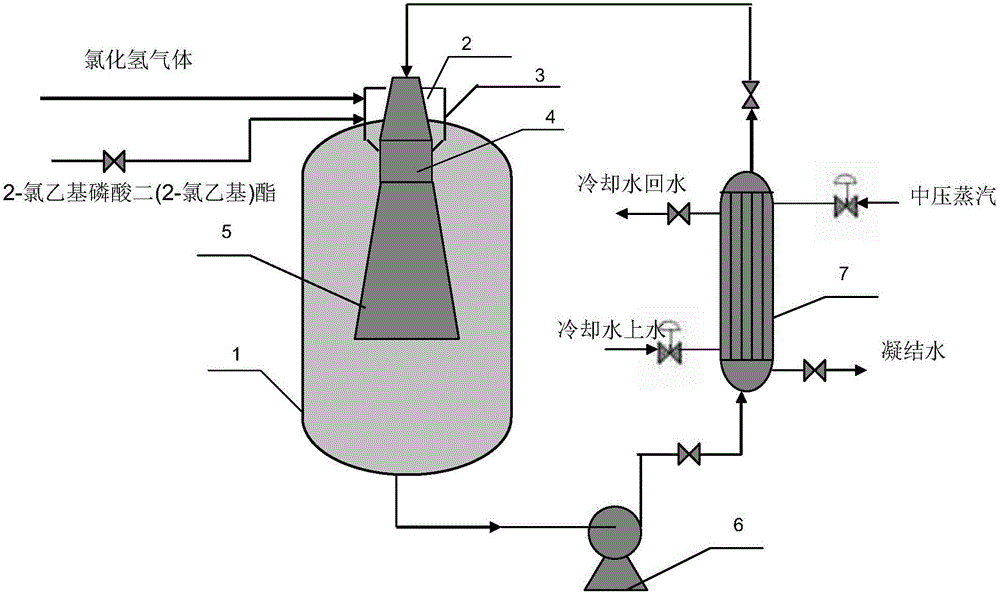

Venturi circulation loop reactor for continuous production of ethephon and method

A Venturi-type, circulating-loop technology, applied in the field of material processing, can solve the problems of insufficient gas-liquid mass transfer, unstable product quality, affecting the reaction rate, etc., to improve the intrinsic safety, compact structure, and reduce side reactions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

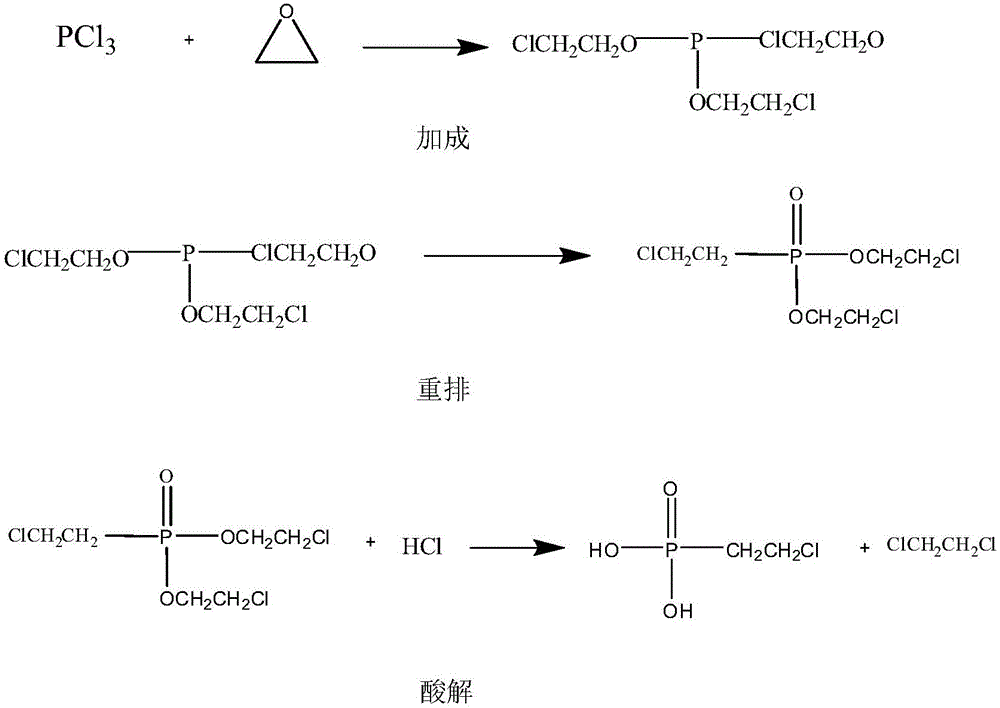

Method used

Image

Examples

Embodiment 1

[0029] The raw material 2-chloroethyl phosphate bis(2-chloroethyl) is preheated to 90° C. and then pumped into the Venturi mixer of the Venturi loop reactor, and the injection velocity is controlled to be 50 m / s. After the hydrogen chloride gas reacts with the raw material 2-chloroethyl phosphate bis(2-chloroethyl) in the Venturi loop reactor, part of it is extracted after passing the test, and the remaining part is pumped to the heat exchanger for heat exchange by circulating pumps Back cycle to Venturi mixer. The conversion rate of the reaction was 95% through analytical test.

Embodiment 2

[0031] The raw material 2-chloroethyl phosphate bis(2-chloroethyl) is preheated to 100°C and then pumped into the Venturi mixer of the Venturi loop reactor, and the injection flow rate is controlled to be 60m / s. After the hydrogen chloride gas reacts with the raw material 2-chloroethyl phosphate bis(2-chloroethyl) in the Venturi loop reactor, part of it is extracted after passing the test, and the remaining part is pumped to the heat exchanger for heat exchange by circulating pumps Back cycle to Venturi mixer. The conversion rate of the reaction was 98% through analytical test.

Embodiment 3

[0033] The raw material 2-chloroethyl phosphate bis(2-chloroethyl) is preheated to 115°C and then pumped into the Venturi mixer of the Venturi loop reactor, and the injection flow rate is controlled to be 70m / s. After the hydrogen chloride gas reacts with the raw material 2-chloroethyl phosphate bis(2-chloroethyl) in the Venturi loop reactor, part of it is extracted after passing the test, and the remaining part is pumped to the heat exchanger for heat exchange by circulating pumps Back cycle to Venturi mixer. The conversion rate of the reaction was 99% through analytical test.

[0034] It can be seen from the above examples that the higher the injection velocity, the better the mixing effect and the higher the corresponding conversion rate. But if it exceeds 70m / s, the circulation volume of the circulation system is too large, the energy consumption and production requirements of the circulation pump are too high, and the investment is uneconomical. Due to the precise match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com