Patents

Literature

33results about How to "Capacity impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

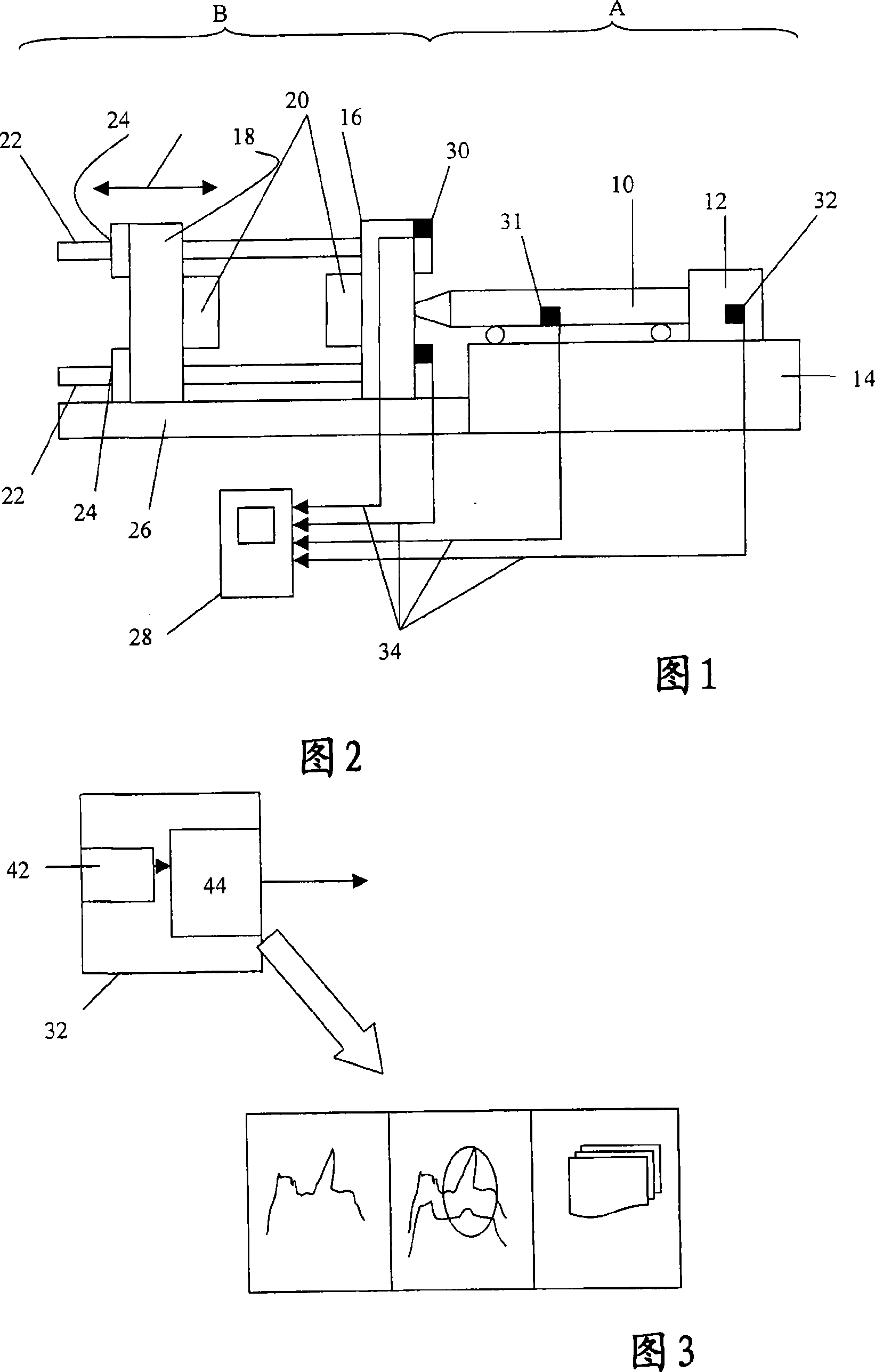

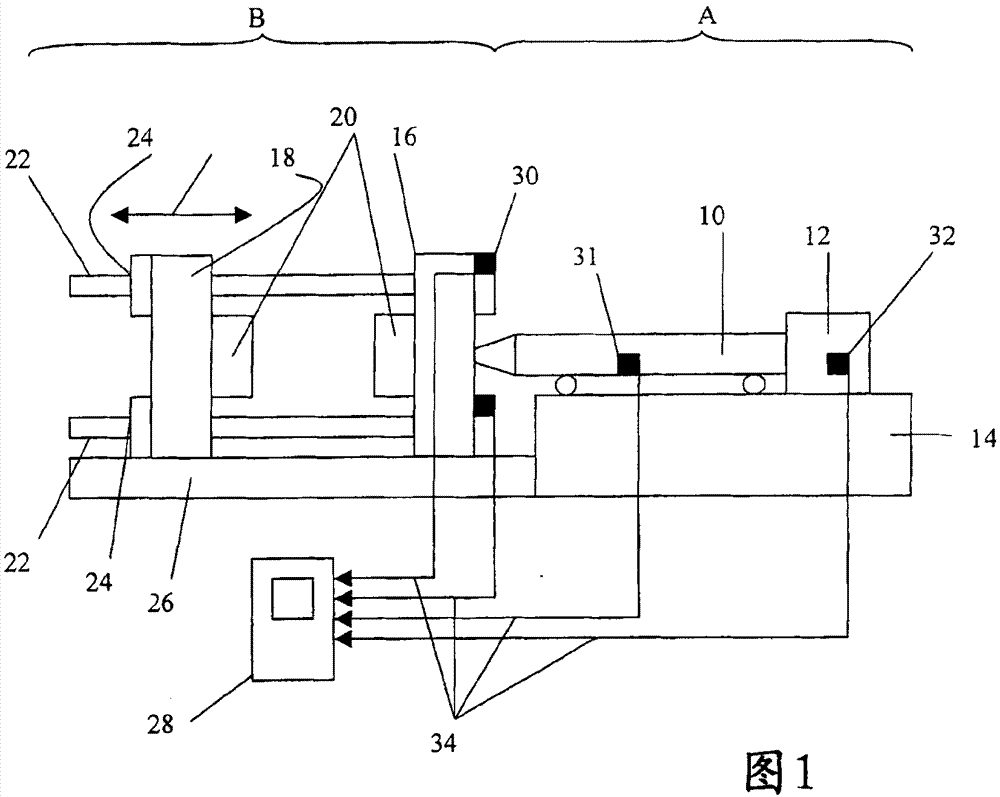

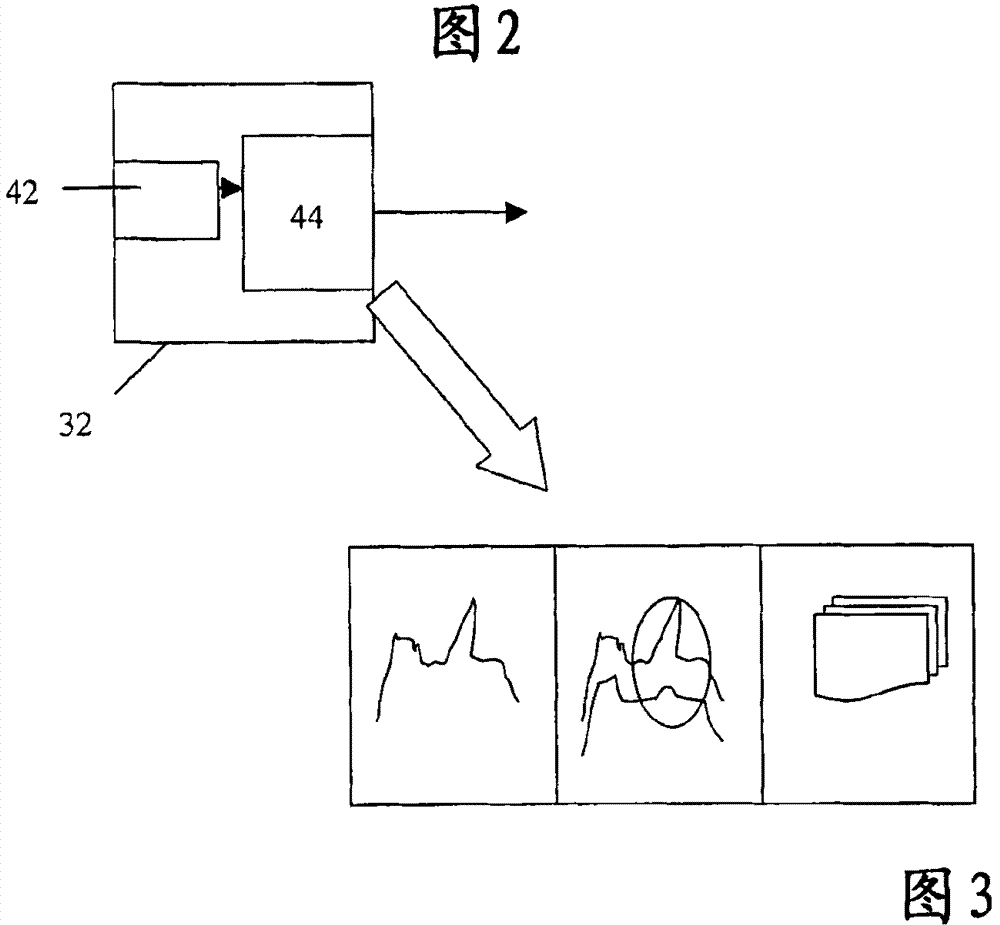

Sensor for use in a plastics processing machine and method for operating such a sensor

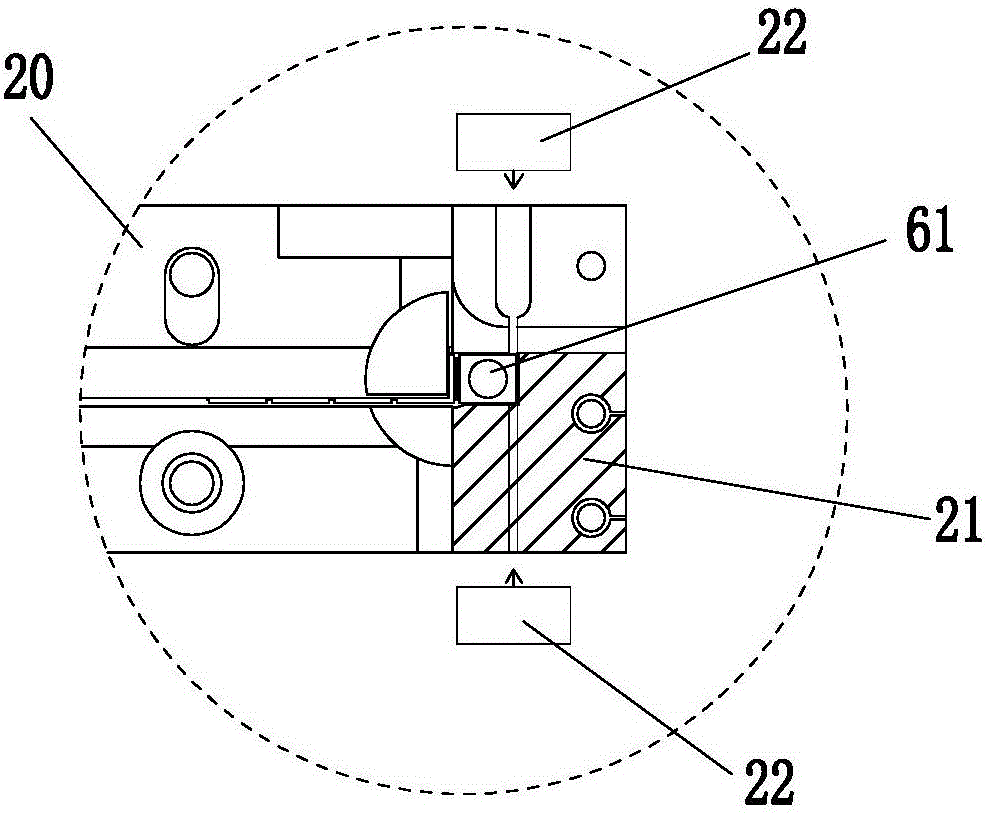

ActiveCN101110130ACapacity impactLow costRegistering/indicating quality control systemsMeasurement arrangements for variablePlastics processorEngineering

Sensor (32) for injection molding machines or extruders comprises a probe (42) and an integral processing unit (44). The processing unit categorizes the signals it receives from the probe by comparison with a classification table and sends an error signal to a control unit if a defect is detected. An independent claim is included for: a method for operating a sensor, as described.

Owner:KRAUSSMAFFEI TECH GMBH

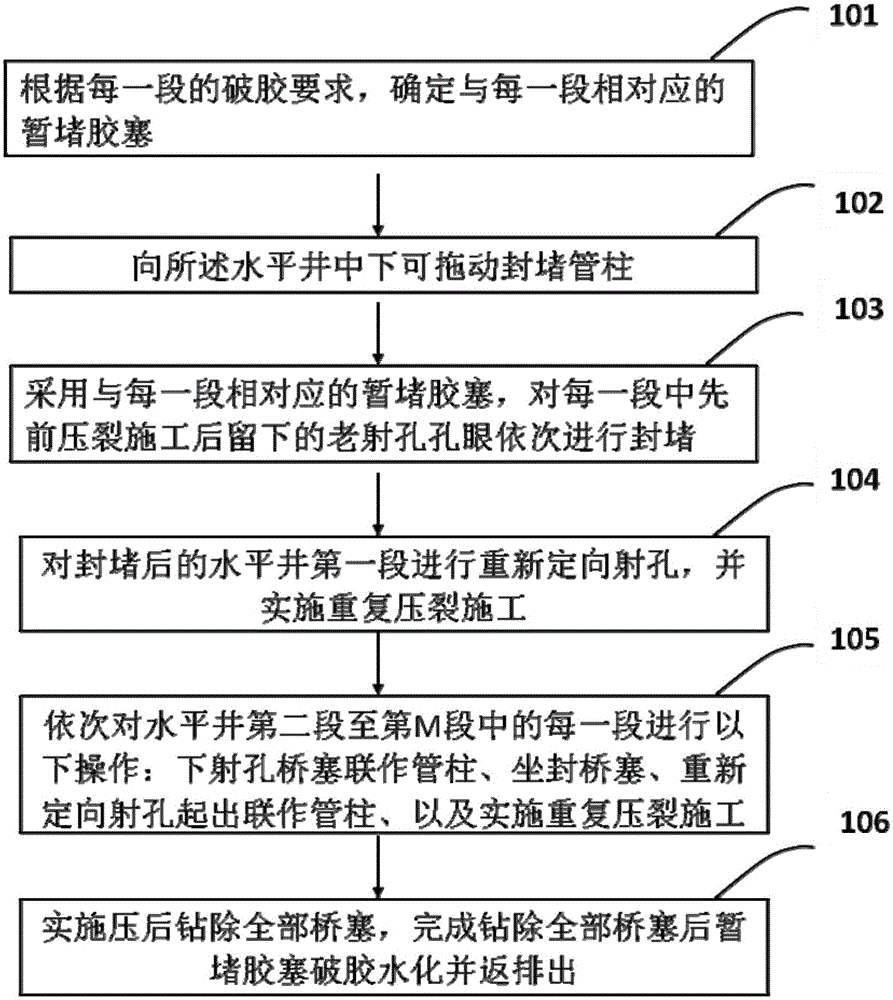

Casing horizontal well multi-segment refracturing method

ActiveCN106351634ASolve many problems such as easy failureGuaranteed successFluid removalSealing/packingMulti segmentMaterial Perforation

A multi-stage refracturing method for casing horizontal wells is proposed. This method is used for refracturing horizontal wells containing multiple stages. The method includes: according to the gel breaking requirements of each stage, determine the corresponding Temporary plugging; the plugging string can be dragged down the horizontal well; the temporary plugging corresponding to each section is used to seal the old perforation holes left after the previous fracturing operation in each section in sequence Re-orientate perforation on the first section of the horizontal well after plugging, and implement refracturing construction; perform the following operations on each section from the second section to the M section of the horizontal well in turn: lower the perforation bridge plug joint Manipulating strings, setting bridge plugs, reorienting perforating strings, and implementing repeated fracturing operations, wherein the first section is the section farthest from the wellhead, and the Mth section is the closest to the wellhead One section; and after the pressure is applied, all the bridge plugs are drilled and removed, and after all the bridge plugs are drilled and removed, the temporarily blocked rubber plug is broken and hydrated and then discharged.

Owner:CHINA PETROLEUM & CHEM CORP +1

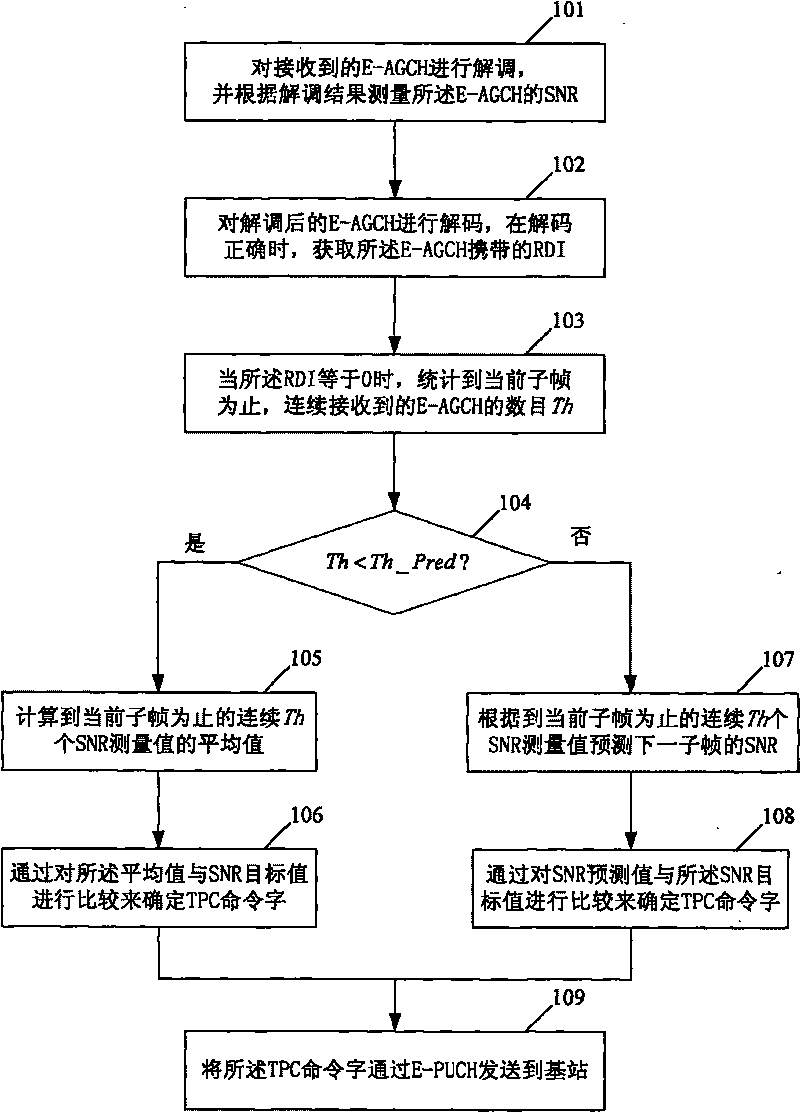

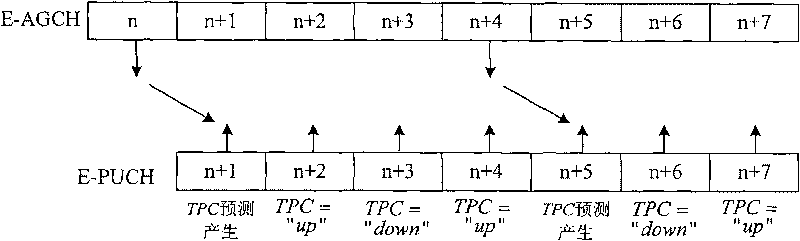

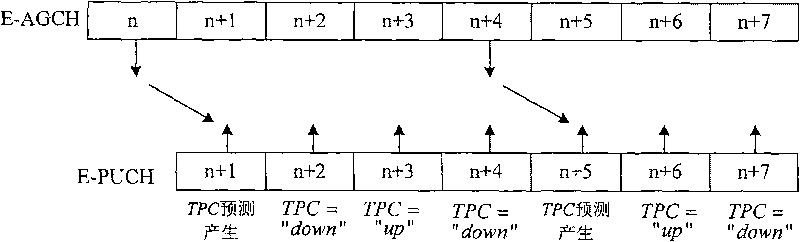

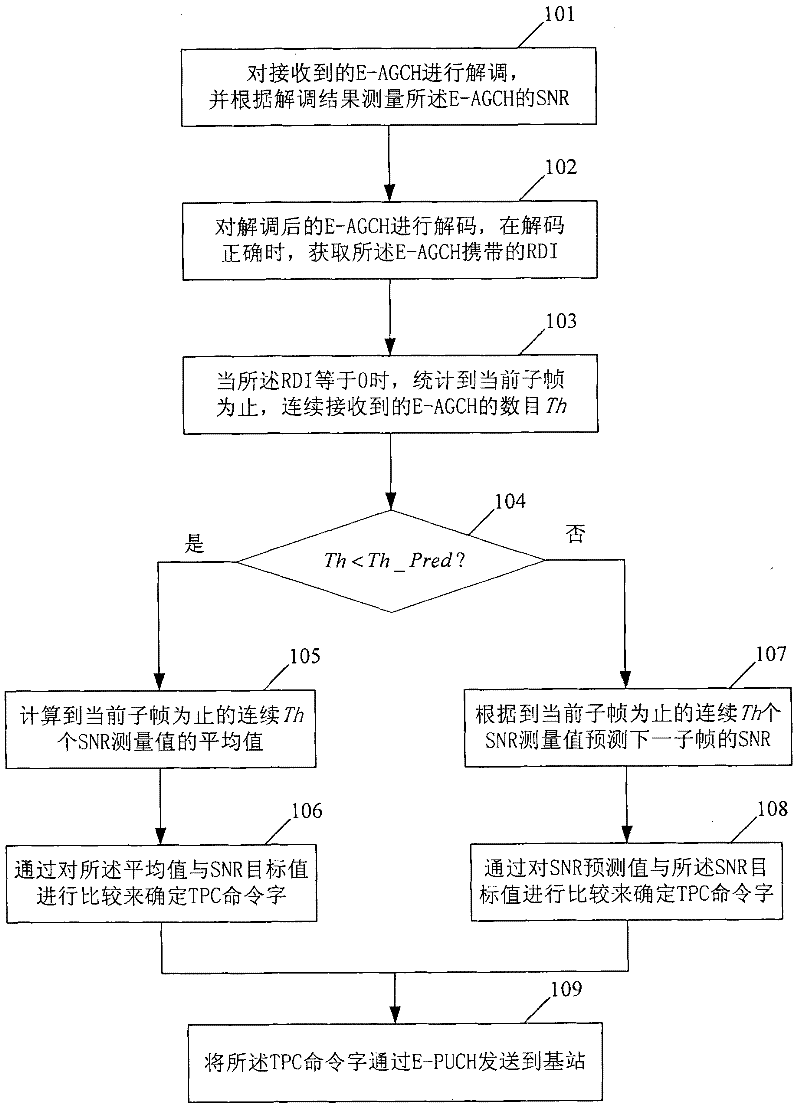

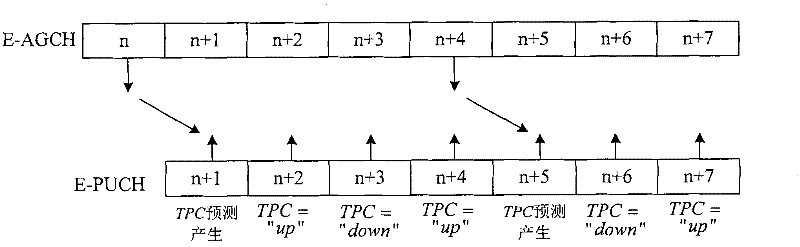

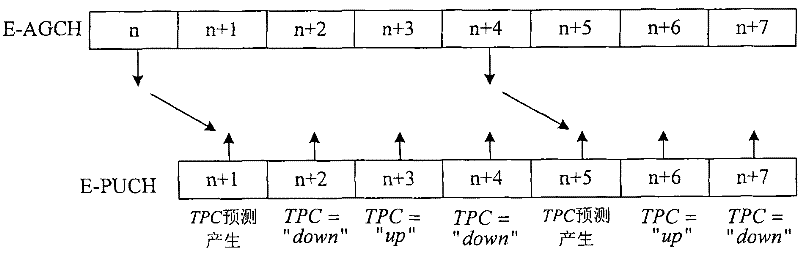

Method for controlling power of enhanced uplink absolute grant channel and subscriber terminal

InactiveCN101702824APower Control ConvergenceAccurate and efficient power controlPower managementSignal-to-noise ratio (imaging)Transmitted power

The invention provides a method for controlling the power of an enhanced uplink absolute grant channel (E-AGCH) and a subscriber terminal. The method comprises the following steps: demodulating a received E-AGCH and measuring the SNR (signal-to-noise ratio) of the E-AGCH according to the demodulation results; decoding the demodulated E-AGCH and acquiring the RDI (resource duration indicator) carried by the E-AGCH when the E-AGCH is correctly decoded; counting the number Th of the continuously received E-AGCHs until the current sub-frame when the RDI is equal to 0; averaging the Th continuous SNR measured values until the current sub-frame when Th is smaller than the preset threshold, and comparing the average value with the SNR target value to determine the TPC (transmit power control) command word; and predicting the SNR of the following sub-frame according to the Th continuous SNR measured values until the current sub-frame when Th is no smaller than the preset threshold, and comparing the SNR predicted value with the SNR target value to determine the TPC command word. Accordingly, the invention is capable of controlling the power of the E-AGCH more accurately and more effectively.

Owner:ST ERICSSON SEMICON BEIJING

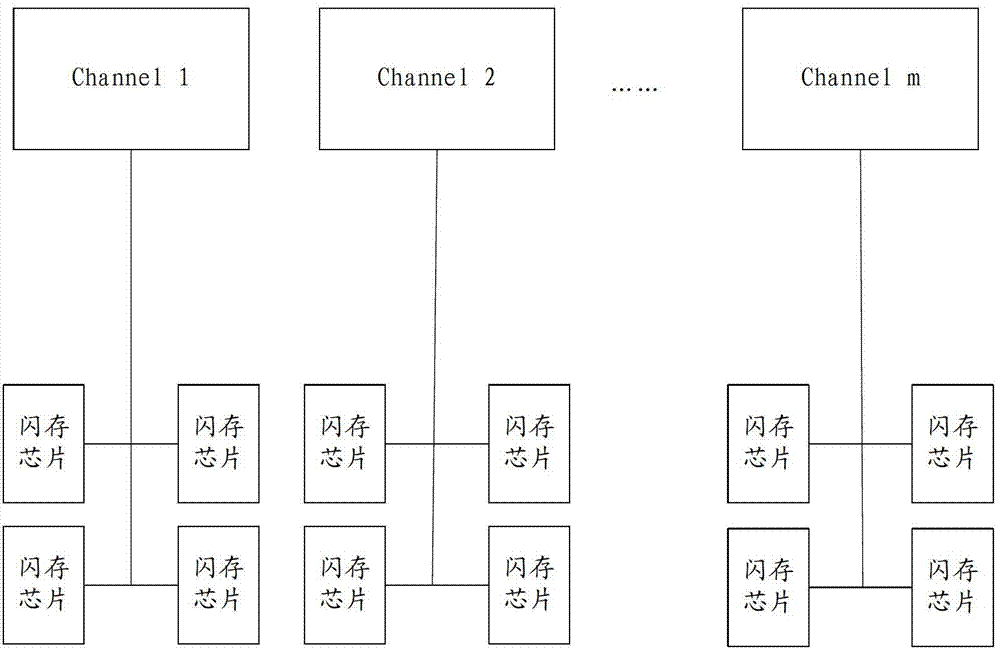

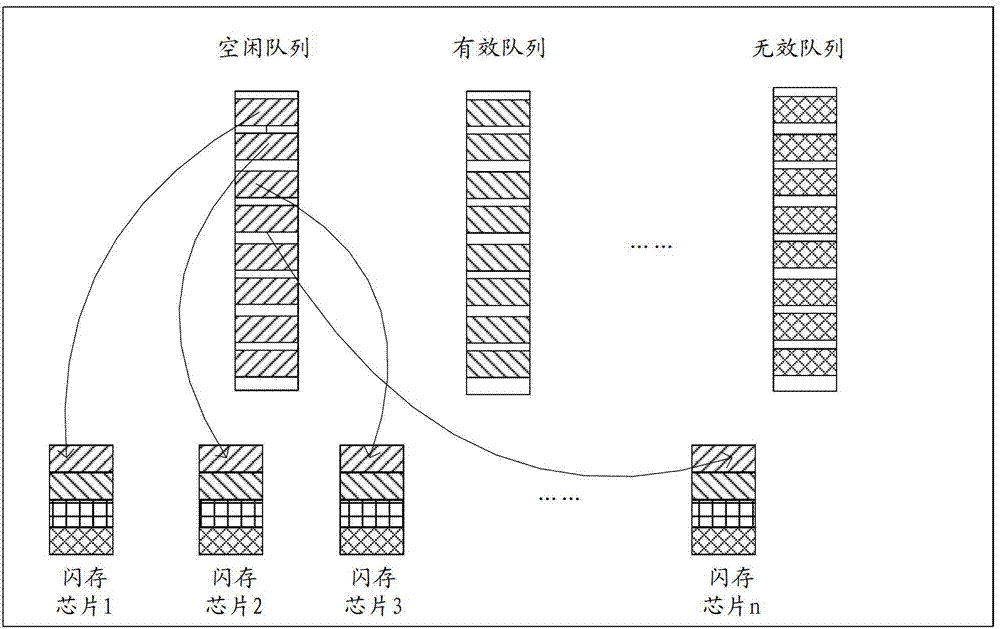

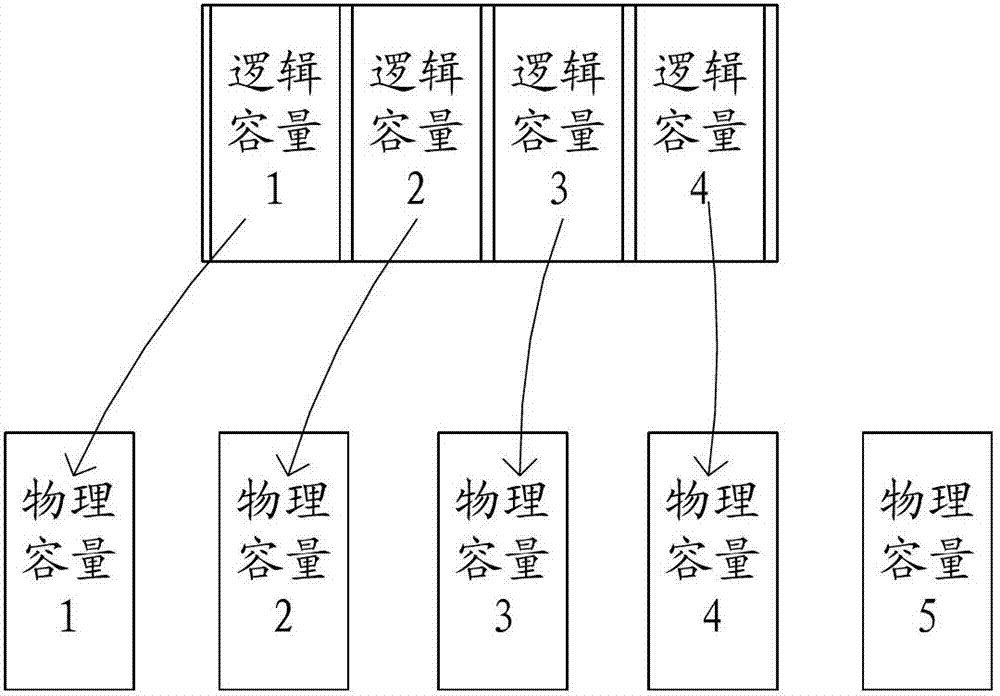

Solid state disk and data processing method and system thereof

ActiveCN103049216AImprove performanceImprove overall lifespanInput/output to record carriersMemory adressing/allocation/relocationChipsetSolid-state drive

The invention is applied to the technical field of storage, and provides a solid state disk and a data processing method and system thereof. The data processing method of the solid state disk comprises the following steps: dividing a plurality of flash memory channels into at least two flash memory channel groups, and each flash memory channel corresponds to a flash memory chipset; each flash memory channel group is respectively provided with a different logical physical management array and a different redundancy, the redundancy relates to an excessive part of a physical capacity of flash memory medium in the flash memory channel group according to a logical capacity of the flash memory channel group; storing high read and write performance and frequency requirements data to the flash memory chip corresponding to the high-redundancy flash memory channel group; storing low read and write performance and frequency requirements data to the flash memory chip corresponding to the low-redundancy flash memory channel group. Therefore, the solid state disk and the data processing method and system of the solid state disk enable the solid state disk to be capable of providing a higher capacity and having better performance and longer service life, and achieve the balance of the flash memory capacity, the performance and the service life.

Owner:RAMAXEL TECH SHENZHEN

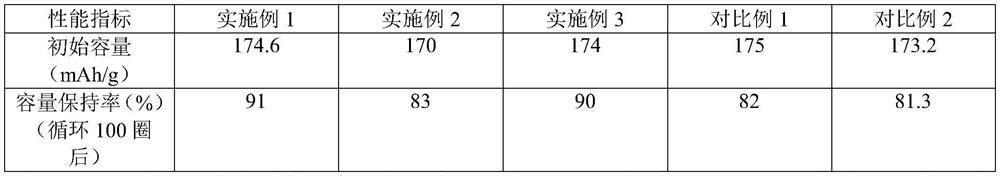

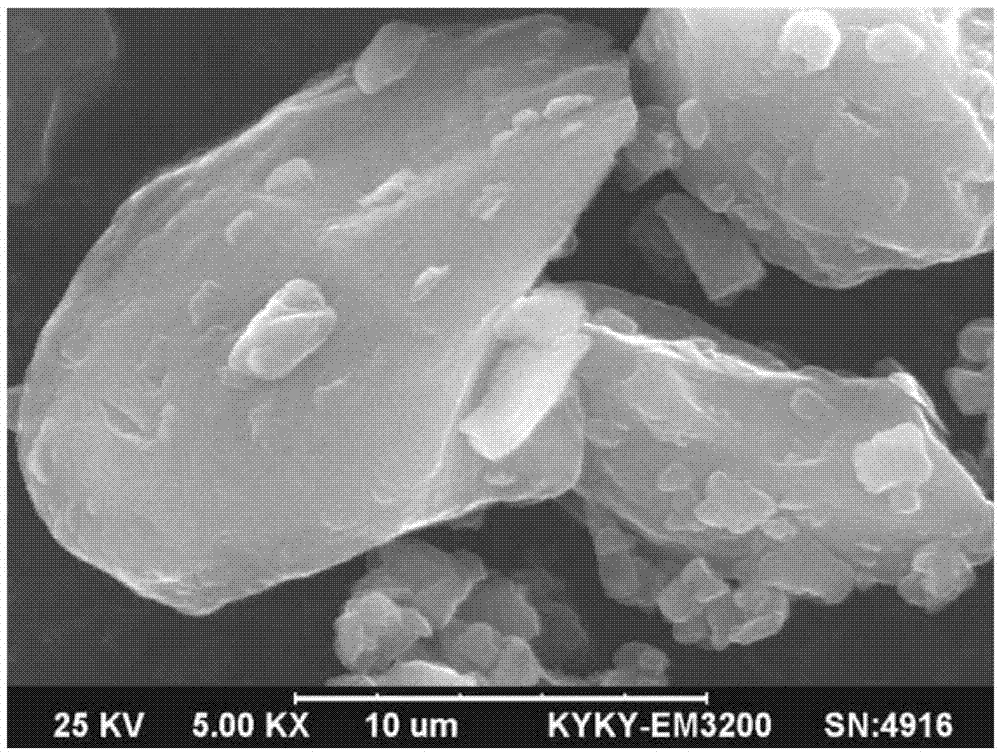

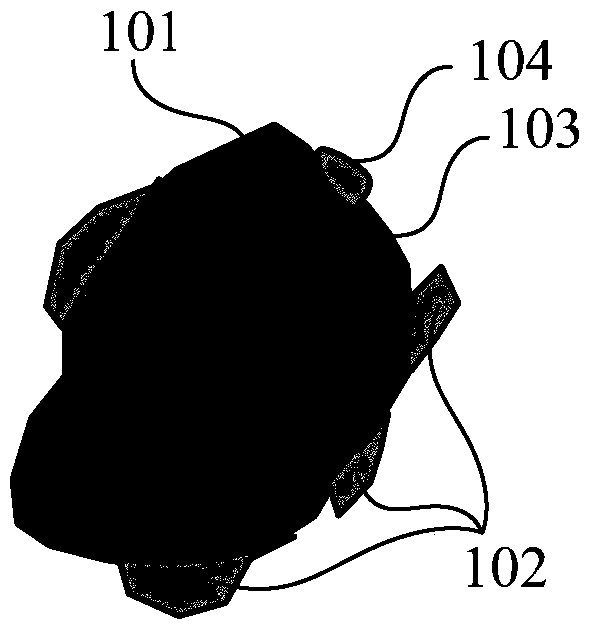

Spherical ternary composite positive electrode material of lithium ion battery and preparation method thereof

InactiveCN112366295ACapacity impactHigh lithium ion conductivitySecondary cellsPositive electrodesSolid state electrolyteGraphite

The invention relates to the technical field of lithium ion batteries, in particular to a spherical ternary composite positive electrode material of a lithium ion battery and a preparation method thereof. The spherical ternary composite positive electrode material of the lithium ion battery is prepared from the following components in percentage by mass: 80-90% of NCM powder balls, 5-10% of solidelectrolyte LLZO and the balance of graphene. On the basis of an NCM ternary material pure sample, a layer of graphene is coated again, so that the electronic conductivity of the material can be improved, the rate capability of the material is improved, and meanwhile, the flexible graphene can slow down irreversible reduction of capacity caused by mentioned deformation in the charging and discharging process of the NCM, and the cycle performance of the material is improved.

Owner:WANXIANG 123 CO LTD

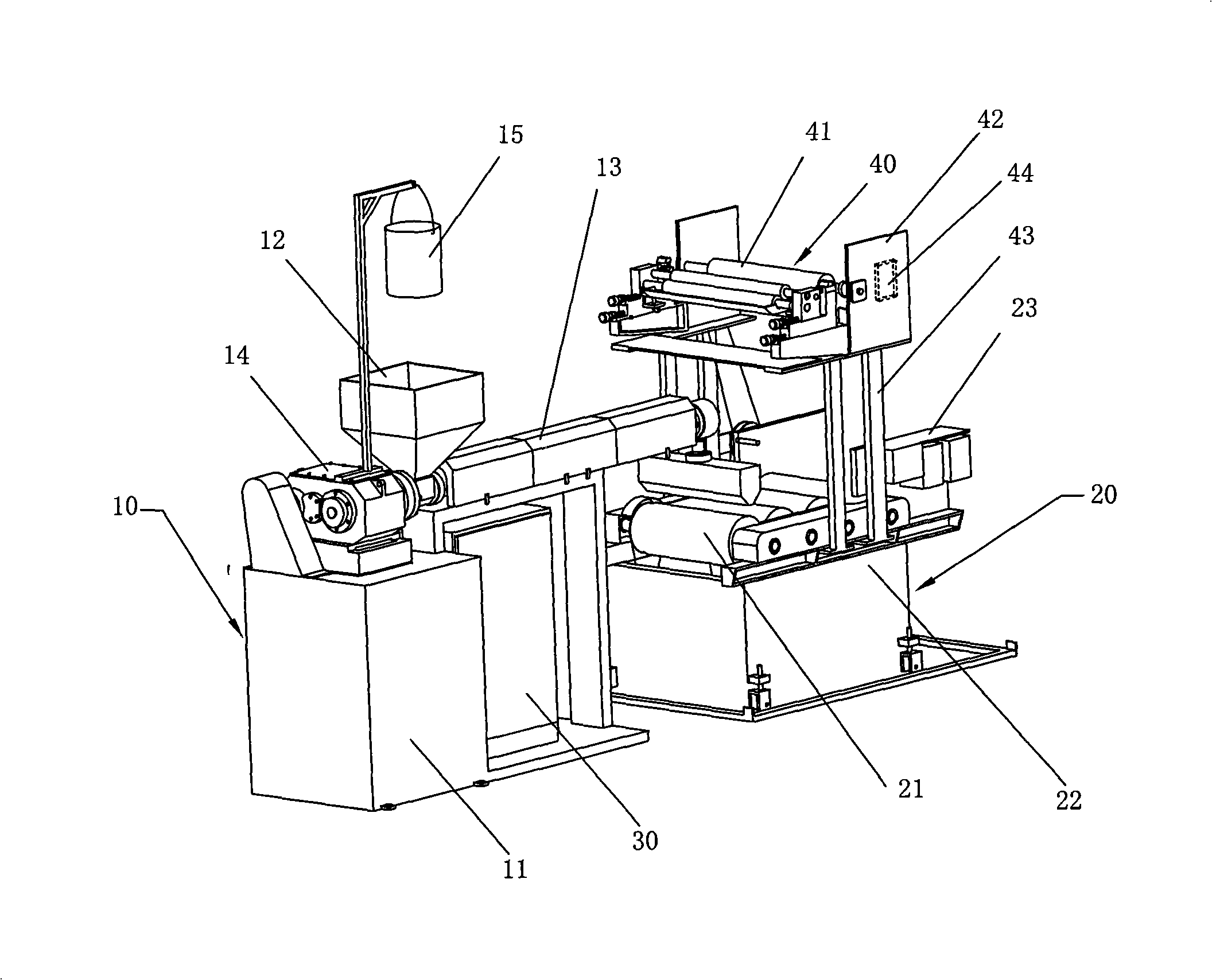

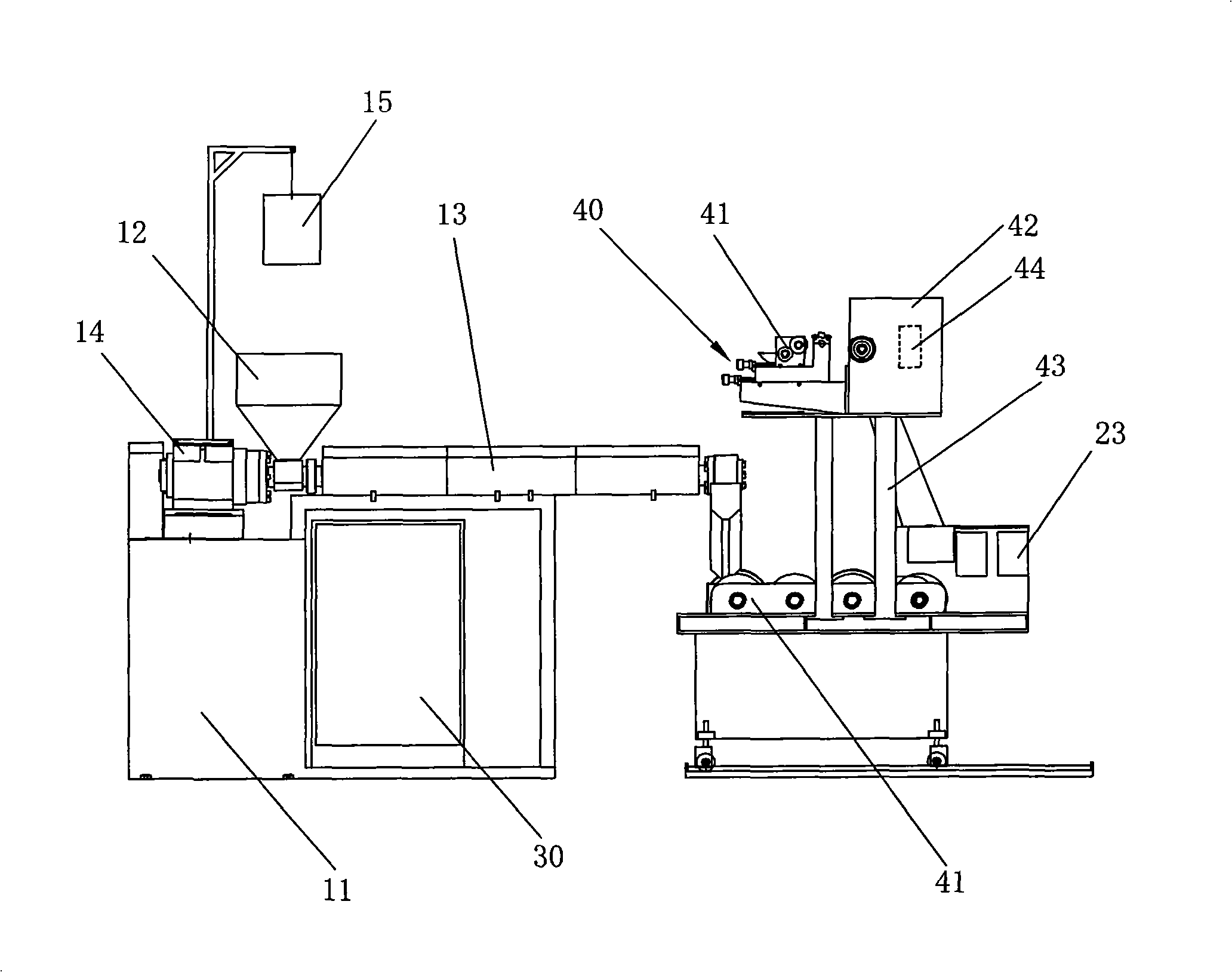

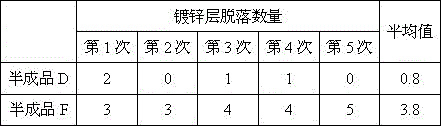

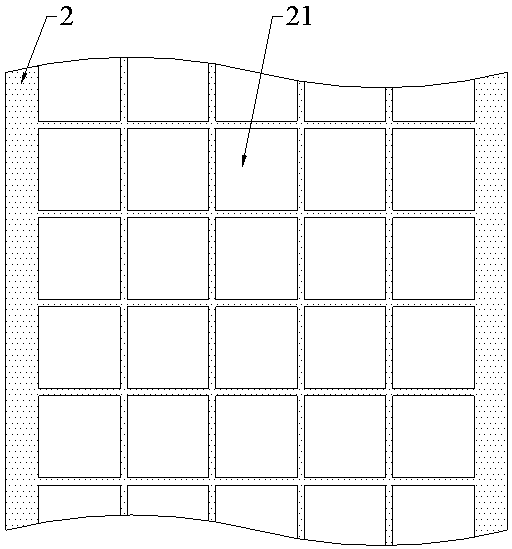

Film stretching machine

InactiveCN101537683AEasy to removeCapacity impactFlat articlesCoatingsMachine partsElectrical control

The invention relates to a film stretching machine, in particular to a film stretching machine with the function of integral printing. The film stretching machine comprises a main machine part, an auxiliary machine part and an electrical control part; the main machine part consists of a main frame, a feed hopper, a charging barrel screw and a speed reducer; the auxiliary machine part consists of a smooth roll transmission mechanism, a material receiving device and a slide rail base; the charging barrel screw is connected with the smooth roll transmission mechanism; the auxiliary machine part is provided with a printing device at the upper side; the printing device consists of a printing plate roll and a printing ink shelf which is used for containing the printing ink and fixed on the upper part of the auxiliary machine part through a bracket. The film stretching machine has the beneficial effects: (1) the stretching film produced by the stretching film machine can be used for printing contents such as trademarks of companies and the like according to the requirements of customers, and can be dismantled simply and conveniently; (2) the process of pattern printing can be completed simultaneously at a time when the stretching film is produced, which does not affect the productivity; and (3) various patterns can be printed according to the requirements of customers, and can be used as advertisement.

Owner:孙和永

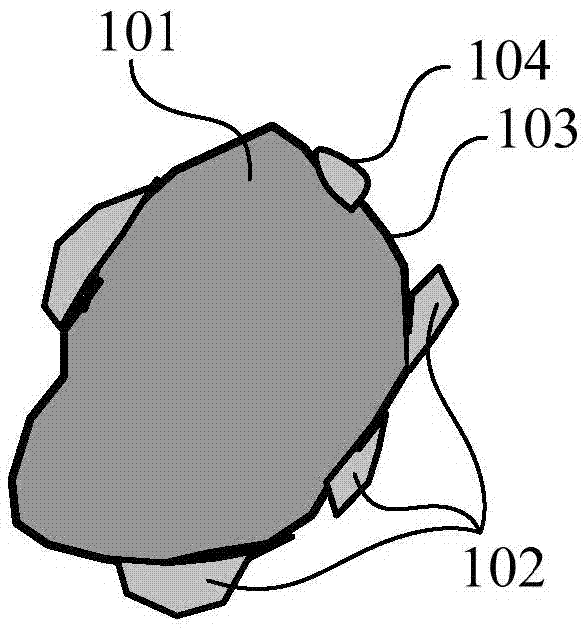

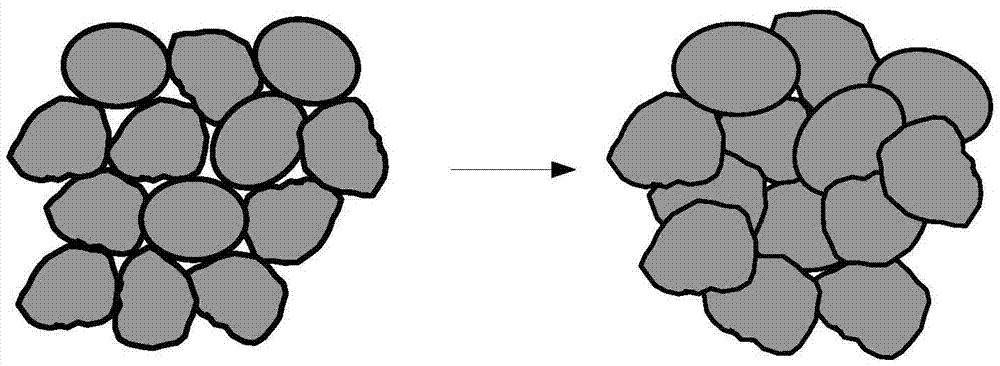

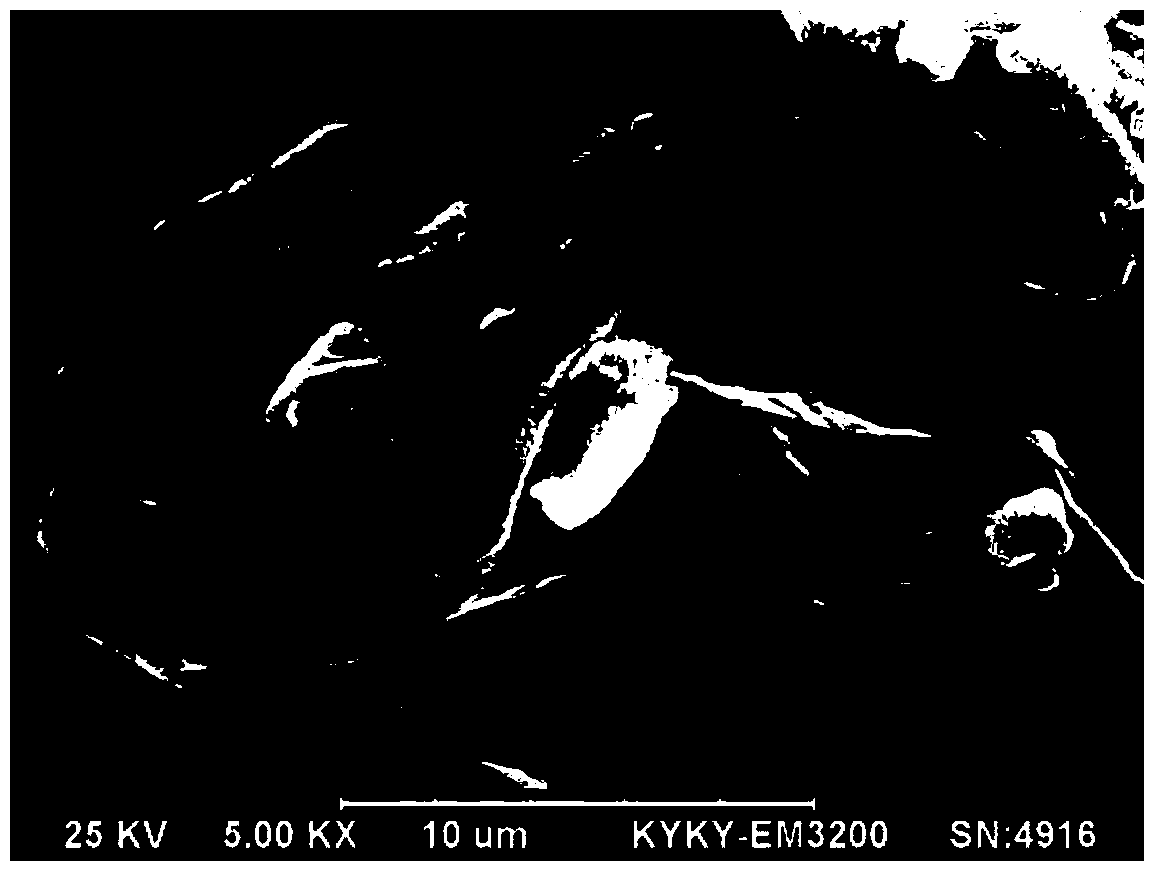

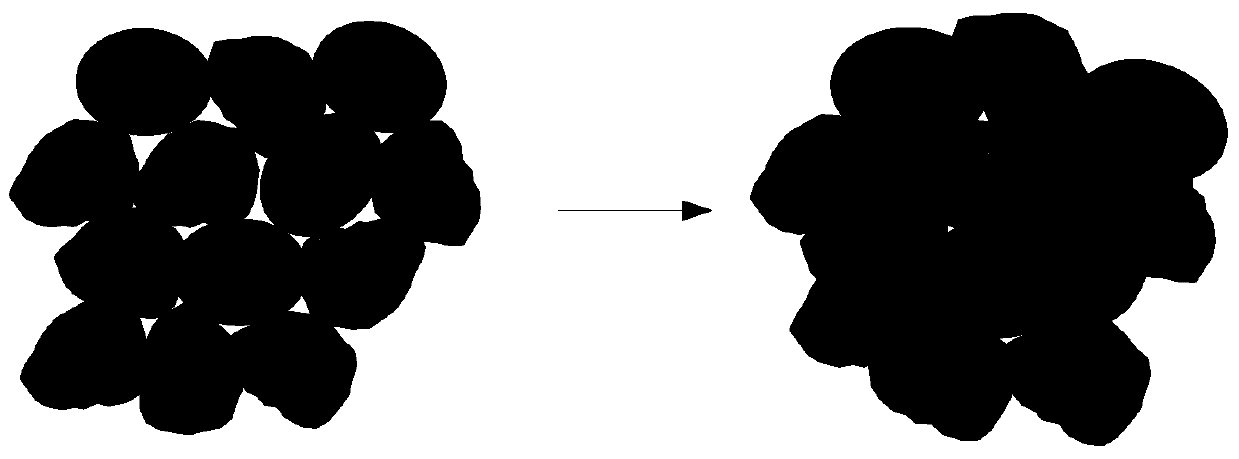

Battery anode material and preparation method thereof

The invention relates to a battery anode material, comprising first particles and first coating layers coated on the surfaces of the first particles, and second particles and second coating layers coated on the surfaces of the second particles; the second particles are adhered on the surfaces of the first particles; the average grain diameter of the first particles is 12-25 mu, the average grain diameter of the second particles is 2-6 mu, the first particles, the second particles, the first coating layers and the second coating layers are all graphite. The invention also relates a preparation method of the battery anode material. The battery anode material is adhered on the surfaces of the first particles through the second particles with relatively small average grain diameter, contact of the battery anode material and the first particles is increased; function of conductive agent is realized; compared with the conductive agent adding inactive substances, the capacity of the battery anode material of the invention is not influenced; relatively much gaps are kept among the first particles on account of spacing of the first particles, relatively much electrolyte retaining amount is kept, more diffusion channels are provided for the electrolyte.

Owner:深圳市金润能源材料有限公司

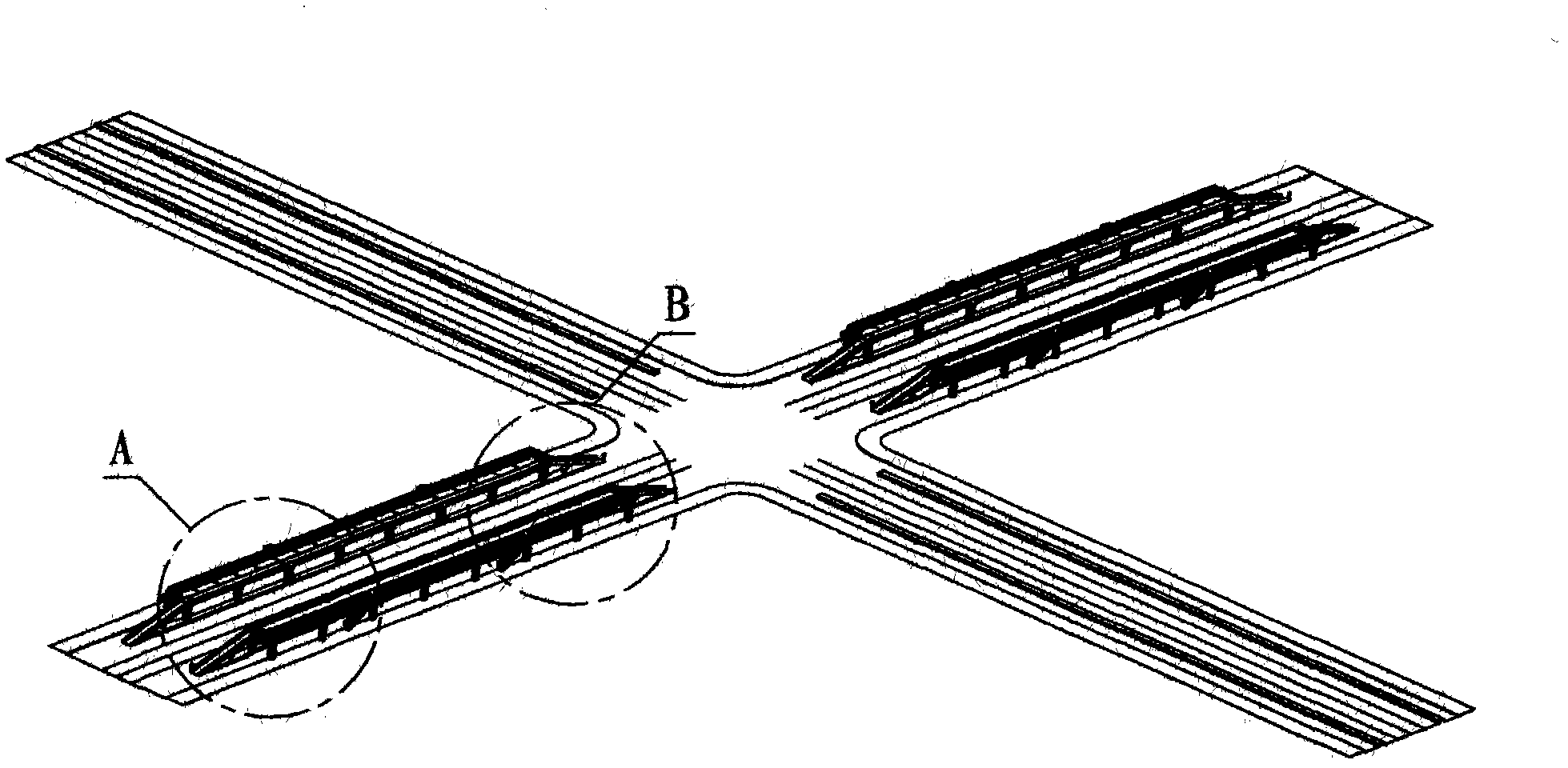

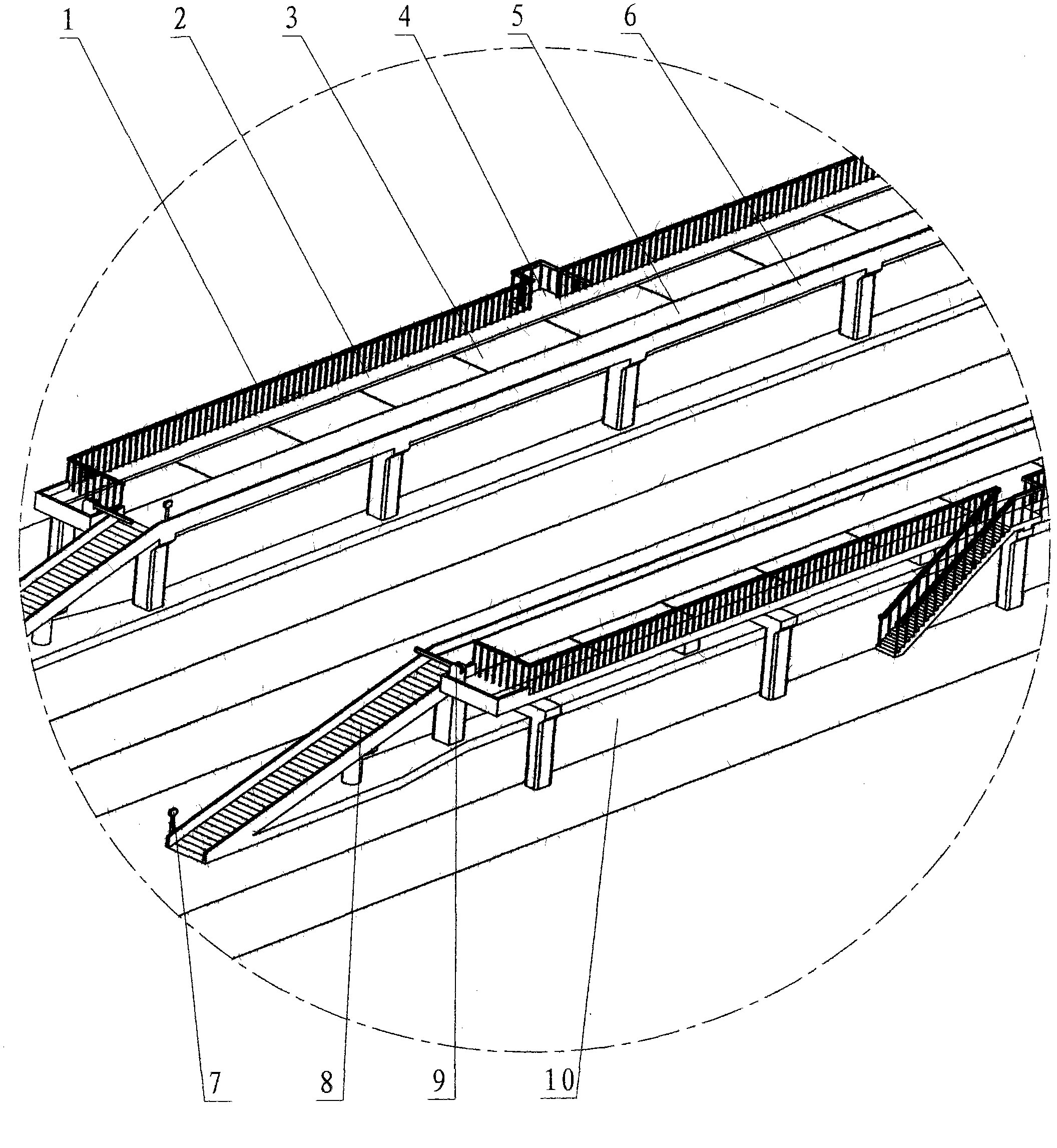

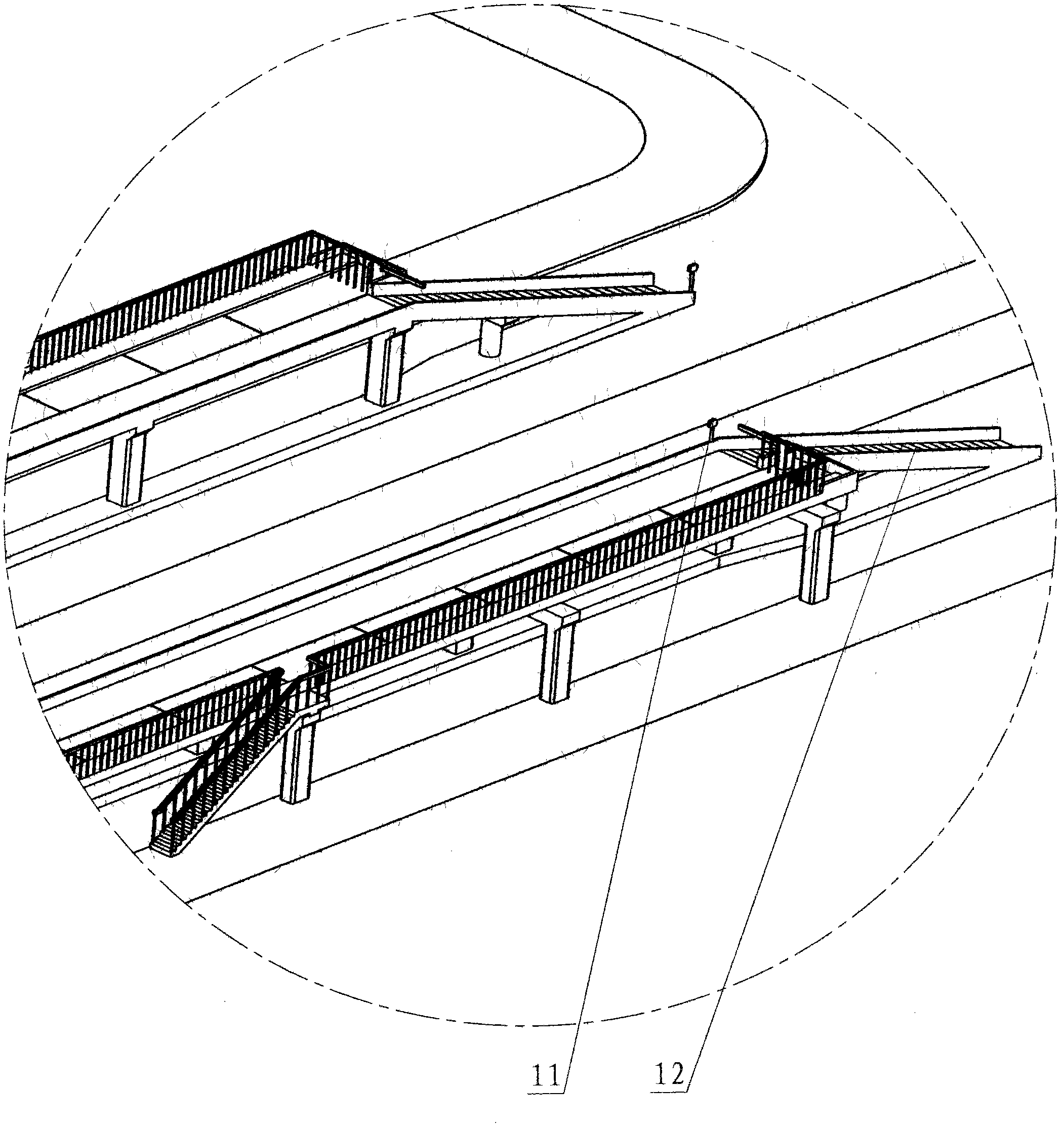

Overhead type parking lot beside urban road

The invention discloses an overhead type parking lot beside an urban road. The overhead type parking lot comprises an overhead building and a management facility, and is characterized by being erected on a non-motorized vehicle lane of a surface road; the net height of the overhead type parking lot is not less than a national standard permissive passage height of a non-motorized vehicle; the two ends of the overhead type parking lot are communicated with the surface road through an entrance slope bridge and an exit slope bridge; parking spaces are formed beside a passage of the overhead type parking lot side by side; pedestrian passages are formed beside the parking spaces and are communicated with surface sidewalks through stairs at certain intervals; curtain walls are arranged beside the lanes of the overhead type parking lot, the entrance slope bridge and the exit slope bridge; guardrails are arranged beside the pedestrian passages and the stairs; an entrance magnetic card scanner, a door control device and a parking space allowance indicator are arranged at the entrance of the overhead type parking lot; an exit magnetic card scanner and a door control device are arranged at the exit of the overhead type parking lot; and a speed reduction and skid resistance device is arranged on the lanes of the entrance slope bridge and the exit slope bridge.

Owner:张光裕

Production technology of stretching film

The invention relates to a stretching film, in particular to a production technology of stretching film provided with a printing procedure. The invention comprises a feeding procedure in which raw material solid LDPE granules are delivered to the sequential procedures through a feeding orifice, the sequential procedures comprise: 1) high temperature melting procedure; 2) die orifice extruding procedure; 3) pulling and cooling procedure; 4) printing procedure; and 5)rolling and packaging procedure. The invention has the beneficial effects that: (1) the stretching film produced by a stretching film machine can be used for printing company trademarks and other contents according to the requirements of customers and can be demounted conveniently; (2) when the stretching film is produced, the pattern printing procedure can be finished in one step at the same time, exerting no impact on the productivity; and (3) various patterns can be printed according to the requirements of customers and can be used in advertisements.

Owner:孙和永

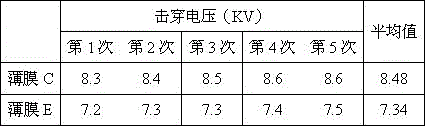

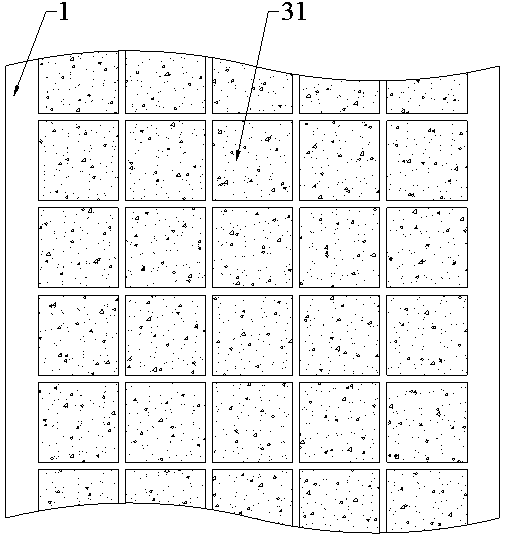

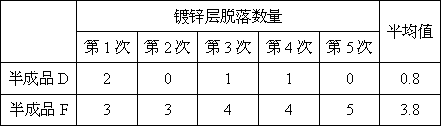

Production technology of metallized film

ActiveCN106298242AImprove self-healing abilityReduce the rate of erosionFixed capacitor electrodesThin/thick film capacitorSelf-healingErosion rate

The invention relates to a production technology of a metallized film. The production technology is characterized in that an insulation base film is performed with an insulation base film pretreatment technology, a primary evaporation technology, a galvanized layer surface treatment technology, a secondary evaporation technology and a silver plating layer surface treatment technology, so as to form the metallized film. The production technology has the advantages that the surface of the insulation base film is treated by hydrosulphuric acid solution, so that the large-scale oxidizing of metal zinc on the surface of the insulation base film is avoided, the bonding force between a zinc plating layer and the insulation base film is guaranteed, and the self-healing capability of the metallized film is improved; a metal layer on the surface of the insulation base film is of a zinc plating layer, zinc oxide layer, silver plating layer and silver oxide oxide film four-layer structure, so that the erosion rate of the metal layer is effectively reduced, the capacity of a capacitor is not decreased, and the breakthrough accident is avoided; the service life of the metal layer is obviously prolonged.

Owner:TONGLING CHAOYUE ELECTRON CO LTD

Pore-forming method for diaphragms of lithium ion batteries

ActiveCN102655229BNo restrictionsSimple and flexible adjustment methodCell electrodesPhysical chemistryPorous membrane

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a pore-forming method for diaphragms of lithium ion batteries. The method comprises the following steps: fully dissolving a pore-forming agent into a solvent so as to prepare a pore-forming agent solution; uniformly coating the pore-forming agent solution on the surface of a to-be-cold-pressed diaphragm, and carrying out baking on the diaphragm at a temperature lower than the sublimation or decomposition temperature of the pore-forming agent, so that a solvent of the pore-forming agent solution is volatilized, and the pore-forming agent is recrystallized in the diaphragm; and carrying out cold pressing on the diaphragm, and then carrying out baking on the diaphragm at a temperature higher than the sublimation or decomposition temperature of the pore-forming agent, so that the pore-forming agent recrystallized in the diaphragm is sublimated or decomposed, thereby obtaining a porous diaphragm. According to the invention, through regulating the viscosity of the pore-forming agent solution, a diaphragm with adjustably-distributed pores can be obtained, and the regulating method is simple and flexible, and wide in applicable range; and particularly, according to the invention, an efficient gradient pore distribution structure that more pores are distributed on the surface layer of the diaphragm and less pores are distributed on the inner layer of the diaphragm can be realized just through selecting an appropriate viscosity of the pore-forming agent solution..

Owner:NINGDE AMPEREX TECH +1

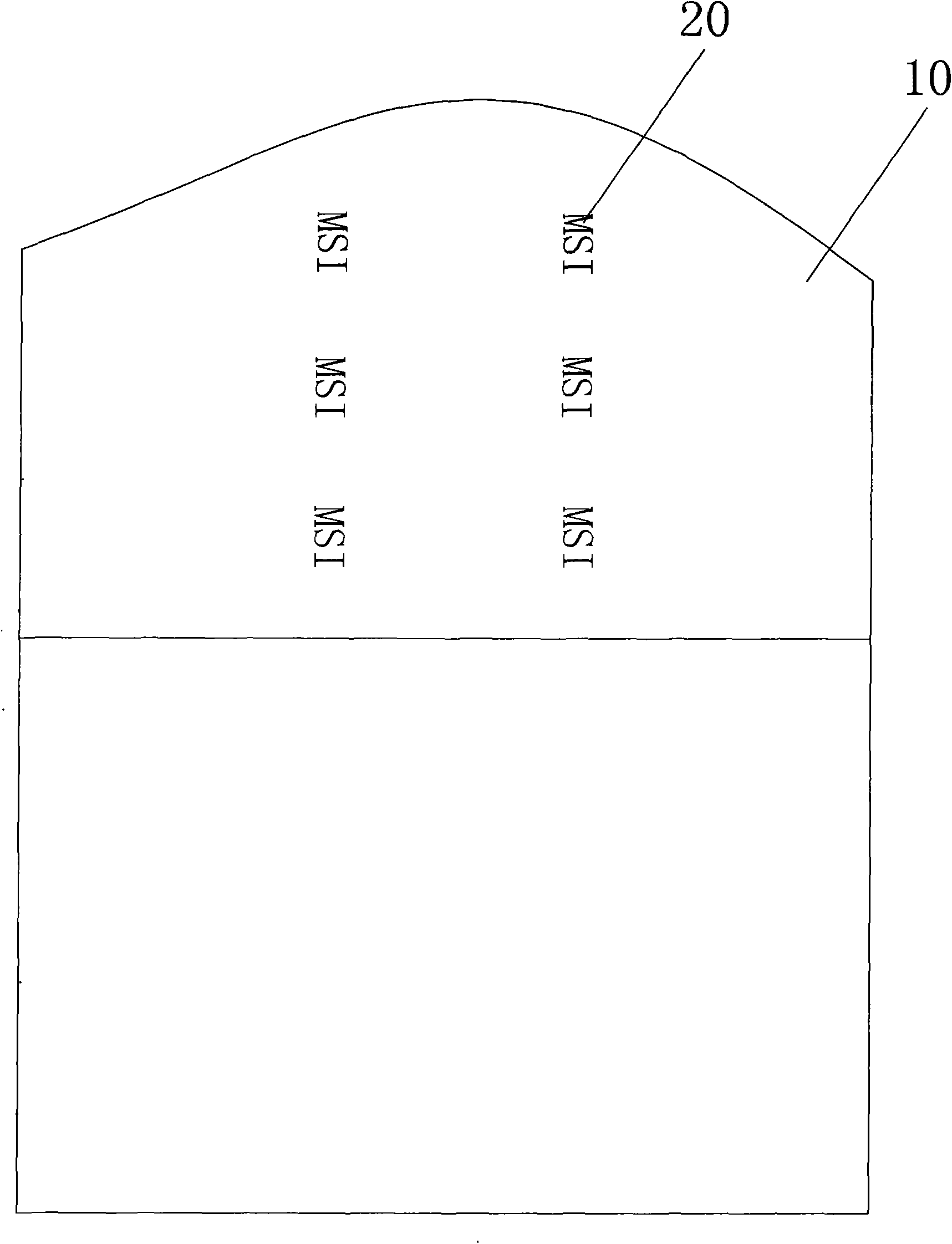

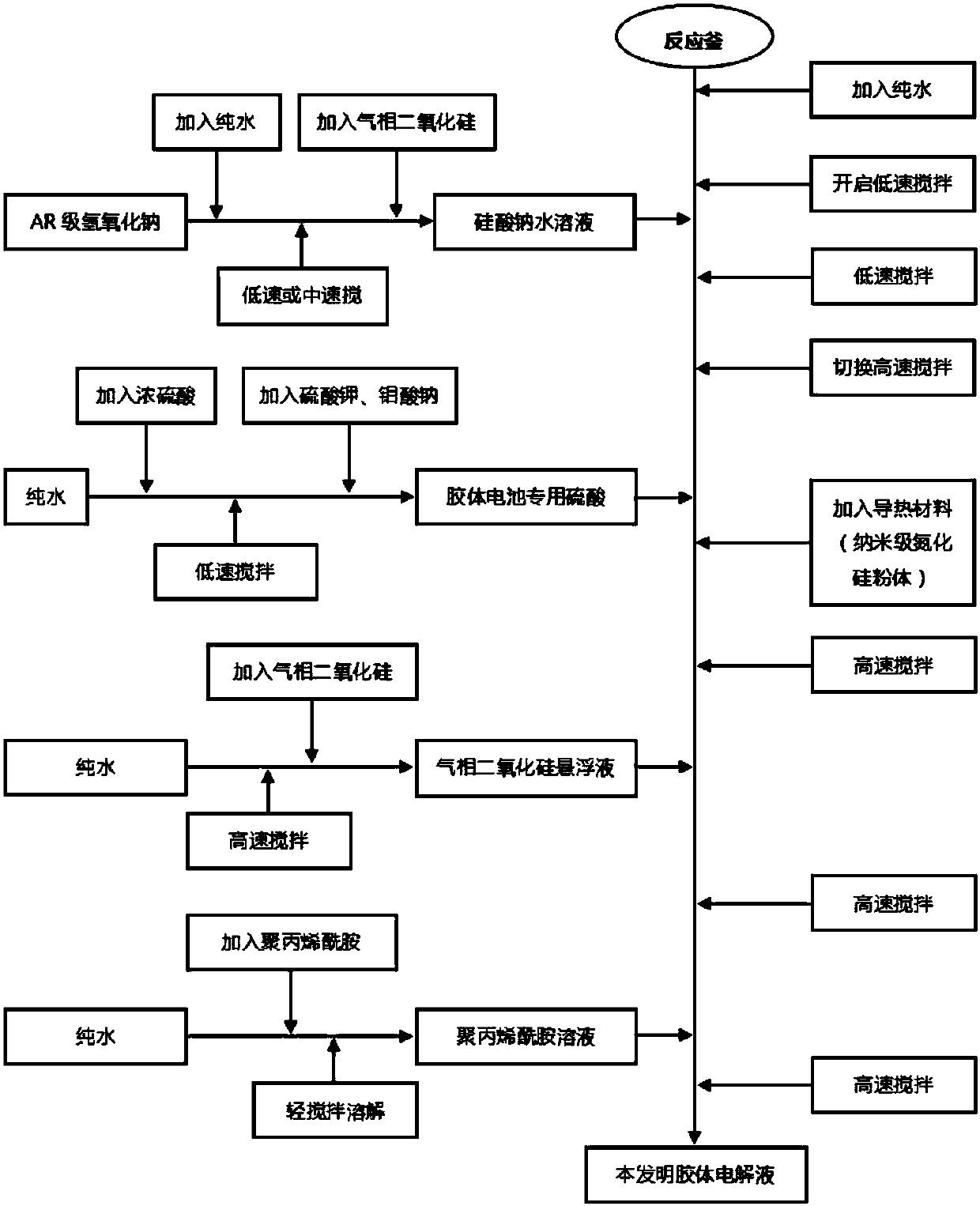

Container-formed gelled electrolyte and preparation method thereof

InactiveCN107785621AImprove cooling speedImprove the disadvantage of slow thermal diffusionLead-acid accumulatorsSodium molybdateColloid

The invention discloses a container-formed gelled electrolyte and a preparation method thereof. The container-formed gelled electrolyte is characterized by containing effective chemical components including, by weight percentage, 29.4%-36.6% of sulfuric acid, 3.5%-4.8% of silicon dioxide, 0.05%-0.50% of potassium sulfate, 0.8%-1.8% of sodium sulfate, 1.0%-6.0% of thermal conduction materials, 0.001%-0.020% of polyacrylamide, 0.005%-0.200% of sodium molybdate and 50.080%-65.244% of water. The container-formed gelled electrolyte has the advantages of integrating the physical and chemical properties of total-sodium silicate gelled electrolytes and total-fumed silica amorphous structured gels, and effectively solving the problem of low heat dissipating speed of gel batteries.

Owner:安徽艾克瑞德科技有限公司

Tunnel structure having power generation function

PendingCN108194120AStable power supplyReduce the impactMining devicesMachines/enginesEngineeringWater diversion

The invention discloses a tunnel structure having a power generation function, belongs to the field of tunnel structures and aims to lower impact on structures of tunnels themselves and reduce engineering quantity. The tunnel structure comprises a ventilation shaft of a vertical shaft or an inclined shaft and a hydraulic power generation system, the power generation system comprises a power generator room positioned adjacent to the bottom end of the ventilation shaft, power generation equipment mounted in the power generator room, a water diversion pipeline for supplying water to the power generation equipment and a tail water passage, the water diversion pipeline is laid in the ventilation shaft, extends to the power generator room through the ventilation shaft from the outside of a tunnel and is connected with the power generation equipment. A pressure pipeline is paved in the ventilation shaft, so that stability of power generation is ensured; existing structure of the tunnel is utilized, so that additional digging of a ditch for paving the pressure pipeline is not needed, a whole power generation system is enabled to utilize the existing structure of the tunnel as much as possibly, impact of setup of the power generation system on the tunnel structure is lowered to greatest extent, construction difficulty is lowered, and workload is reduced.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

A metallized film production process

ActiveCN106298242BImprove self-healing abilityReduce the rate of erosionThin/thick film capacitorFixed capacitor electrodesSelf-healingErosion rate

Owner:TONGLING CHAOYUE ELECTRON CO LTD

Tire pads that prevent the vehicle from backing up when climbing a hill

The invention discloses a tire cushion for preventing a vehicle from reversing when the vehicle climbs a slope. The tire cushion for preventing the vehicle from reversing when the vehicle climbs the slope is a device which prevents the vehicle from reversing when the vehicle climbs the slope in a mode similar to a mode of manually padding a vehicle tire with stone. The tire cushion for preventing the vehicle from reversing when the vehicle climbs the slope is arranged on the vehicle, uses actions of gravity, can continuously work, prevents the vehicle from reversing, and further achieves a safe guarantee function to a certain extent especially under the abnormal conditions that a brake fails, a half shaft is fractured and the like.

Owner:HEBEI ZONGSHEN GEMEILI AGRI MACHINERY MFG CO LTD

Tire cushion for preventing vehicle from reversing when vehicle climbs slope

The invention discloses a tire cushion for preventing a vehicle from reversing when the vehicle climbs a slope. The tire cushion for preventing the vehicle from reversing when the vehicle climbs the slope is a device which prevents the vehicle from reversing when the vehicle climbs the slope in a mode similar to a mode of manually padding a vehicle tire with stone. The tire cushion for preventing the vehicle from reversing when the vehicle climbs the slope is arranged on the vehicle, uses actions of gravity, can continuously work, prevents the vehicle from reversing, and further achieves a safe guarantee function to a certain extent especially under the abnormal conditions that a brake fails, a half shaft is fractured and the like.

Owner:HEBEI ZONGSHEN GEMEILI AGRI MACHINERY MFG CO LTD

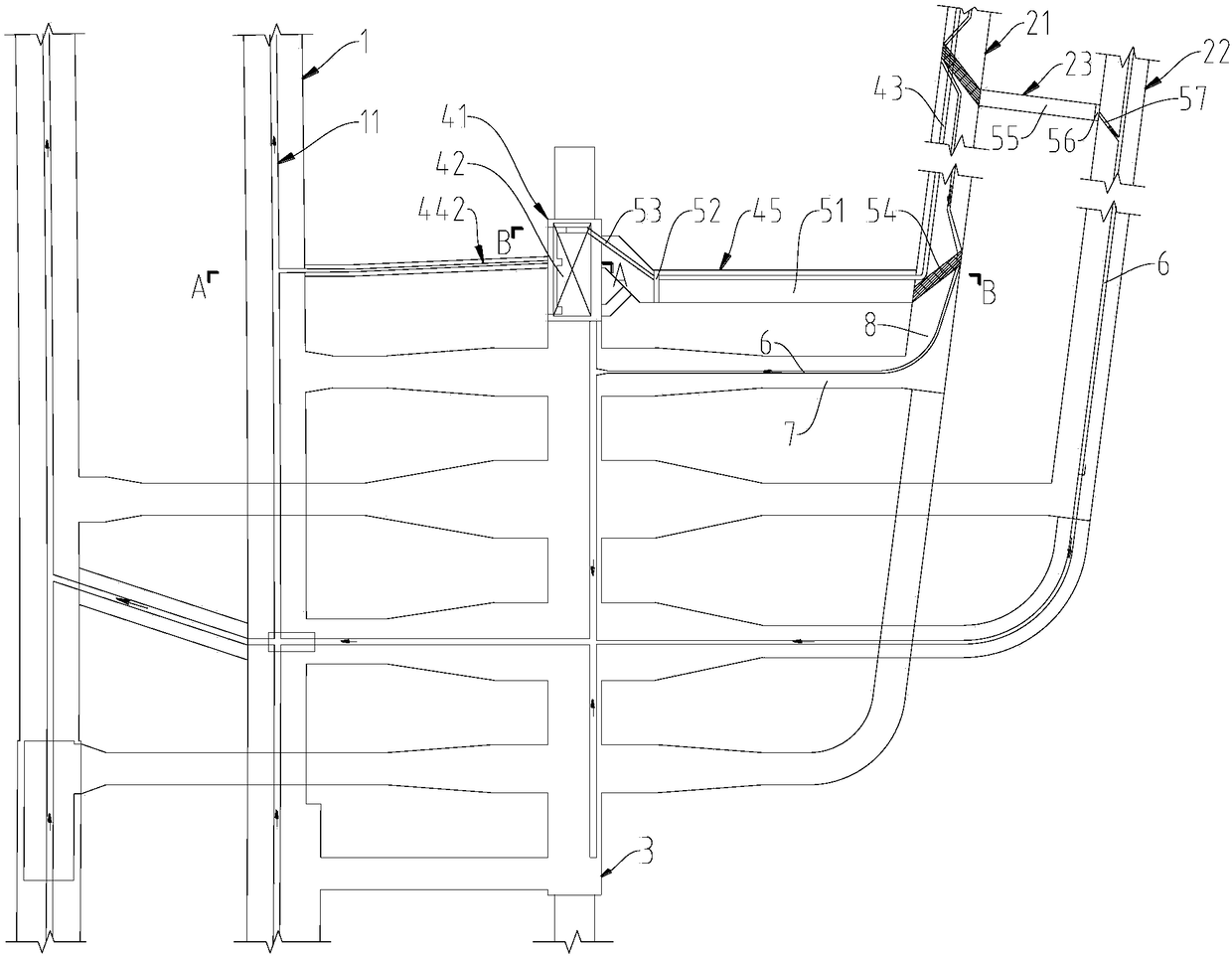

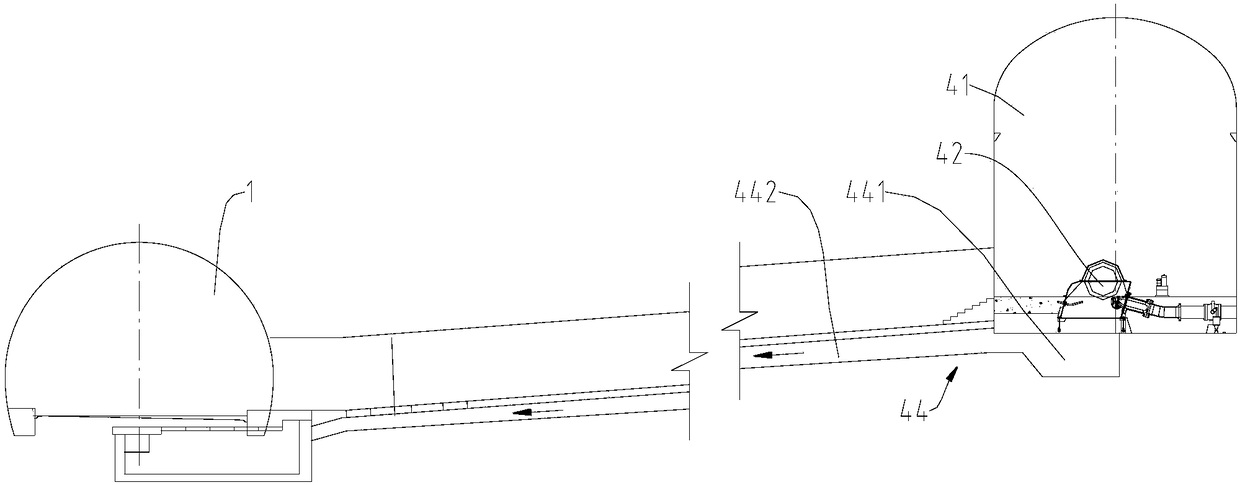

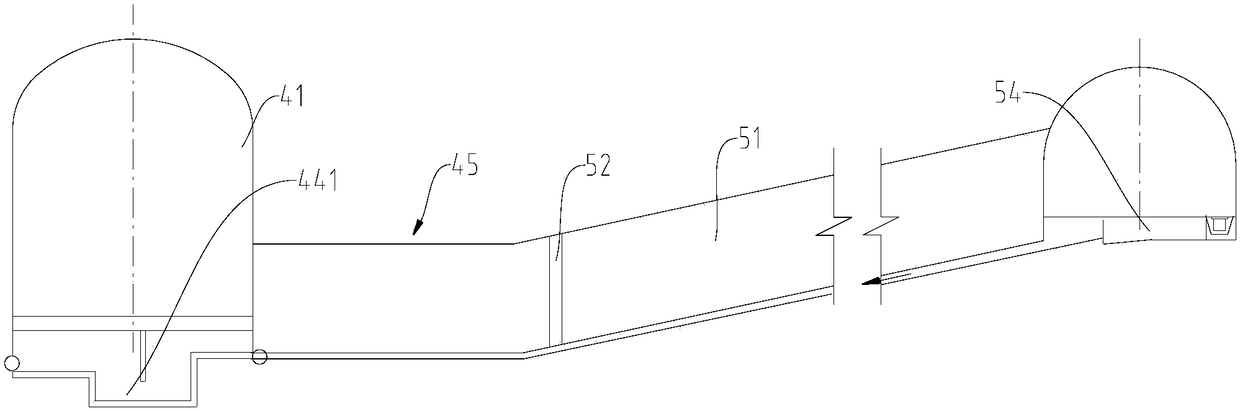

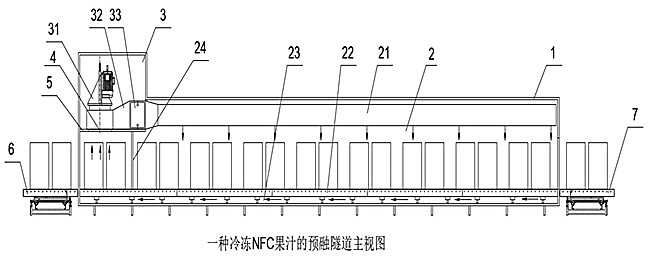

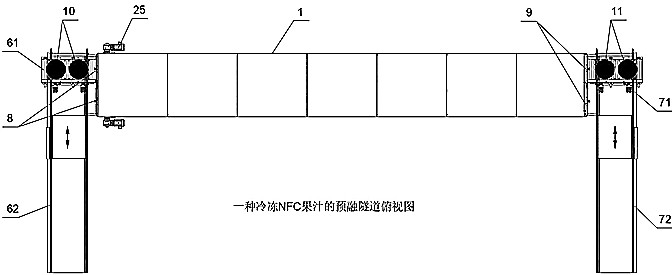

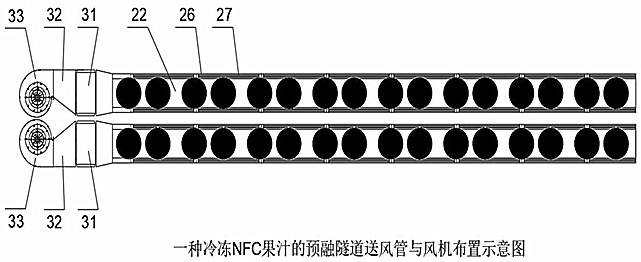

Frozen NFC fruit juice pre-melting tunnel

PendingCN114246278AReduce pre-thawing and thawing timeImprove qualityFood thermal treatmentFood preservationFruit juiceMechanical engineering

The invention relates to the field of fruit juice product unfreezing, in particular to a frozen NFC fruit juice pre-melting tunnel. The device comprises an enclosure structure, a pre-melting chamber, a fan chamber, a partition plate, a fan return air inlet, a feeding device, a discharging device, a feeding door and a discharging door. Fruit juice is fed into the pre-melting chamber through a feeding trolley on feeding equipment, and then a centrifugal fan in a fan chamber feeds hot air with the temperature not exceeding 90 DEG C into the pre-melting chamber along an air supply pipeline. Hot air exchanges heat with frozen juice, and the juice is melted with the edge of the juice barrel. And the hot air returns to the steam heat exchanger of the fan chamber from the air return pipeline for heat exchange, and then is circulated into the pre-melting chamber. And the fruit juice is conveyed along the tunnel roller conveyor and is finally carried away by the discharging equipment.

Owner:广州中臣碧阳科技集团有限公司

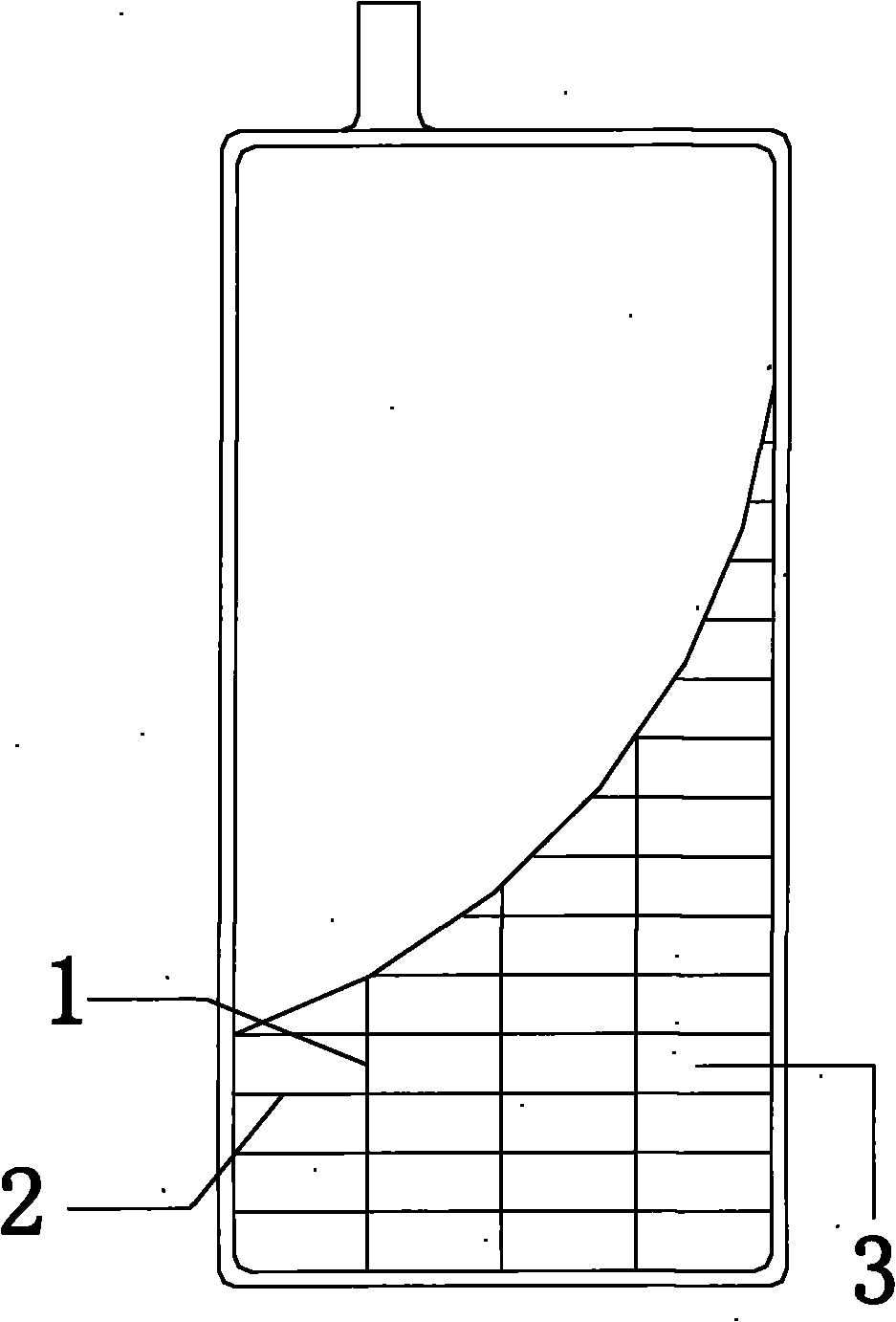

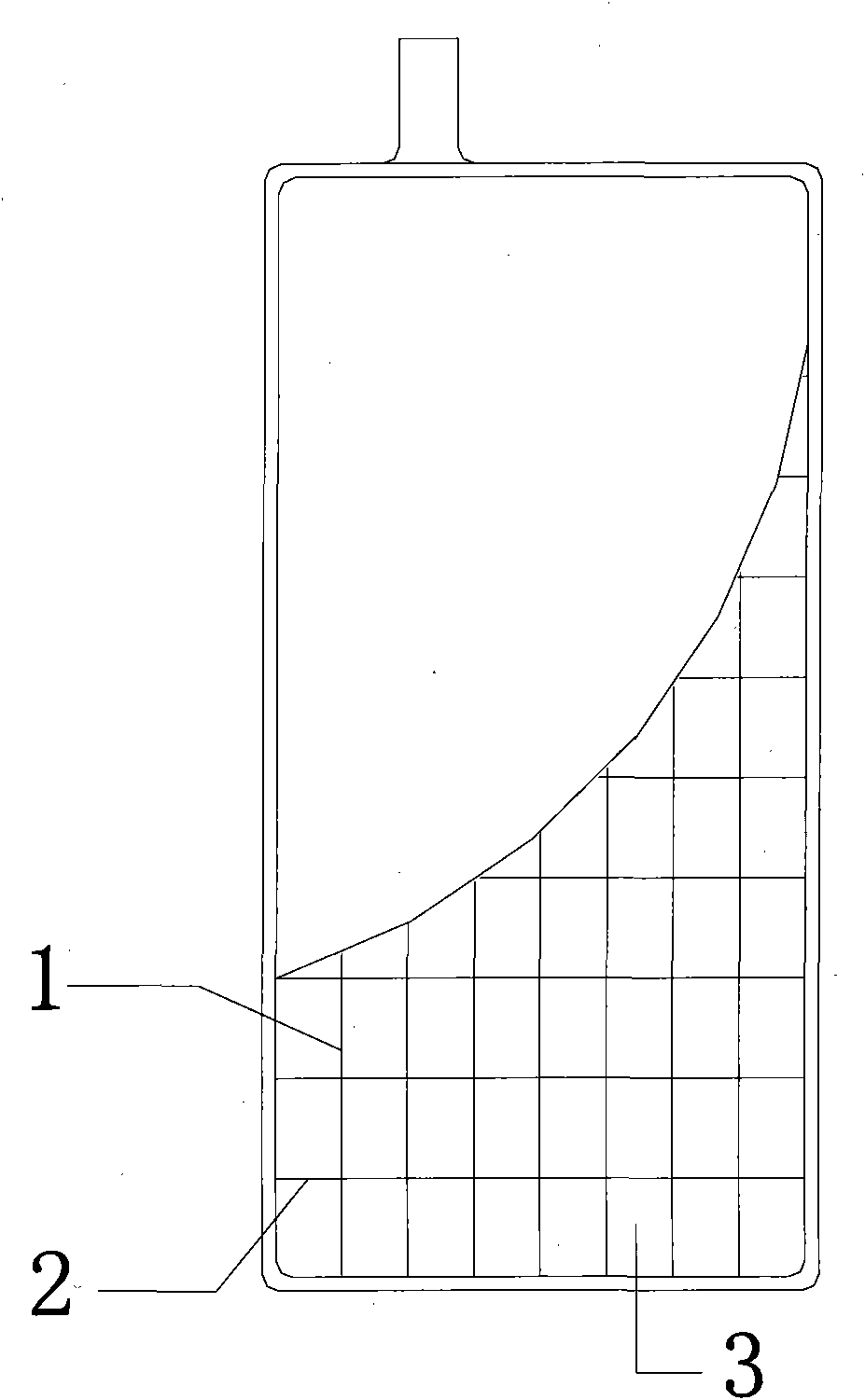

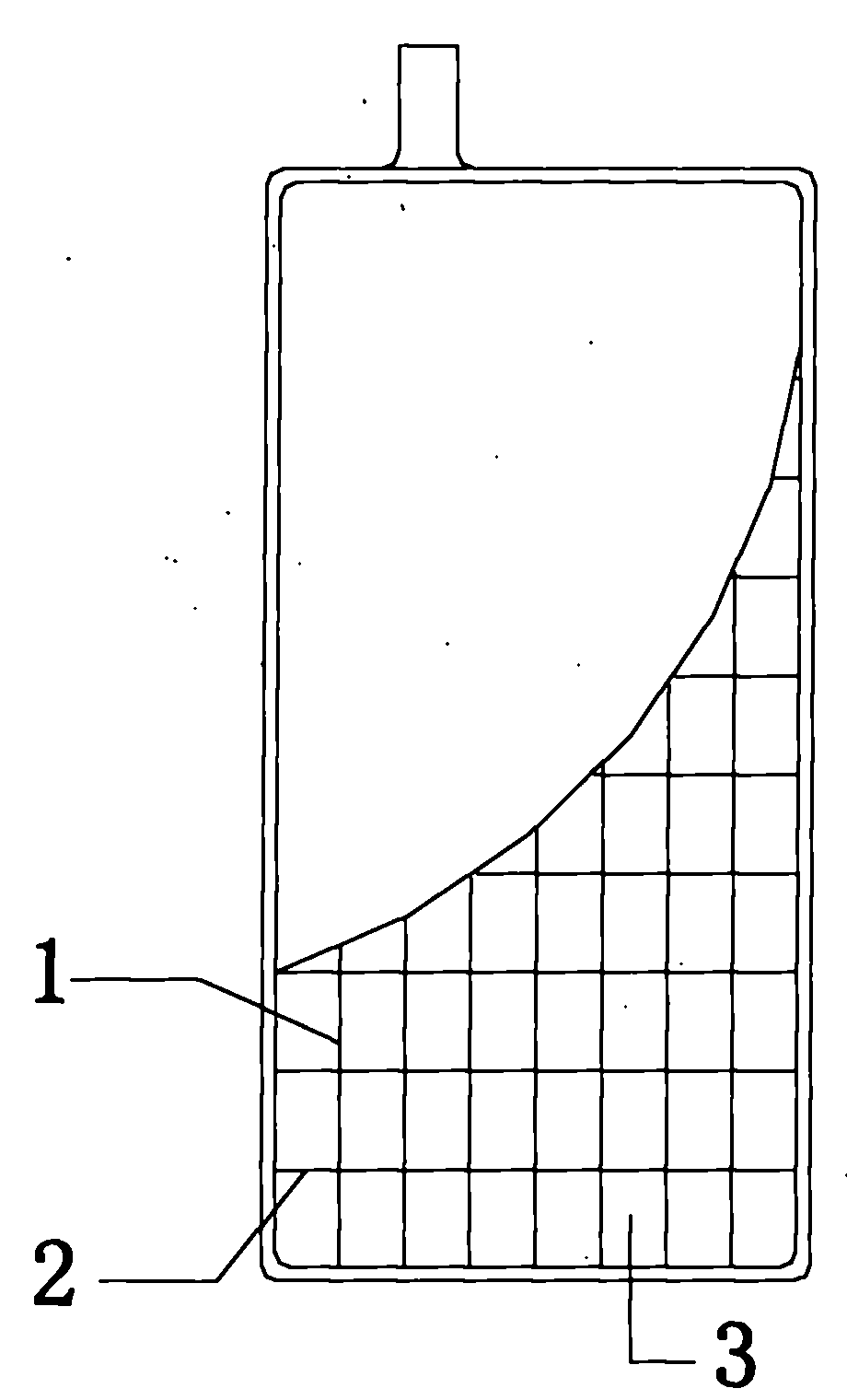

Pole plate of lead-acid battery

InactiveCN101807693AImprove conductivityIncrease the number ofLead-acid accumulator electrodesEngineeringStructural distribution

The invention discloses a pole plate of a lead-acid battery. The pole plate of the lead-acid battery comprises a plurality of vertical ribs which are arranged longitudinally and a plurality of horizontal ribs which are arranged transversely, wherein the vertical ribs and the horizontal ribs are in a cross distribution to form a rectangular mesh which has a longitudinal length greater than a transverse length. Under the condition of ensuring invariable size of the mesh in a pole plate grid structure, the pole plate of the lead-acid battery regulates the structural distribution of the vertical ribs and the transverse ribs, and increases the number of the vertical ribs and decreases the number of the transverse ribs to form a structure with more vertical ribs and less transverse ribs, so that the transmission of current is more rational and smooth, the electric conductivity of the pole plate is improved; the cost is equivalent to the original cost; even phenomena, such as ruptures, severe corrosion and the like, of individual vertical ribs do not influence the capacity of the whole battery; the performance is improved; and the service life is prolonged.

Owner:ZHEJIANG ZHENLONG BATTERY

Battery negative electrode material and preparation method thereof

The invention relates to a battery anode material, comprising first particles and first coating layers coated on the surfaces of the first particles, and second particles and second coating layers coated on the surfaces of the second particles; the second particles are adhered on the surfaces of the first particles; the average grain diameter of the first particles is 12-25 mu, the average grain diameter of the second particles is 2-6 mu, the first particles, the second particles, the first coating layers and the second coating layers are all graphite. The invention also relates a preparation method of the battery anode material. The battery anode material is adhered on the surfaces of the first particles through the second particles with relatively small average grain diameter, contact of the battery anode material and the first particles is increased; function of conductive agent is realized; compared with the conductive agent adding inactive substances, the capacity of the battery anode material of the invention is not influenced; relatively much gaps are kept among the first particles on account of spacing of the first particles, relatively much electrolyte retaining amount is kept, more diffusion channels are provided for the electrolyte.

Owner:深圳市金润能源材料有限公司

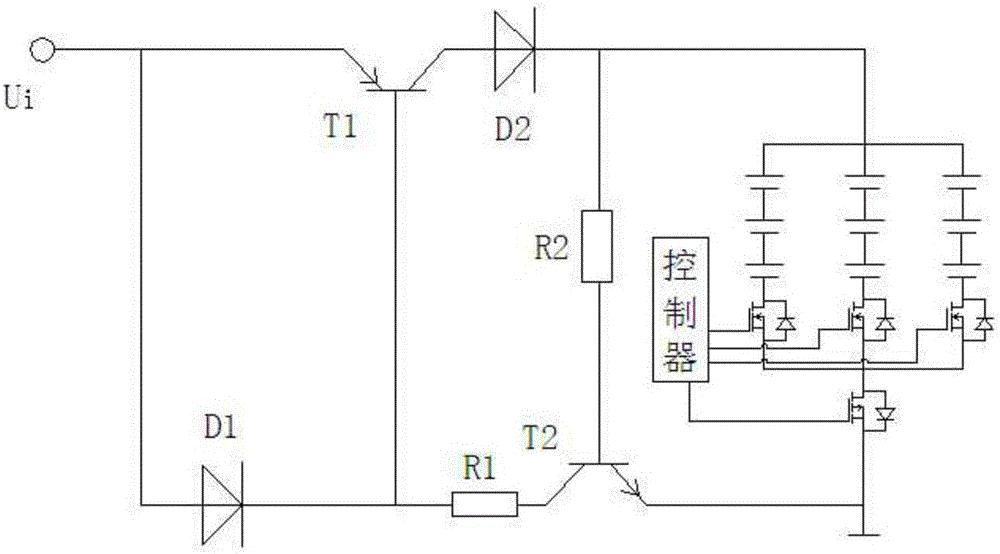

Storage battery circuit structure

InactiveCN106685013ASimple structureCapacity impactElectric powerArrangements for several simultaneous batteriesEngineeringBattery pack

The invention discloses a storage battery circuit structure. The storage battery circuit structure comprises a battery pack and a charging circuit connected onto the battery pack and is characterized in that a charging protection circuit is connected onto the battery pack, wherein the charging protection circuit comprises a first triode, a first diode and a second diode, an emitter of the first triode and a positive electrode of the first diode are both connected onto a charging port, a negative electrode of the first diode is connected with a base of the first triode, a collector of the first triode is connected with a positive electrode of the second diode, a negative electrode of the second diode is connected with a positive electrode of the battery pack, the charging protection circuit comprises a second triode, a collector of the second triode is connected with the negative electrode of the first diode through a first resistor, a base of the second triode is connected with the negative electrode of the second diode through a second resistor, and an emitter of the second diode is connected with a negative electrode of the battery pack. The circuit structure has a charging protection function and is simple.

Owner:四川升能泰科技有限公司

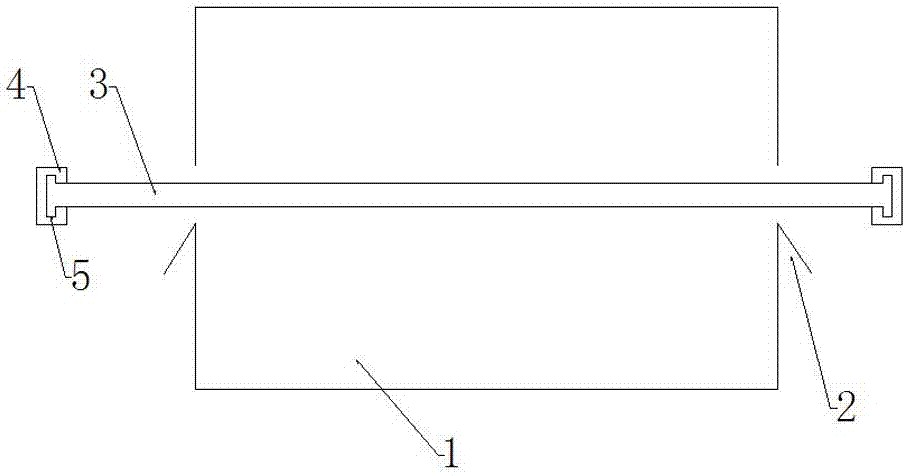

Square storage device for paperboards

InactiveCN107444744AUnbiased placementReduce frictionInternal fittingsSquare cross sectionPaperboard

The invention discloses a square cardboard storage device, which is characterized in that it includes a main body and a partition assembly; the main body adopts a columnar structure with a square cross section; movable plates are arranged on a group of opposite surfaces of the main body; The plate is vertically arranged, and its height is the same as that of the main body; the movable plate is turned over on one side to form a gap on the main body; the partition plate assembly includes a partition plate and two storage plates; the storage plate is provided with convex groove; both ends of the partition are matched with the groove; the partition is used to connect the two notches on the main body. The beneficial effects achieved by the present invention: the device can greatly reduce the frictional force by inserting the partition between the cardboards, and can make the cardboards be placed in the main body without deviation; the partition can be drawn out through the storage board, and the Capacity has no effect.

Owner:窦玉莲

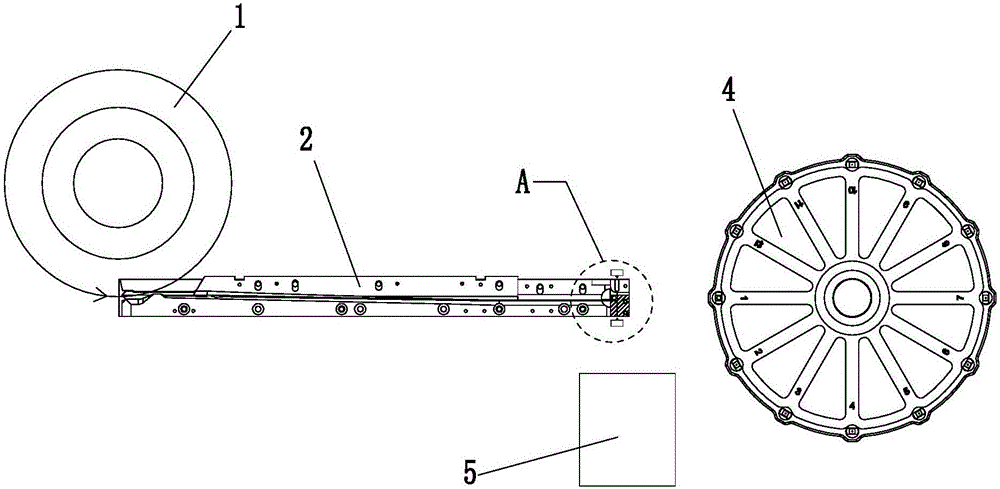

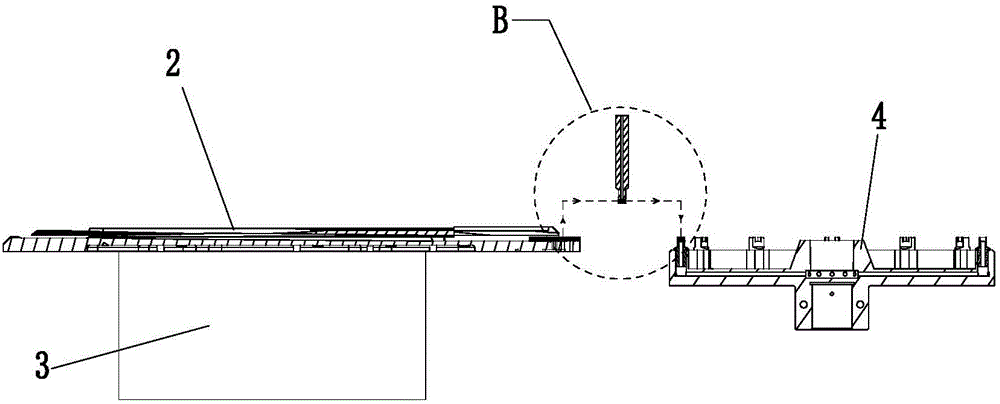

Stuck material removal device for directly-access type SMD track and stuck material removal method of stuck material removal device

PendingCN106829400AReduce equipment costsImprove equipment reliabilityConveyorsControl devices for conveyorsManipulatorEngineering

The invention discloses a stuck material removal device and method for a directly-access type SMD track. The device comprises a movable sliding block and a spring. An arc-shaped groove is formed in one side of the tail end of a track body. The movable sliding block is slidably arranged in the arc-shaped groove and extends out under the elastic function of the spring. By the adoption of the stuck material removal method and the directly-access type SMD track with the stuck material removal device adopting the technical scheme, an SMD material can be directly supplied to a station rotary disc without a mechanical hand, the equipment cost can be saved, the reliability of the equipment is improved, and importantly, the yield can be increased; the yield of common SMD equipment is 40 K / hour, by the adoption of the directly-access type SMD track, in cooperation with the station rotary disc with more stations, the yield can be easily increased to 60 K / hour above; and no halt, no pause and no error report exist in the whole process, so that the stability of the whole machine is improved greatly, and it is guaranteed that the yield is not influenced by a stuck material.

Owner:深圳市辉睿达科技有限公司

Method for controlling power of enhanced uplink absolute grant channel and subscriber terminal

InactiveCN101702824BPower Control ConvergenceAccurate and efficient power controlPower managementSignal-to-noise ratio (imaging)Transmitted power

The invention provides a method for controlling the power of an enhanced uplink absolute grant channel (E-AGCH) and a subscriber terminal. The method comprises the following steps: demodulating a received E-AGCH and measuring the SNR (signal-to-noise ratio) of the E-AGCH according to the demodulation results; decoding the demodulated E-AGCH and acquiring the RDI (resource duration indicator) carried by the E-AGCH when the E-AGCH is correctly decoded; counting the number Th of the continuously received E-AGCHs until the current sub-frame when the RDI is equal to 0; averaging the Th continuous SNR measured values until the current sub-frame when Th is smaller than the preset threshold, and comparing the average value with the SNR target value to determine the TPC (transmit power control) command word; and predicting the SNR of the following sub-frame according to the Th continuous SNR measured values until the current sub-frame when Th is no smaller than the preset threshold, and comparing the SNR predicted value with the SNR target value to determine the TPC command word. Accordingly, the invention is capable of controlling the power of the E-AGCH more accurately and more effectively.

Owner:ST ERICSSON SEMICON BEIJING

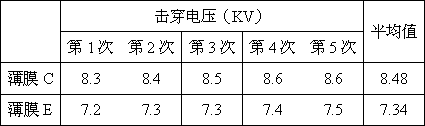

Processing technique of metallized film

InactiveCN106222609AImprove AC voltage resistance performanceExtended service lifeVacuum evaporation coatingSputtering coatingCorona dischargeEvaporation

The invention relates to a processing technique of a metallized film. Corona discharge pretreatment is conducted on an insulating base film twice, and then primary evaporation, surface treatment of a zinc coating, secondary evaporation, and surface treatment of an aluminized coating are conducted, so that the metallized film is obtained. The bonding strength of a metal layer of the metallized film and the insulating base film is high, and the alternating voltage resistance is remarkably improved; the metal layer is of a four-layer structure including the zinc coating, an zinc oxide coating, the aluminized coating and an oxide film so that the corrosion rate of the metal layer can be effectively decreased, the capacity of a capacitor cannot be decreased even if the zinc coating is corroded, the adaptability to high high-voltage alternating currents cannot be affected, insulating defects are avoided, and the breakdown accidents are avoided; and according to the processing technique of the metallized film, the processing technique is simple, the loss of the zinc coating is reduced, the production efficiency is high, the production cost is low, and the service life of the metallized film is long.

Owner:ANHUI NINGGUO HAIWEI ELECTRONICS

Metallized film for rail transit locomotive and processing technology thereof

InactiveCN107331510BOxidation barrierReduce capacityThin/thick film capacitorStacked capacitorsSelf-healingEvaporation

The invention relates to a metalized film used for a rail transit locomotive and a processing technology thereof. The processing technology comprises the steps of insulation basal film pretreatment, primary evaporation for preparing an aluminum coated layer, insulation basal film secondary treatment and performing secondary evaporation on the aluminum coated layer for composite preparing a tin coated layer. Oxidation of the aluminum coated layer can be effectively prevented by the tin coated layer, and sharp declining of the capacity of the capacitor does not occur in working under the AC high voltage and high current. The subsequent capacity of the capacitor does not influenced even insulation defects exist on the insulation basal film; and continuous breakdown of the multilayer insulation basal film does not occur in case of self-healing so that the phenomenon of large-area burning can be avoided. Therefore, the capacitor prepared by coiling of the metalized film can be massively applied to the rail transit locomotive to act as the energy storage component.

Owner:宋仁祥

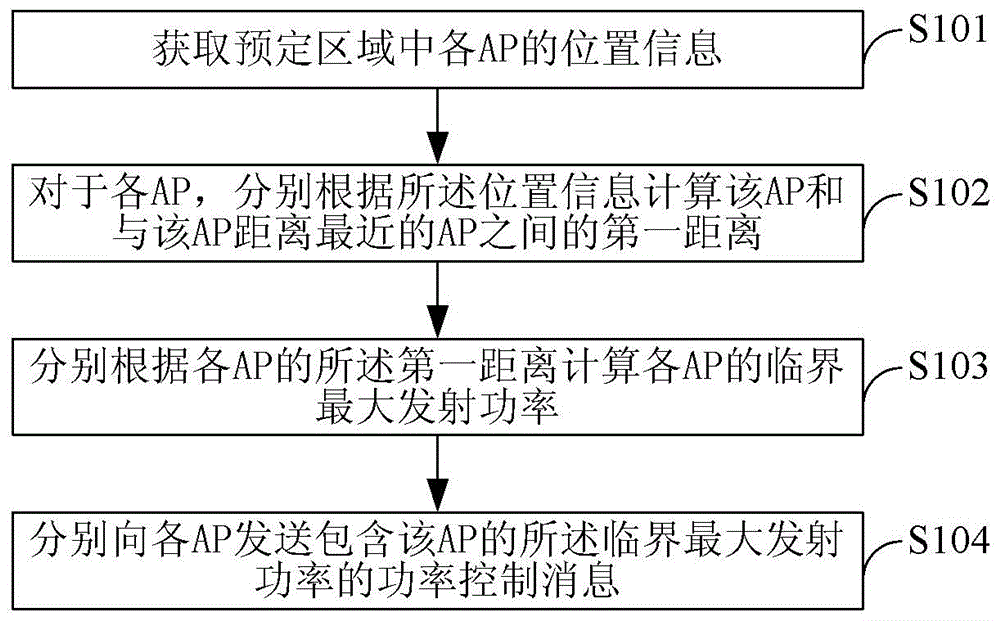

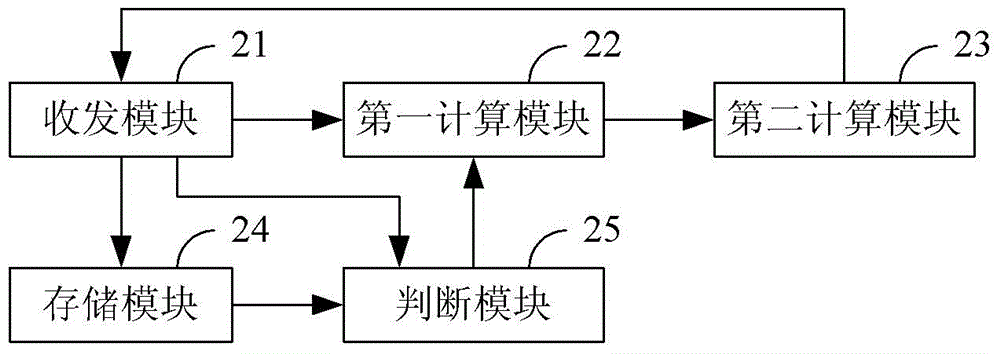

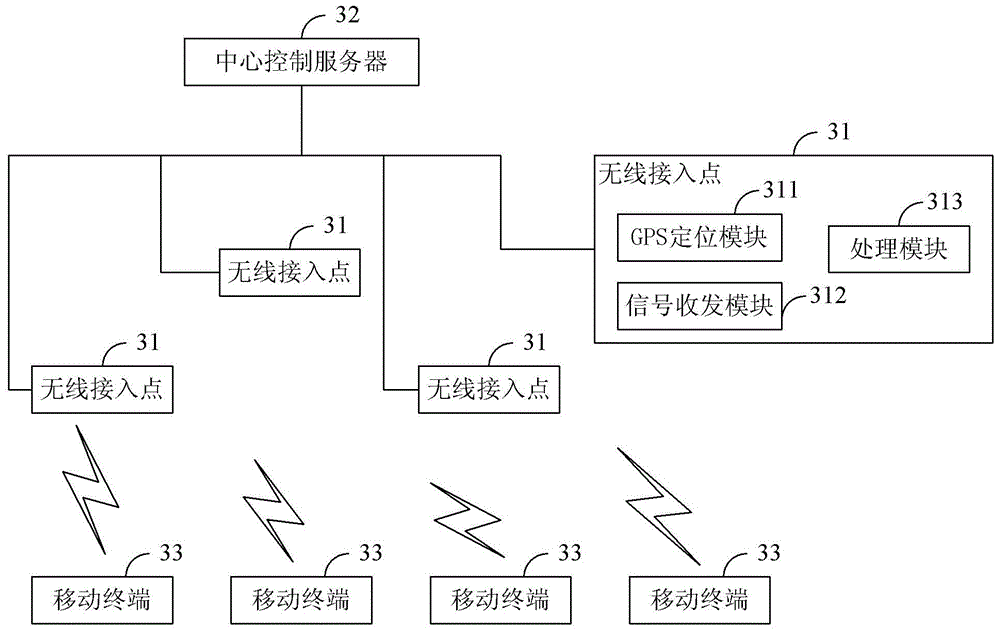

A power control method and device

The invention provides a power control method and device. The method includes the steps that position information of each wireless AP in a preset area is acquired; for each AP, a first distance between the AP and the closest AP is calculated according to the position information; the critical maximum transmitting power of each AP is calculated according to the first distance of the AP, wherein the critical maximum transmitting power of the AP is the maximum transmitting power capable of preventing signals transmitted by the AP from causing interference at the position the first distance away from the AP; power control massages containing the critical maximum transmitting power of all the APs are transmitted to the APs respectively. The power control method and device can reduce interference caused by dense WiFi distribution.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Lead storage battery production method and lead storage battery

ActiveCN111180674ACapacity does not have a big impactCapacity impactFinal product manufactureLead-acid accumulator electrodesSulphate IonSea transport

The invention discloses a lead storage battery production method. The production method comprises the following steps: (1) preparing a positive plate and a negative plate; (2) respectively soaking thepositive plate and the negative plate in a sulfuric acid solution for reaction; (3) drying the positive and negative plates after soaking to obtain a positive plate and a negative plate after pickling; and (4) assembling the positive plate and the negative plate which are pickled into a battery without additionally adding electrolyte. Required sulfate ions are obtained by pickling the manufactured green polar plates in the sulfuric acid solution, and battery assembly is completed by adopting the polar plates subjected to pickling treatment. The battery can avoid the special regulations of International Marine Transport (Air Transport, Railway Transport and Highway Transport) dangerous goods rules, and can be delivered according to non-dangerous goods. When the battery is used, the batterycan be used only by adding pure water to be fully charged, and the capacity and other related properties of the battery are not greatly influenced.

Owner:TIANNENG BATTERY GROUP

Sensor for use in a plastics processing machine and method for operating such a sensor

ActiveCN101110130BCapacity impactLow costRegistering/indicating quality control systemsMeasurement arrangements for variableEngineeringInjection molding machine

Owner:KRAUSSMAFFEI TECH GMBH

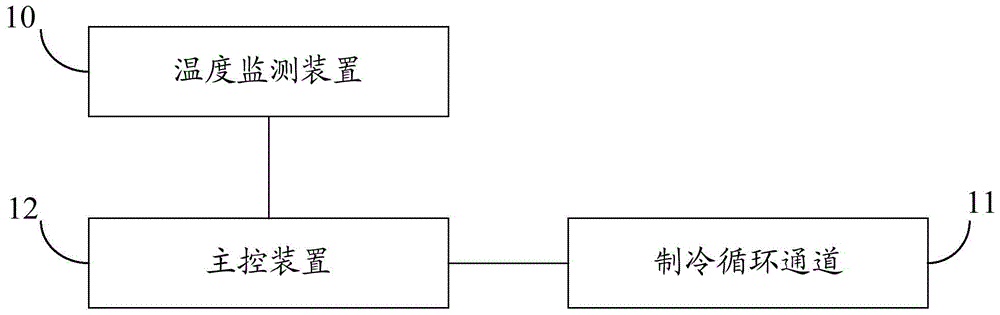

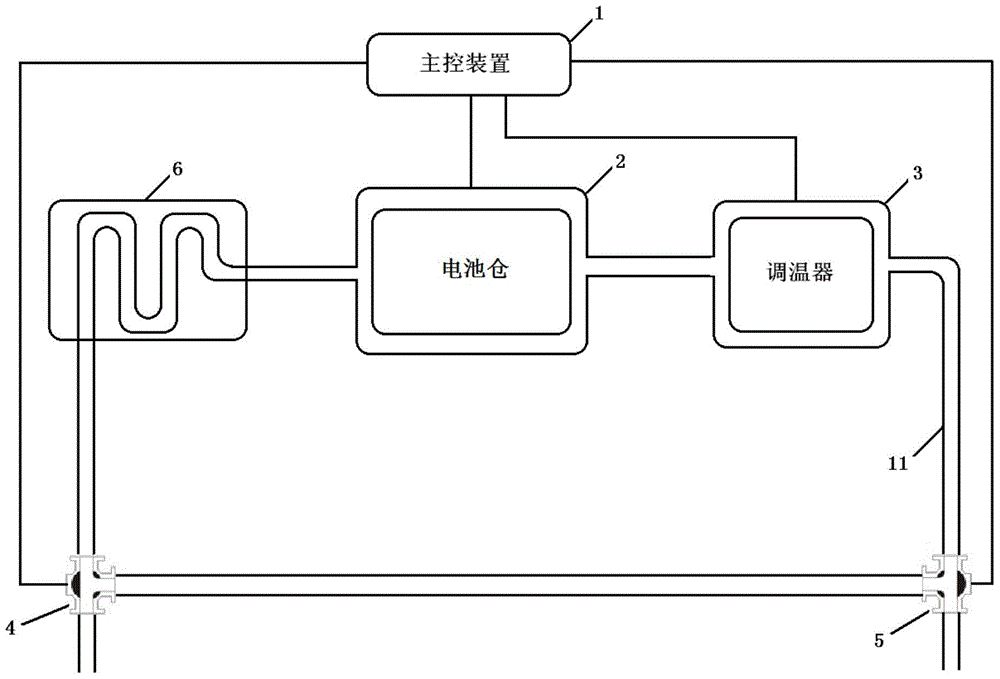

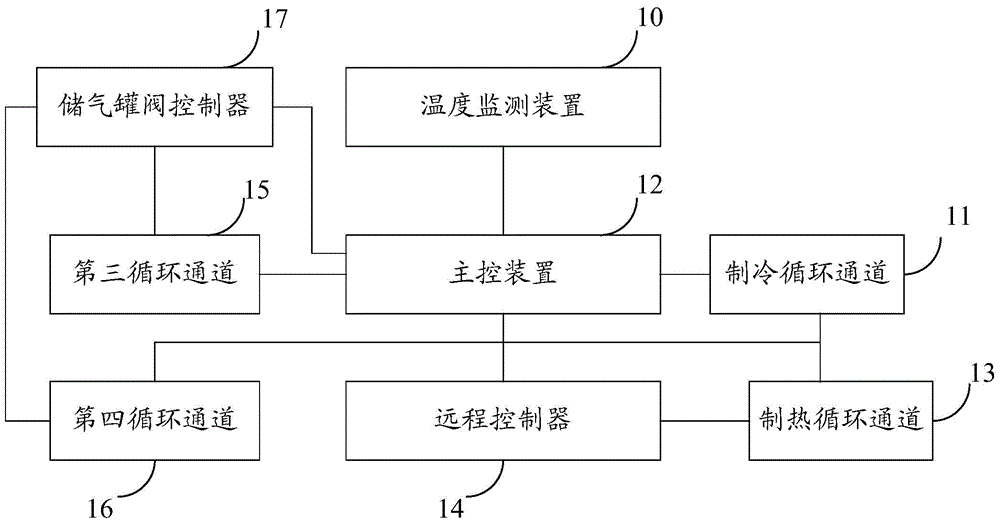

Battery management system and control method for electric vehicle

InactiveCN103825062BReduce the temperatureLife expectancySecondary cellsPower batteryElectrical battery

The invention provides a battery management system of an electric vehicle and a control method of the battery management system, and aims to solve the problem of performance influences of pure electric vehicle power batteries due to high temperature. The battery management system of the electric vehicle comprises a temperature monitoring device connected with a battery compartment of the electric vehicle, used for monitoring battery temperature in the battery compartment and sending the battery temperature to a master control device, a refrigeration circulation channel connected with the battery compartment of the electric vehicle and used for refrigerating a battery in the battery compartment by a circulating refrigerant, the master control device respectively connected with a collecting device and the refrigeration circulation channel, used for controlling the refrigerant to refrigerate the battery in the battery compartment circularly in the refrigeration circulation channel when the battery temperature exceeds the preset upper limit value. The battery management system of the electric vehicle and the control method of the battery management system can reduce influences on the service life and the capacity of the battery due to the high temperature and prolong the service life of the battery.

Owner:BEIJING HAIKE ZHIDONG TECH DEV +2

A metallized thin film processing technology

InactiveCN106222609BImprove AC voltage resistance performanceExtended service lifeVacuum evaporation coatingSputtering coatingCorona dischargeEvaporation

Owner:ANHUI NINGGUO HAIWEI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com