Container-formed gelled electrolyte and preparation method thereof

A technology of colloidal electrolyte and preparation method, applied in the field of electrolyte, can solve the problems of high glue filling and formation temperature, difficult glue filling in production, slow heat dissipation, etc., and achieves simple production operation, stable colloidal gel structure, and large thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The percentage ratio of each active chemical component of the colloidal storage electrolyte of the invention formula to the total weight:

[0054] Sulfuric acid 29.4% ~ 36.6%;

[0055] Nanoscale fumed silica 3.5% to 4.8%;

[0056]Potassium sulfate 0.05% to 0.50%;

[0057] Sodium sulfate 0.8% ~ 1.8%;

[0058] Thermally conductive material (nano-scale silicon nitride powder) 1.0% to 6.0%;

[0059] Polyacrylamide 0.001% ~ 0.020%;

[0060] Sodium molybdate 0.005% ~ 0.200%;

[0061] The rest is 50.080% to 65.244% of pure water with conductivity ≤2 μs / cm (hereinafter simply referred to as pure water).

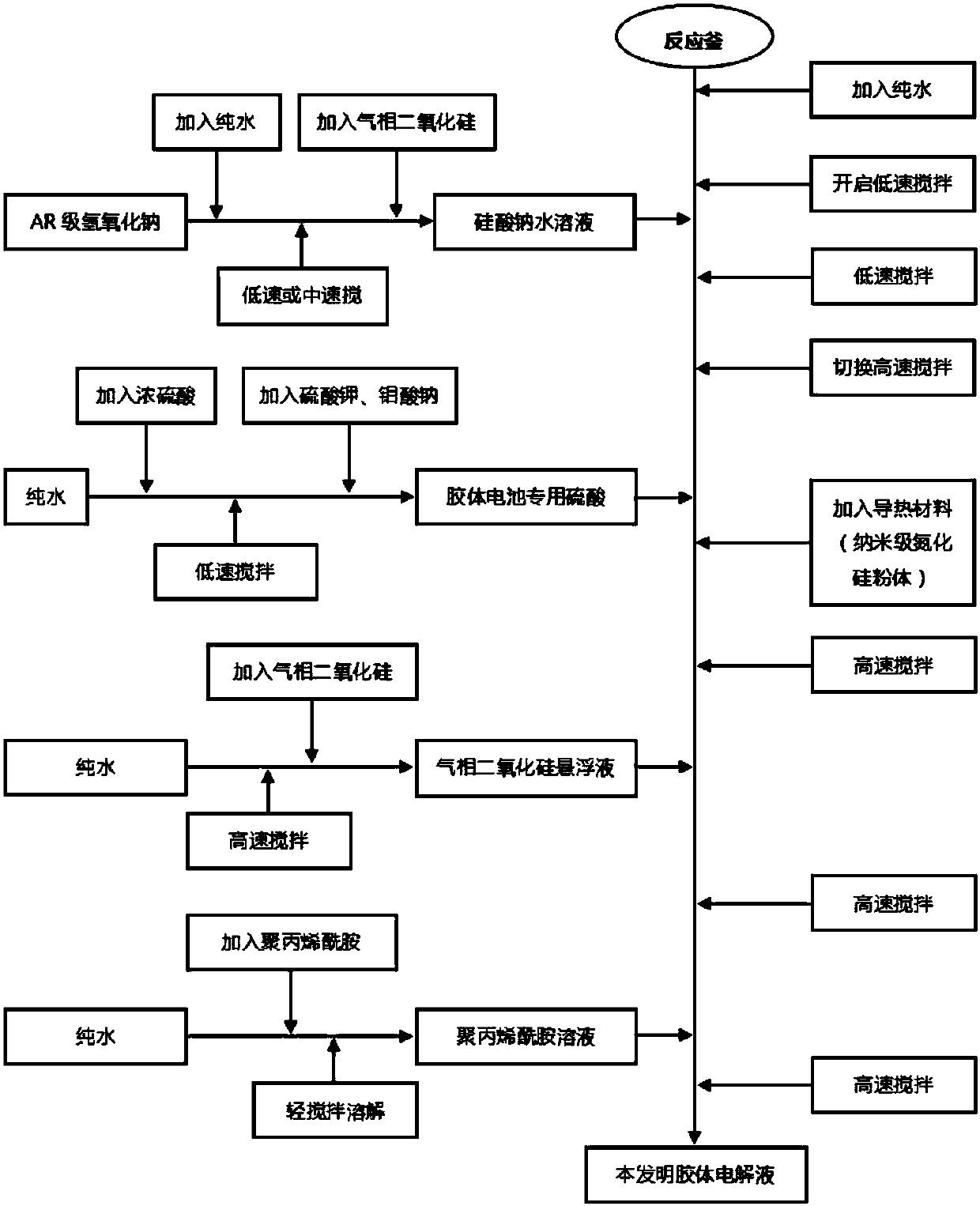

[0062] The preparation method of the above-mentioned colloidal storage electrolyte is as follows: figure 1 shown, including the following steps:

[0063] Step 1, preparing sodium silicate aqueous solution, silicon dioxide suspension, sulfuric acid solution and polyacrylamide solution in advance;

[0064] 1) Prepare sodium silicate aqueous solution:

[0065] Add pure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com