mold 8 for fixing the wire detection part 7 in the limit fire pipe mold 6 is located on the detection table 2 , the wire detection part 7 is just below the detection column 5 .

[0016] In the above scheme, the side of the detection table 2 is provided with a reject board 9, one end of the reject board 9 is movably connected to the support 1, and the lower part of the free end of the other end is connected with the reject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com