High-efficiency pulverized coal burner for dried pulverized coal fluidized bed gasification furnace

A fluidized bed gasifier, dry coal powder technology, applied in the direction of granular/powder fuel gasification, etc., can solve the problem of difficult ignition, achieve stable combustion, prolong service time, and reduce the generation of steam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

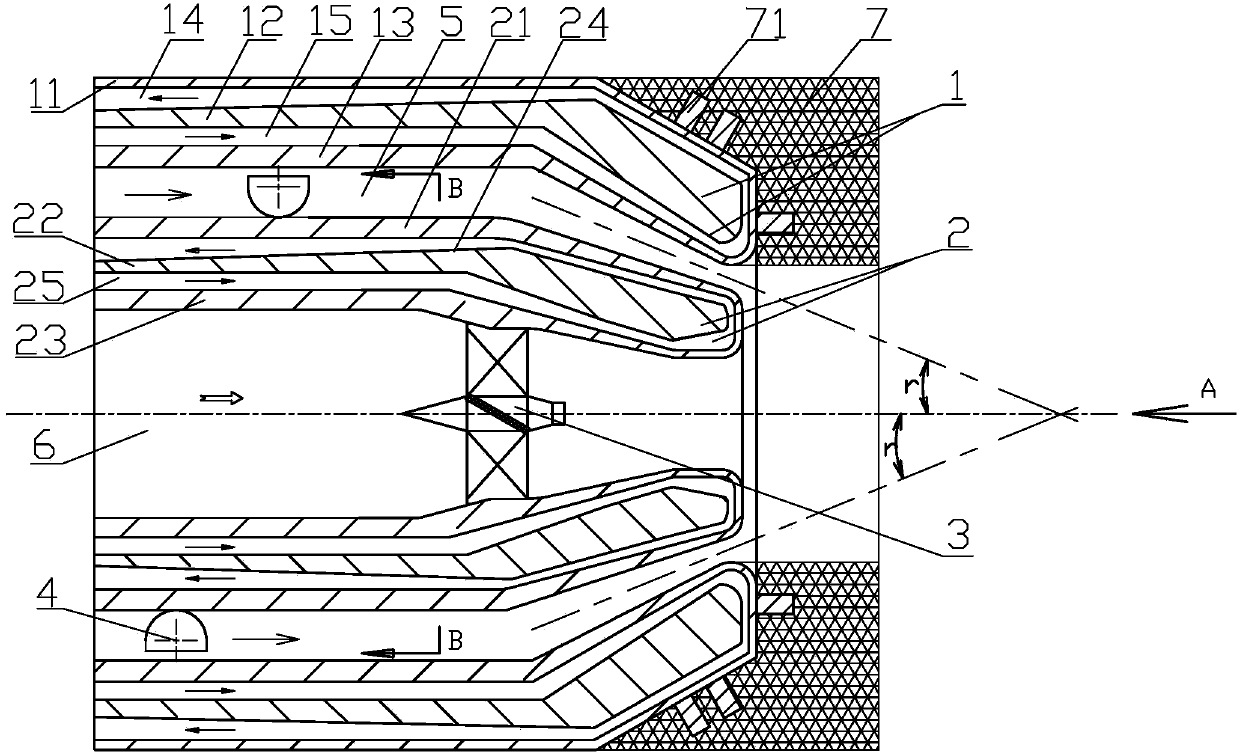

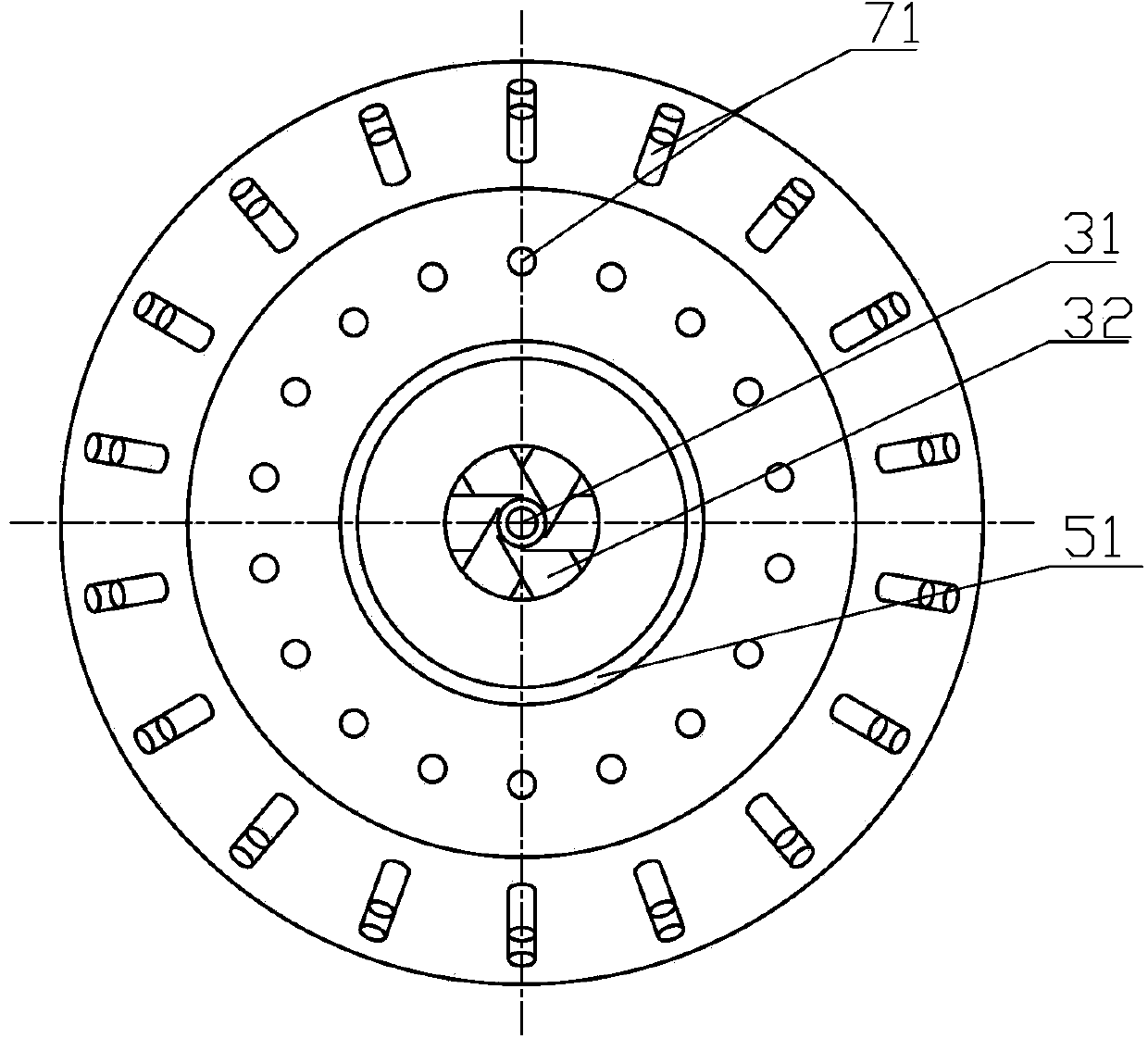

[0019] Such as Figure 1 to Figure 5 As shown, a high-efficiency pulverized coal burner for a dry pulverized coal fluidized bed gasifier includes an outer ring body 1 and an inner ring body 2 arranged coaxially.

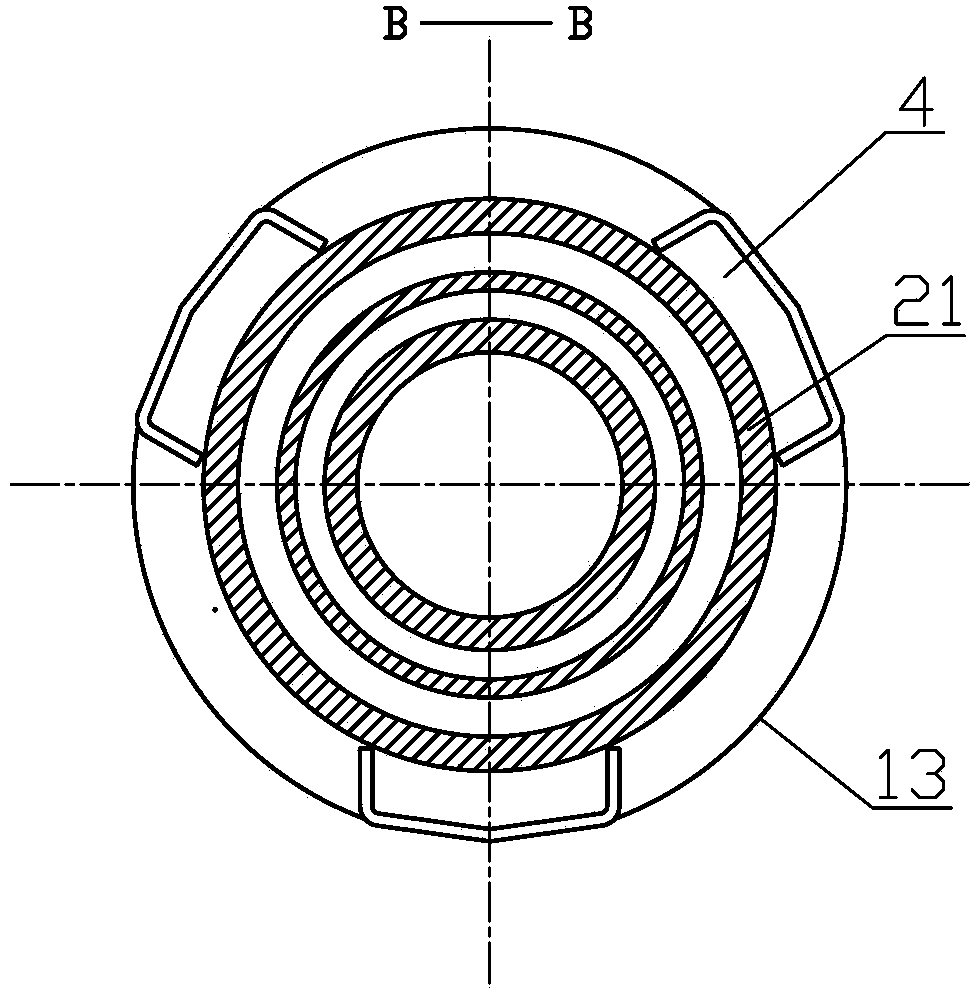

[0020] The front end of the outer ring body 1 is an open end. The outer torus 1 includes an outer wall 11, an intermediate spacer 12 of an annular structure, and an inner wall 13. The front end of the outer wall 11 is hermetically connected to the front end of the inner wall 13, and the middle spacer 12 seals the front end of the outer torus 1. The wall body (that is, the part between the outer wall 11 and the inner wall 13) is divided into an outer annular channel 14 and an inner annular channel 15 whose front ends communicate with each other, and the two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com