Production technology of stretching film

A production process and stretch film technology, which is applied to flat products, household utensils, and other household utensils. It can solve the problems of no printing function, no function, etc., and achieve the effects of increasing popularity, easy dismantling, and solving industry problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

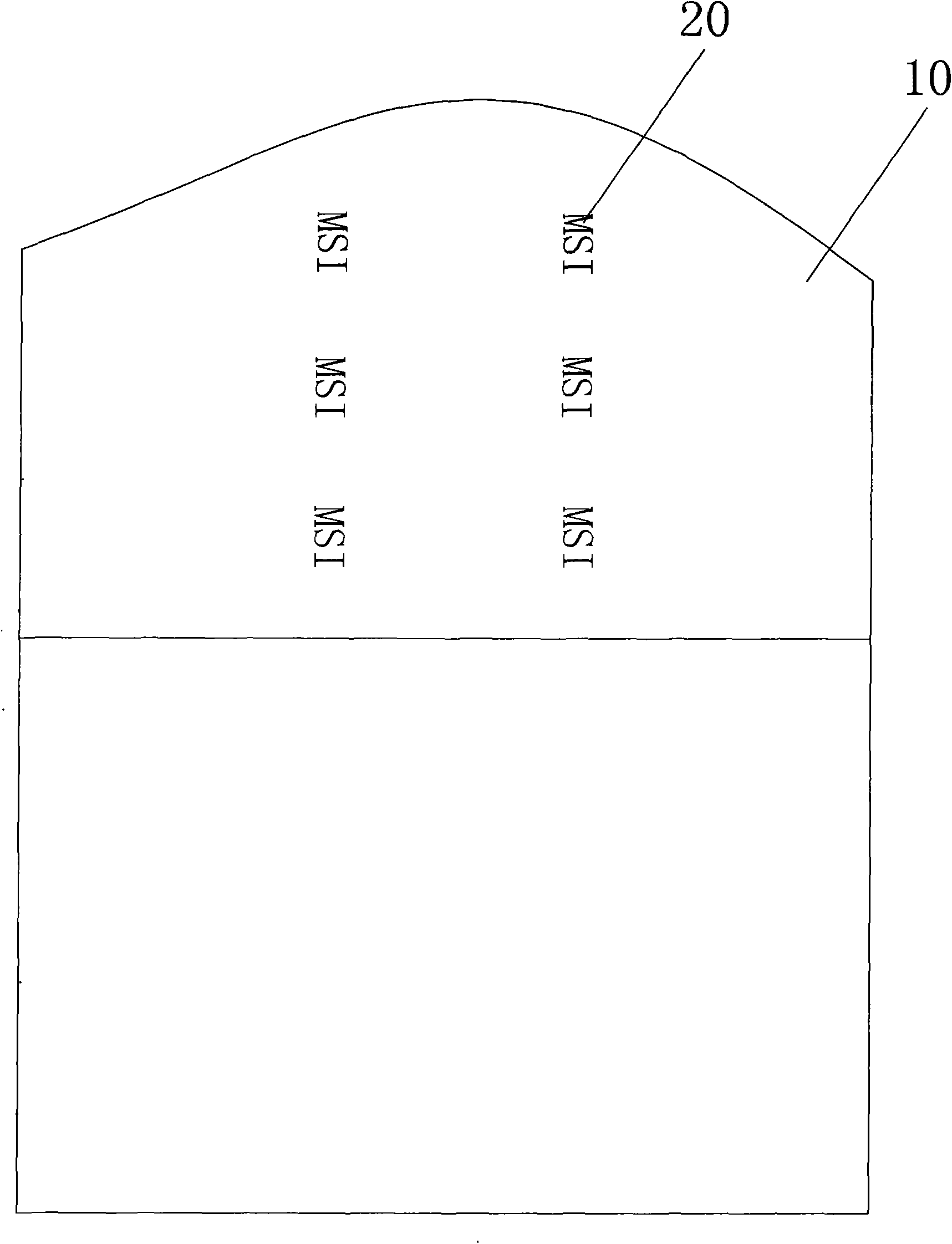

[0026] The present invention is implemented like this:

[0027] A stretch film production process, including a feeding process, the feeding process enters the raw material solid LDPE particles through the feed port into the subsequent process, and the subsequent process includes the following processes,

[0028] 1) High-temperature melting process: Melt LDPE particles into liquid LDPE, and the melting temperature is 120°C to 160°C; the inside of the solid particles is driven by a screw, and the external electric heating ring, and the high-temperature (about 140°C) hot wall slowly melts the LDPE melt into liquid

[0029] 2), die extrusion process: the liquid LDPE in step 1) is extruded from the die with high pressure, and the extrusion volume is balanced with the raw material intake in the feeding process;

[0030] 3), traction cooling process: the LDPE forming film extruded from the die is drawn by the rotating roller to the winding process, the circulating cooling water insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com