Double-molten channel three-body alloy smelting furnace with boosted stirring of liquid level

A smelting furnace and liquid level technology, applied in the field of alloy smelting furnaces, can solve the problems of easy ditch breaking and uneven diffusion of alloy elements in the smelting furnace, and achieve the effect of small segregation of components, compact and reasonable structure, and increased stirring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

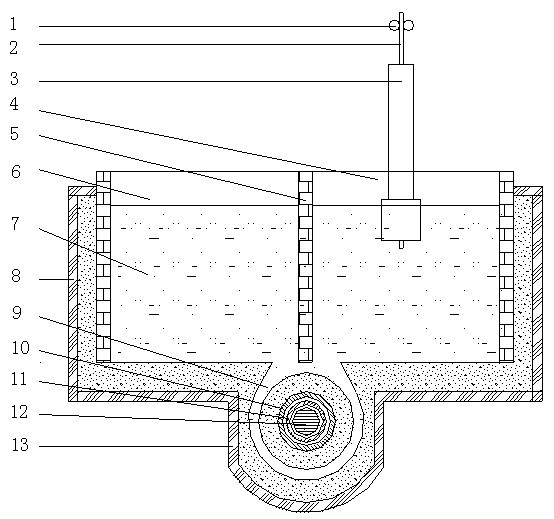

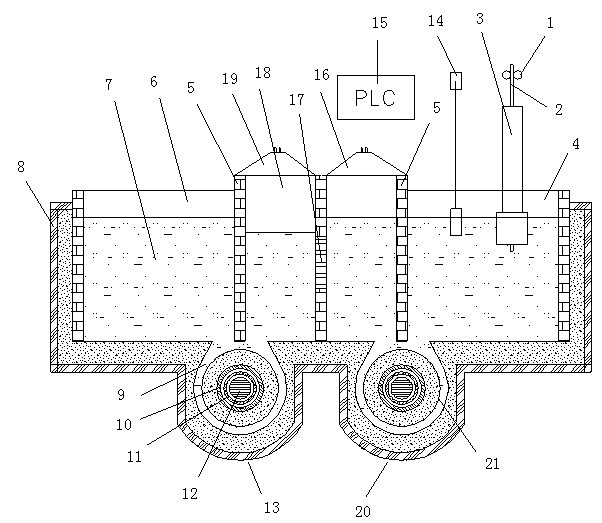

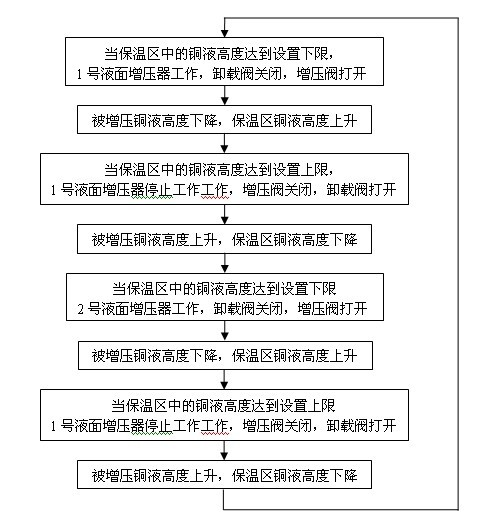

[0016] see figure 2 , figure 2 It is a structural schematic diagram of a three-body alloy smelting furnace with double melting groove liquid surface pressurization and stirring in the present invention. Depend on figure 2 It can be seen that the alloy smelting furnace of the present invention includes a body of furnace 8, and the body of furnace 8 is divided into three zones, a melting zone 6, a diffusion zone 18 and a heat preservation zone 4, from front to back by two partition walls 5, wherein the melting zone 6 and The diffusion areas 18 are connected by the melting groove I9 in the 1# induction chamber 13 arranged at the bottom of the furnace body 8, and the diffusion area 18 and the heat preservation area 4 are connected by the melting groove I9 in the 2# induction chamber 20 arranged at the bottom of the furnace body 8. Groove II 21 is connected, and the diffusion area 18 is divided into front and rear two areas by a partition plate 17 with a communication hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com