Automatic suction filtration and tray distributing machine

A kind of disc separation and automatic technology, applied in the direction of filtration separation, separation method, gravity filter, etc., can solve the problems of low operation efficiency and inability to guarantee safety, and achieve the effect of simple equipment structure, improved intrinsic safety, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

[0019] preferred embodiment

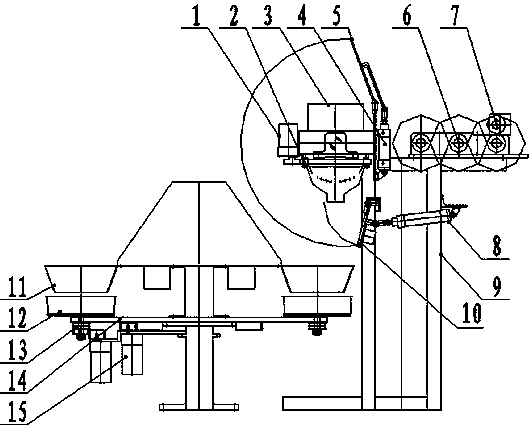

[0020] Such as figure 1 Shown is the structural representation of the present invention, below in conjunction with the work process of concrete production equipment the present invention is described further:

[0021] Initial state: There is a pure cotton barrel-shaped filter bag in the suction filter barrel, and a 5cm long cotton rope is reserved between the bottom of the filter bag and the filter plate of the filter barrel and tied firmly. The drug-receiving surface of the drug-receiving platform is welded on the same plane by 8 drug discs of the same size and shape to form a circular drug-receiving groove. There is a vacuum pipeline on the connecting seat, that is, a suction filter device, which is generally designed as a suction filter cylinder and a medicine hopper connected to its front end, wherein the medicine ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com