Patents

Literature

33results about How to "Suitable for processing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

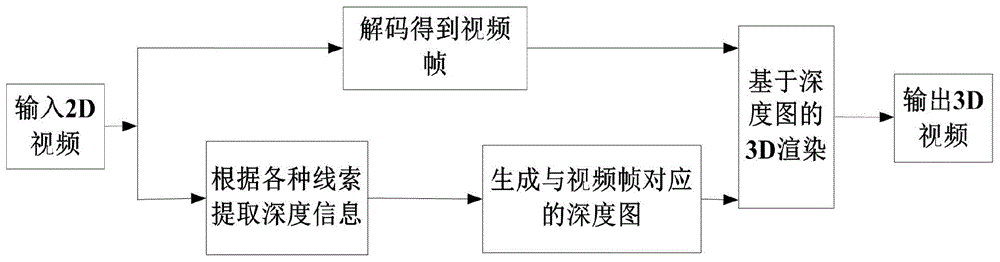

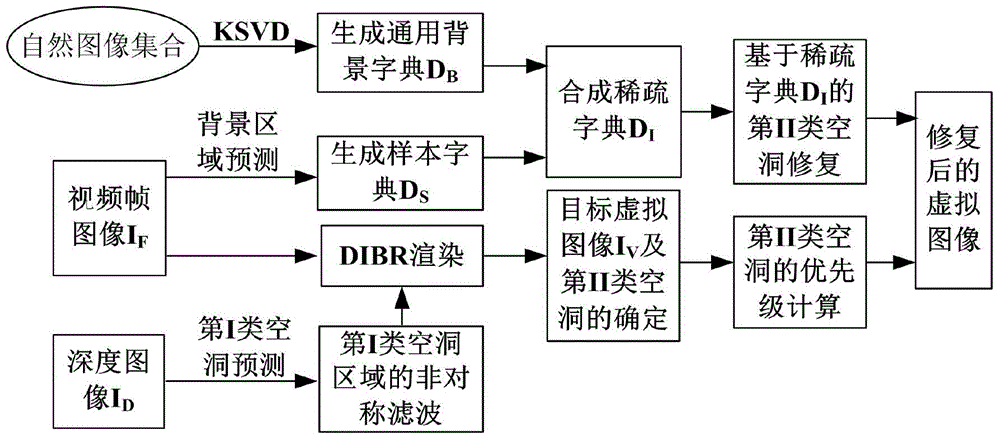

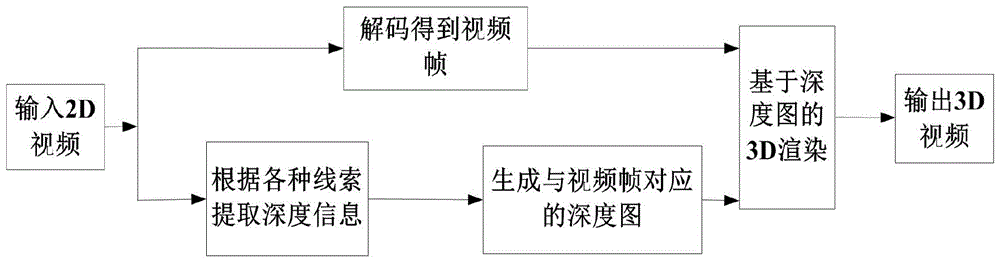

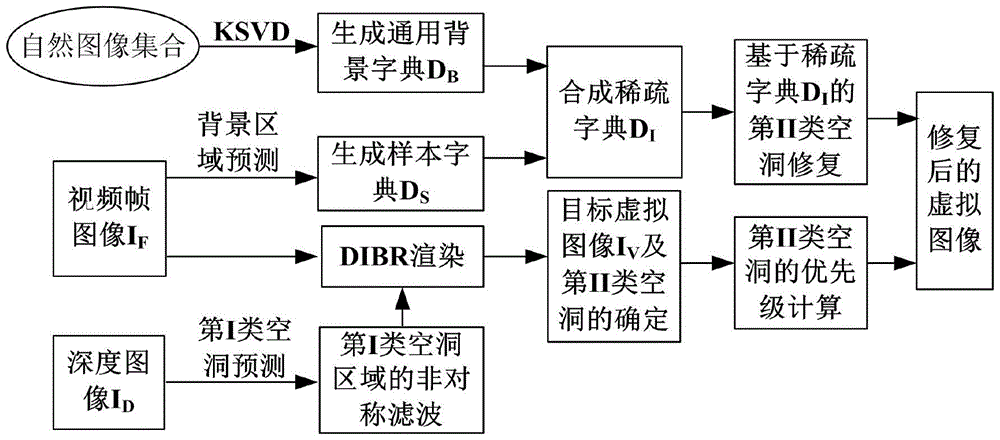

DIBR (depth image-based rendering) virtual image restoration method applicable to high-definition 2D/3D (two-dimensional/three-dimensional) conversion

InactiveCN104954780AReduce time spent studying onlineGood effectImage enhancementSteroscopic systemsPattern recognitionRestoration method

The invention discloses a DIBR (depth image-based rendering) virtual image restoration method applicable to high-definition 2D / 3D (two-dimensional / three-dimensional) conversion. The method comprises steps as follows: generating a general background dictionary DB; synthesizing a sparse dictionary DI: constructing a sample dictionary DS in a background area of a video frame image IF, and synthesizing the sparse dictionary DI according to the generated general background dictionary DB and the sample dictionary DS; performing void estimation and classification processing; performing filling restoration processing on each II-class void RHII. With the adoption of the method, through classification processing and sparse dictionary expression, the complexity of calculation is significantly reduced while the 3D virtual image rendering effect is improved, and the method is more applicable to processing of mass video information in high-definition 2D / 3D conversion.

Owner:NANYANG NORMAL UNIV

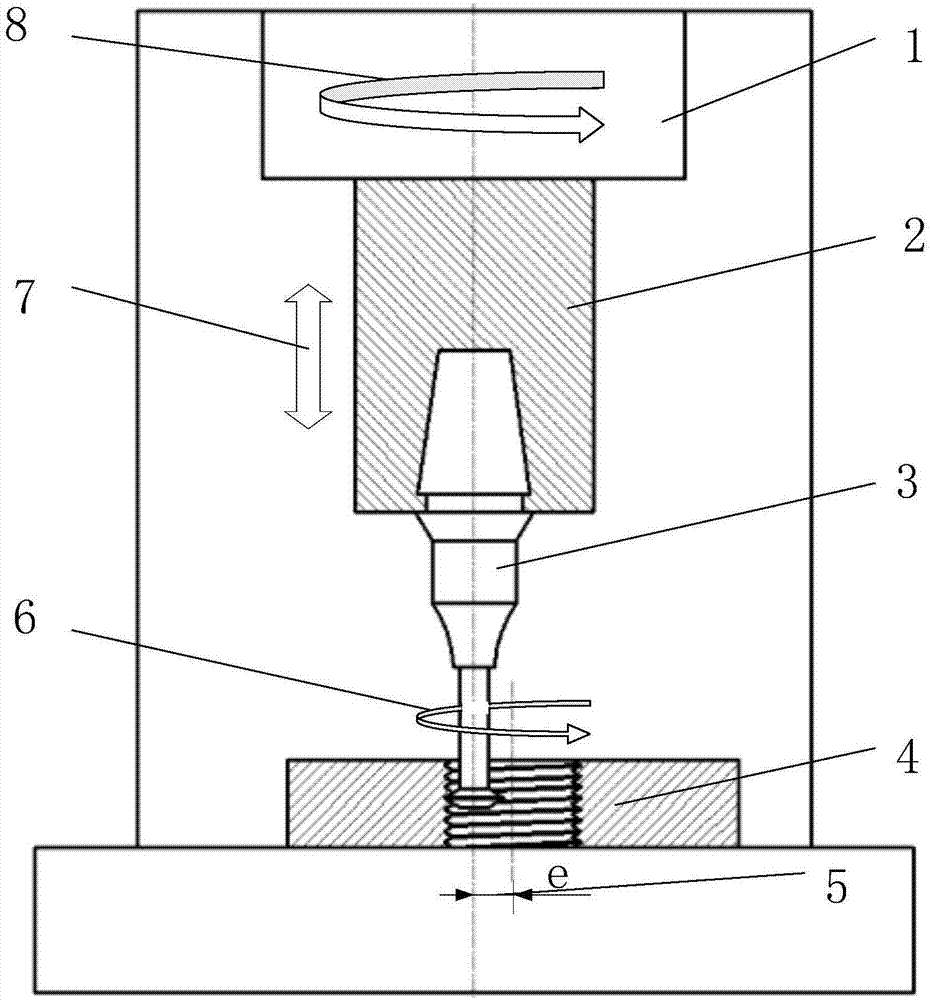

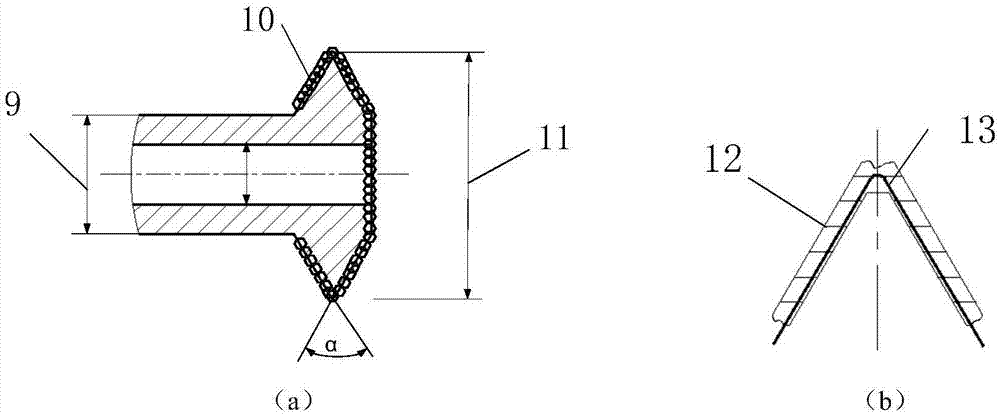

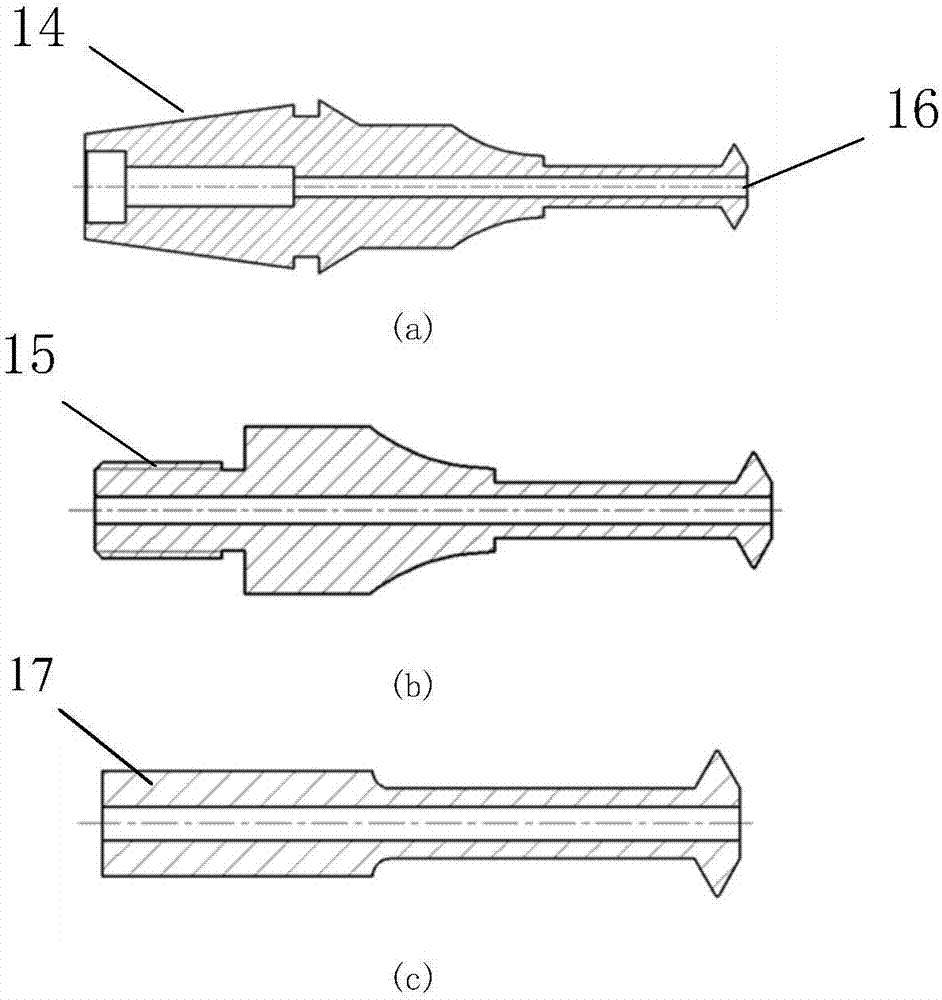

Ultrasonic vibration assisted spiral thread milling and grinding method

InactiveCN107442873AReduce cutting forceImprove use reliabilityThread cutting machinesUltrasonic vibrationCutting force

The invention provides an ultrasonic vibration assisted spiral thread milling and grinding method, and belongs to the technical field of machining and tools. A profiling grinding wheel tool is used in the method, and the tool is mounted on a spindle of an ultrasonic machine tool by an ultrasonic vibration hilt. In the method, the axis of the tool is parallel to the center of the axis of a threaded hole, and a spiral milling mode which is formed by compounding four movements including rotation of the grinding wheel tool, revelation of the profiling grinding wheel tool around the axis of the threaded hole, axial feeding of the profiling grinding wheel tool and axial vibration of the profiling grinding wheel tool along with the ultrasonic vibration hilt is adopted. By the method, a cutting force of hard and crisp materials difficult to machine in a thread machining process can be reduced effectively, the circumstance that a screw tap is broken in a tapping process due to insufficient strength to cause scrapping of parts is avoided, the thread machining quality and machining efficiency are improved, and abrasion of the tool is improved.

Owner:TSINGHUA UNIV

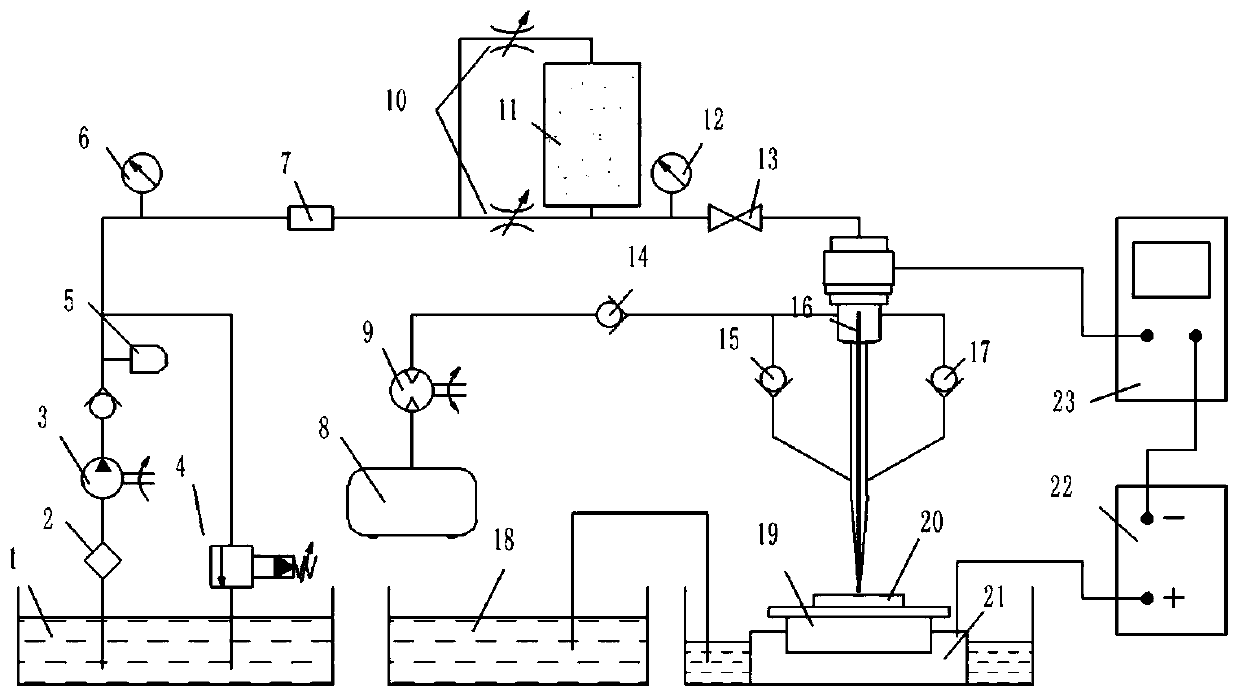

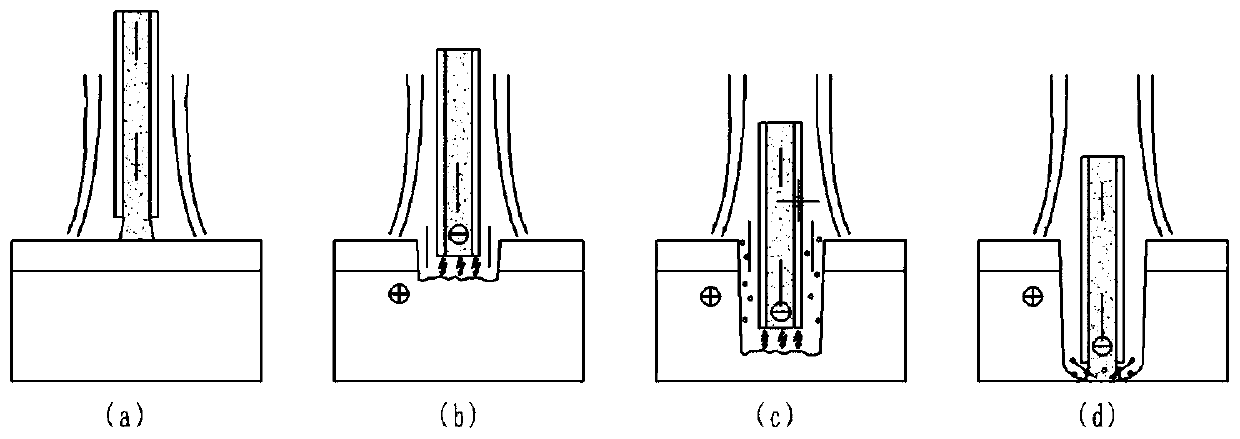

Electric spark-electrolysis combined machining device and machining method with micro abrasive inward spraying function

The invention discloses an electric spark-electrolysis combined machining device and machining method with a micro abrasive inward spraying function, and belongs to the field of micro-hole combined machining. The electric spark-electrolysis combined machining method with the micro abrasive inward spraying function is combined with abrasive grinding, electric spark corrosion and electrolytic corrosion, work liquid is sprayed out of a tube electrode with a certain pressure, the abrasive continuously impacts a workpiece, through the grinding effect, the surface insulation coating material is removed, after a metal matrix is exposed, the tube electrode is continuously fed, when the gap between the end face and the workpiece is smaller than the electric spark discharge gap, electric spark discharging appears in the end face and the workpiece under the high-pressure pulse effect, and high-speed punching is carried out; when the gap between the electrode side wall and the hole wall is largerthan the electric spark discharge gap, electrolysis corrosion removing is executed in the electrode side wall and the hole wall under the low-pressure pulse effect, the hole wall re-cast layer is removed, in the machining process, the abrasive is continuously supplied, machining efficiency is improved, small hole one-time rapid forming machining is achieved, operation is easy, and machining efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

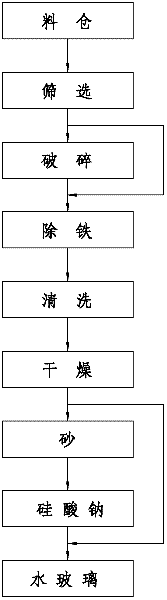

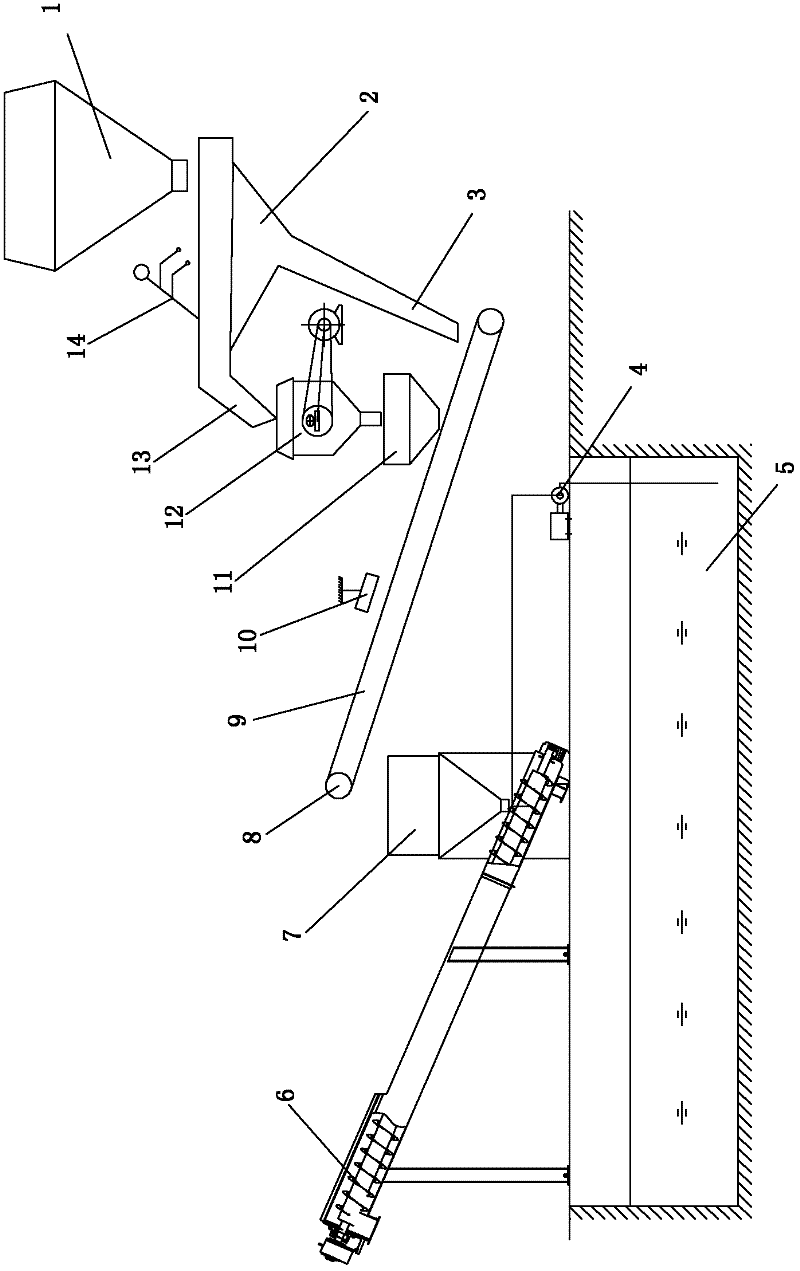

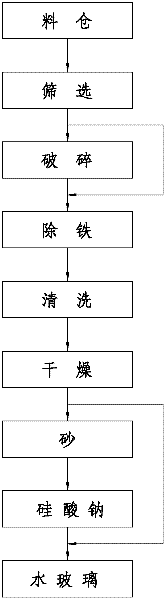

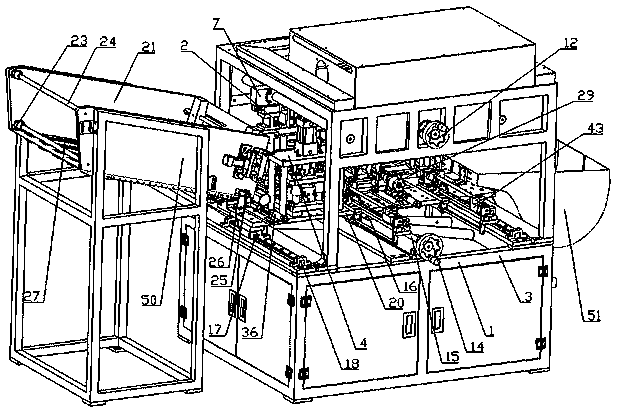

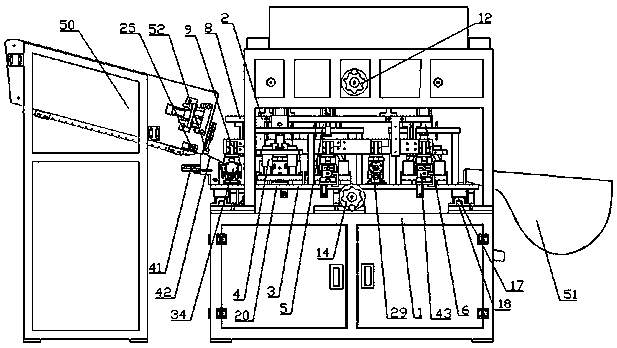

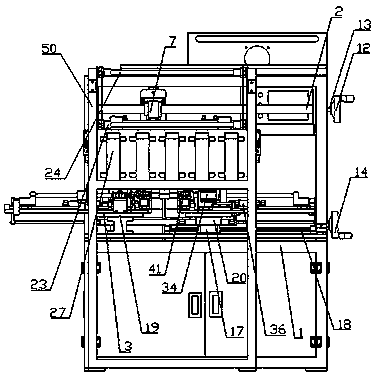

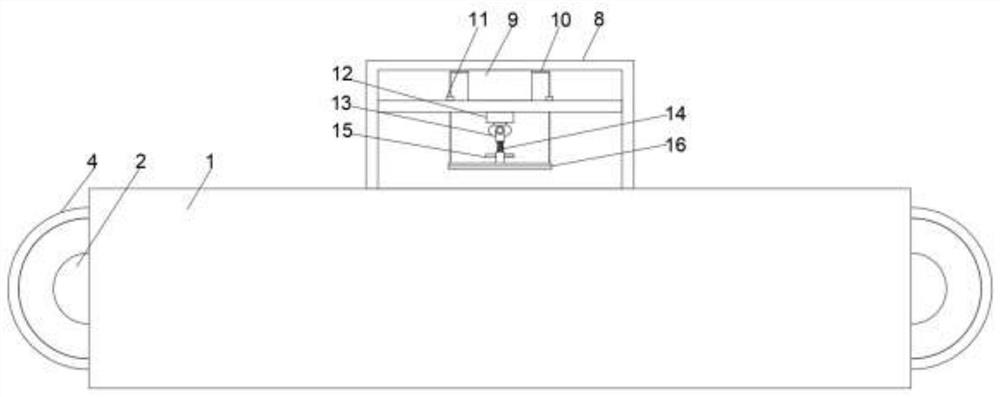

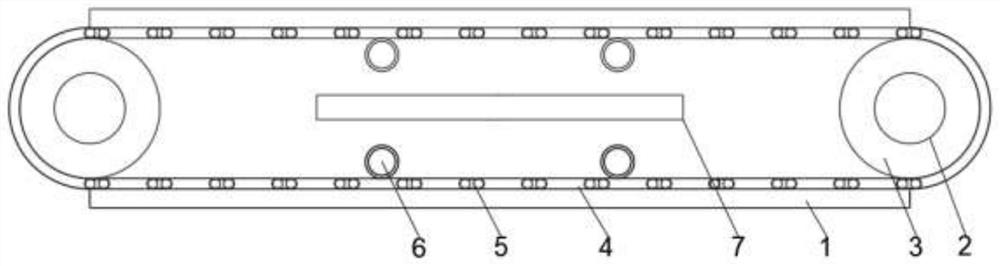

Process and device for reusing waste foundry sand

InactiveCN102335720ASuitable for processing needsSave resourcesMould handling/dressing devicesFoundryLand resources

The invention relates to a device for reusing waste foundry sand, which comprises vibrating screens, a belt conveyer, a crusher and a hopper. The device is characterized in that a vibrating screen I is mounted under a discharging port of the hopper; the discharging port of the vibrating screen I corresponds to a feeding port of the crusher; a vibrating screen II is mounted under the discharging port of the crusher; the discharging port of the vibrating screen II corresponds to the belt conveyer; and the discharging port of the belt conveyer corresponds to the feeding port of a sand cleaning machine. The technical scheme of the invention is that screening, crushing, iron-removing and cleaning devices are organically combined and foundry sand and sodium silicate in the waste foundry sand are extracted, thereby solving the problems of the prior art, such as waste foundry sand influence, ecological environmental pollution, land resource occupation, and the like, while efficiently saving resources. The device for reusing waste foundry sand is characterized by reasonable structure, high recovery efficiency, low cost, and the like, and is suitable for the processing of waste foundry sand.

Owner:NINGXIA HUAYUAN MACHINERY MFG

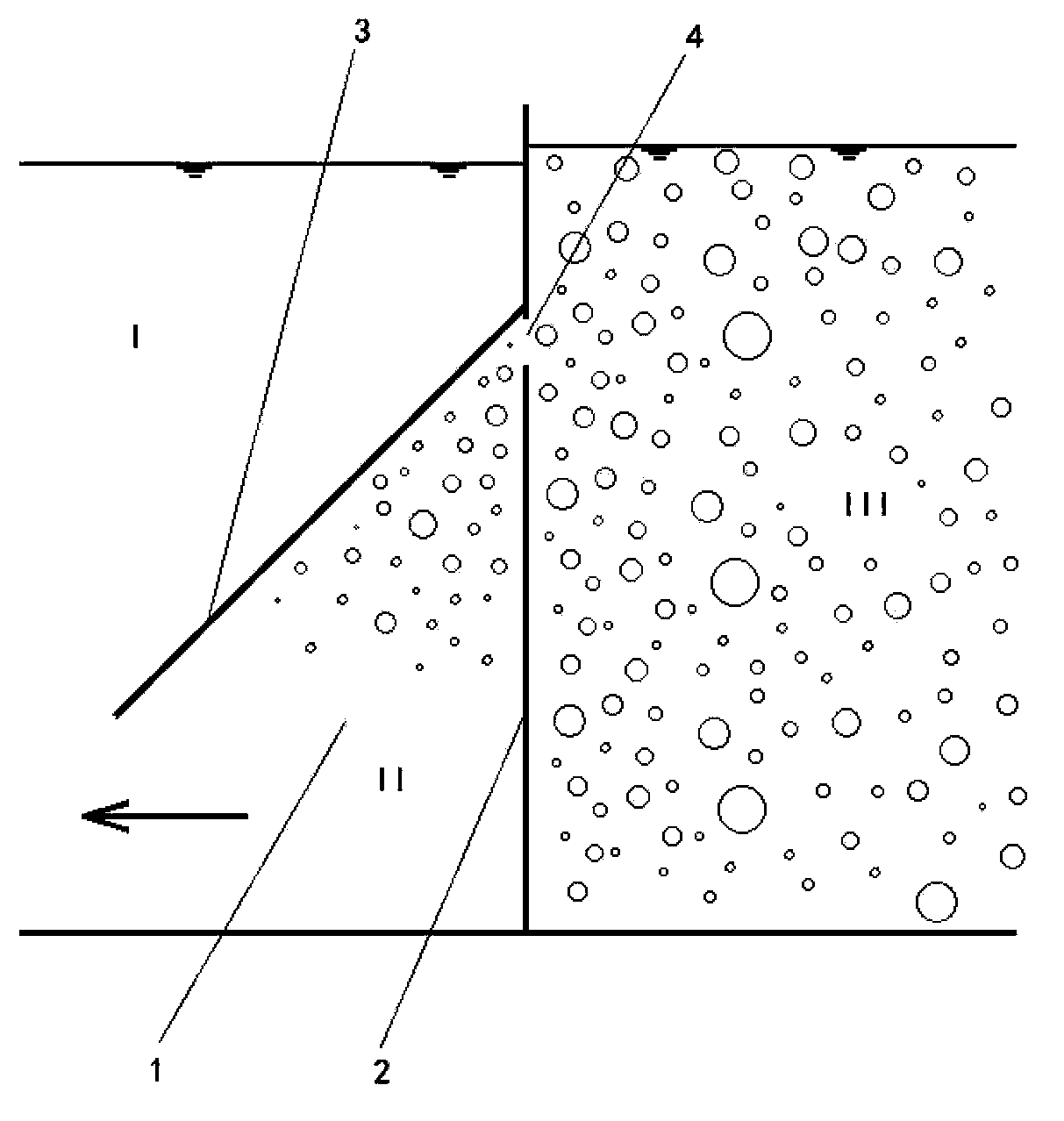

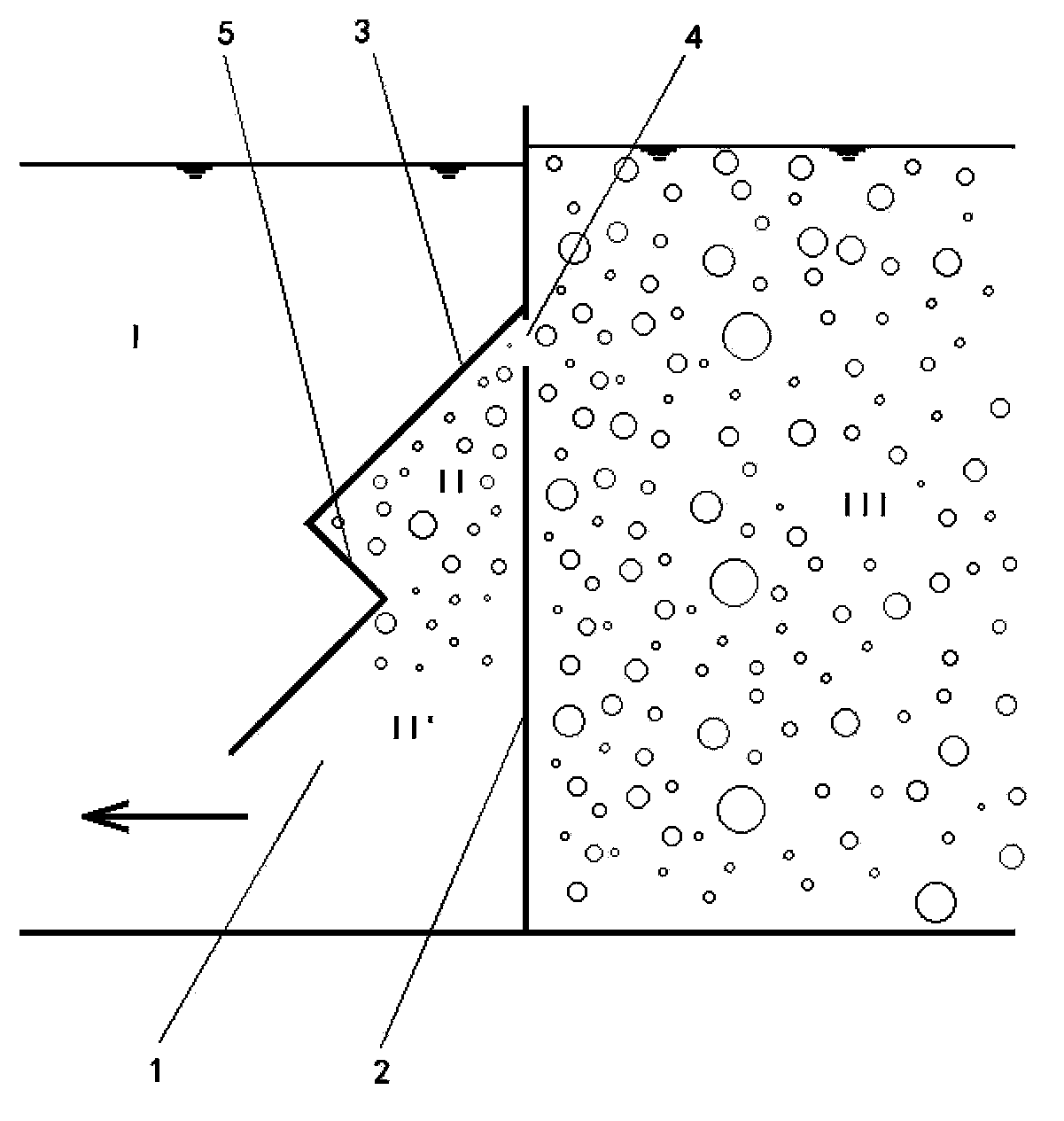

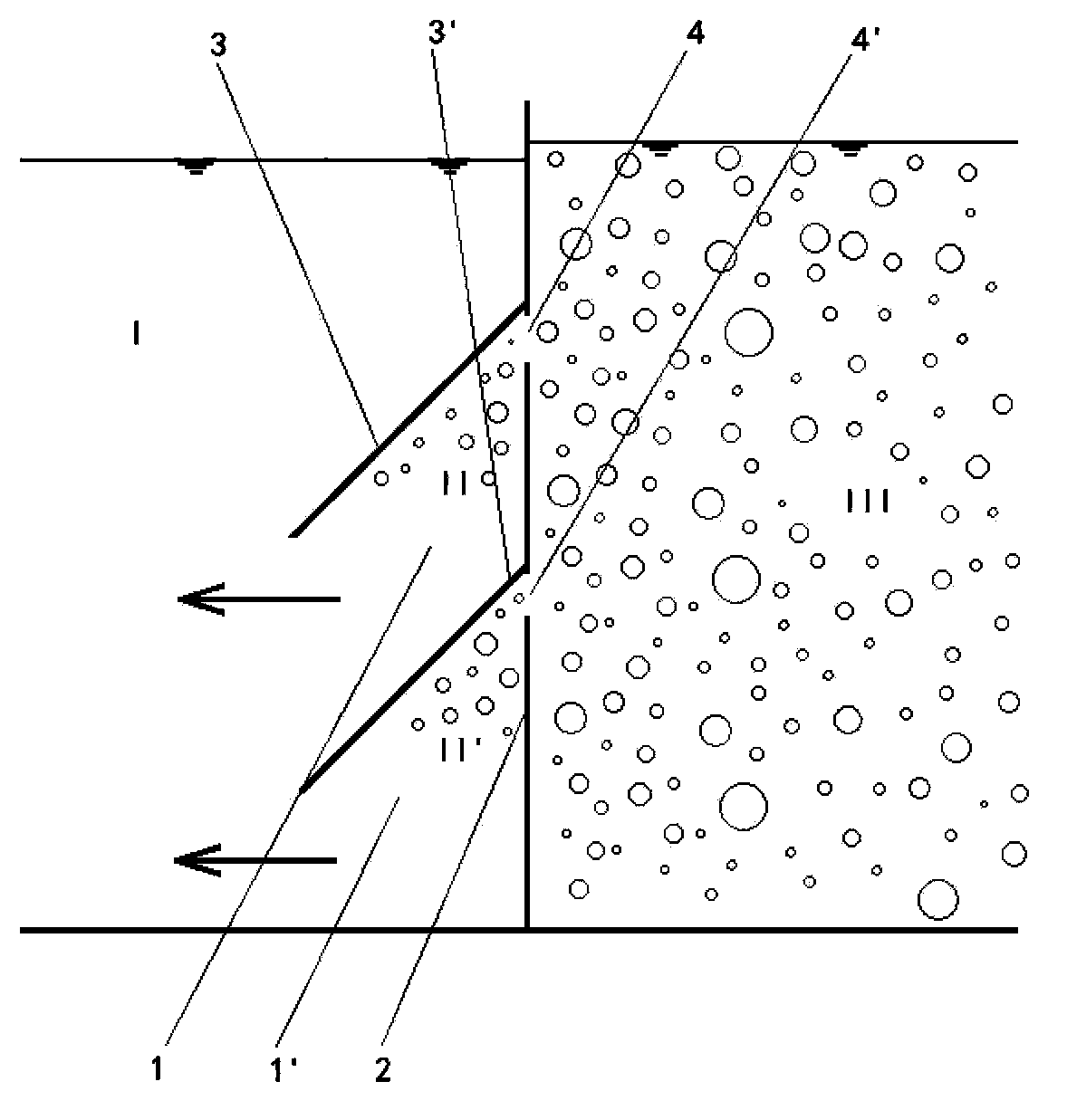

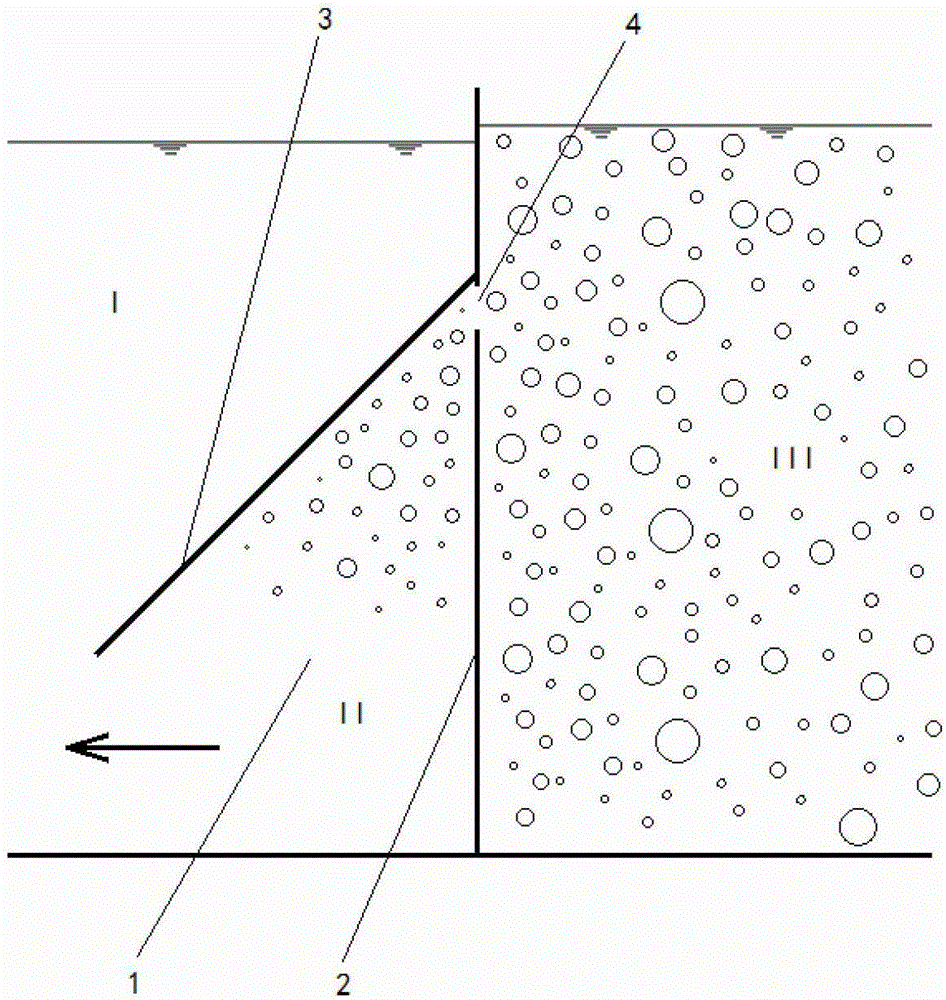

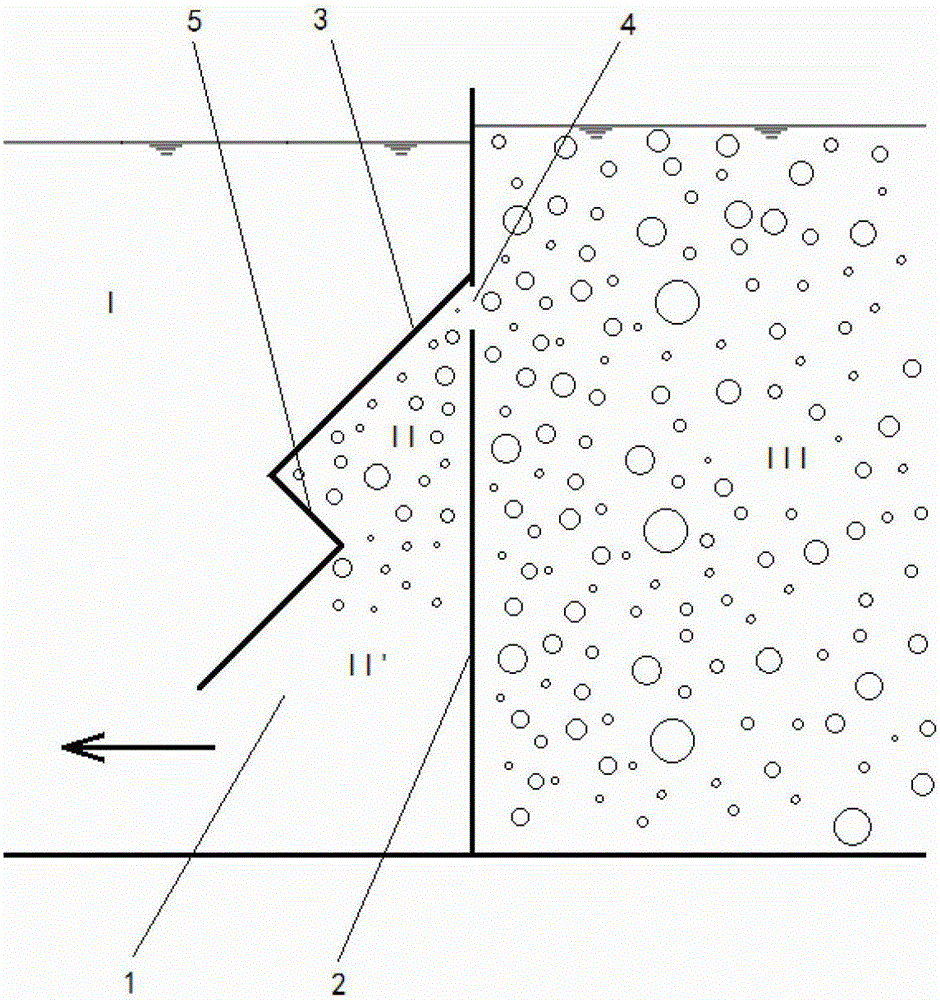

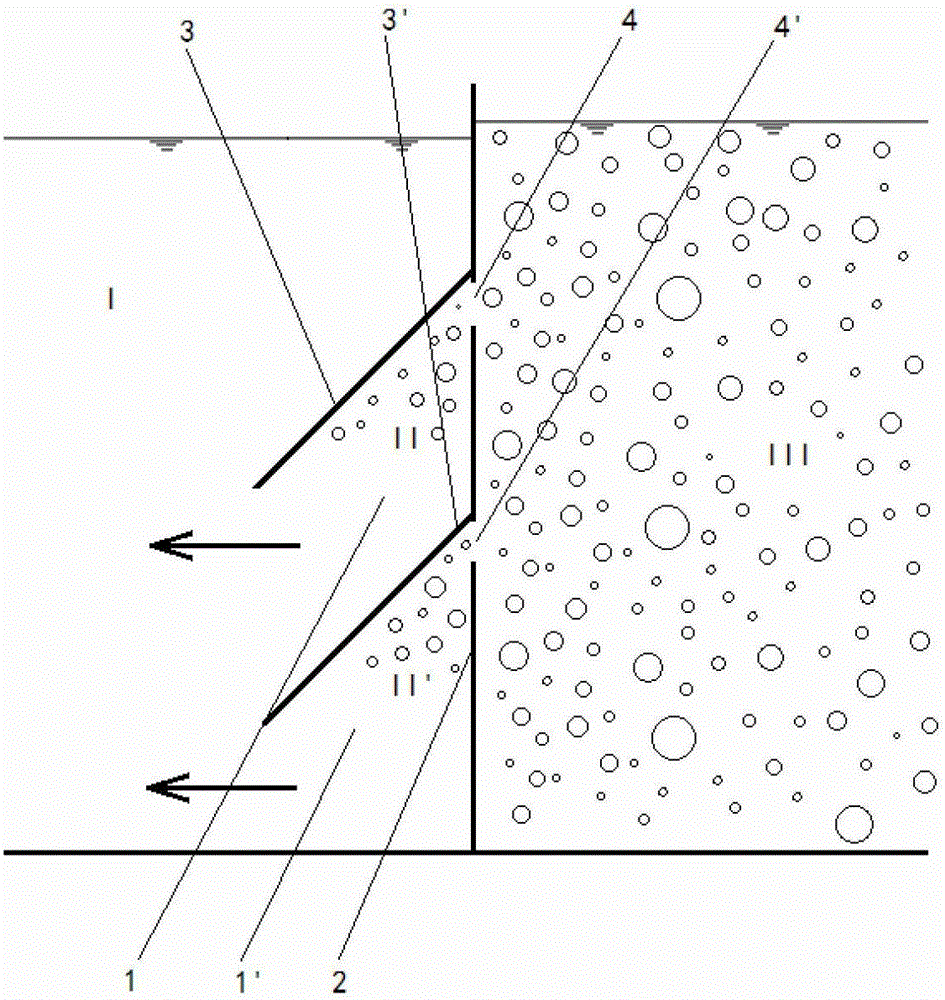

Gas-liquid separating device and sewage treatment device with gas-liquid separating device

ActiveCN103977602ACompact structureImprove separation efficiencyTreatment with aerobic and anaerobic processesSustainable biological treatmentMiniaturizationSewage treatment

The invention relates to a gas-liquid separating device. The gas-liquid separating device comprises a gas-liquid separating region arranged between a bubble-containing liquid region and a liquid region which does not basically contain bubbles, wherein the gas-liquid separating region is provided with an inlet which is in liquid communication with the bubble-containing liquid region, an outlet which is in liquid communication with the liquid region which does not basically contain the bubbles and a separating chamber arranged between the inlet and the outlet, the inlet is arranged above the outlet, and the separating chamber is provided with an expanding section which is continuously increased in the horizontal section area along the direction from the inlet to the outlet. The invention also relates to a sewage treatment device with the gas-liquid separating device. The gas-liquid separating device and the sewage treatment device have the advantages of simple and compact structure, high separating efficiency, high reliability, no movement parts, little equipment investment, small energy consumption and the like; and the gas-liquid separating device and the sewage treatment device are easy to operate and can be miniaturized.

Owner:金锣水务有限公司

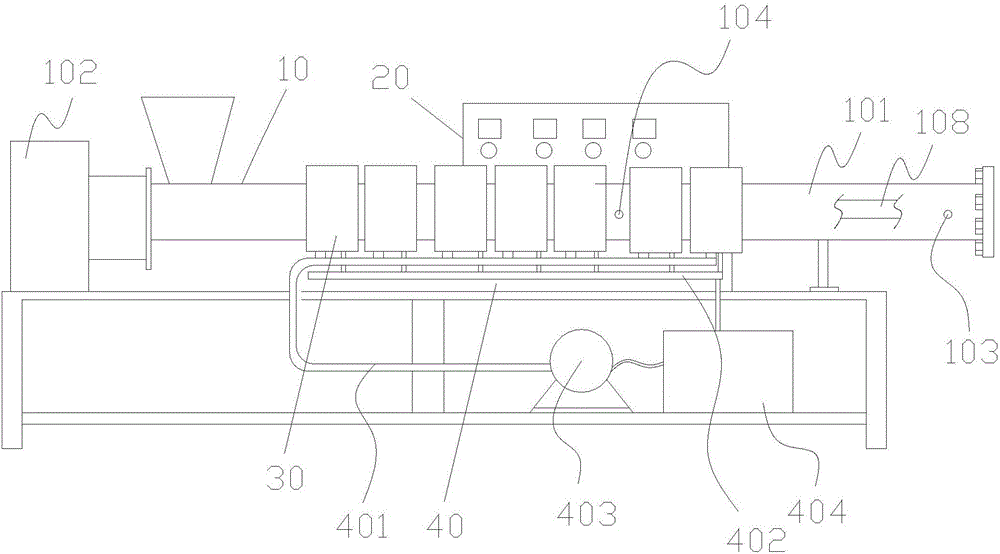

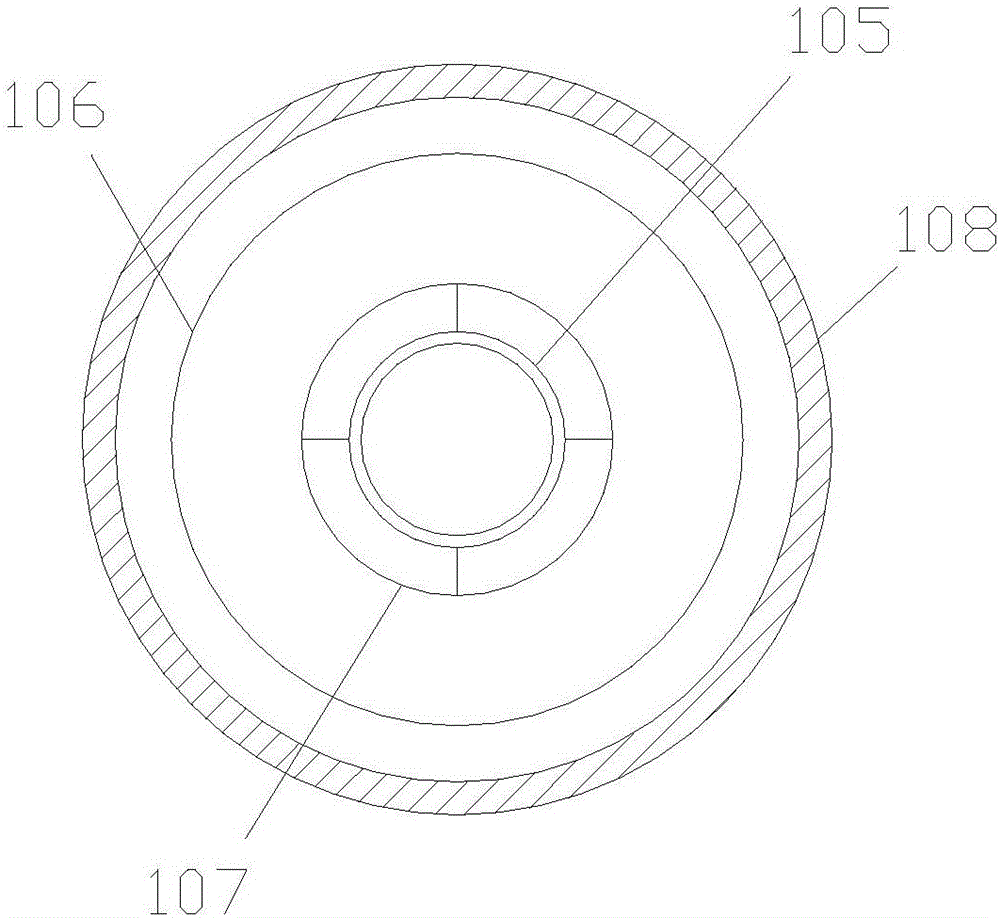

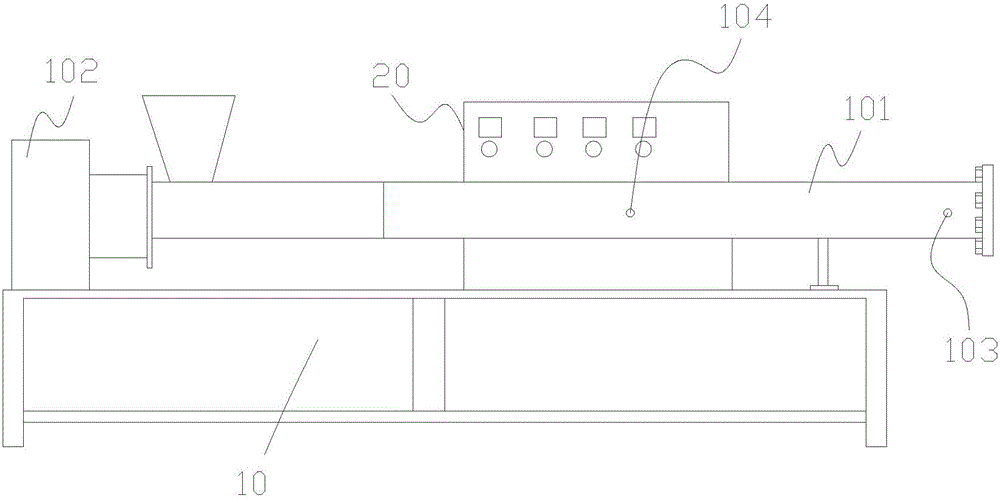

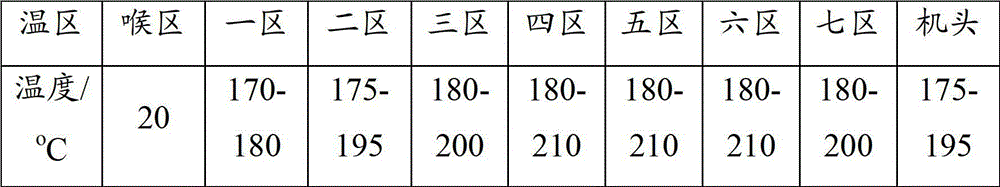

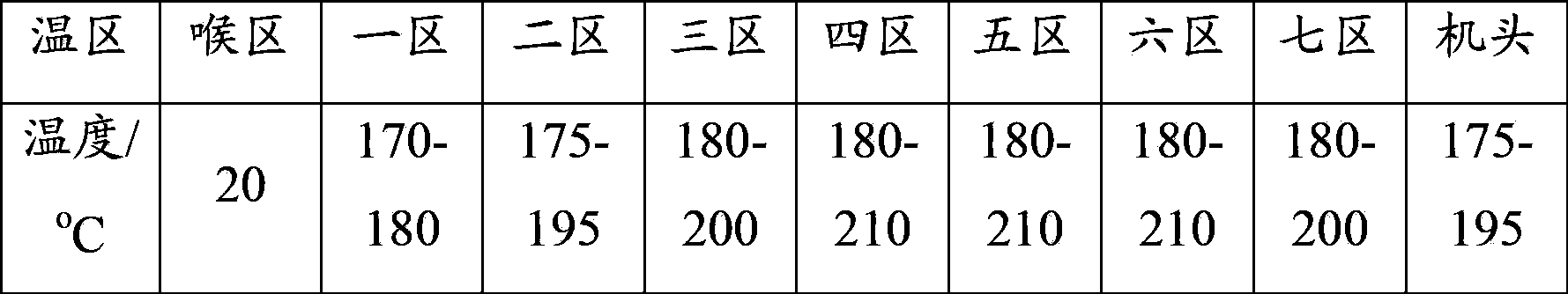

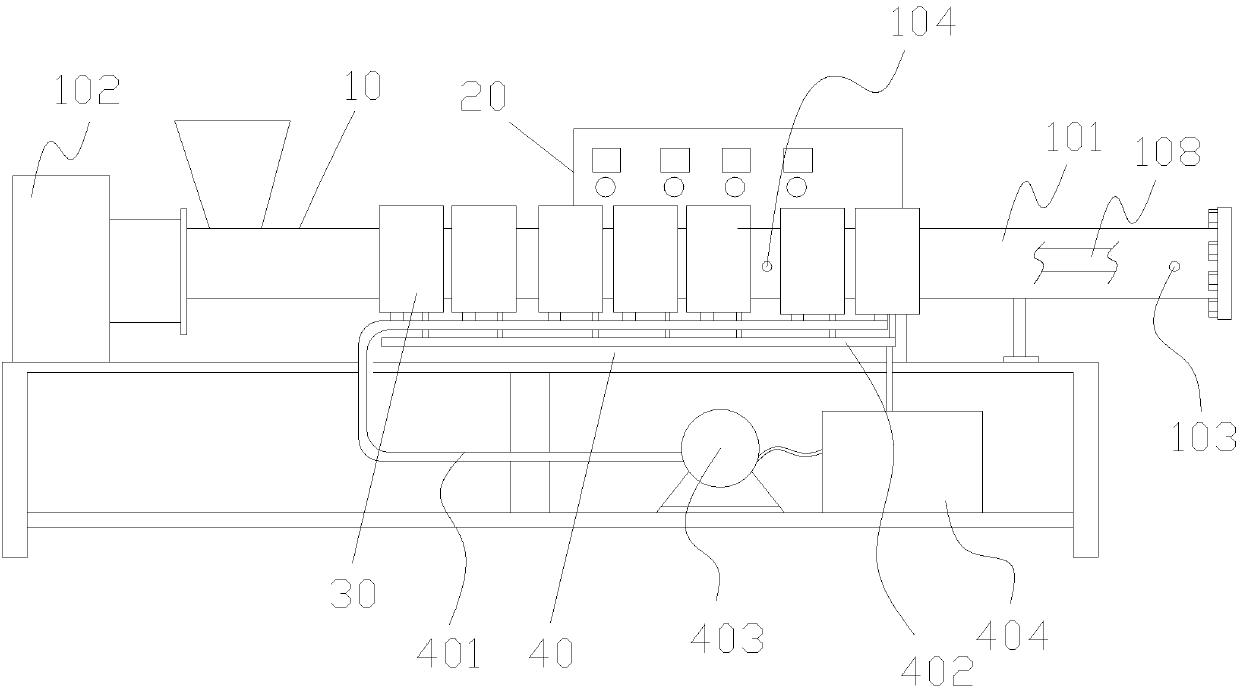

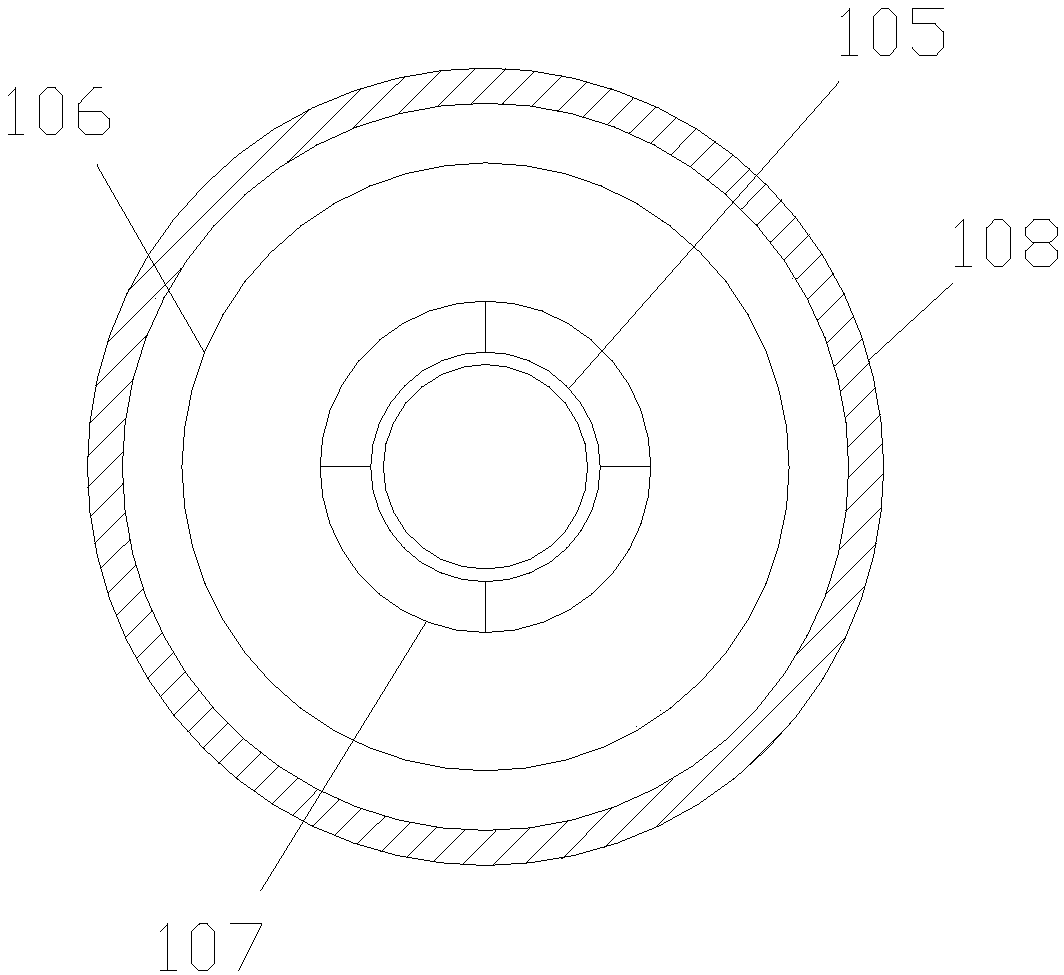

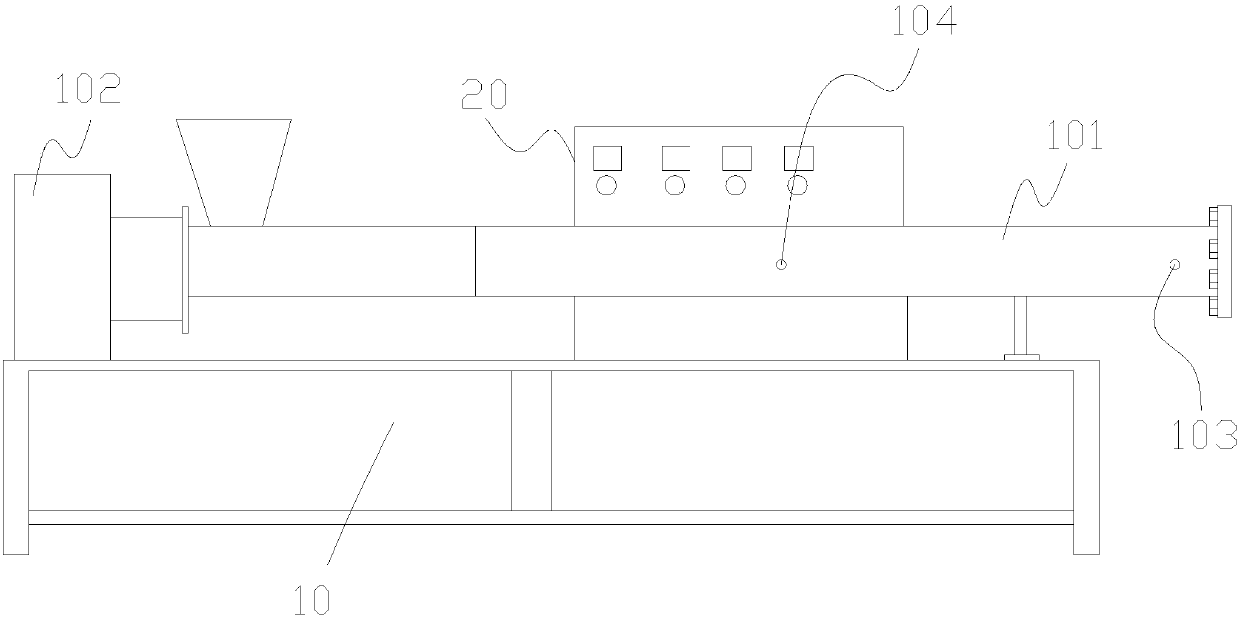

Energy-saving environment-friendly extrusion device for intelligently controlling recycled plastic based on PLC

ActiveCN105922540AAdapt to the needs of different product processingAdapt to processing needsHeating timeDirect observation

An energy-saving environment-friendly extrusion device for intelligently controlling recycled plastic based on a PLC comprises an extrusion part and the PLC; the extrusion part mainly comprises an extrusion material barrel and a transmission mechanism in transmission connection with the extrusion material barrel; a heating screw is arranged in the extrusion material barrel, a heating wire is arranged in the heating screw, the extrusion material barrel is divided into seven heating segments, the seven heating segment are independent of one another, and each heating segment comprises an electromagnetic heating oil arranged on the extrusion material barrel in a sleeving manner; a cooling cavity is formed in the middle of the extrusion material barrel and is connected with a cooling system; the heating wire is connected with the PLC, and the heating temperature and the heating time of the heating wire are controlled through logic programming; PLC data are transmitted to an office computer through the internet, the data can be directly observed through the computer, and therefore production is guided, and mechanical monitoring failures are maintained; and the aim of intelligently controlling extrusion of the recycled plastic is achieved, manpower, material resources and financial resources are saved, and the device meets the sustainable development requirement.

Owner:沧州智方药用包装材料科技有限公司

Novel full-automatic punching device with pipe visual inspection function

PendingCN109676013AGuaranteed correctnessAvoid overvoltagePerforating toolsMetal-working feeding devicesPunchingVisual inspection

The invention discloses a novel full-automatic punching device with a pipe visual inspection function. The novel full-automatic punching device comprises a machine body, a feeding funnel, an upper rack, a lower rack and a discharging funnel. The feeding funnel, the upper rack, the lower rack and the discharging funnel are all arranged on the machine body. A feeding station, a punching station, a turnover station and a discharging station are arranged on the lower rack. Shaking plates, a pipe adjusting assembly and a jacking assembly are arranged on the feeding funnel, and the shaking plates are arranged at the bottom of the feeding funnel at intervals. A pipe visual inspection assembly is arranged at the feeding station. A punching mold further comprises a pipe pushing in-mold assembly, apipe waste clearing assembly and an oil supply lubricating device. The novel full-automatic punching device is suitable for carrying out punching on pipes of different types; automatic feeding and discharging are achieved; the machining efficiency is high; the problem of pipe collision is effectively solved; surface scratching and damage are avoided; the machining quality is high; demounting is convenient; problems happening to equipment in the production process can be found in time; maintenance is carried out rapidly; and the maintenance cost is reduced.

Owner:广州英固特智能装备有限公司

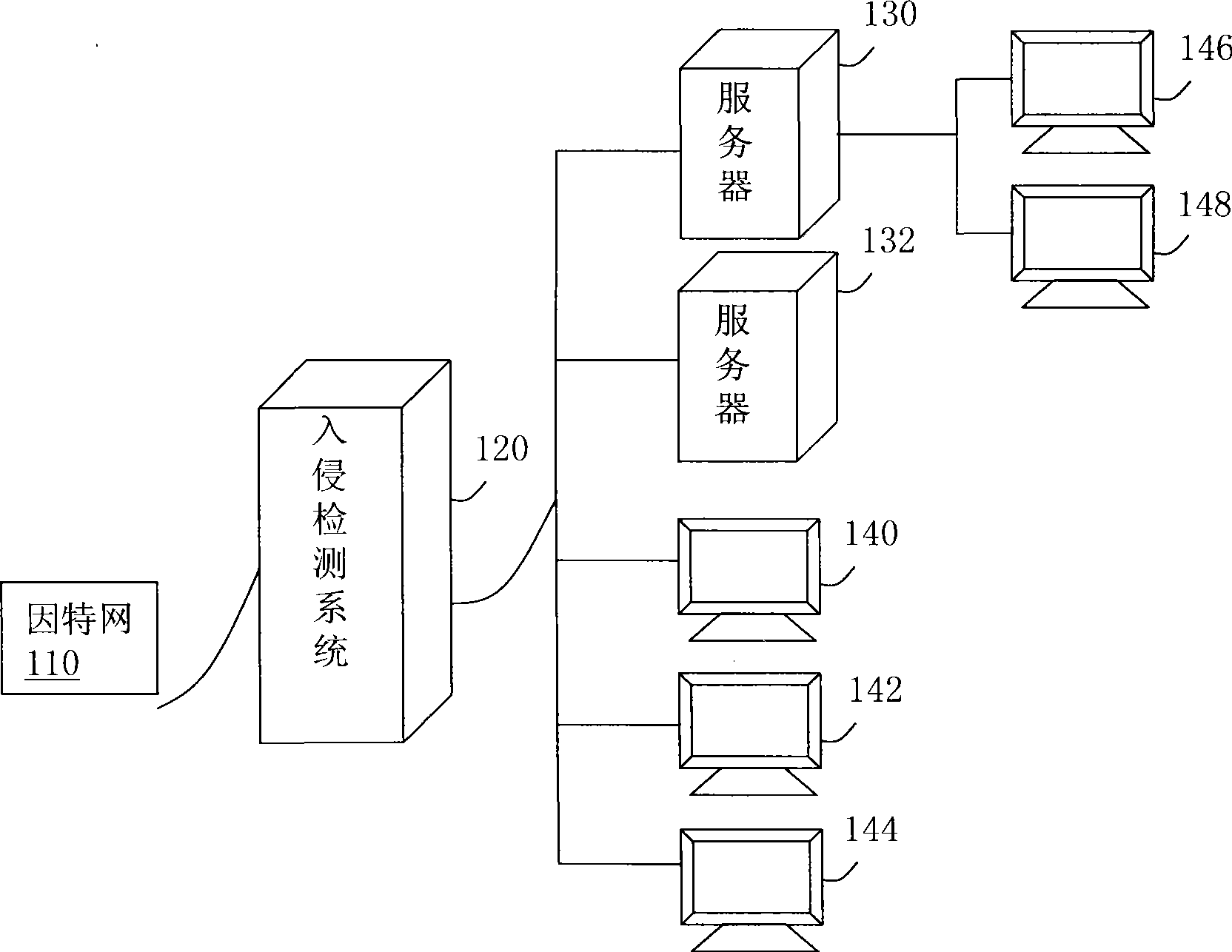

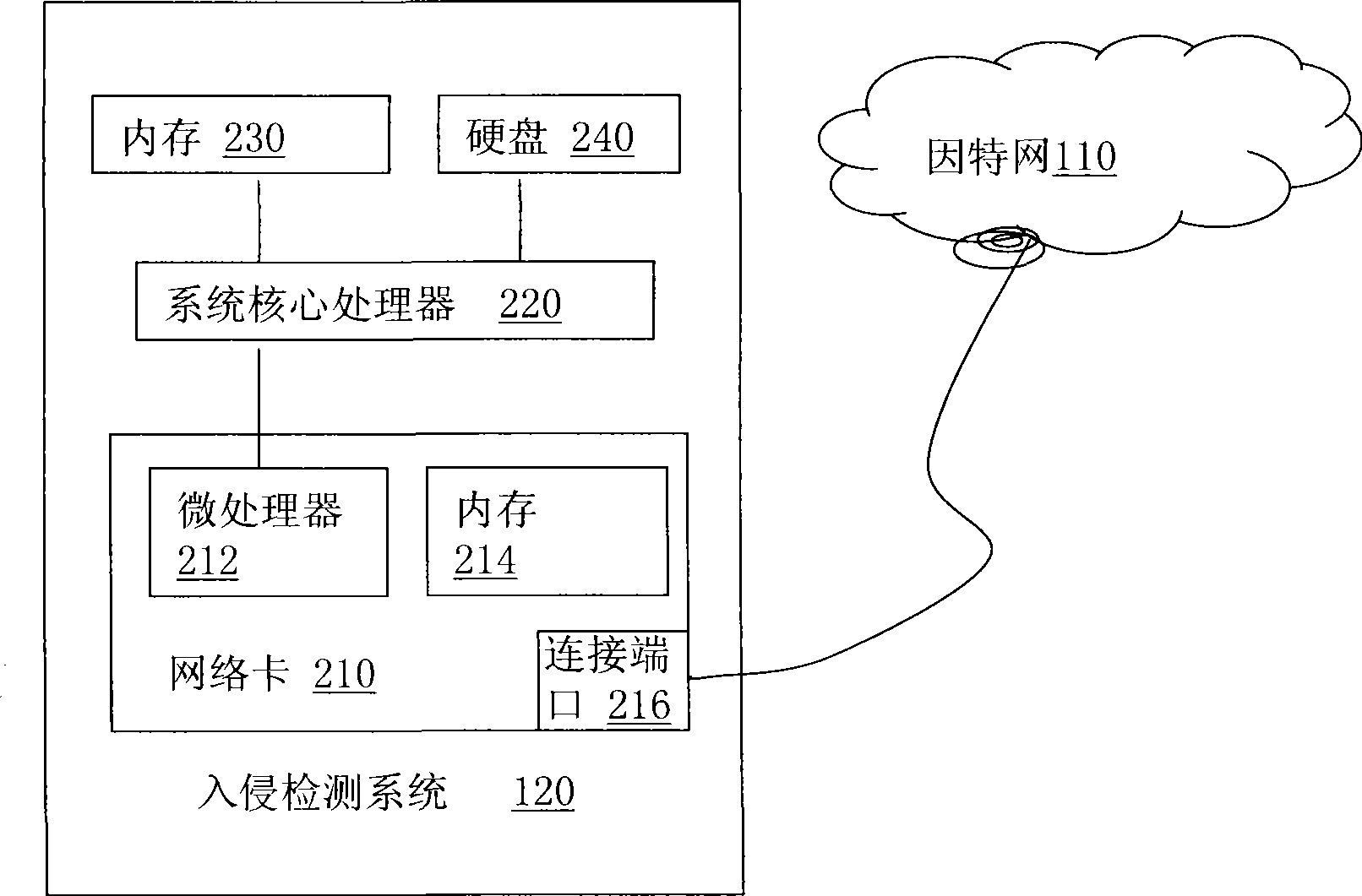

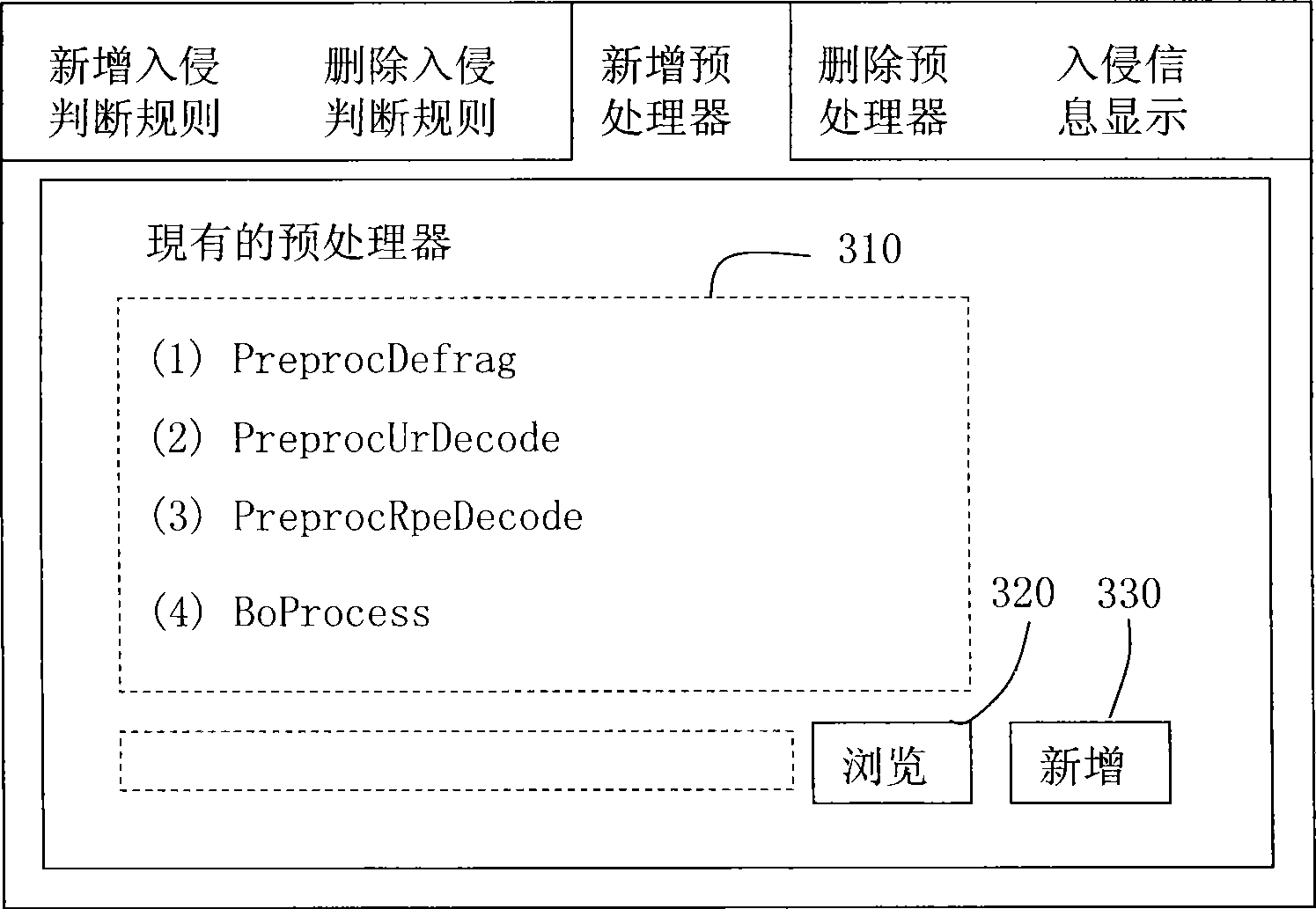

Network intrusion detection system

InactiveCN101453363ASuitable for processing needsData switching networksNetwork intrusion detectionSource address

The invention relates to a network intrusion detection system, which is arranged at an important network node, and used for detecting and monitoring a network packet. The network intrusion detection system comprises a network card and a system core processor. When the network packet is received, a microprocessor of the network card performs a packet parsing program and a packet preprocessing program to distinguish packet type and source address and convert the packet into an intrusion detection format packet in advance. Later, the system core processor judges whether the intrusion detection format packet is an intrusion packet. Because calculation burden of the programs for parsing the packet and preprocessing is shared by the network card, the network intrusion detection system is not easy to lose the packet due to overweight calculation burden, and improves accuracy greatly.

Owner:INVENTEC CORP

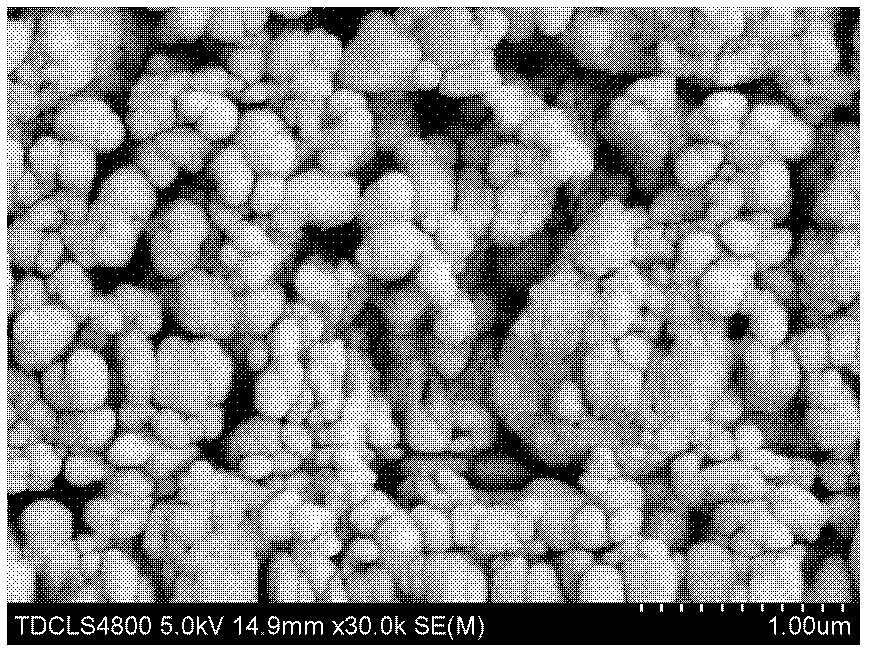

Toughening polylactic acid resin composition

The invention provides a toughening polylactic acid resin composition comprising 100 parts by weight of polylactic acid, 5-25 parts by weight of toughening agent and 0.1-1 part by weight of first antioxidant, wherein the toughening agent is a copolymer of a core-shell structure which takes butadiene-styrene copolymer as a core and takes epoxypropyl methacrylate compolymer as a shell. According to the toughening polylactic acid resin composition provided by the invention, the copolymer of the core-shell structure which takes butadiene-styrene copolymer as the core and takes epoxypropyl methacrylate compolymer as the shell is taken as the toughening agent to toughen polylactic acid, and the toughening agent can be used for effectively improving the breaking elongation, impact strength and tensile strength of the polylactic acid, so that the polylactic acid with good comprehensive performance is obtained. Mechanics performance testing results show that the impact strength of the toughening polylactic acid resin composition provided by the invention reaches up to 66.8KJ / m<2>, the breaking elongation is about 200% and the tensile strength reaches up to 56.4MPa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

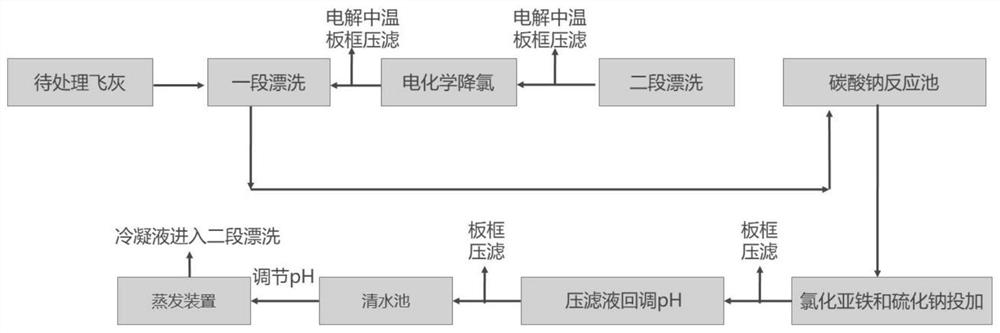

Efficient household garbage incineration fly ash two-stage washing process

InactiveCN112775145AHigh dechlorination efficiencyReduce Chloride ContentTransportation and packagingSolid waste disposalElectrolysisEnvironmental engineering

The invention discloses an efficient household garbage incineration fly ash two-stage washing process. According to the efficient household garbage incineration fly ash two-stage washing process, electrolysis dechlorination is performed on effluent after second-stage rinsing, the chlorine content of the second-stage rinsing entering first-stage rinsing is reduced, meanwhile, medium-temperature electrolytic plate frame pressing filtering is adopted, the pressing filtering fly ash water content is controlled to be less than 25%, the dissolution and adsorption effects of bound water on chloride ions are reduced, so that the chloride ion content in fly ash after the second-stage rinsing is guaranteed to be less than 0.8%, and the requirements for entering a cement kiln are met; and meanwhile, according to the efficient household garbage incineration fly ash two-stage washing process, the chlorine ion dissolution process in the first-stage rinsing process is promoted by reducing the chlorine ion content in the second-stage rinsing pressing filtering effluent, and the efficient household garbage incineration fly ash two-stage washing process is one efficient and economical household garbage fly ash washing process.

Owner:江山市虎鼎环保科技有限公司

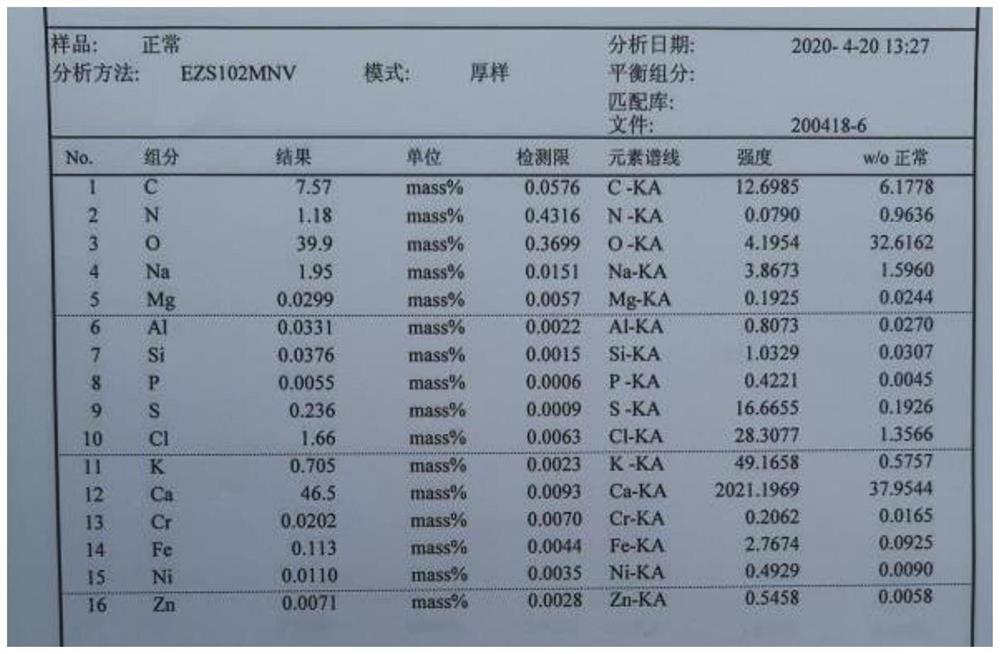

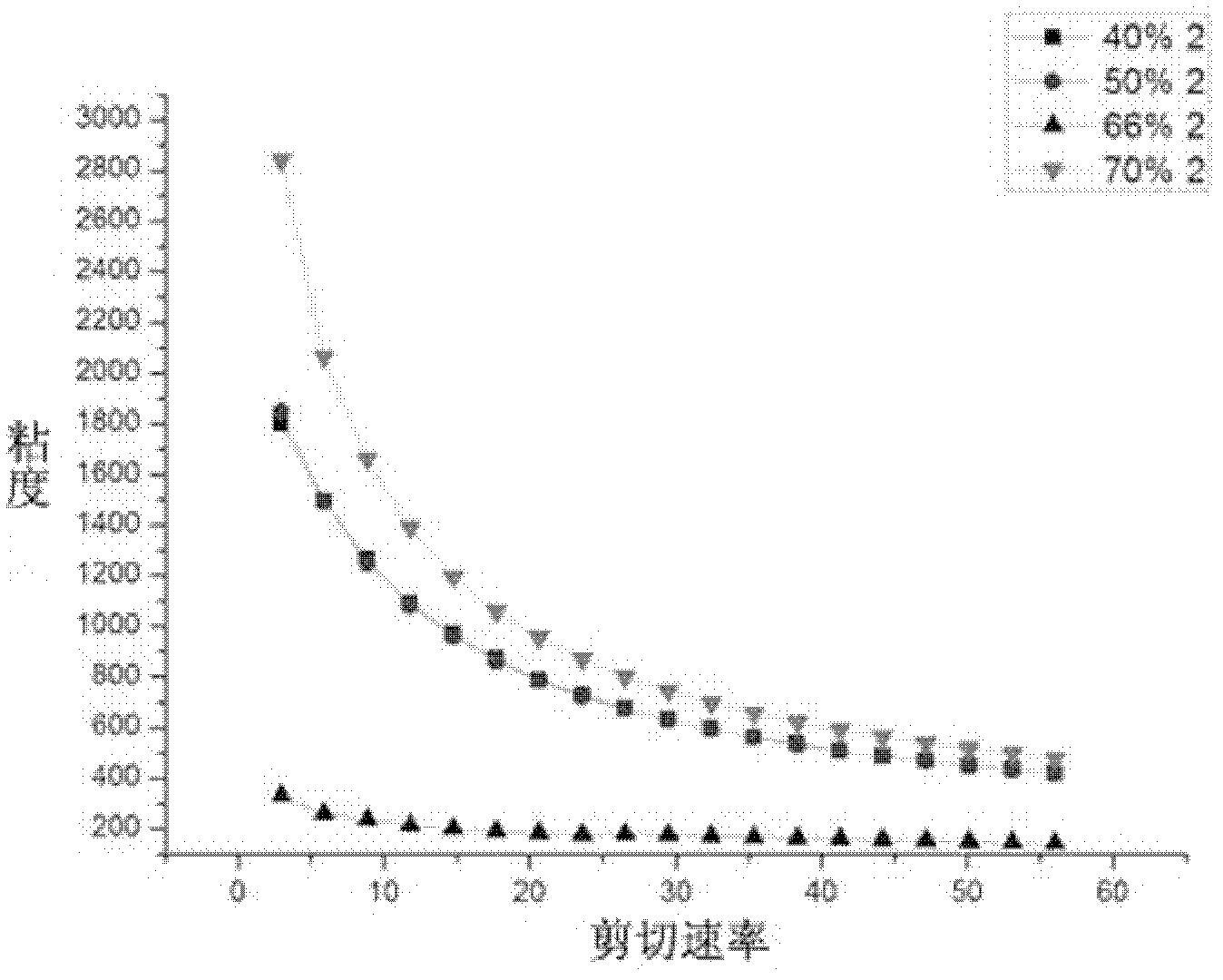

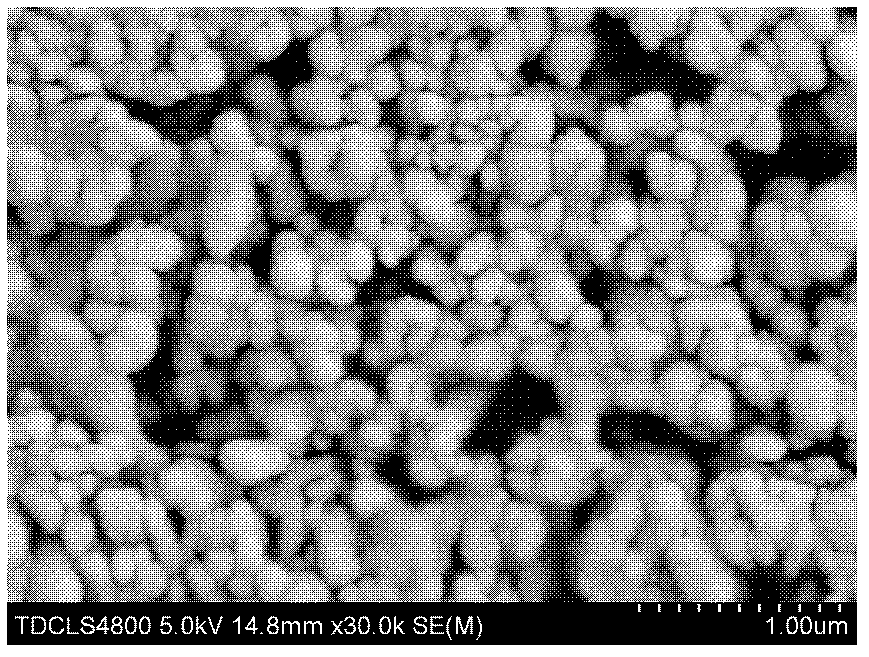

Method for preparing BST-MgO (barium strontium titanate-magnesium oxide) based ceramic tape-casting slurry and blanks

InactiveCN102408232AImproved rheological propertiesLow viscosityBarium strontium titanatePolyethylene glycol

The invention relates to a method for preparing BST-MgO (barium strontium titanate-magnesium oxide) based ceramic tape-casting slurry and blanks, which is characterized in that through the selection of organic additives and the pretreatment of powder and the like, the reaction between B2O3 and PVB in a formula is restrained, then, a tape-casting slurry system which is moderate in viscosity and good in liquidity is obtained, and finally, a BST-MgO tape-casting blank which is good in structure and performance is prepared. The method provided by the invention is implemented according to the following technical scheme: through taking ethanol-xylene as a solvent, polyvinyl butyral (PVB) as an adhesion agent, polyethylene glycol (PEG) as a dispersant and dibutyl phthalate (DBP) as a plasticizer, BST-MgO based tape-casting slurry taking B2O3-Li2CO3 as a sintering assistant is prepared, and finally, a high-quality tape-casting blank is formed for laying an application foundation for LTCC (low temperature co-fired ceramic) devices. The slurry prepared by using the method disclosed by the invention is good in rheological properties and low in viscosity; and the blank prepared by using the method disclosed by the invention is uniform and compact in microstructure, and the strength of the blank is suitable for machining needs.

Owner:TIANJIN UNIV

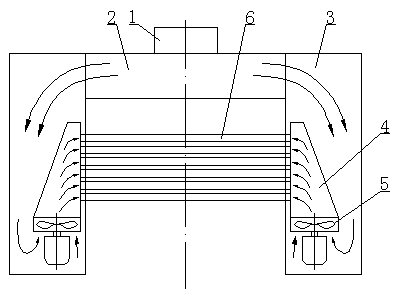

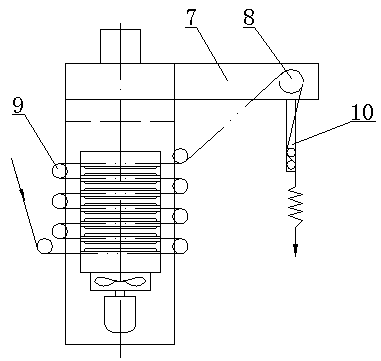

Air cooling device used for textile printing and dyeing industry

InactiveCN103510317ASuitable for processing needsImprove cooling effectTextile treatment machine partsLiquid/gas/vapor treatment of indefinite length materialsTextile printerCooling effect

The invention relates to an air cooling device used for the textile printing and dyeing industry. The air cooling device used for the textile printing and dyeing industry comprises a refrigeration air conditioner, a packaged air conditioner, tanks, tapered air hoses, axial fans, air blowing boxes, a cloth draw-out machine frame, a cloth draw-out pull roller, cloth guide rollers and a swinging cloth draw-out device, wherein the tanks are arranged on the two sides of the packaged air conditioner provided with the refrigeration air conditioner, an inner cavity of the packaged air conditioner is communicated with inner cavities of the tanks, the tapered air hoses of which the lower ends are provided with the axial fans are installed inside the tanks, the air blowing boxes are arranged in an up-and-down mode, penetrate through panels on the inner sides of the tanks and are connected and communicated with the tapered air hoses, a fabric channel is formed between two adjacent air blowing boxes, the cloth guide rollers are installed on the front face and the back face of each tank in a staggered mode and can enable fabric to be located in the middle of the fabric channel, the cloth draw-out machine frame is installed at the front end of the packaged air conditioner, the cloth draw-out pull roller is installed at the front end of the cloth draw-out machine frame, and the swinging cloth draw-out device is installed at the lower end of the cloth draw-out pull roller. The air cooling device used for the textile printing and dyeing industry is simple in structure and good in cooling effect; as the front face and the rear face of the fabric are cooled in a penetrating mode, cooling is even, and the hand feeling of the fabric is fluffy.

Owner:扬州市江都印染机械有限公司

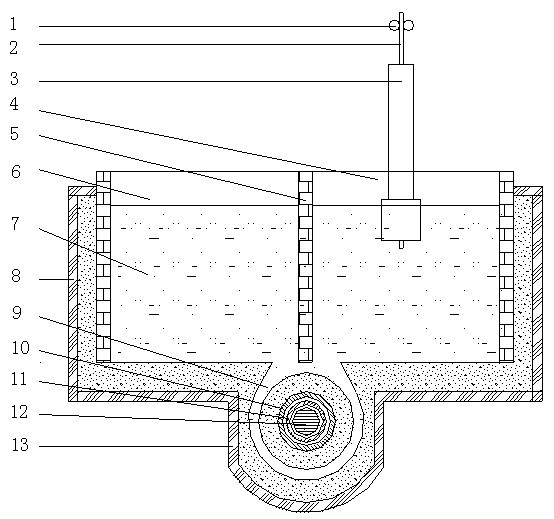

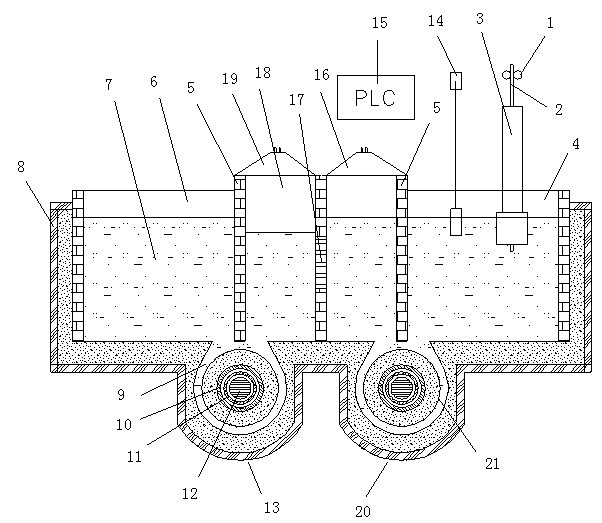

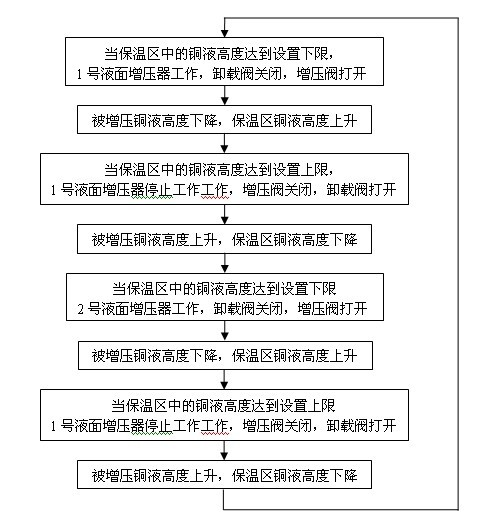

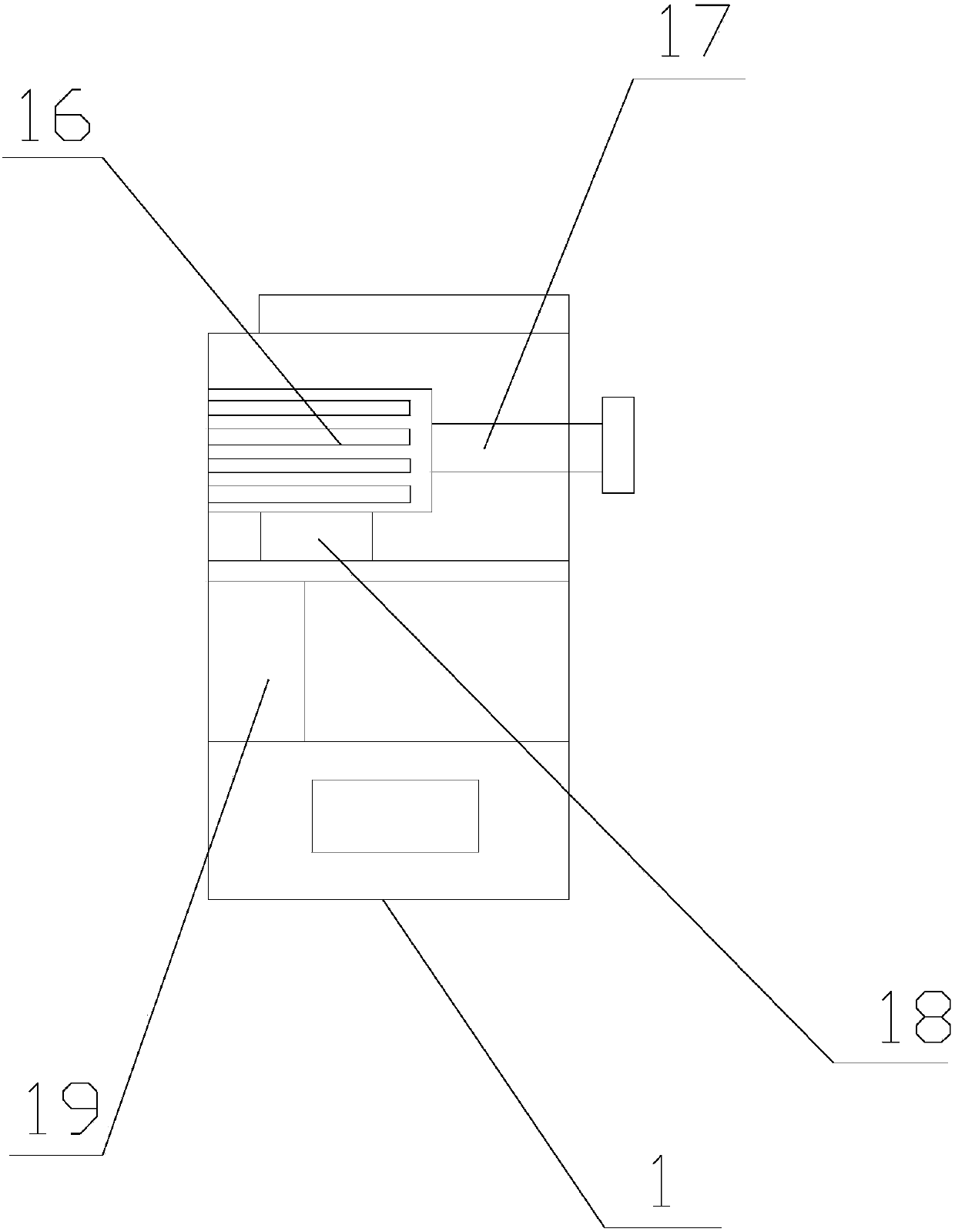

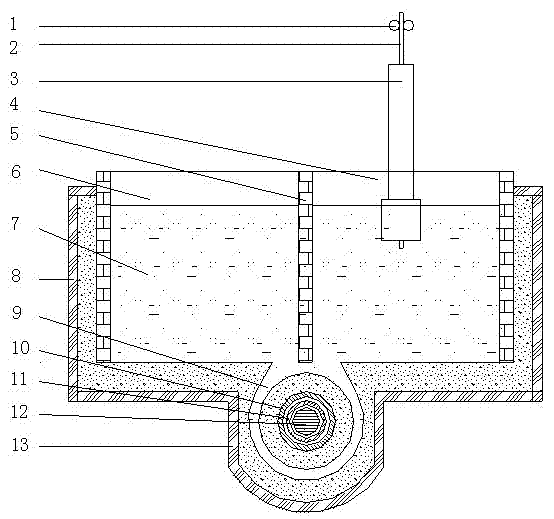

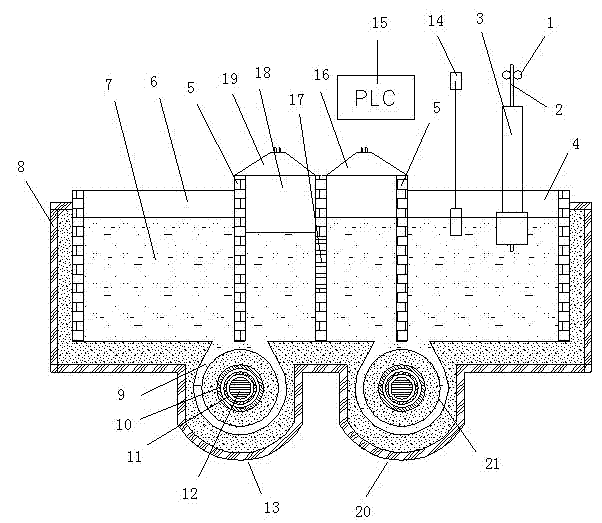

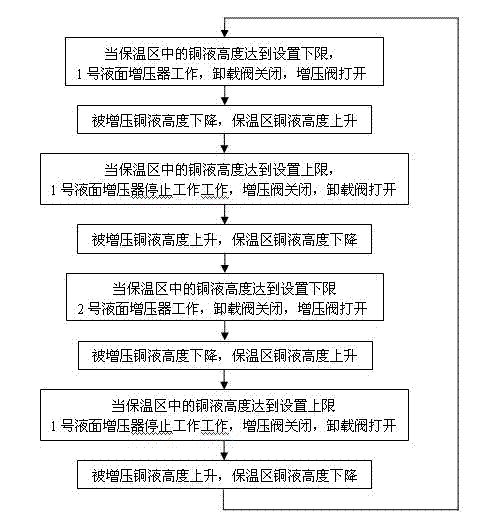

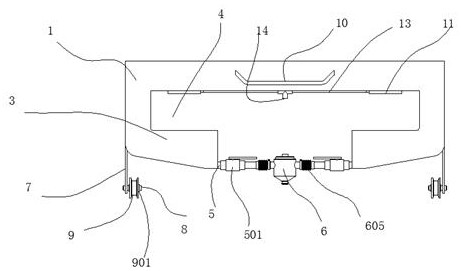

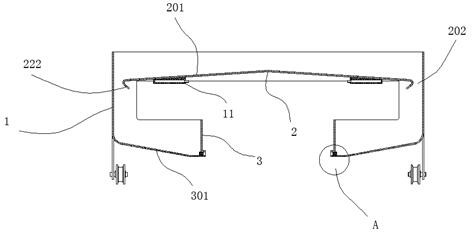

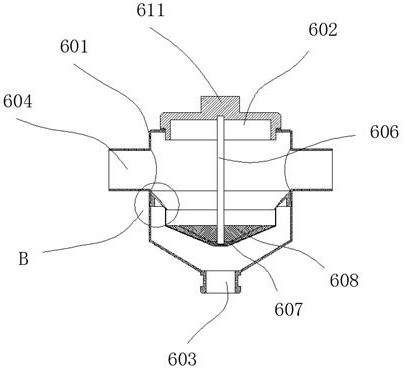

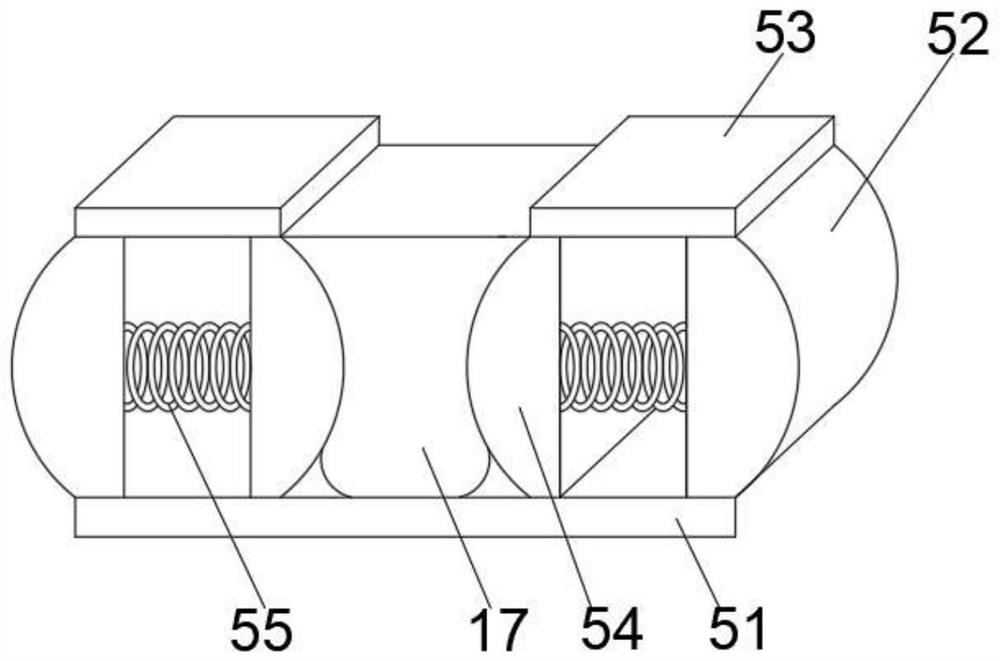

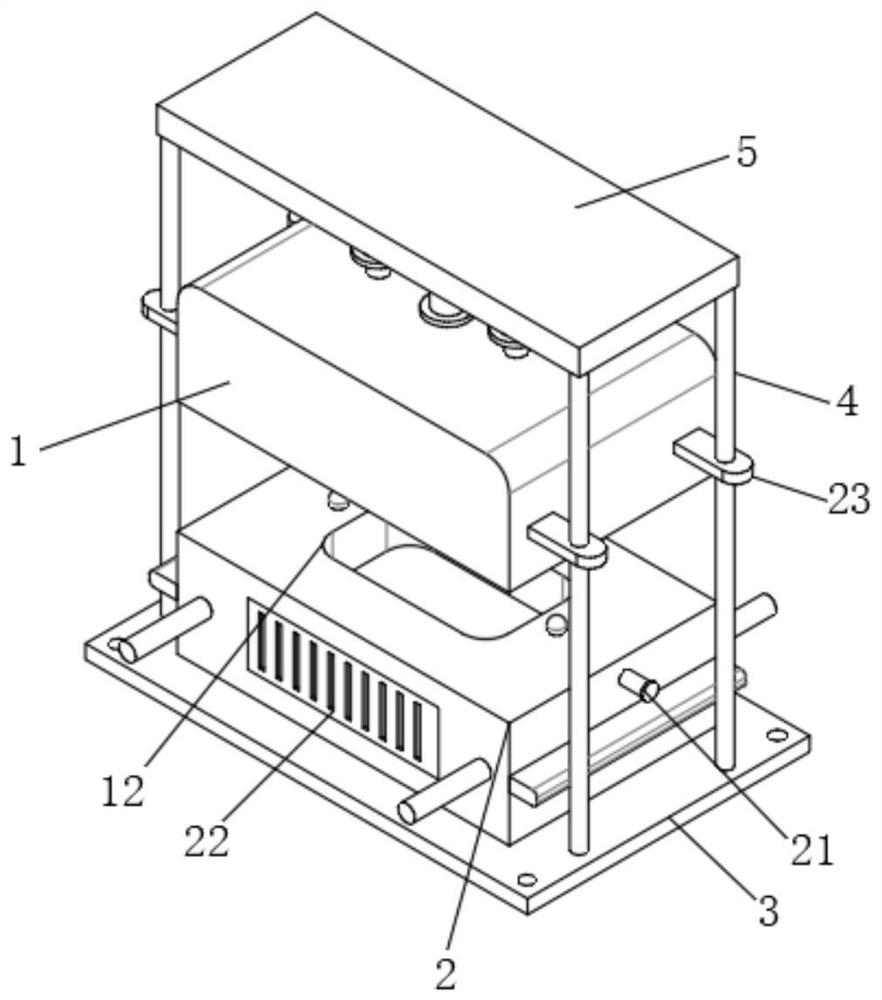

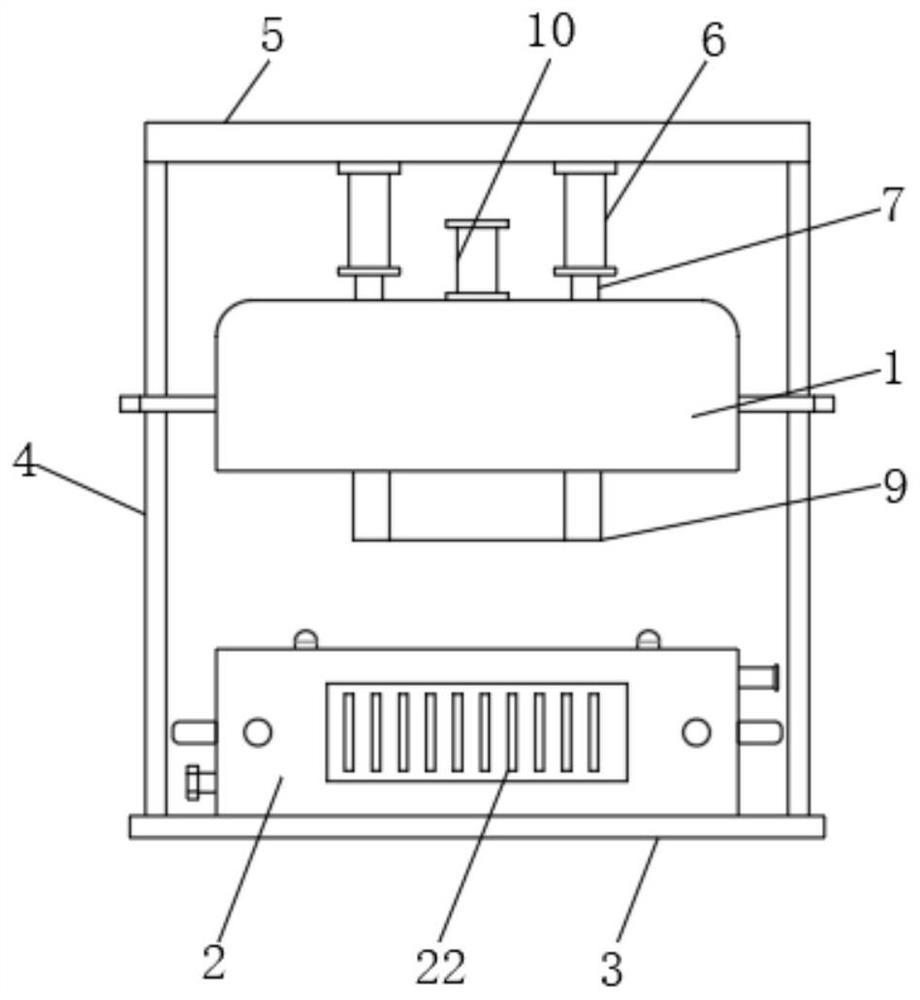

Double-molten channel three-body alloy smelting furnace with boosted stirring of liquid level

ActiveCN102022911AIncreased diffusion areaSpread evenlyCrucible furnacesEndless core furnacesDiffusionAlloy element

The invention relates to a double-molten-channel three-body alloy smelting furnace with boosted stirring of liquid level, comprising a furnace body (8). The three-body alloy smelting furnace is characterized in that the furnace body (8) is divided into three zones in total from front to back, namely, a smelting zone (6), a diffusion zone (18) and an insulating zone (4), wherein the smelting zone (6) and the diffusion zone (18) are connected by a molten channel I (9) arranged in a sensing chamber 1 (13) at the bottom of the furnace body (8), and the diffusion zone (18) and the insulating zone (4) are connected by a melting channel II (21) arranged in a sensing chamber 2 (13) at the bottom of the furnace body (8); the diffusion zone (18) is divided into a front zone and a rear zone by a partitioning plate (17) with a intercommunicating pore in the middle, the tops of the front zone and the back zone are respectively provided with a liquid level booster 1 (16) and a liquid level booster 2 (19); and the top of the insulating zone (4) is provided with a crystallizer (3), and also is provided with a liquid level control device (14) with a floating block. By utilizing the double-molten-channel three-body alloy smelting furnace, the blocking of the molten channels can be prevented, and alloy elements are uniformly diffused.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

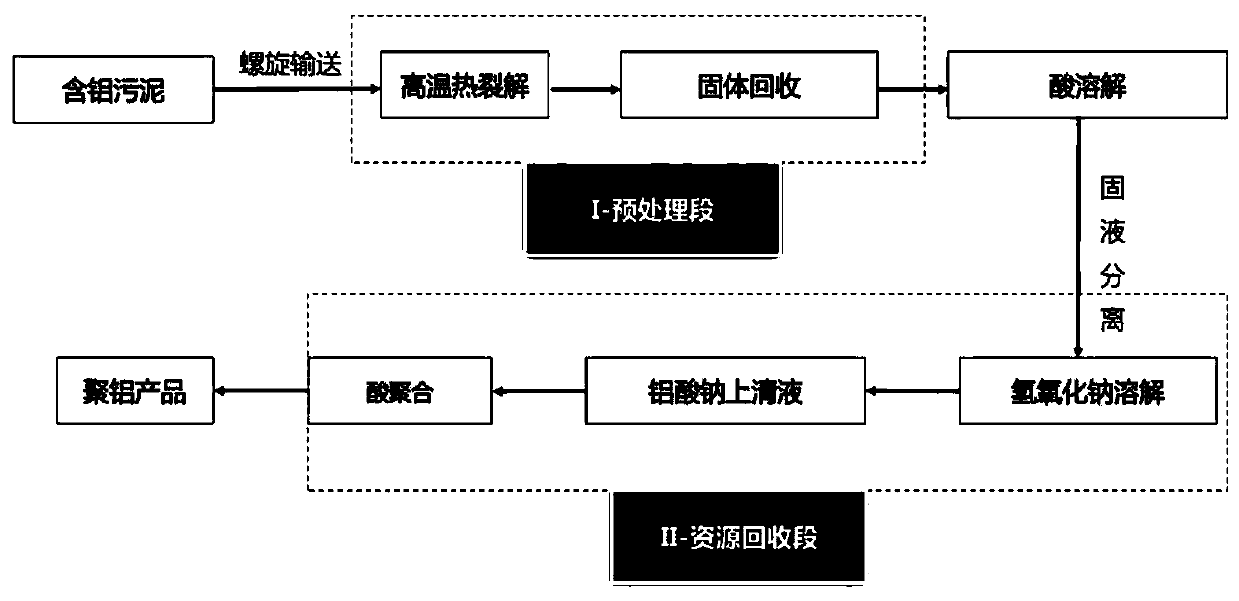

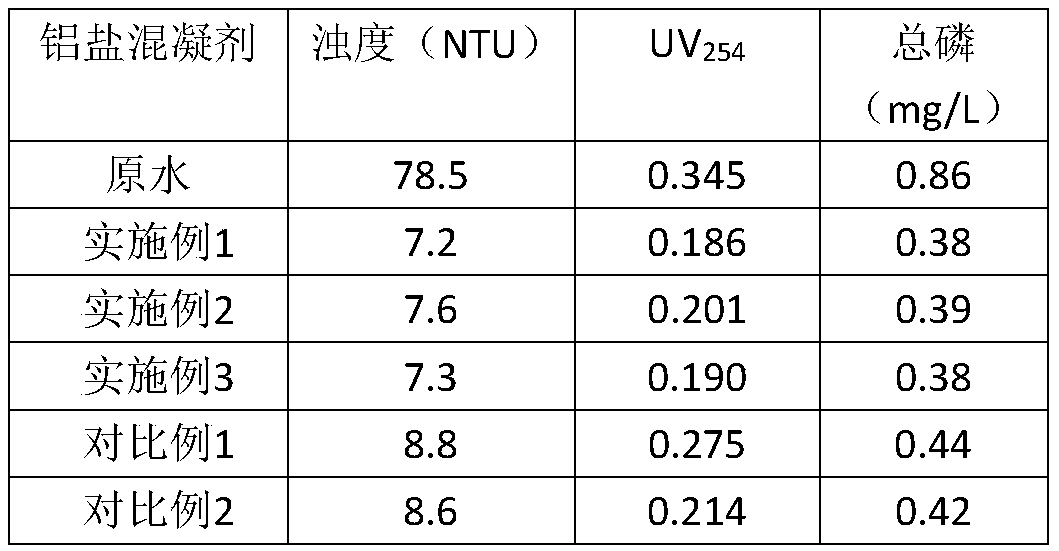

Method for recovering aluminum salt coagulant from aluminum-containing sludge

InactiveCN110963662ASuitable for processing needsSimple and fast operationSludge treatment by pyrolysisWater/sewage treatment by flocculation/precipitationSludgeSodium aluminate

The invention discloses a method for recovering an aluminum salt coagulant from aluminum-containing sludge, and belongs to the technical field of sludge treatment. The method comprises the following steps: firstly, conveying aluminum-containing sludge to a high-temperature oxygen-free thermal cracking system, and carrying out thermal cracking reaction under a high-temperature oxygen-free condition; secondly, acidifying and dissolving aluminum oxide-containing solid particles generated by the thermal cracking reaction by adopting hydrochloric acid, and filtering out insoluble substances to obtain an acidolysis solution; thirdly, adding an alkaline agent into the acidolysis solution to adjust the pH value of the system to be greater than 12, and filtering out insoluble substances to obtain asodium aluminate solution; and finally, adding hydrochloric acid into the sodium aluminate solution to adjust the pH value of the system to 1-2 to form a solution with polymerized soluble aluminum salt, and concentrating or drying the solution to obtain the aluminum salt coagulant. According to the method, the aluminum salt in the aluminum-containing sludge can be recovered and reused, and the aluminum salt coagulant is high in recovery rate and good in use effect.

Owner:上海净屹环保科技有限公司

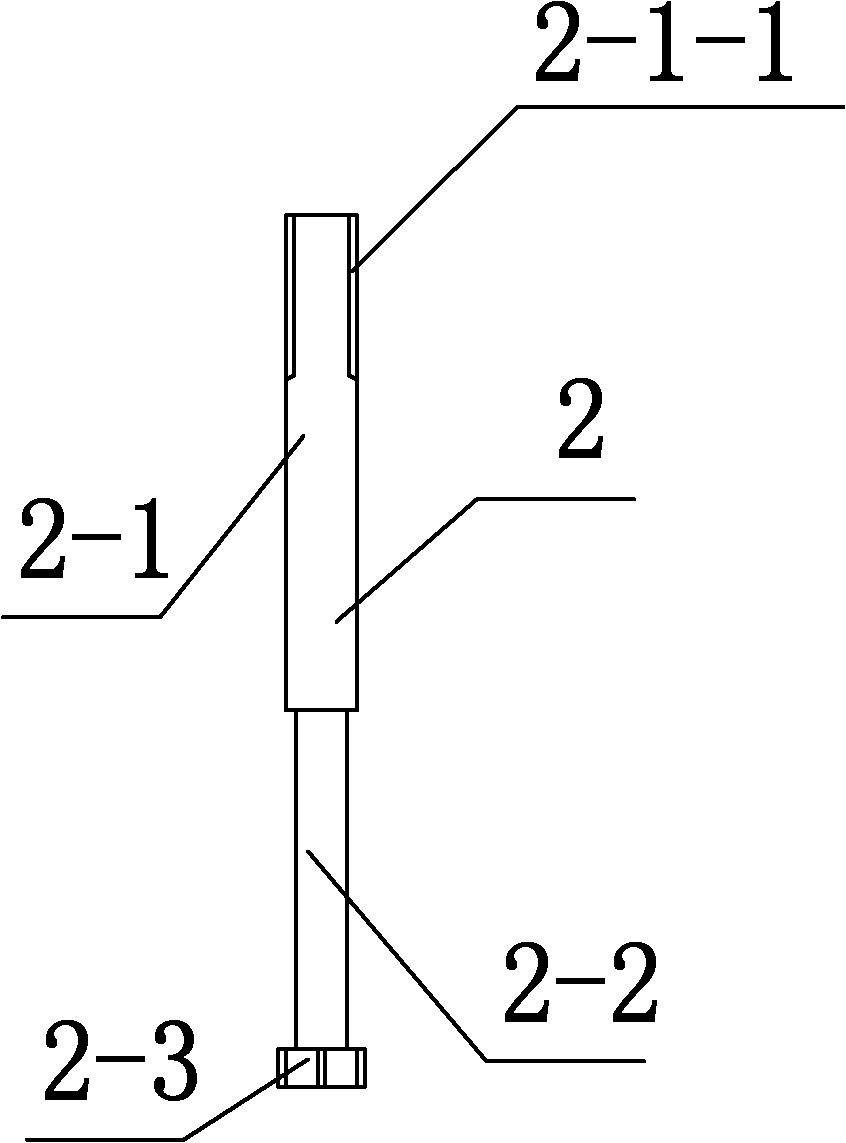

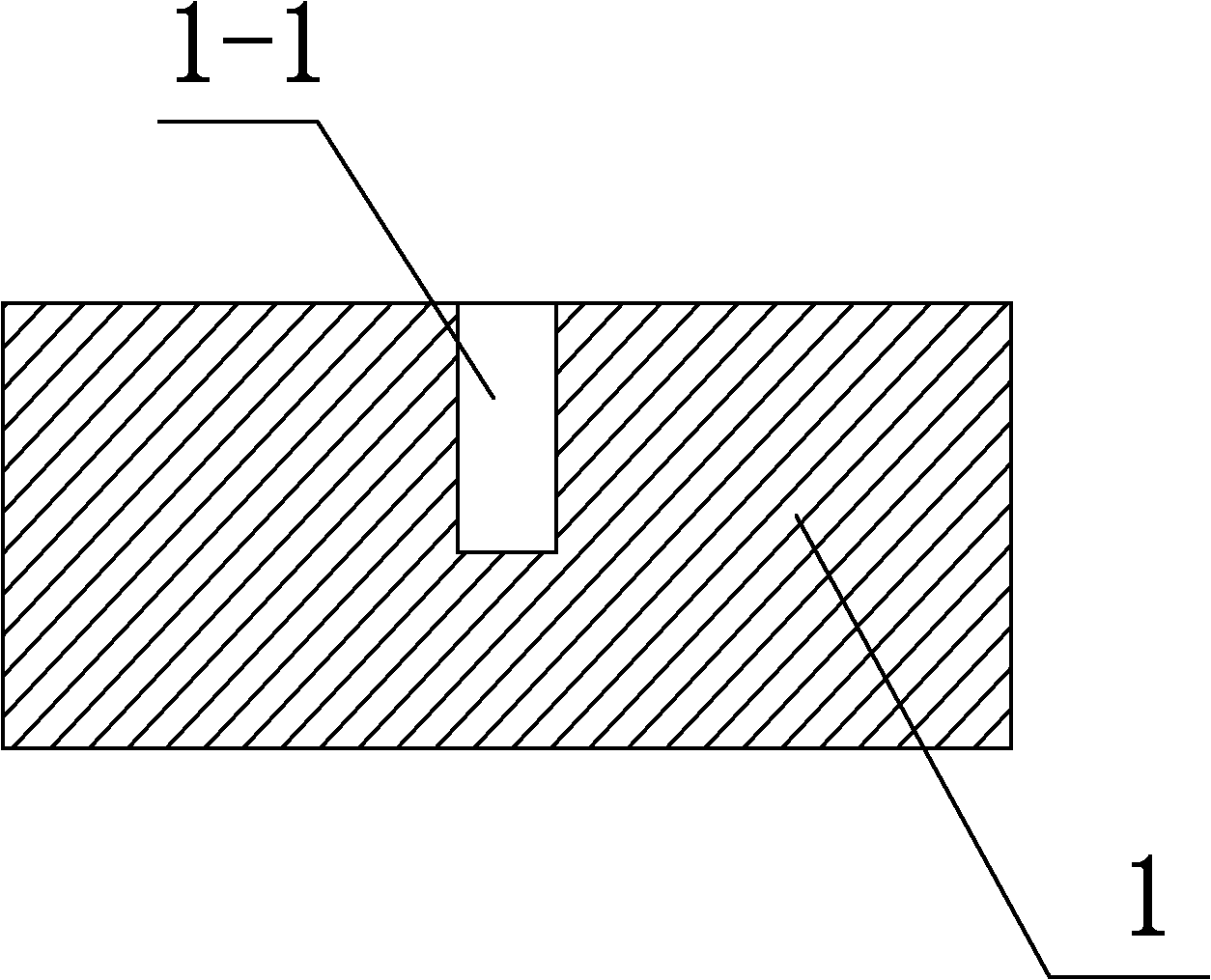

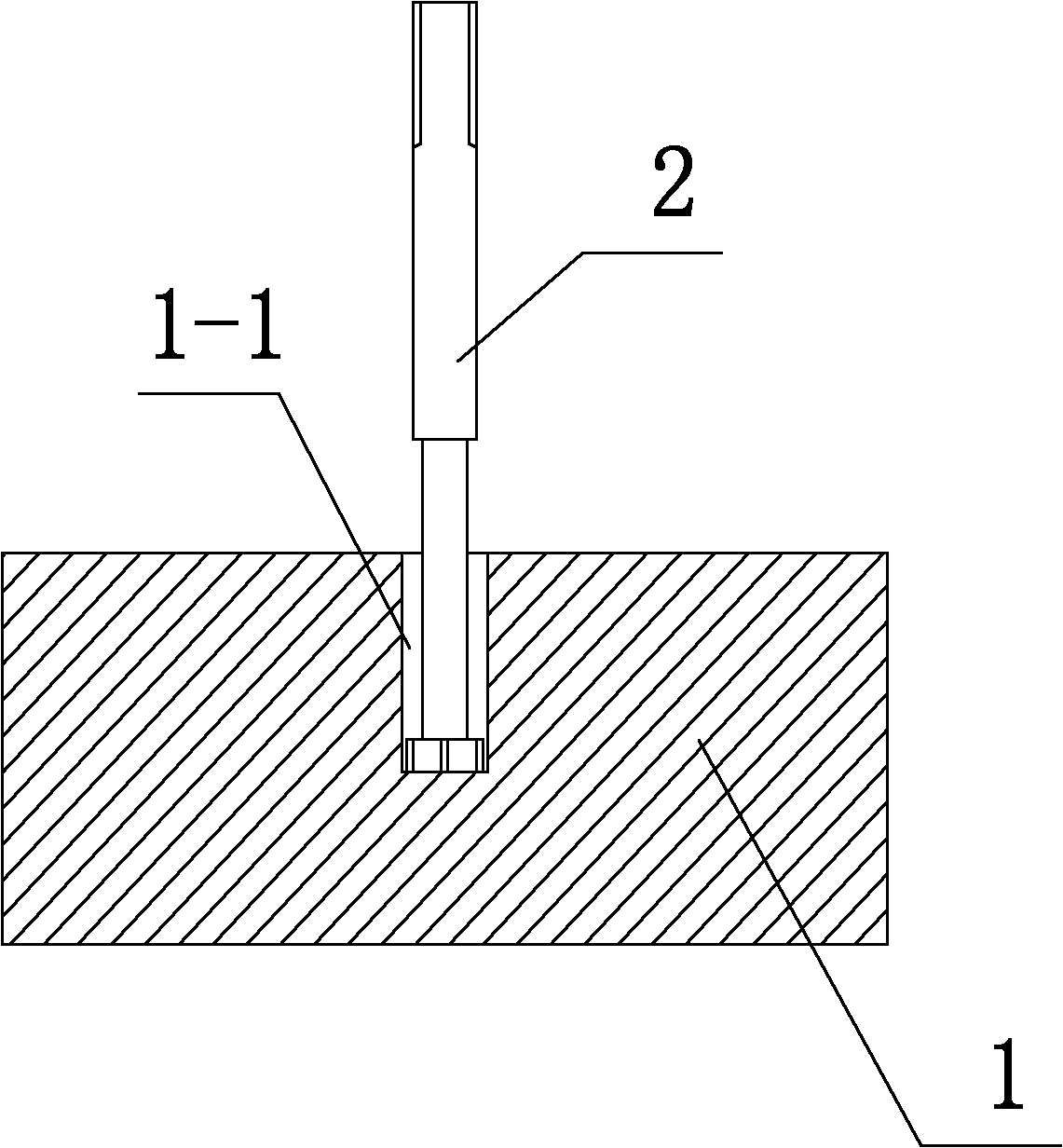

Threaded hole machining tool and method for machining threaded hole

InactiveCN102000892ASuitable for processing needsImprove machining accuracyThread cutting toolsEngineeringMachine tool

A threaded hole machining tool comprises a tool handle, a tool bar and a blade. The tool handle is arranged on the tool bar. A machining blade of which the diameter is less than the diameter of a hole to be machined is arranged at the bottom end of the tool bar. A clamping position is arranged on the tool handle. The invention provides a threaded hole machining tool and a method for machining a threaded hole by using the tool, which can machine the root of the hole, greatly improve the machining accuracy and meet the demand of machining the high-accuracy threaded hole by modern technology. The machined threaded hole can reach ultra-high machining accuracy.

Owner:JOHNSON PRECISION ENG SUZHOU

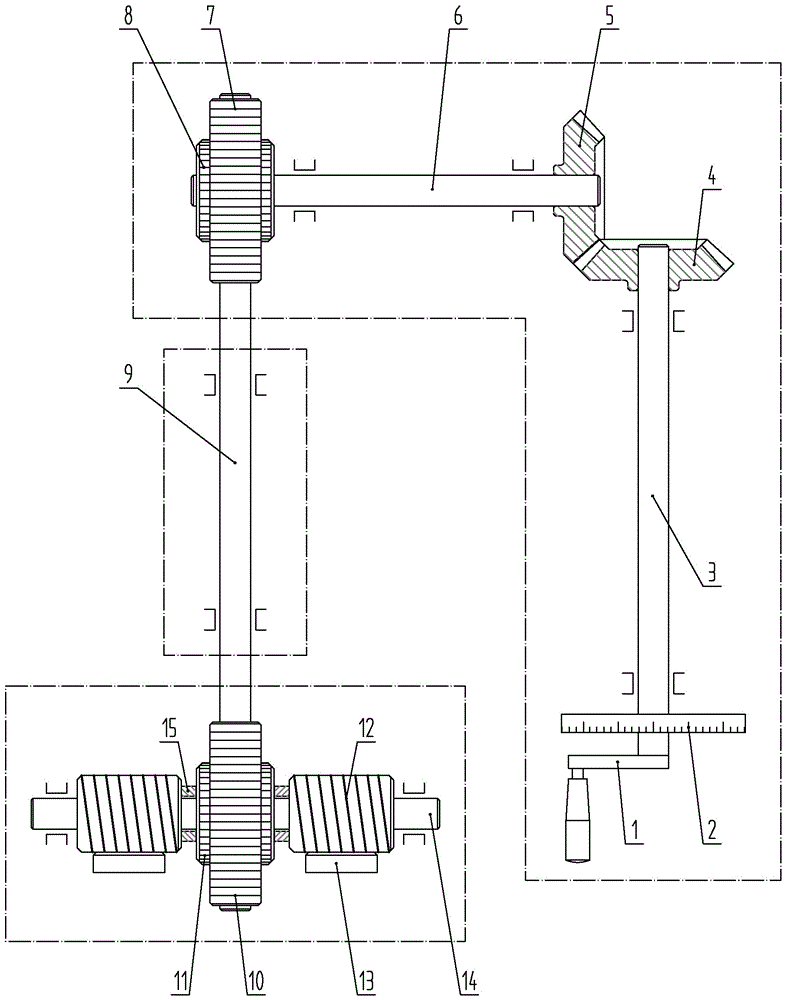

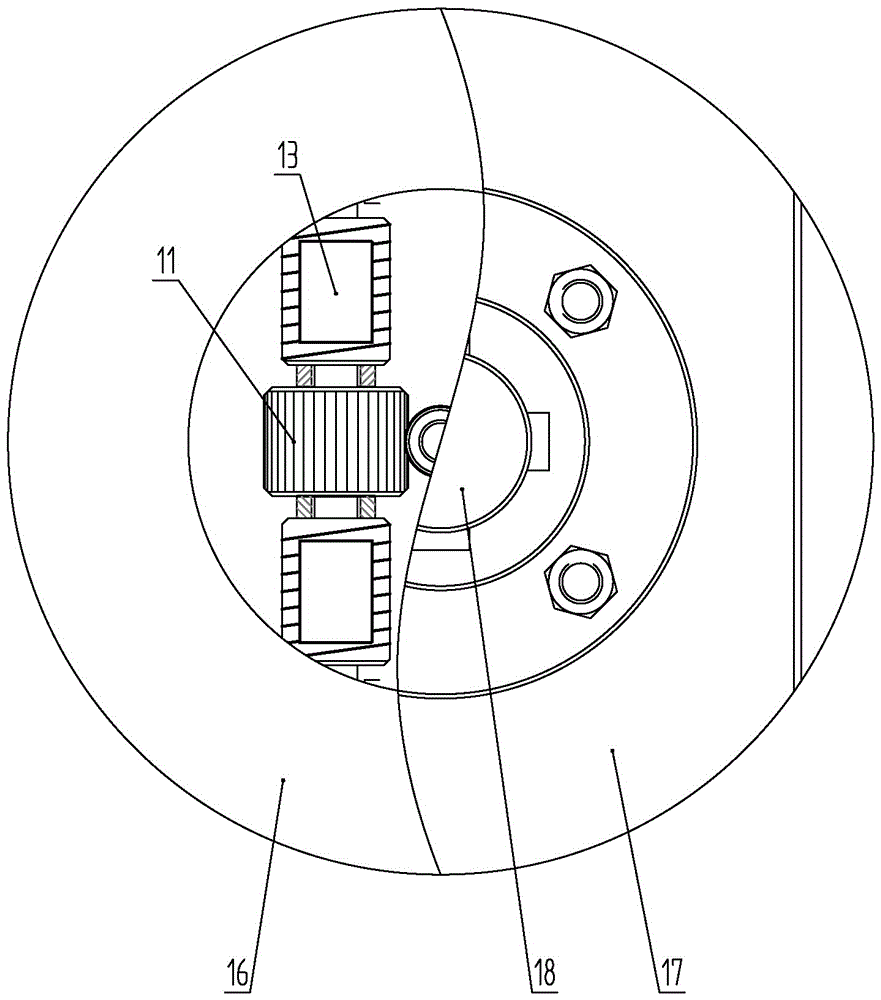

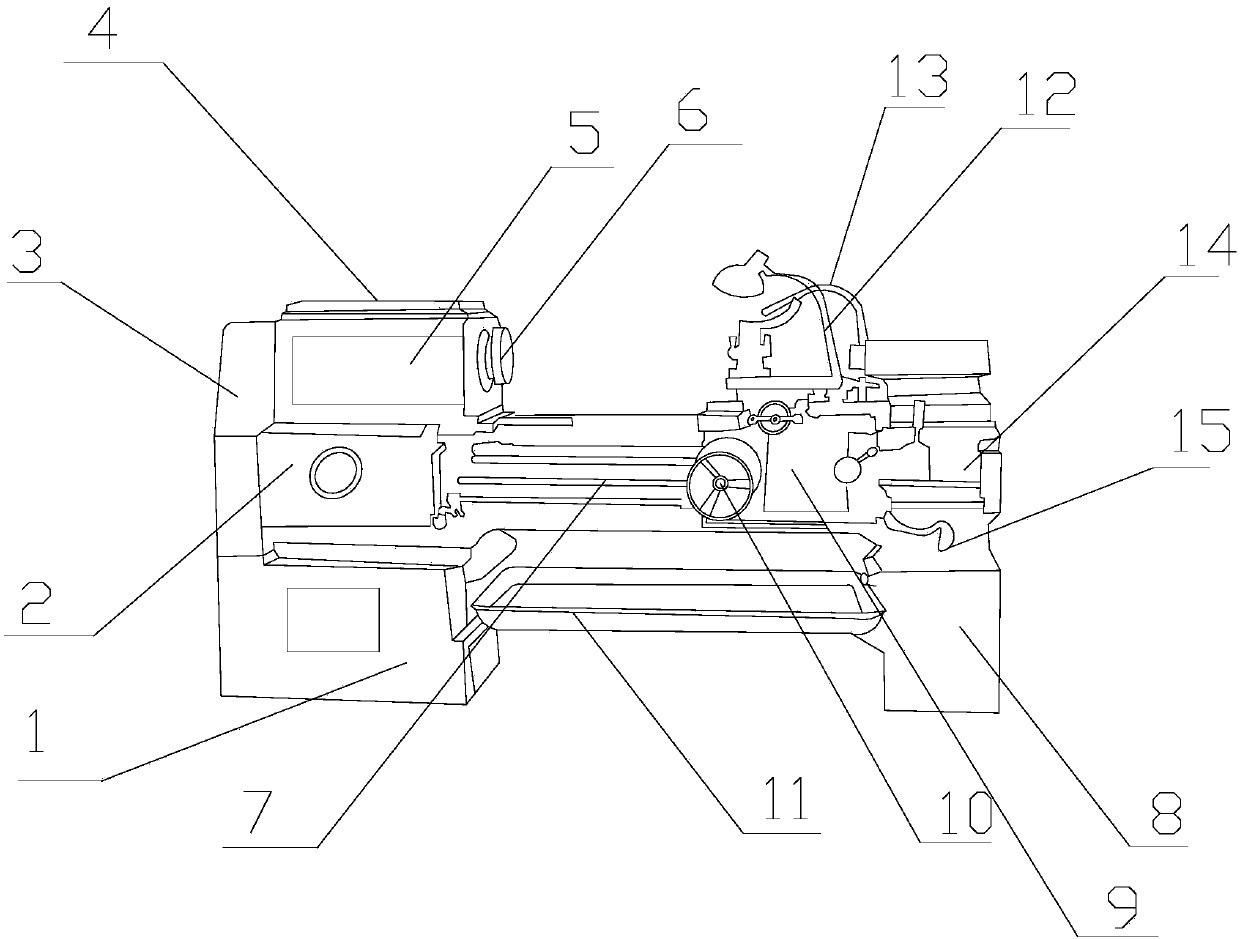

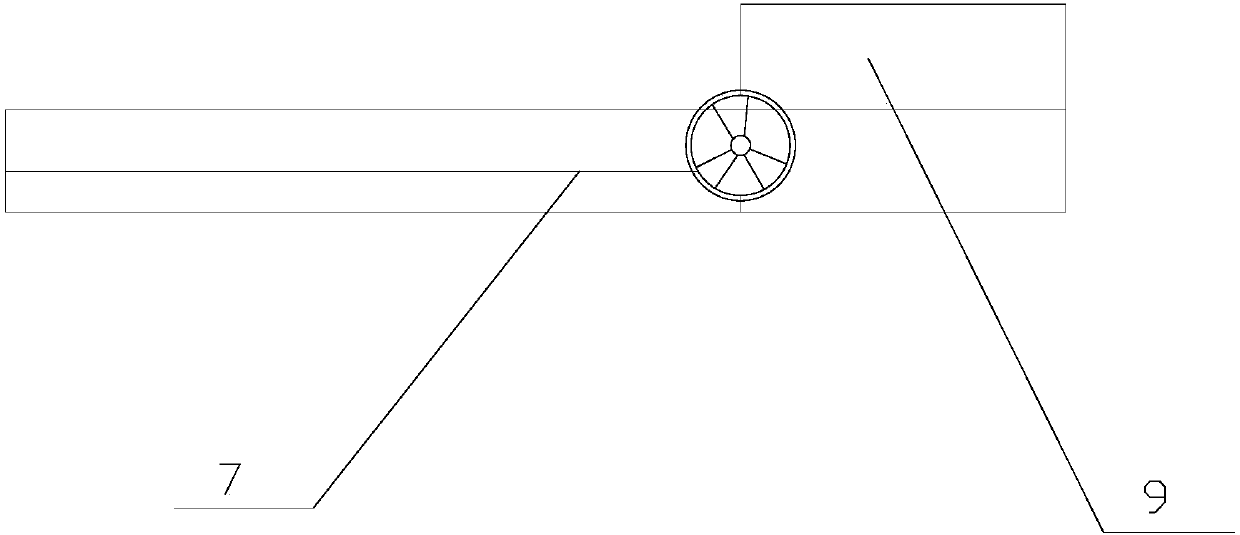

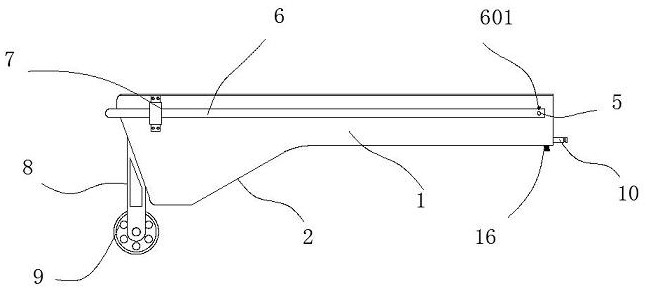

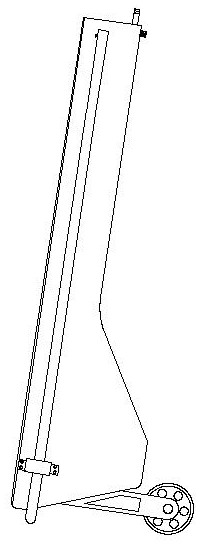

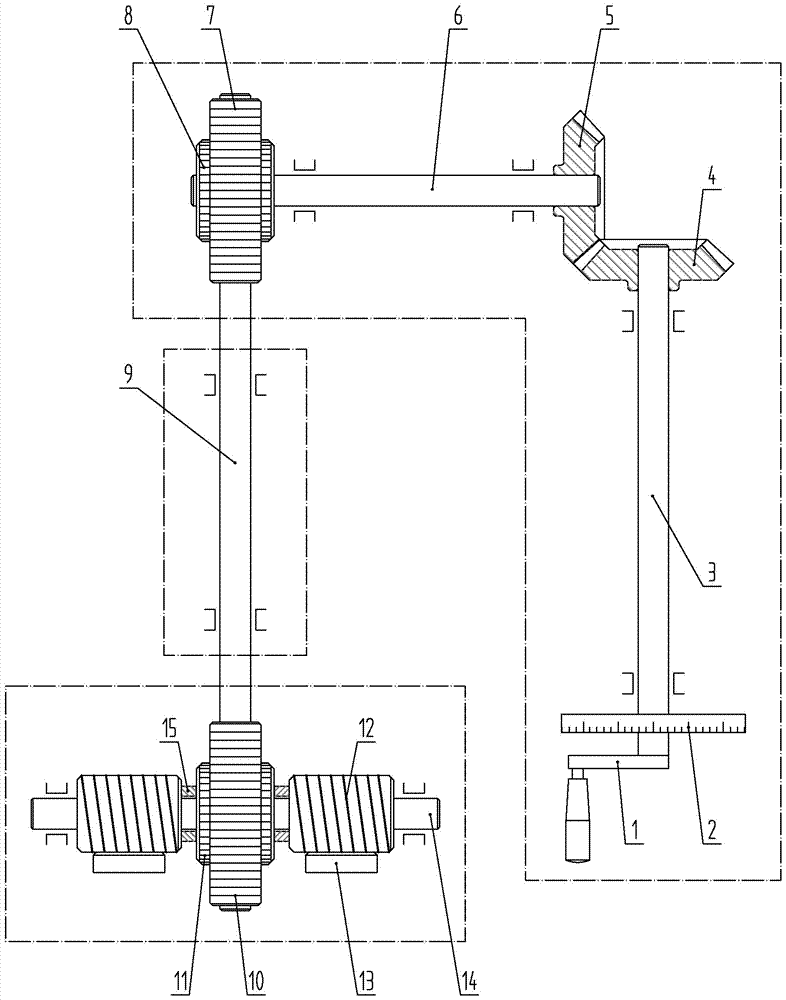

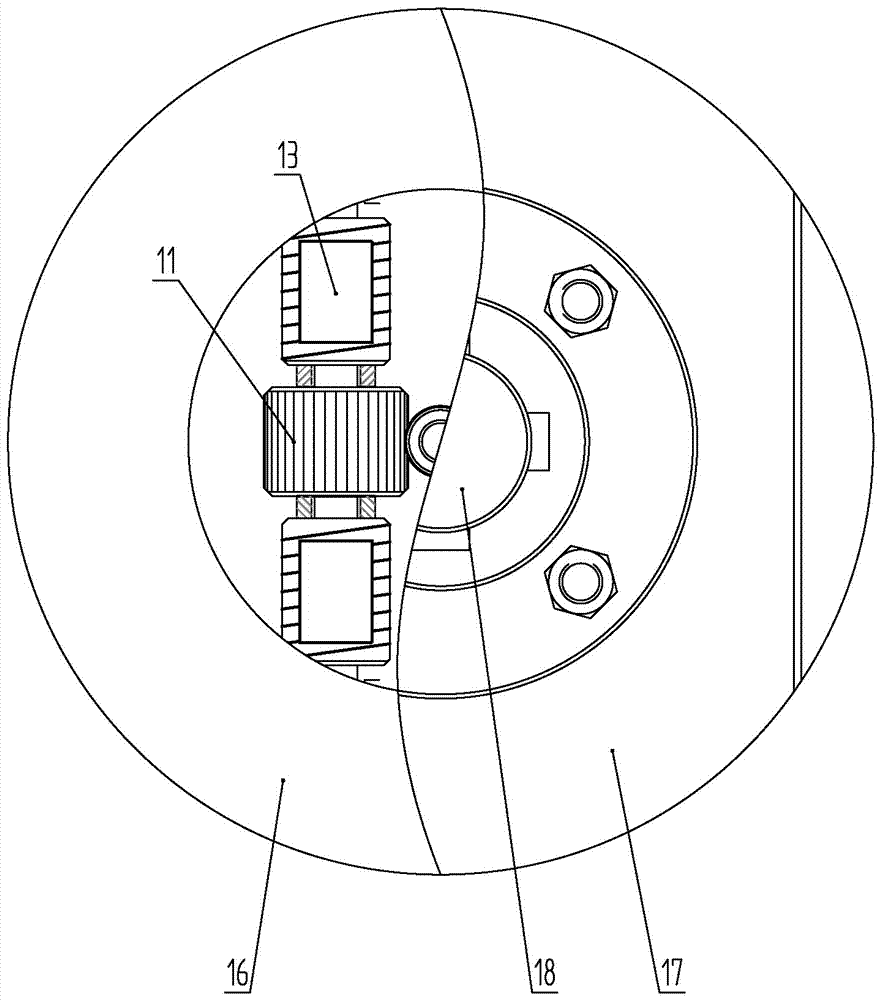

Boring assistance tool

ActiveCN105710405AMeet production requirementsEasy to disassembleFeeding apparatusBoring headsDrive shaftEngineering

The invention discloses a boring assistance tool which comprises a boring assembly and a transmission assembly. The boring assembly comprises a boring cutter head, a ram and a boring cutter. The ram is mounted on the surface of one side of the boring cutter head in a sliding manner, and the boring cutter is mounted in the center of the ram. The transmission assembly comprises a handle, a first transmission shaft, a second transmission shaft, a connecting shaft and a fixed shaft. The boring assistance tool has the beneficial effects that an existing lathe can have a boring function by being simply dismounted and mounted, the production requirements of small and medium fabrication plants are met greatly, the machining capacity of the fabrication plants is improved, and therefore the profit level is raised; the modification process is simple and easy to operate, the main structure of the lathe does not need to be destroyed, and therefore precision is guaranteed, and meanwhile additional functions are added; small displacement of the boring cutter is adjusted through a motion pair large in transmission ratio, and the machining precision is further improved; and the tool is simple and reliable in structure, low in cost and especially suitable for the machining needs of the small and medium fabrication plants.

Owner:日照市双驱机械制造有限公司

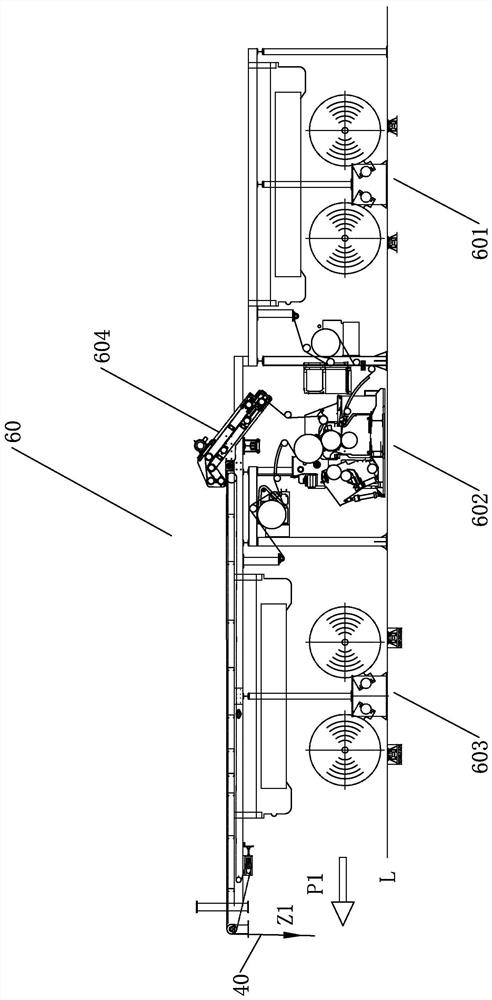

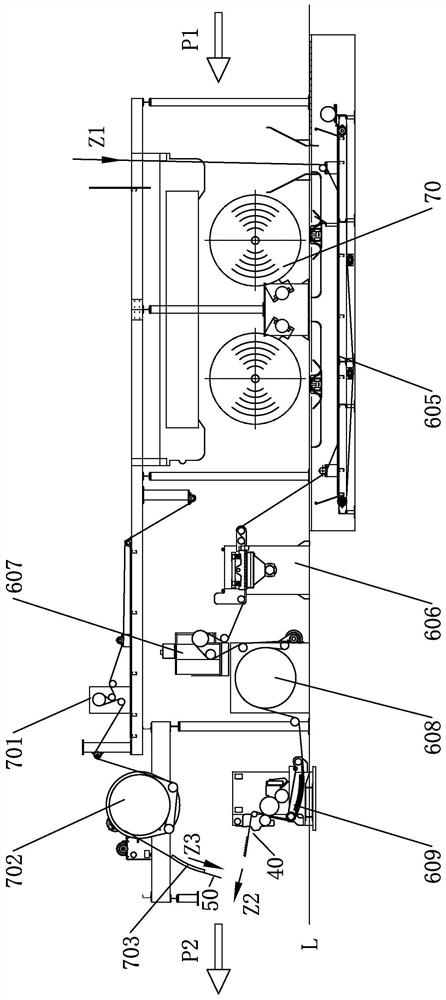

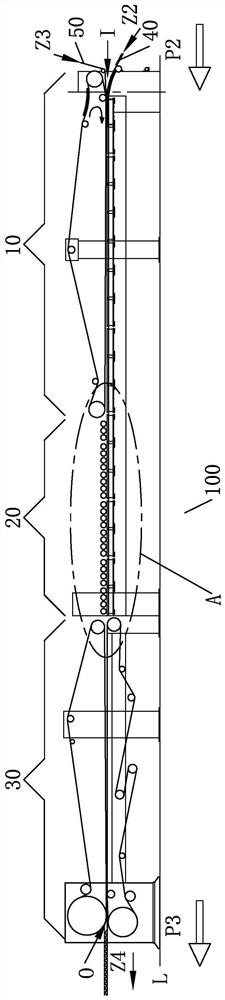

Low-loss environmental-friendly preprinted sheet upward production line and production process thereof

PendingCN111746053AReduce wasteAvoid wear and tearMechanical working/deformationLamination ancillary operationsPaperboardPaper production

The invention discloses a low-loss environmental-friendly preprinted sheet upward production line and a production process thereof. The low-loss environmental-friendly preprinted sheet upward production line structurally comprises a corrugated paper forming part, a preprinted sheet and corrugated paper conveying section and a double-faced machine, wherein the double-faced machine comprises a fronthot plate conveying part, a ventilating heating transition section and a back conveying part, heat sources are arranged on the upper and lower sides of a ventilating heating channel of the ventilating heating transition section, a plurality of rollers which are used for preventing the printing layer on the outer surface of a preprinted sheet from being scraped are arranged on the upper side of the ventilating heating channel, and ventilating clearances are formed between the rollers; when the preprinted sheet and corrugated paper on a preprinted sheet frame enter the double-faced machine, theprinting layer of the preprinted sheet is upward and synchronously moves together with the front hot plate conveying part, the rollers and the back conveying part so as to prevent from being scraped.According to the corrugated paper production line, the preprinted sheet frame approaches to the inlet end of the double-faced machine, so that the waste of the preprinted sheet is reduced; additionally, the printing layer of the preprinted sheet is upward, so that the printing layer can synchronously moves together with the conveying component of the double-faced machine, the abrasion is avoided,and the loss caused by scraping is reduced.

Owner:GUANGDONG WANLIAN PACKAGING MACHINERY

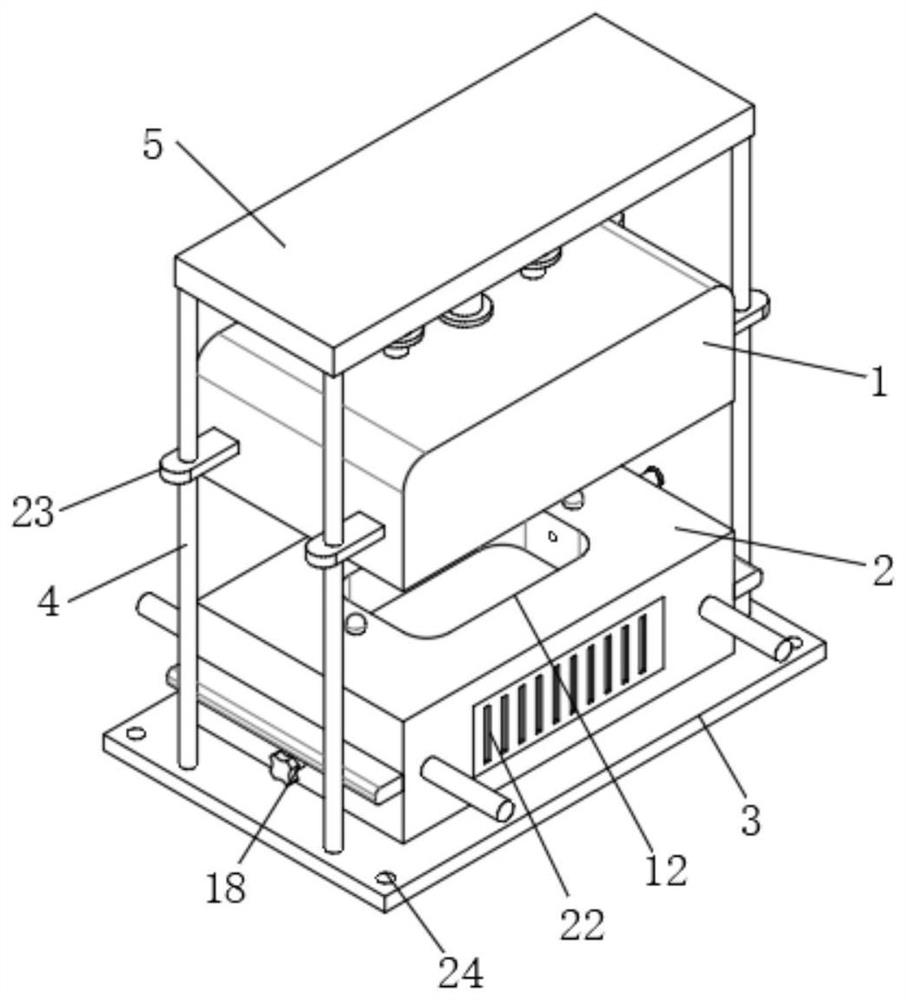

High-precision synchronous device for forging equipment

InactiveCN107716829AExpand coverageImprove usabilityForging/hammering/pressing machinesJoystickComputer engineering

The invention discloses a high-precision synchronous device for forging equipment. The structure includes: a base, a casing, a working casing, a storage table, an inspection window, a triangular clip, a slide rail, a fixed base, a processing device, a moving turntable, Waste collection tray, lighting lamp, water injection pipe, slide rail fixing seat, control lever, motor, rotating shaft, motor fixing seat, power supply device; the base is connected with an organic casing, and the casing is connected with a working casing. A storage table is provided on the working case, an inspection window is provided on the working case, a triangular clip is connected beside the working case, and a processing device is movably connected to the slide rail. The present invention can place the processing device in the Move on the guide rail, adjust the position of the processing device, locate the specific position for processing, and process some difficult-to-process positions, greatly improving the coverage and availability of processing, more convenient and easy to use, suitable for large-scale The industrial production and today's people's demand for processing.

Owner:TIANJIN JITAI HEAVY CASTING & FORGING

Toughening polylactic acid resin composition

The invention provides a toughening polylactic acid resin composition comprising 100 parts by weight of polylactic acid, 5-25 parts by weight of toughening agent and 0.1-1 part by weight of first antioxidant, wherein the toughening agent is a copolymer of a core-shell structure which takes butadiene-styrene copolymer as a core and takes epoxypropyl methacrylate compolymer as a shell. According to the toughening polylactic acid resin composition provided by the invention, the copolymer of the core-shell structure which takes butadiene-styrene copolymer as the core and takes epoxypropyl methacrylate compolymer as the shell is taken as the toughening agent to toughen polylactic acid, and the toughening agent can be used for effectively improving the breaking elongation, impact strength and tensile strength of the polylactic acid, so that the polylactic acid with good comprehensive performance is obtained. Mechanics performance testing results show that the impact strength of the toughening polylactic acid resin composition provided by the invention reaches up to 66.8KJ / m<2>, the breaking elongation is about 200% and the tensile strength reaches up to 56.4MPa.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

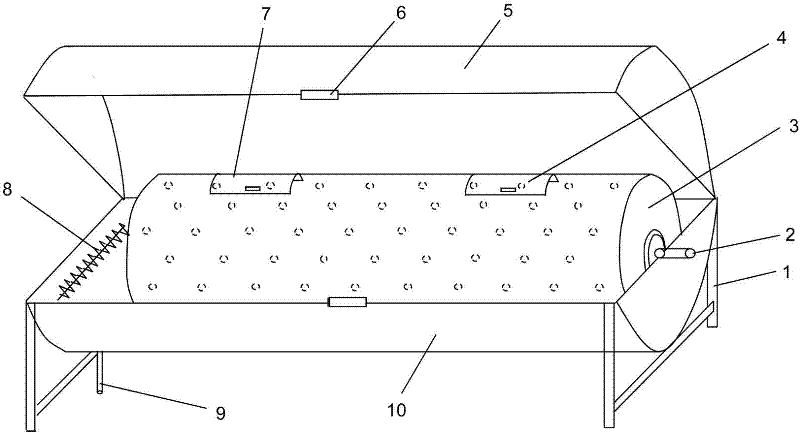

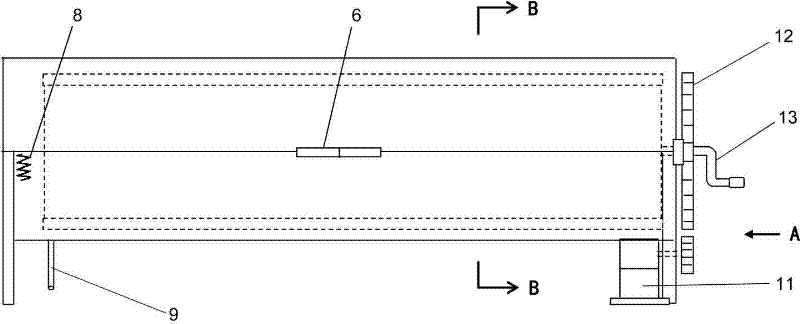

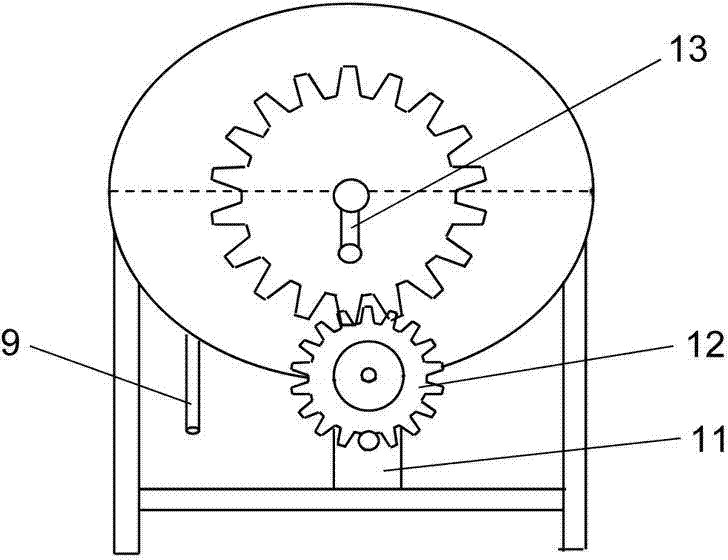

A drum type kitchen waste aerobic fermentation treatment device

InactiveCN102260098AFully stir fermentationFerment as soon as possibleClimate change adaptationOrganic fertilisersAgricultural engineeringFermentation

The invention relates to a drum-type aerobic fermentation treatment device for kitchen waste, which belongs to the technical field of aerobic fermentation of garbage. Shell; the porous drum in the shell is arranged horizontally, the two ends of the porous drum are connected to the two ends of the lower shell through the drum shaft, one end of the drum shaft is fixedly connected with the handle, and the inner surface of the porous drum is fixedly connected with the stirring blade in the axial direction; the lower A water outlet pipe is arranged under the casing, and a heater is arranged between the inner side of the casing and the perforated drum. The invention has the advantages that the perforated drum is arranged horizontally, the stirring blades can fully stir and ferment the organic waste, and at the same time, the fermentation temperature can be controlled by the heating tube, so as to promote the fermentation and decomposition of the kitchen waste as soon as possible, so that the kitchen waste can be decomposed quickly and become usable. Cooked mud for growing flowers and vegetables. The processing device is simple in structure, easy to use, meets environmental protection requirements, and is suitable for the needs of kitchen waste treatment in families and living quarters.

Owner:王佳萍

Waste gas treatment method of cutting machine for machining

PendingCN114082292ASuitable for processing needsImprove the degree of refinementGas treatmentDispersed particle filtrationProcess engineeringMachining

The invention discloses a waste gas treatment method of a cutting machine for machining, which comprises the following steps: S1, movably connecting a fan to the outer side of a cutting machine body through a rotary adjusting structure, extracting waste gas generated during cutting through the fan in the treatment process of the cutting machine, and discharging the waste gas into a treatment box, and S2, preliminarily filtering harmful gas with impurities through a filtering material stored in the treatment box. The fan is mounted in the cutting machine, the operation mode of the cutting machine is improved in multiple purification and filtration modes, and meanwhile, a rotary adjusting structure is mounted in the cutting machine to form a displacement system, so that the cutting machine is suitable for waste gas treatment requirements of various cutting directions; the problems that an existing cutting machine does not have the waste gas treatment effect, part of materials can generate a large amount of harmful gas in the treatment process, the environment is prone to being polluted, and the body health of operators is seriously affected are solved.

Owner:黄玉连

Gas-liquid separation device and sewage treatment device having the gas-liquid separation device

ActiveCN103977602BEasy to handleReduce connectionsTreatment with aerobic and anaerobic processesSustainable biological treatmentSewage treatmentEnergy consumption

The invention relates to a gas-liquid separating device. The gas-liquid separating device comprises a gas-liquid separating region arranged between a bubble-containing liquid region and a liquid region which does not basically contain bubbles, wherein the gas-liquid separating region is provided with an inlet which is in liquid communication with the bubble-containing liquid region, an outlet which is in liquid communication with the liquid region which does not basically contain the bubbles and a separating chamber arranged between the inlet and the outlet, the inlet is arranged above the outlet, and the separating chamber is provided with an expanding section which is continuously increased in the horizontal section area along the direction from the inlet to the outlet. The invention also relates to a sewage treatment device with the gas-liquid separating device. The gas-liquid separating device and the sewage treatment device have the advantages of simple and compact structure, high separating efficiency, high reliability, no movement parts, little equipment investment, small energy consumption and the like; and the gas-liquid separating device and the sewage treatment device are easy to operate and can be miniaturized.

Owner:金锣水务有限公司

PLC-based intelligent control of recycled plastic energy-saving and environmental protection extrusion device

Owner:沧州智方药用包装材料科技有限公司

A waste collection device for CNC machine tools that is convenient for chip removal

ActiveCN111673533BAvoid enteringAchieve separationMaintainance and safety accessoriesNumerical controlWaste collection

The invention discloses a waste collection device for a numerically controlled machine tool which is convenient for chip removal, which comprises a tank body, a material receiving part is arranged on the left side of the tank body, and the depth of the material receiving part is greater than that of the tank body. During installation, the tank body is inserted below the main shaft of the machine tool, a partition is arranged inside the tank body, the right end of the partition board is disconnected from the inner right side wall of the tank body, and The front and rear sides are provided with chute correspondingly, the chute is arranged horizontally, and a scraper is arranged inside the trough above the partition; this product is convenient for collecting chips, and at the same time, it is convenient for cutting chips during processing. clean up.

Owner:普锐米勒机床(东莞)有限公司

A boring auxiliary tooling

ActiveCN105710405BMeet production requirementsEasy to disassembleFeeding apparatusBoring headsDrive shaftTransmission ratio

The invention discloses a boring assistance tool which comprises a boring assembly and a transmission assembly. The boring assembly comprises a boring cutter head, a ram and a boring cutter. The ram is mounted on the surface of one side of the boring cutter head in a sliding manner, and the boring cutter is mounted in the center of the ram. The transmission assembly comprises a handle, a first transmission shaft, a second transmission shaft, a connecting shaft and a fixed shaft. The boring assistance tool has the beneficial effects that an existing lathe can have a boring function by being simply dismounted and mounted, the production requirements of small and medium fabrication plants are met greatly, the machining capacity of the fabrication plants is improved, and therefore the profit level is raised; the modification process is simple and easy to operate, the main structure of the lathe does not need to be destroyed, and therefore precision is guaranteed, and meanwhile additional functions are added; small displacement of the boring cutter is adjusted through a motion pair large in transmission ratio, and the machining precision is further improved; and the tool is simple and reliable in structure, low in cost and especially suitable for the machining needs of the small and medium fabrication plants.

Owner:日照市双驱机械制造有限公司

A dibr virtual image restoration method suitable for high-definition 2d/3d conversion

InactiveCN104954780BReduce time spent studying onlineGood effectImage enhancementSteroscopic systemsRestoration methodHigh definition

The invention discloses a DIBR (depth image-based rendering) virtual image restoration method applicable to high-definition 2D / 3D (two-dimensional / three-dimensional) conversion. The method comprises steps as follows: generating a general background dictionary DB; synthesizing a sparse dictionary DI: constructing a sample dictionary DS in a background area of a video frame image IF, and synthesizing the sparse dictionary DI according to the generated general background dictionary DB and the sample dictionary DS; performing void estimation and classification processing; performing filling restoration processing on each II-class void RHII. With the adoption of the method, through classification processing and sparse dictionary expression, the complexity of calculation is significantly reduced while the 3D virtual image rendering effect is improved, and the method is more applicable to processing of mass video information in high-definition 2D / 3D conversion.

Owner:NANYANG NORMAL UNIV

Double-molten channel three-body alloy smelting furnace with boosted stirring of liquid level

ActiveCN102022911BIncreased diffusion areaSpread evenlyCrucible furnacesEndless core furnacesDiffusionAlloy element

The invention relates to a double-molten-channel three-body alloy smelting furnace with boosted stirring of liquid level, comprising a furnace body (8). The three-body alloy smelting furnace is characterized in that the furnace body (8) is divided into three zones in total from front to back, namely, a smelting zone (6), a diffusion zone (18) and an insulating zone (4), wherein the smelting zone (6) and the diffusion zone (18) are connected by a molten channel I (9) arranged in a sensing chamber 1 (13) at the bottom of the furnace body (8), and the diffusion zone (18) and the insulating zone (4) are connected by a melting channel II (21) arranged in a sensing chamber 2 (13) at the bottom of the furnace body (8); the diffusion zone (18) is divided into a front zone and a rear zone by a partitioning plate (17) with a intercommunicating pore in the middle, the tops of the front zone and the back zone are respectively provided with a liquid level booster 1 (16) and a liquid level booster 2 (19); and the top of the insulating zone (4) is provided with a crystallizer (3), and also is provided with a liquid level control device (14) with a floating block. By utilizing the double-molten-channel three-body alloy smelting furnace, the blocking of the molten channels can be prevented, and alloy elements are uniformly diffused.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

A machine tool waste chute capable of bidirectional unloading

ActiveCN111660134BSuitable for processing needsAvoid emergency stopMaintainance and safety accessoriesStationary filtering element filtersStructural engineeringMachine tool

The invention discloses a machine tool waste chute capable of bidirectional unloading. As the side of the tank body is inclined, a blanking gap is formed between the outer side of the material guide surface and the inner surface of the tank body, and a receiving material corresponding to the blanking gap is arranged below the tank body. trough, the receiving chute has an inclined first material guide surface, the first material guide surface is inclined towards the center of the trough, and the front and rear ends of the trough are provided with The operating gap used; this product can realize chip cleaning without stopping the machine.

Owner:平湖市成功机械有限公司

Assembly line ironing device for cotton pullover clothes

PendingCN112609389AImprove efficiencyEasy to useTextile shapingAssembly lineManufacturing engineering

The invention relates to the technical field of ironing equipment, and discloses an assembly line ironing device for cotton pullover clothes. The assembly line ironing device comprises an equipment frame, wherein conveying rollers are arranged on left and right sides of an inner cavity of the equipment frame, conveying wheels are connected to the front ends of the conveying rollers in a sleeving mode, the two conveying wheels are in conveying connection through a conveying chain, clamping sleeves are fixedly connected to the front face of the conveying chain at equal intervals, clamping feet are connected into the clamping sleeves in a sleeving mode, and a containing frame is fixedly connected to the front faces of the clamping feet. When the ironing device is in use, the clamping sleeves are arranged on the conveying chain, and a forming plate is clamped in the clamping sleeves through the clamping feet, so that clothes sleeved on the forming plate can move to the left side in a flat posture, the moving clothes can be ironed by a top ironing plate and a bottom ironing plate, and thus the ironing efficiency is greatly improved compared with the original ironing efficiency, the standard requirements of existing assembly line production are met, and the machining requirements of factories are better met.

Owner:喀什浩朋服装科技有限公司

Automatic demolding injection mold for car trunk storage box assembly

InactiveCN113172840ASuitable for processing needsReduce the phenomenon of cost wasteDomestic articlesTrunk compartmentMechanical engineering

The invention provides an automatic demolding injection mold for a car trunk storage box assembly, and relates to the field of automobile part injection molding. The automatic demolding injection mold for the car trunk storage box assembly comprises a movable mold body and a fixed mold body used in cooperation with the movable mold body, a containing groove is formed inside the movable mold body, a movable mold core is arranged inside the containing groove, a second electric push rod is fixedly connected to the upper surface of the movable mold body, the movable end of the second electric push rod is fixedly connected with a second movable rod, the bottom of the second movable rod extends into the containing groove and is fixedly connected with the upper surface of the movable mold core, an injection molding cavity is formed in the upper surface of the fixed mold body, a fixed mold core is arranged in the injection molding cavity, and the lower surface of the fixed mold core is fixedly connected with a threaded sleeve. Through the design of the adjustable movable mold core and the fixed mold core, one set of mold can meet the machining requirements of products of various sizes, and the phenomenon of cost waste caused by development of multiple sets of molds is greatly reduced.

Owner:重庆缘得科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com