Vacuum cartridge fuse and process for manufacturing the same

A technology of fuse tube and manufacturing process, which is applied in the direction of fuse manufacturing, manufacturing tools, emergency protection devices, etc., which can solve the problems of low welding efficiency, time-consuming and power consumption, and inconformity with energy saving, and achieve good consistency of fusing time and improve Anti-knock level, the effect of shortening the generation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

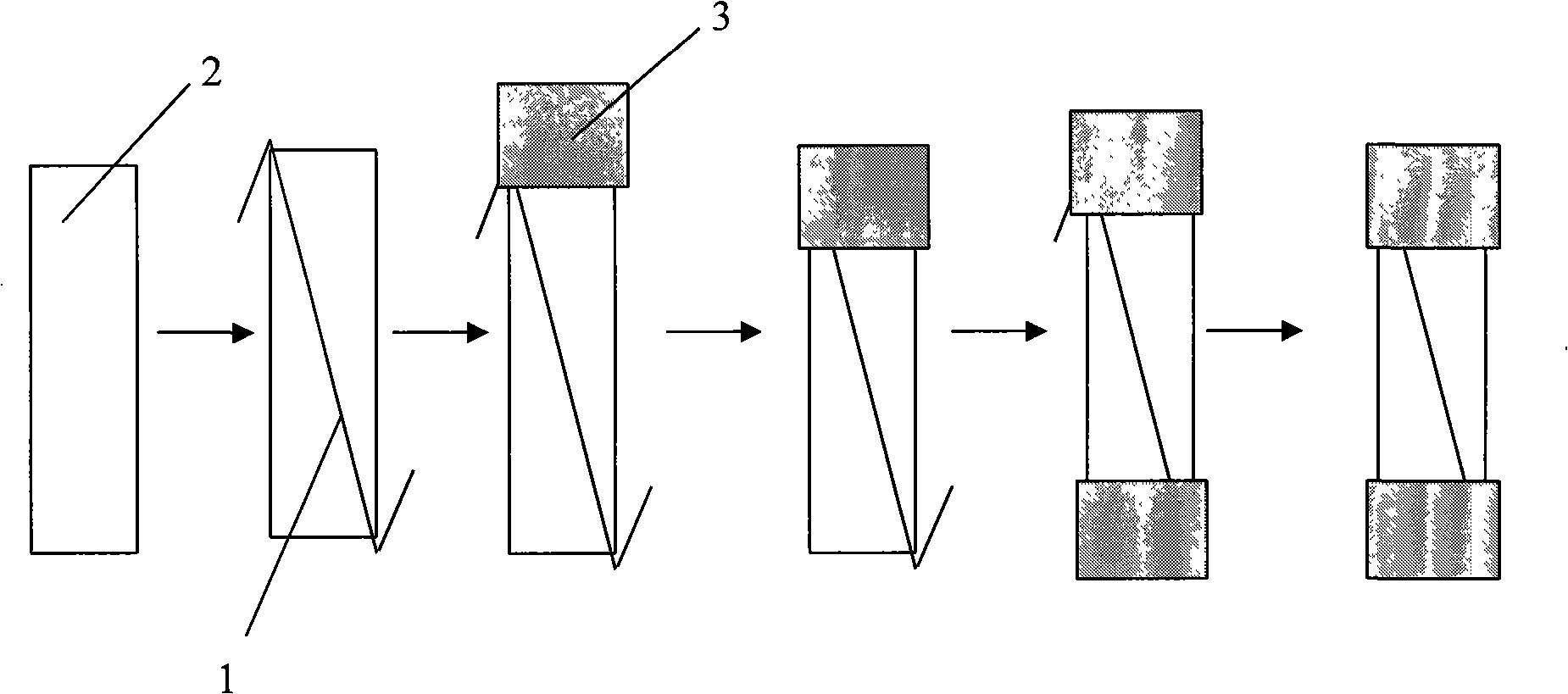

[0044] Combination hint figure 2, 4. First, carry out step A (not shown in the figure), and fix the pipe body 2 on the positioning fixture 4. In this embodiment, in the step B, first place the fuse 1 obliquely in the pipe body 2, and make the Both ends of the fuse 1 are exposed on the outside of the tube body 2; then the exposed two ends are bent outward along the end surface of the tube body 2, that is, the fuse 1 is bent into a "Z" shape. Then put the tinned copper cap 3 on one end of the pipe body, put the pipe body 3 with the copper cap 3 together with the positioning fixture 4 into the openable airtight welding cavity 5 of the high-frequency welding machine, and open the high-frequency welding machine. Frequency welding machine for 1-5 seconds, weld the copper cap at this end; take out the positioning fixture 4, put the copper cap on the other end of the pipe body 2, put them together into the airtight welding cavity 5, and use the airtight welding cavity 5 to draw The ...

Embodiment 2

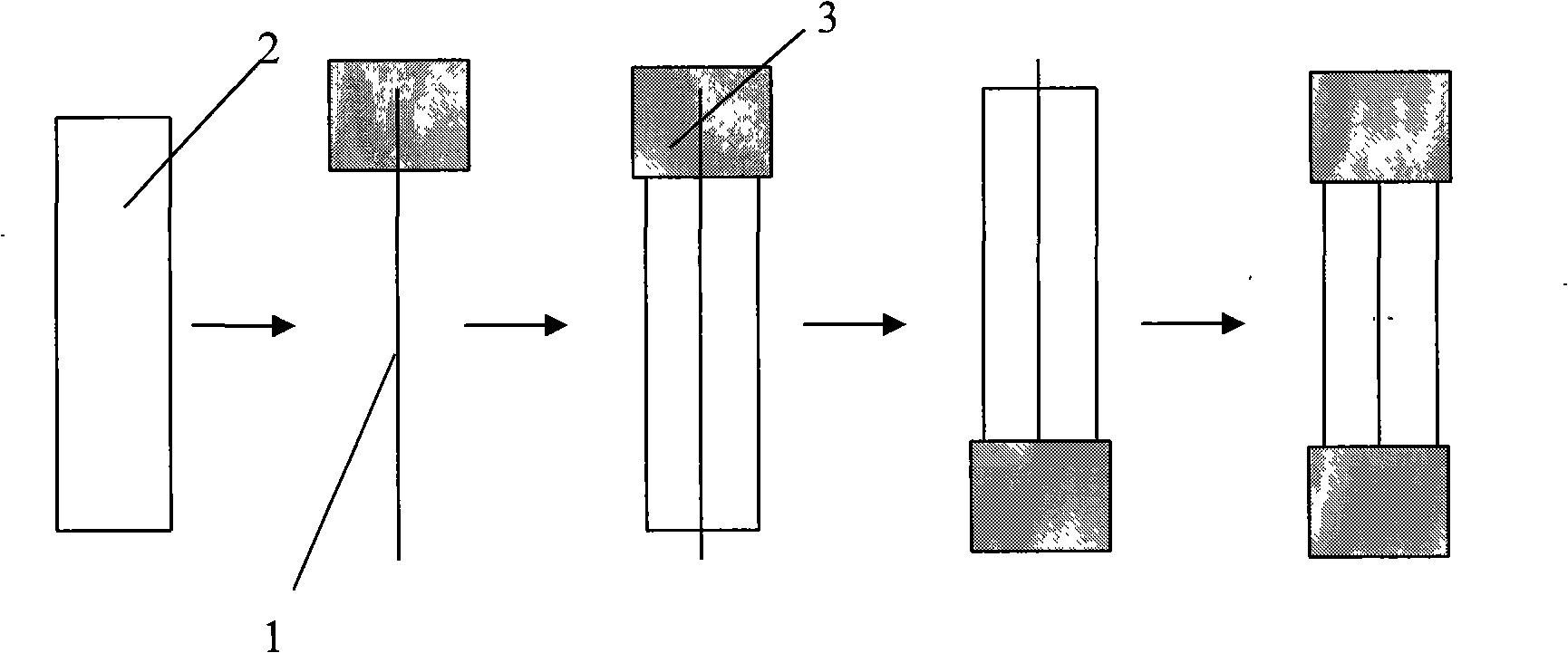

[0046] Combination hint image 3 , 4. First, carry out step A (not shown in the figure), and fix the pipe body 2 on the positioning fixture 4. In this embodiment, steps B and C are combined, that is, the fuse 1 is vertically fixed on the copper cap 3 by tin in advance. Then put the copper cap 3 on the tube body 2 while passing the fuse through the tube body 2, and put the tube body 3 with the copper cap 3 together with the positioning fixture 4 into the openable Open the high-frequency welding machine for 1 to 5 seconds, and weld the copper cap at this end; after taking it out, put another copper cap on it, put it into the sealed welding cavity again, and put the closed welding cap into the closed welding cavity. Cavity 5 is evacuated into a vacuum state by means of an air extraction device, and then the high-frequency welding machine is turned on for 1 to 5 seconds to complete the welding of the copper cap at the other end and take it out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com