Patents

Literature

71results about How to "Reduce drying efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

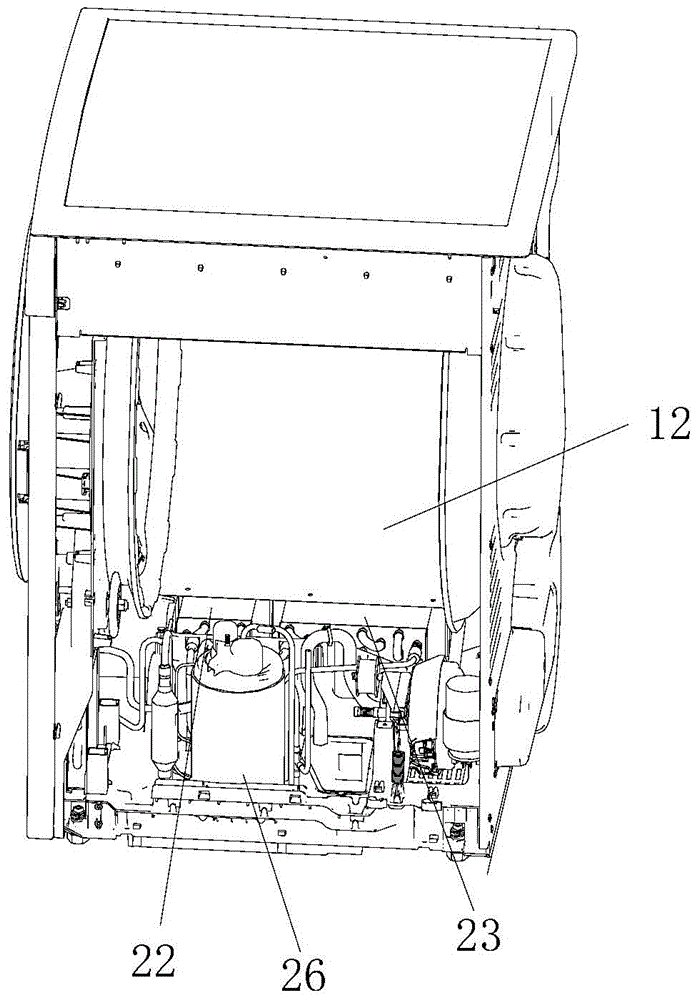

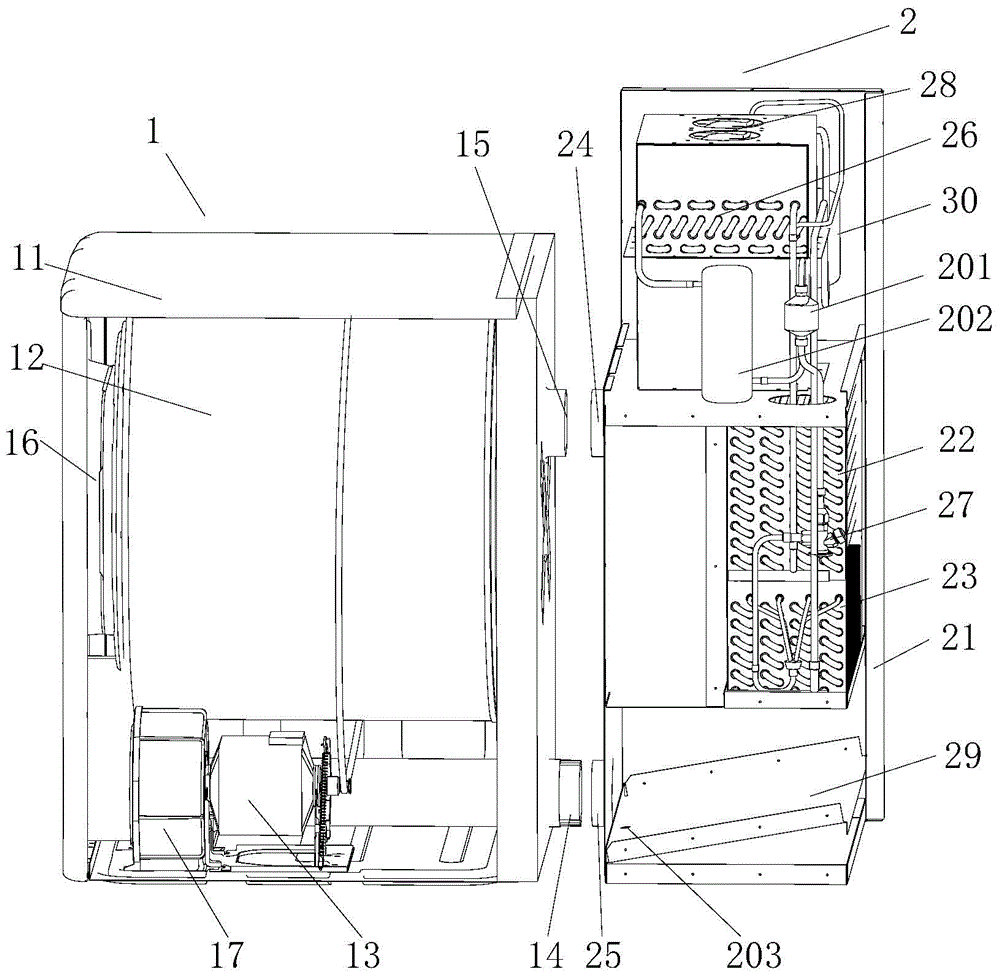

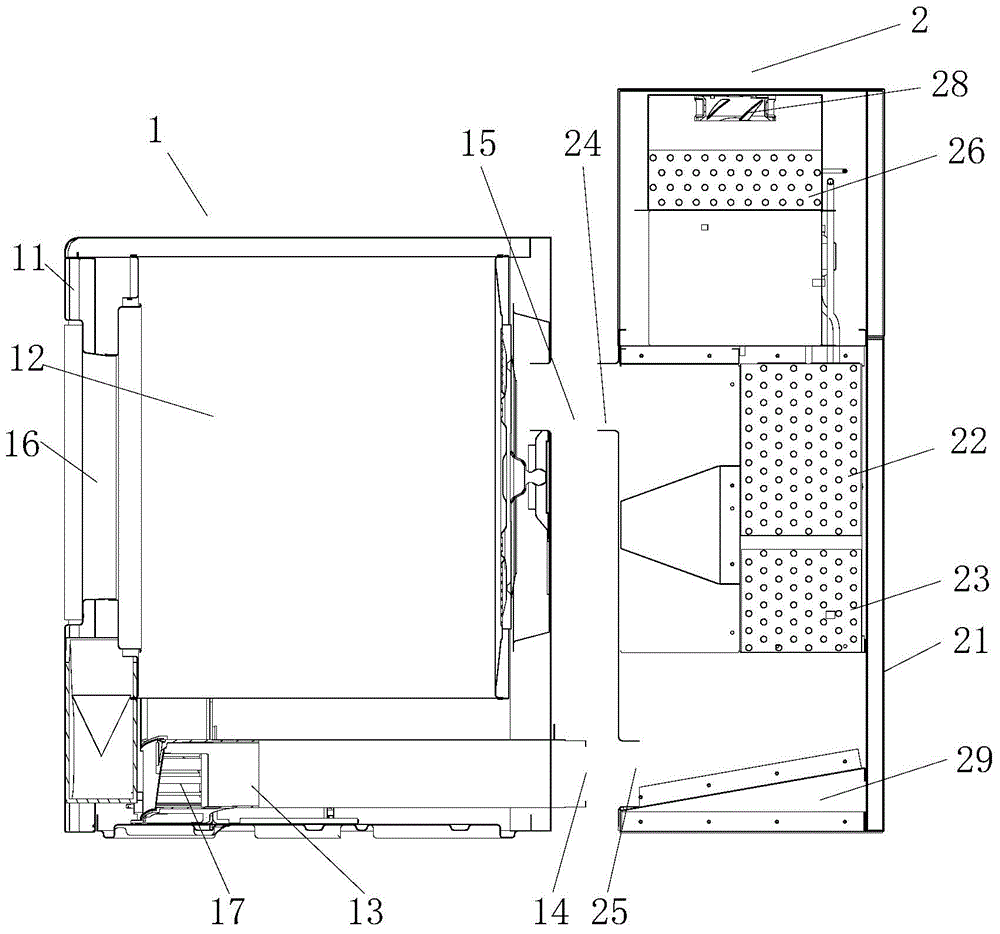

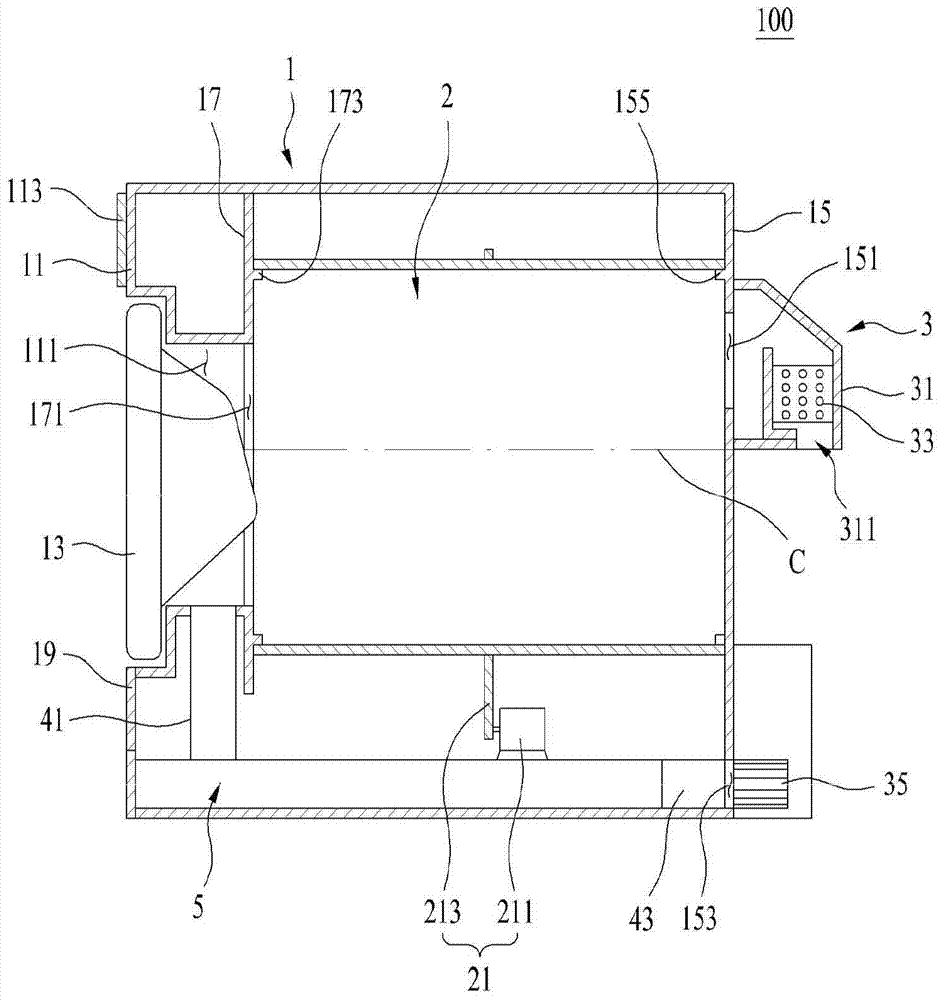

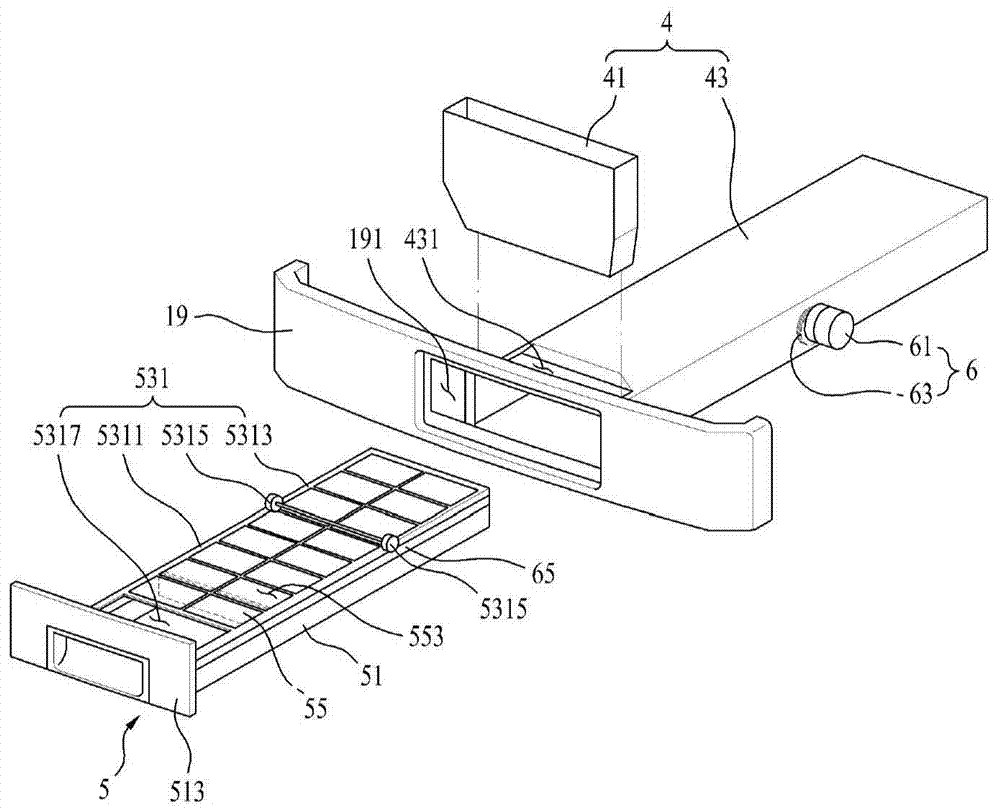

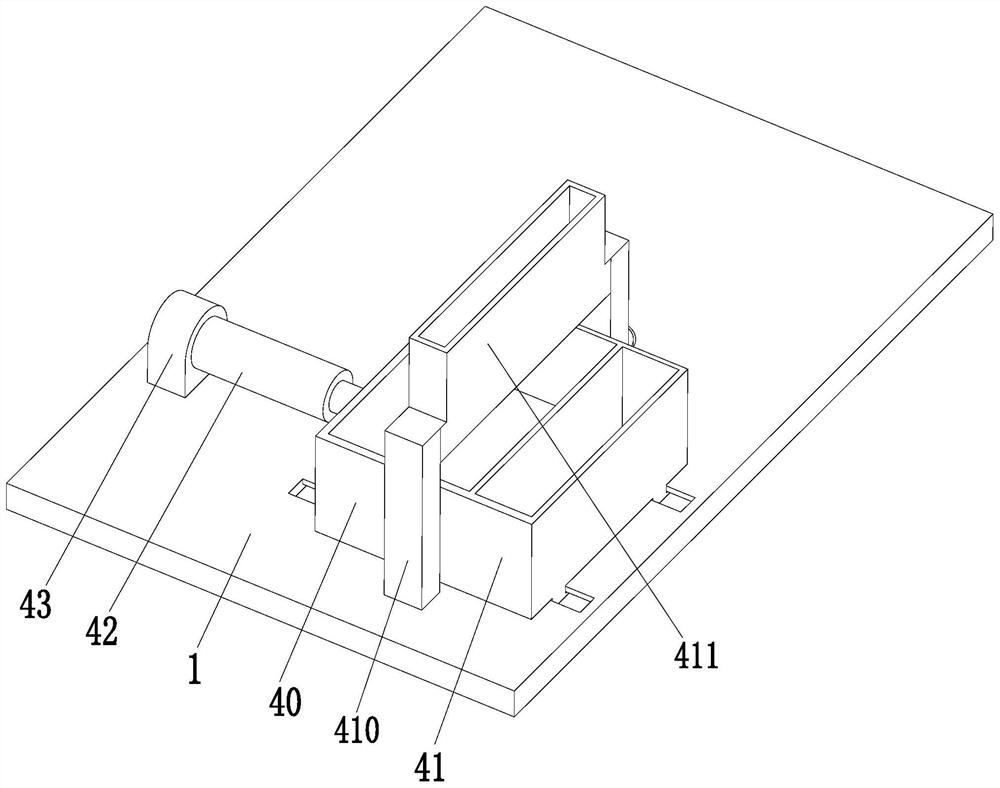

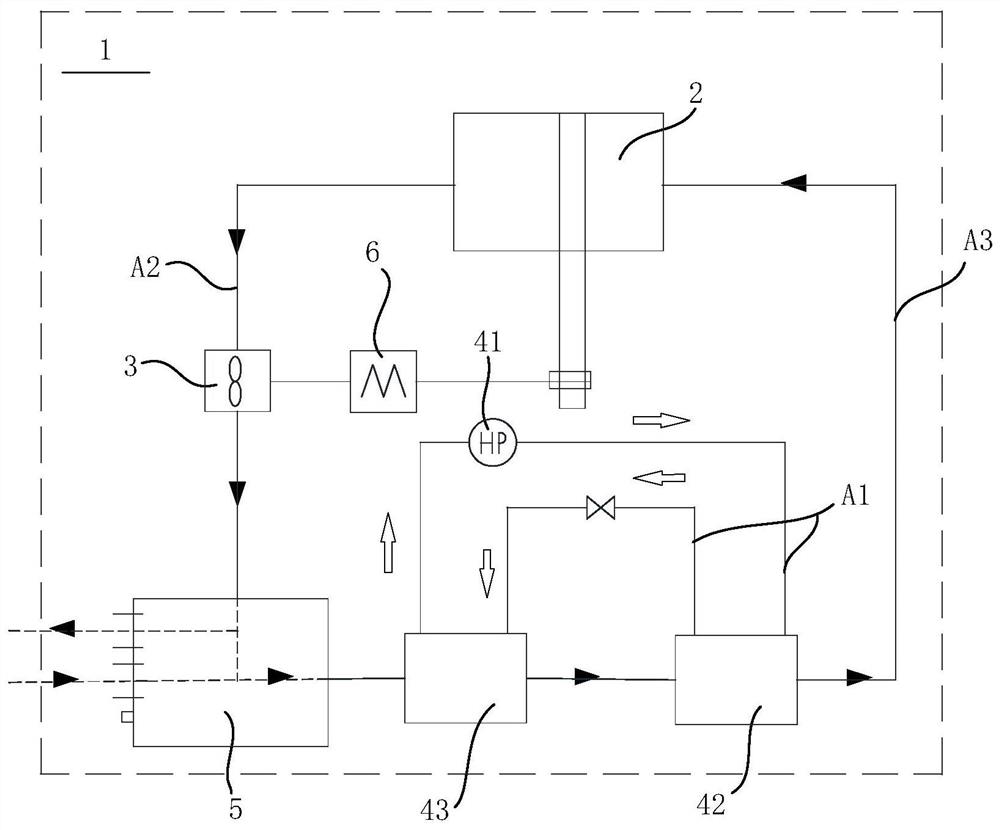

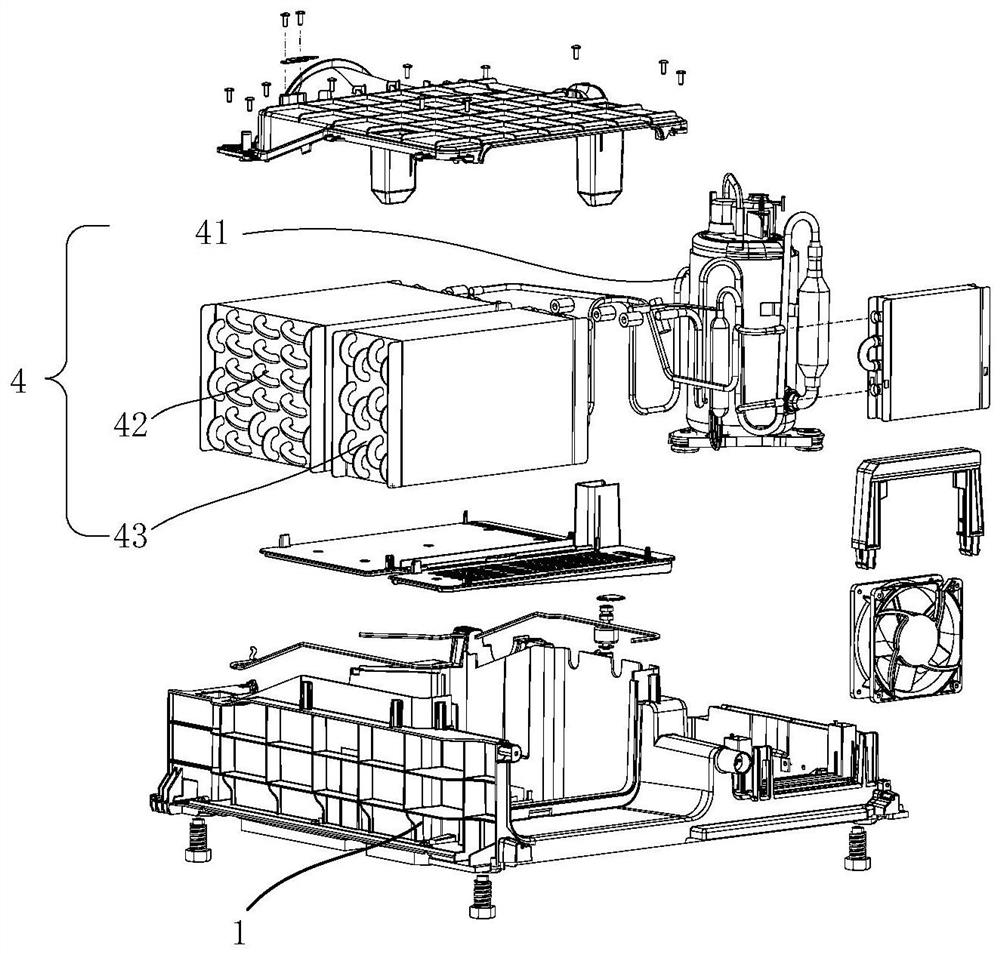

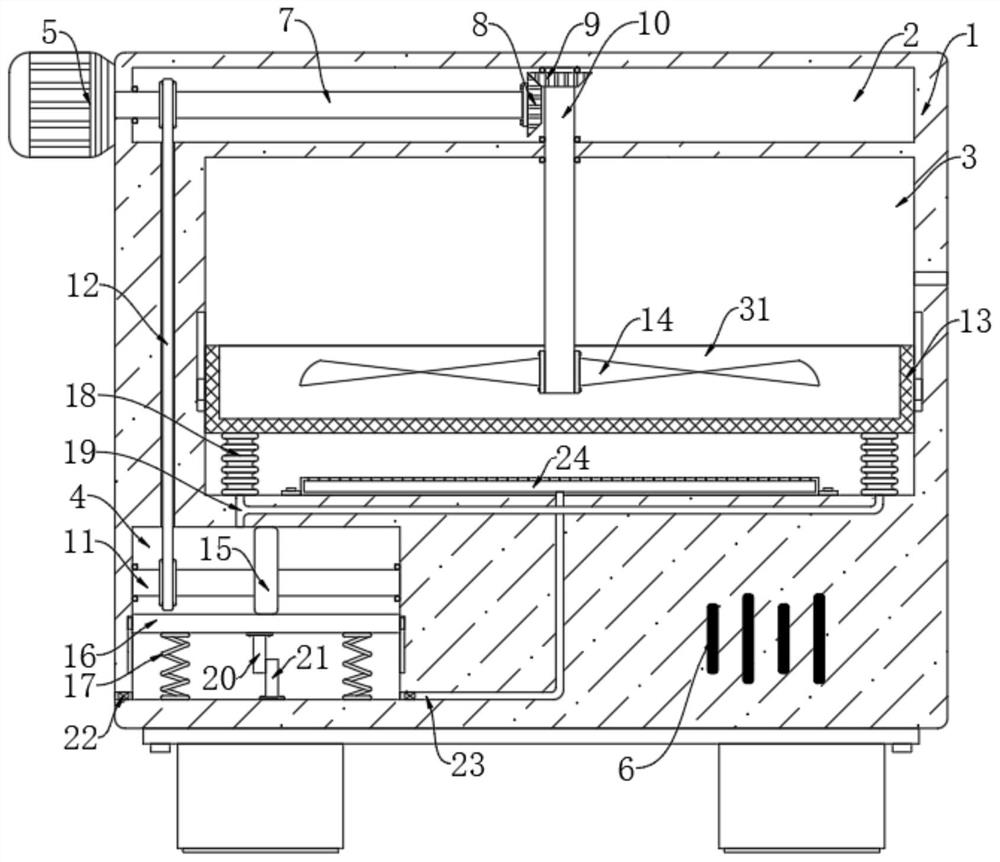

Heat-pump module and clothes dryer

InactiveCN104420144ASimplify the assembly processEasy to transportHeat pumpsTextiles and paperMechanical engineeringHeat pump

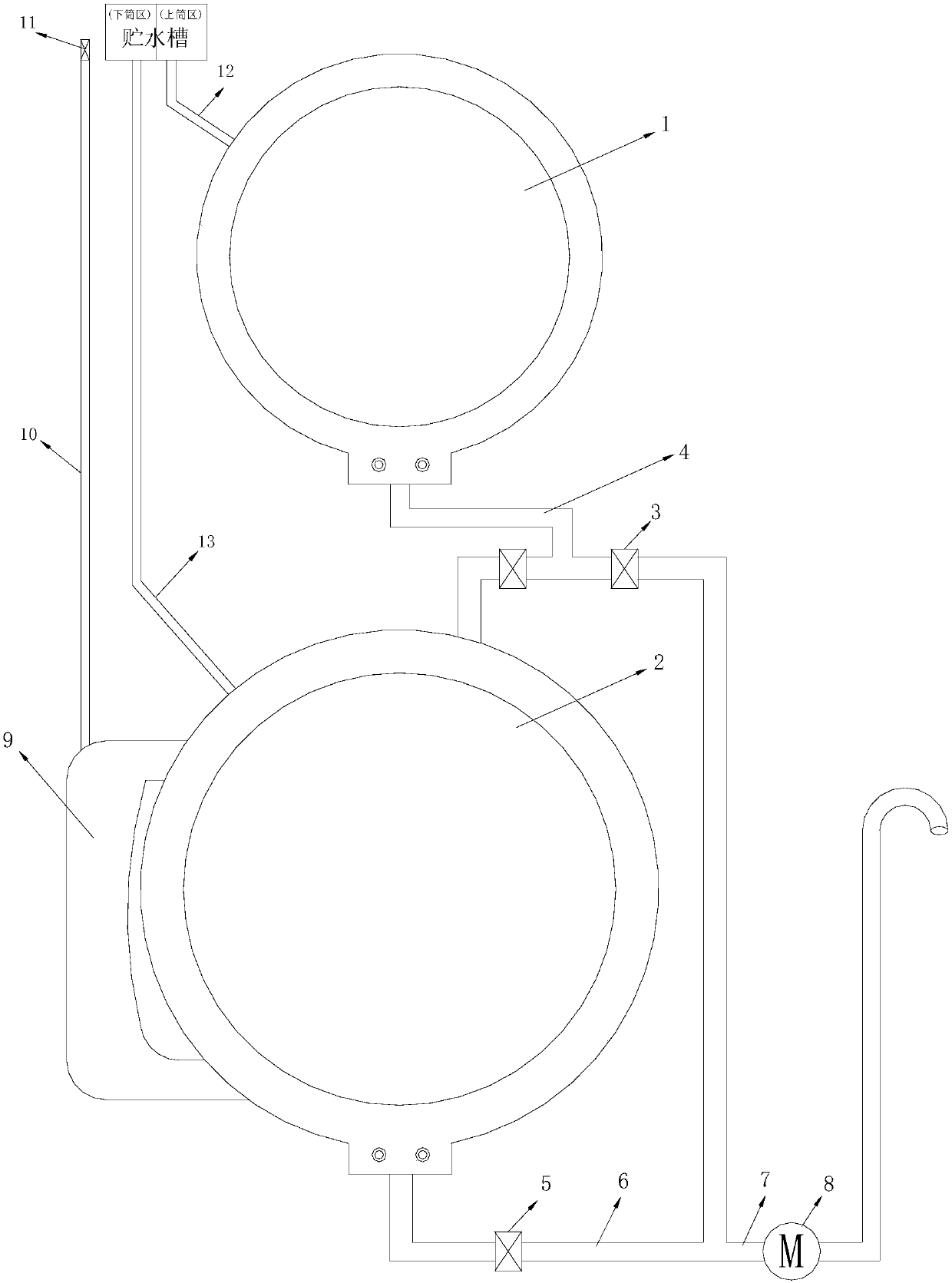

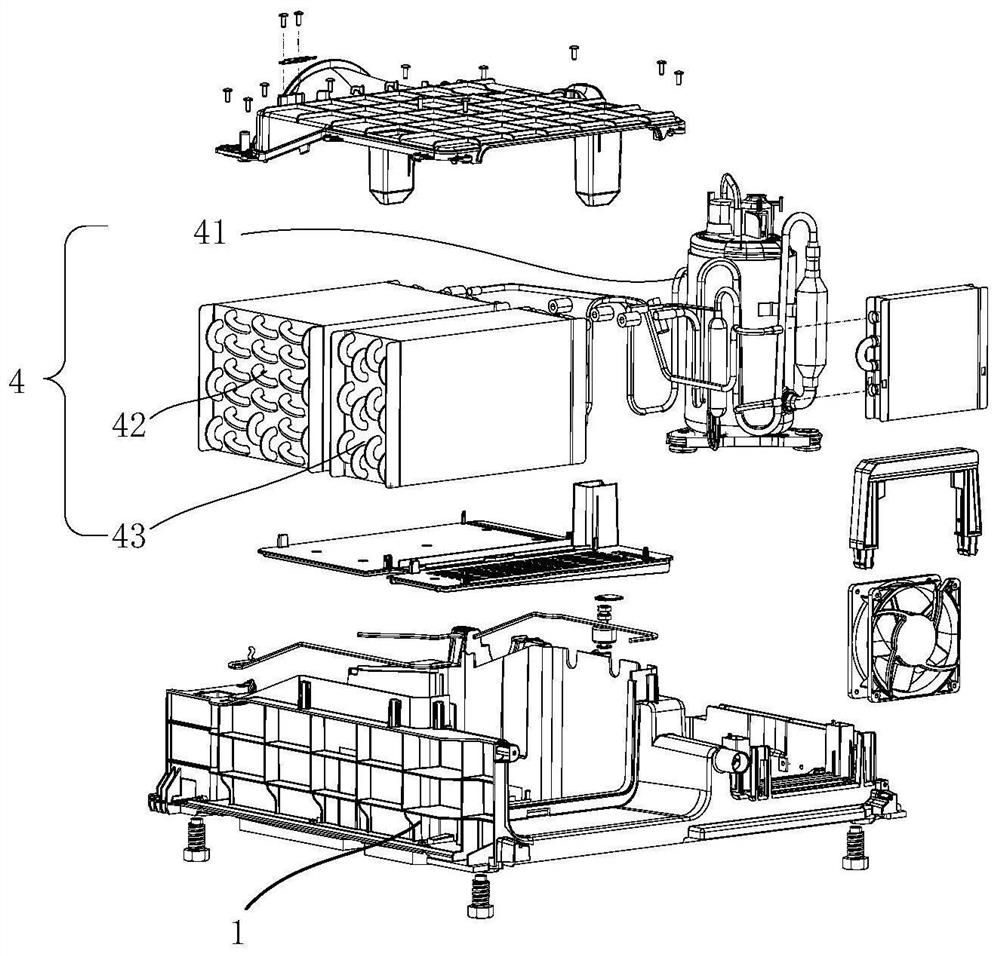

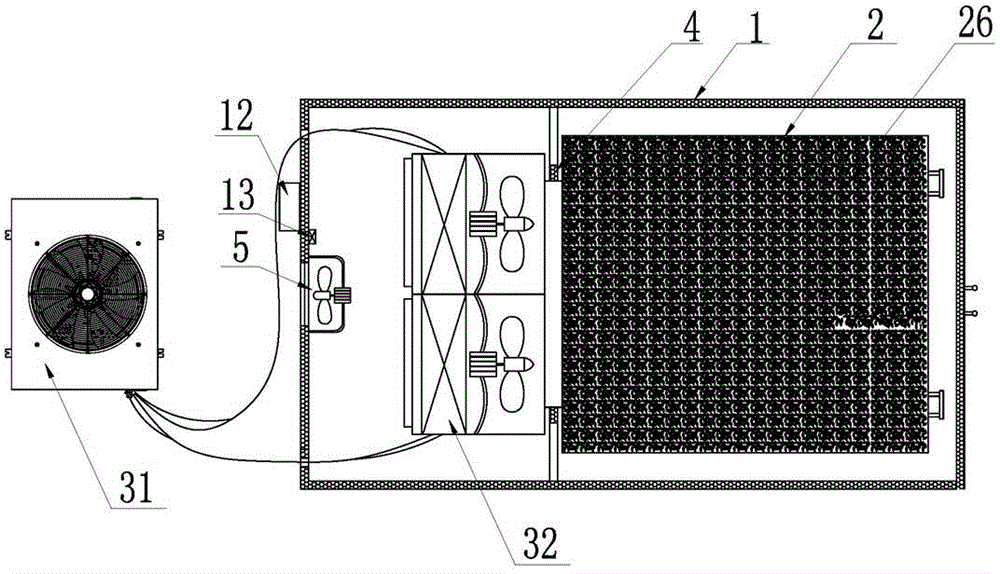

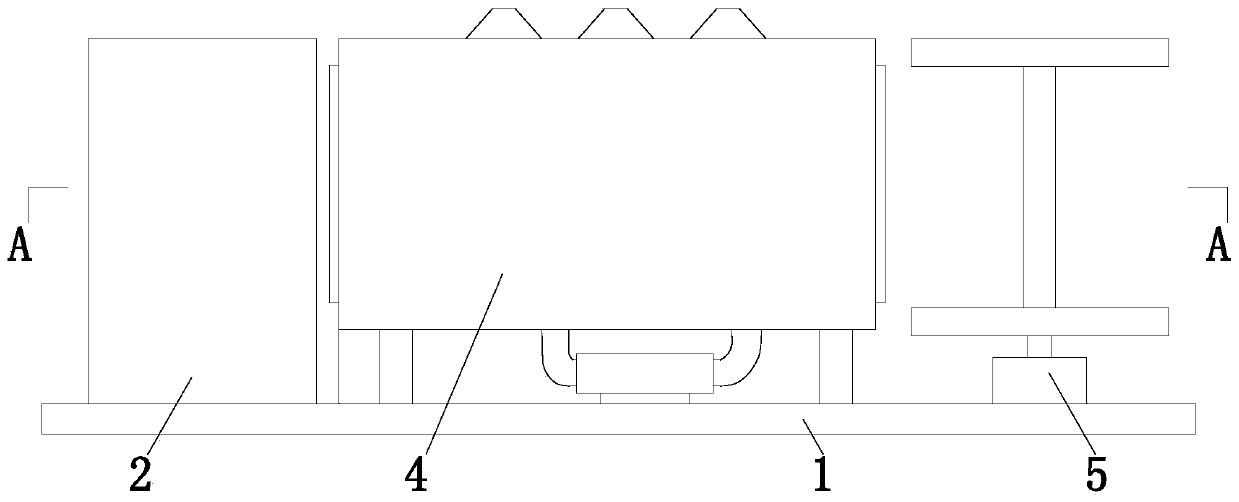

The invention relates to a heat-pump module and a clothes dryer. The heat-pump module comprises a second shell, an evaporator, a condenser, a compressor, a throttling device, a second air outlet and a second air inlet. The second air outlet and the second air inlet are communicated with the outside of the second shell. The clothes dryer further comprises a clothes dryer body. The clothes dryer body comprises a first shell, a clothes drying rotary drum, a driving device, a first air outlet and a first air inlet, the first air outlet and the first air inlet are communicated with the outside of the first shell, the clothes dryer body and the heat-pump module are two modules which are separated and independent from each other, the first air outlet can be connected with the second air inlet, and the first air inlet can be connected with the second air outlet, so that the clothes dryer body and the heat-pump module can be integrated with each other. The heat-pump module and the clothes dryer have the advantages that the heat-pump module and the clothes dryer are modularly assembled, accordingly, assembling processes can be simplified, the heat-pump module and the clothes dryer are convenient to transport, components of a direct discharging type clothes dryer and a heat-pump clothes dryer are universal, and the direct discharging type clothes dryer can be conveniently modified to obtain the heat-pump clothes dryer; the heat-pump module is arranged at the rear of the clothes dryer, the heat exchange areas of the condenser and the evaporator can be enlarged, accordingly, the clothes drying efficiency can be improved, the drying time can be shortened, and energy can be saved.

Owner:HAIER GRP CORP +1

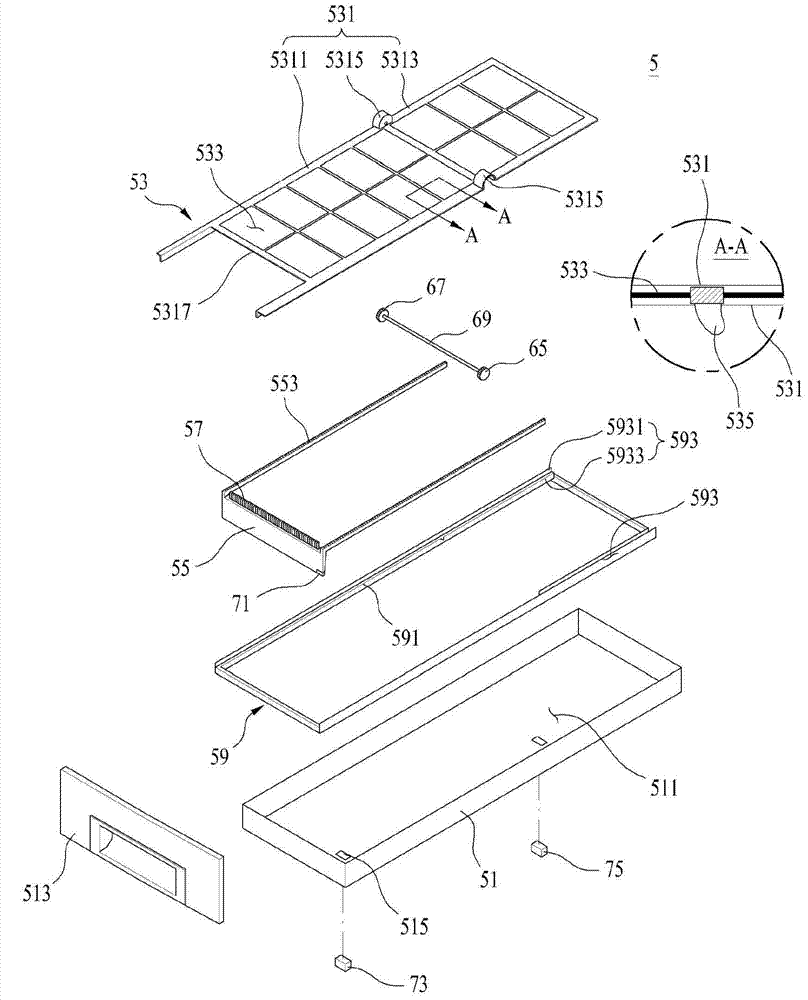

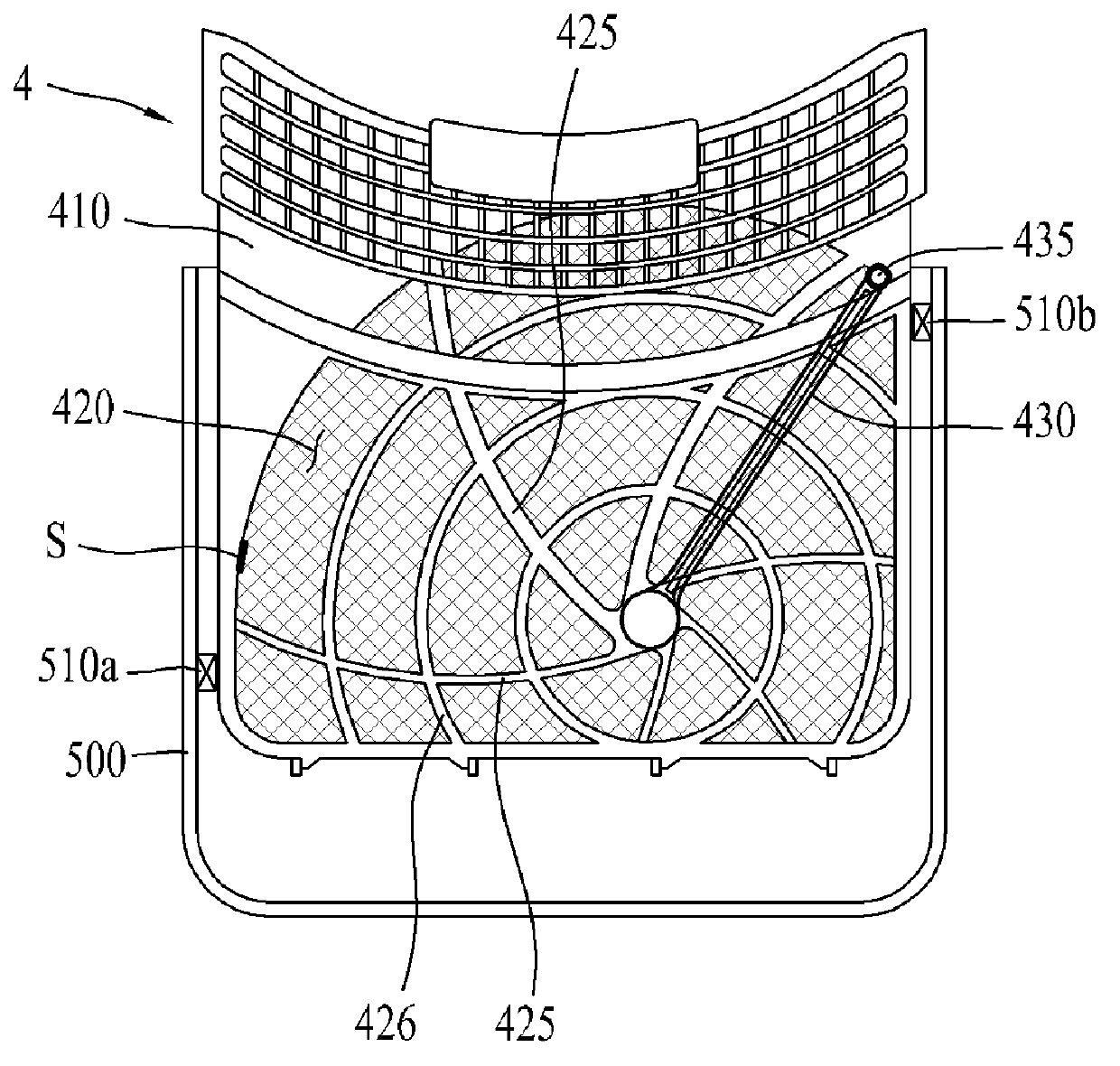

Method for controlling laundry treating apparatus

ActiveCN103866528AHigh trafficLarge filtration capacityDrying gas arrangementsControl devices for washing apparatusForeign matterLaundry

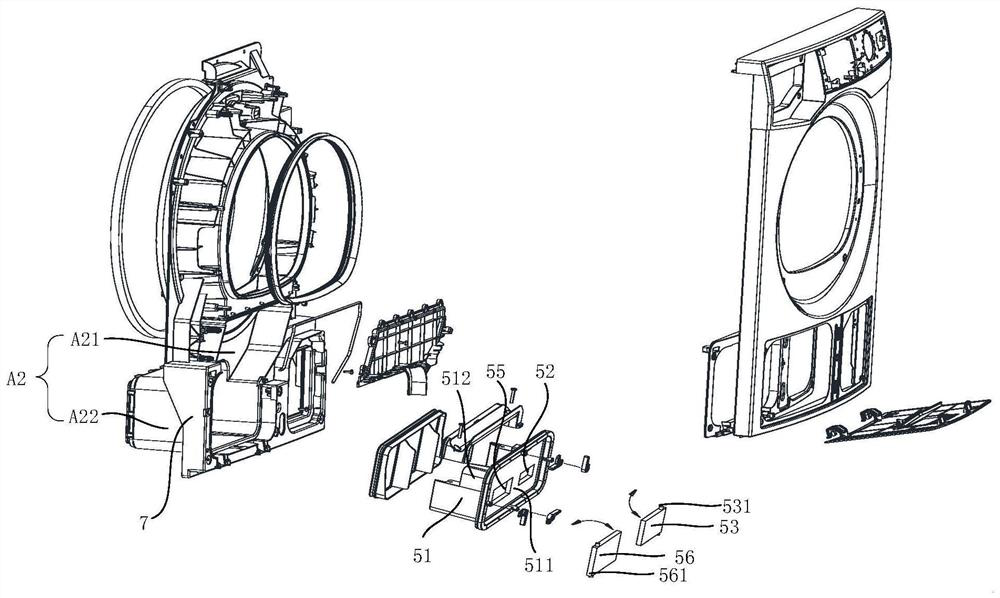

The present invention relates to a method for controlling a laundry treating apparatus including a drum for holding laundry, a connection duct for exhausting air from an inside of the drum, an exhaust duct provided parallel to a length direction of the drum connected to the connection duct, a filter assembly with a filter unit provided to the exhaust duct for filtering the air and a brush for removing foreign matter from the filter unit, a brush drive unit for making the brush to reciprocate a section of the filter unit, and a position sensing unit for sensing a position of the brush.

Owner:LG ELECTRONICS INC

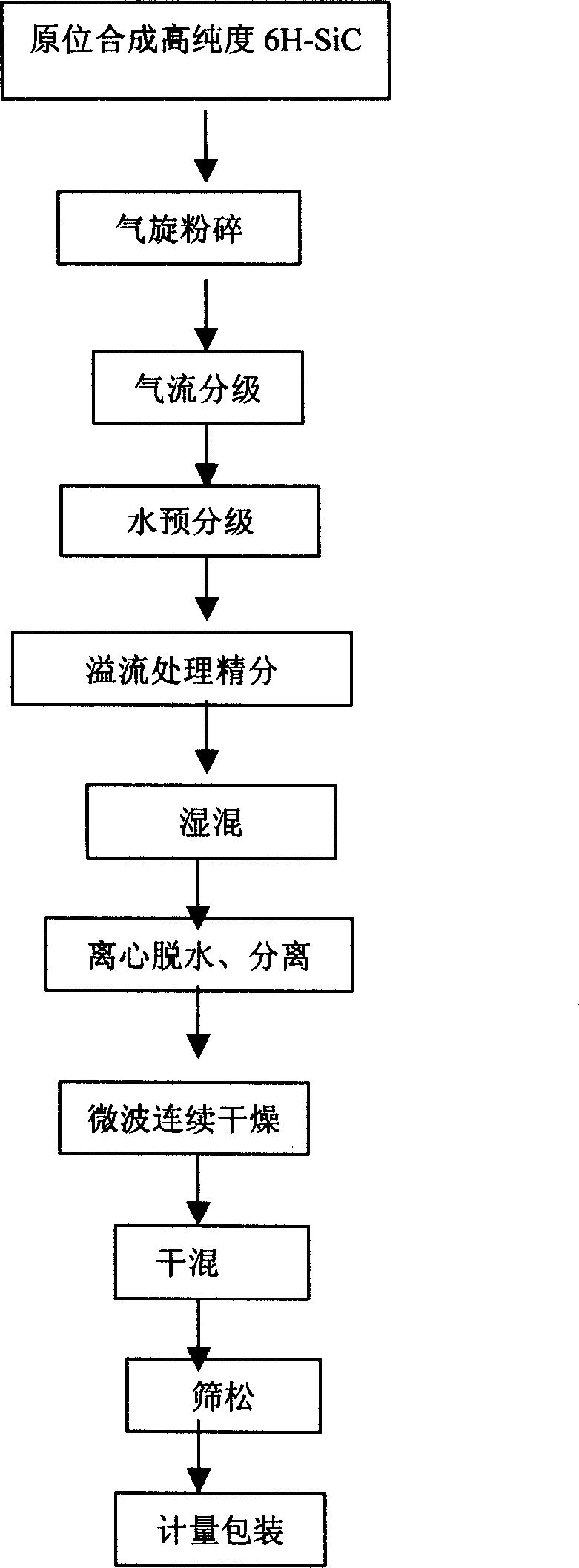

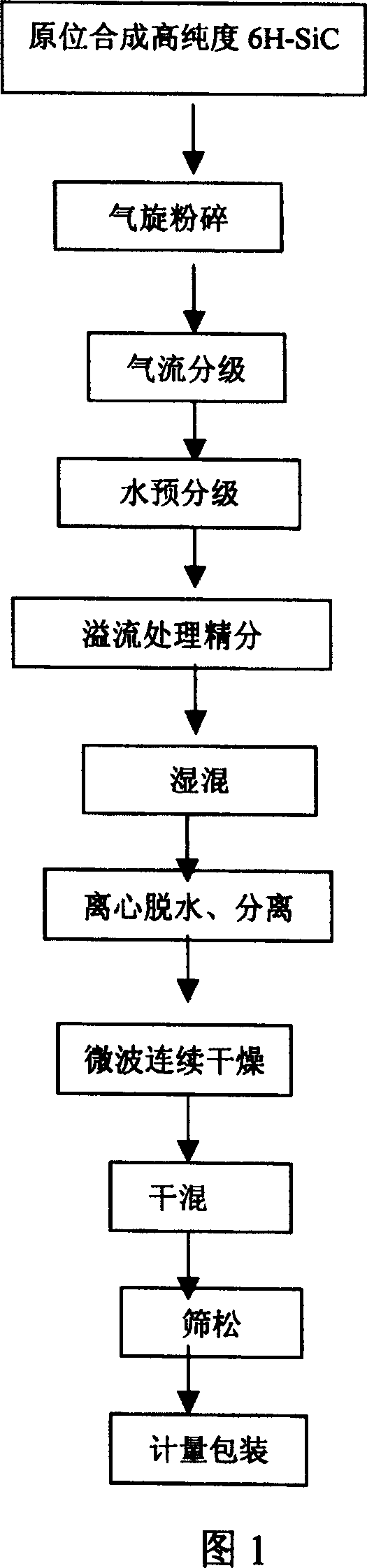

Dedicated blade materials for line cutting of semiconductor materials

InactiveCN1884067AStrong resistance to crushingSharp particle shapeGrain treatmentsWet separationCycloneMicrowave

The invention discloses a specific cutting knife-material of semiconductor material wire (6H-SiC), which comprises the following steps: 1. grinding through cyclone; grading flow; 2. grading water pretreatment; grading finely for overflow; 3. wetting to blend; dehydrating eccentrically; separating; 5. drying through microwave continuously; 6. blending dryly. The invention is compatible with flexibility of black carbofrax, which improves anti-grinding property obviously.

Owner:河南晟道科技有限公司

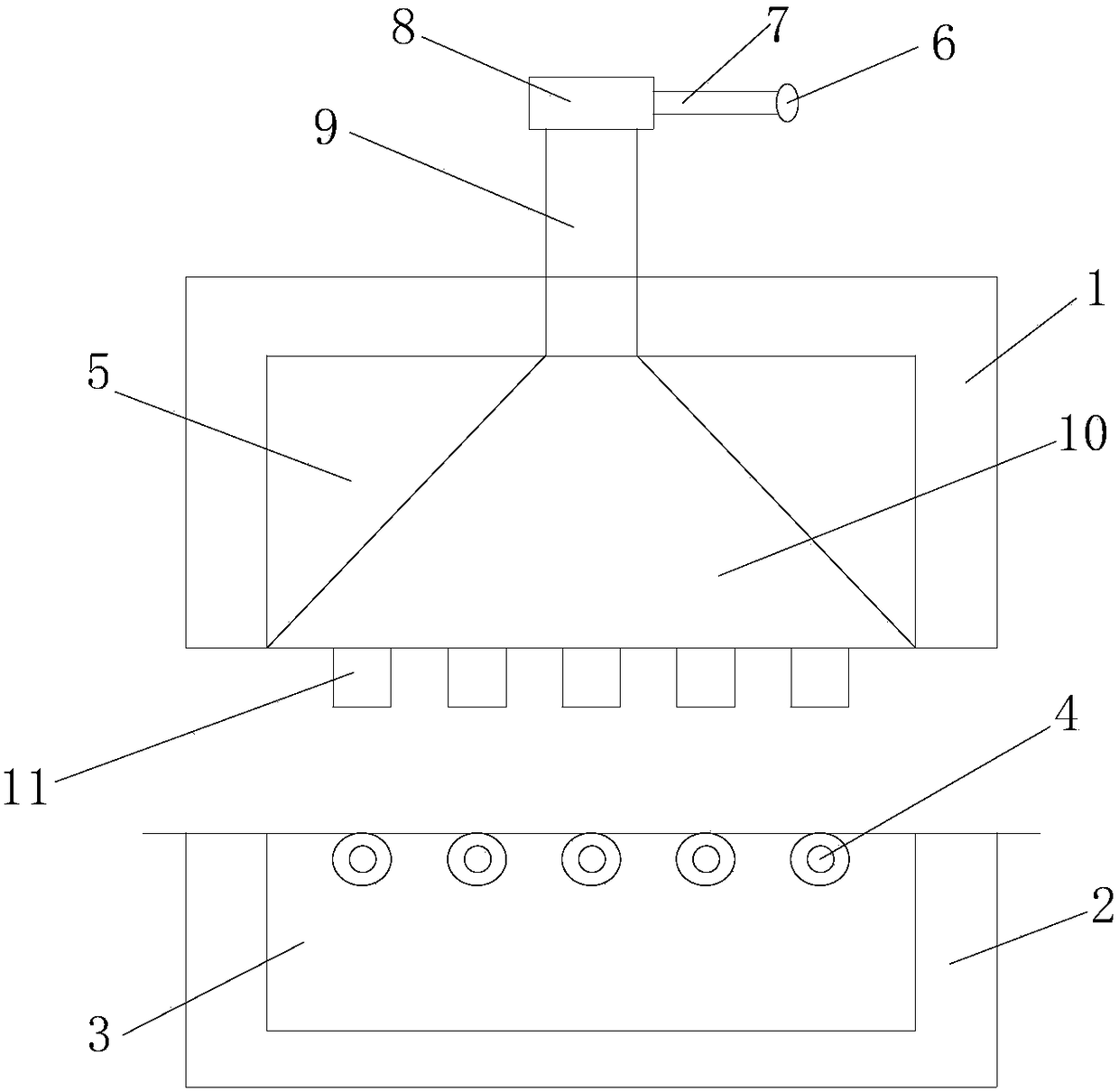

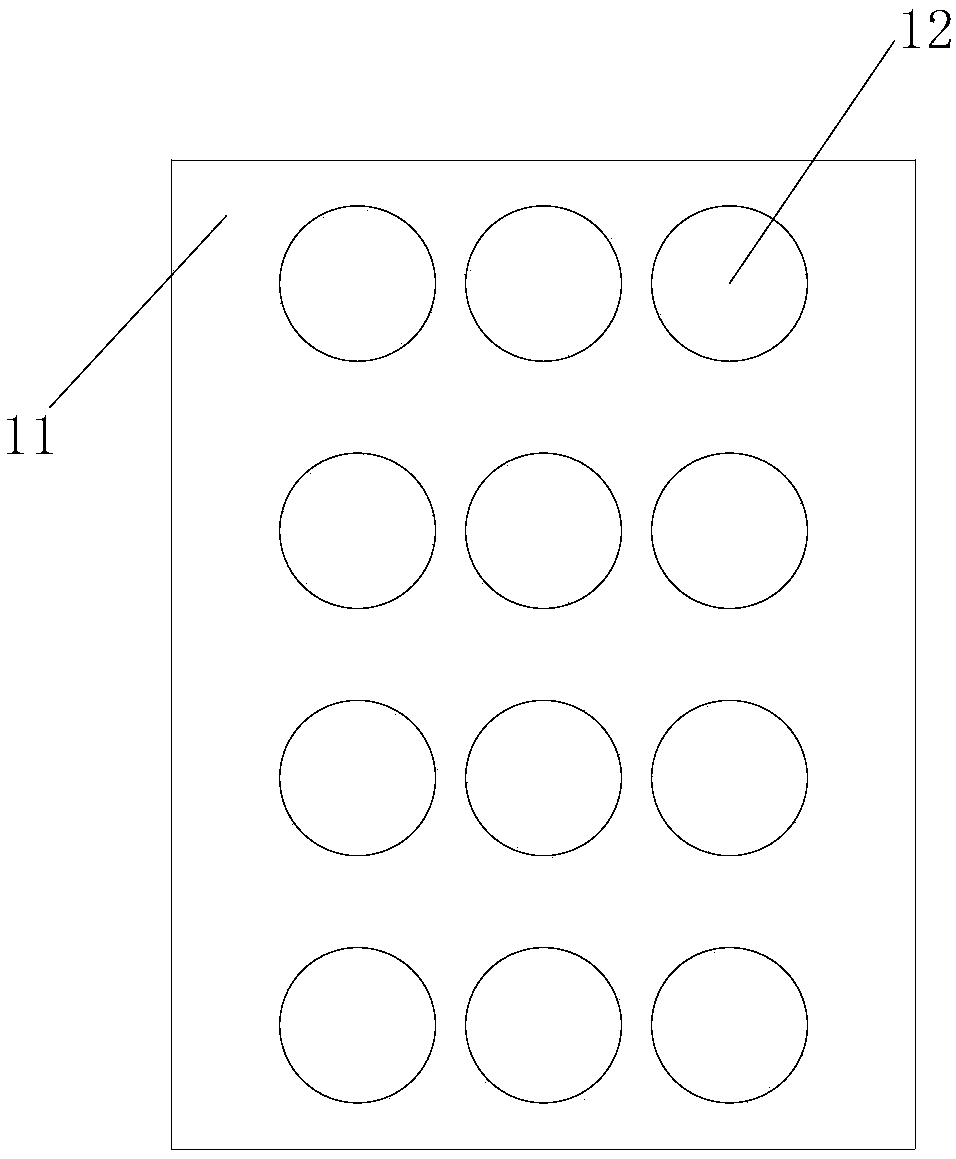

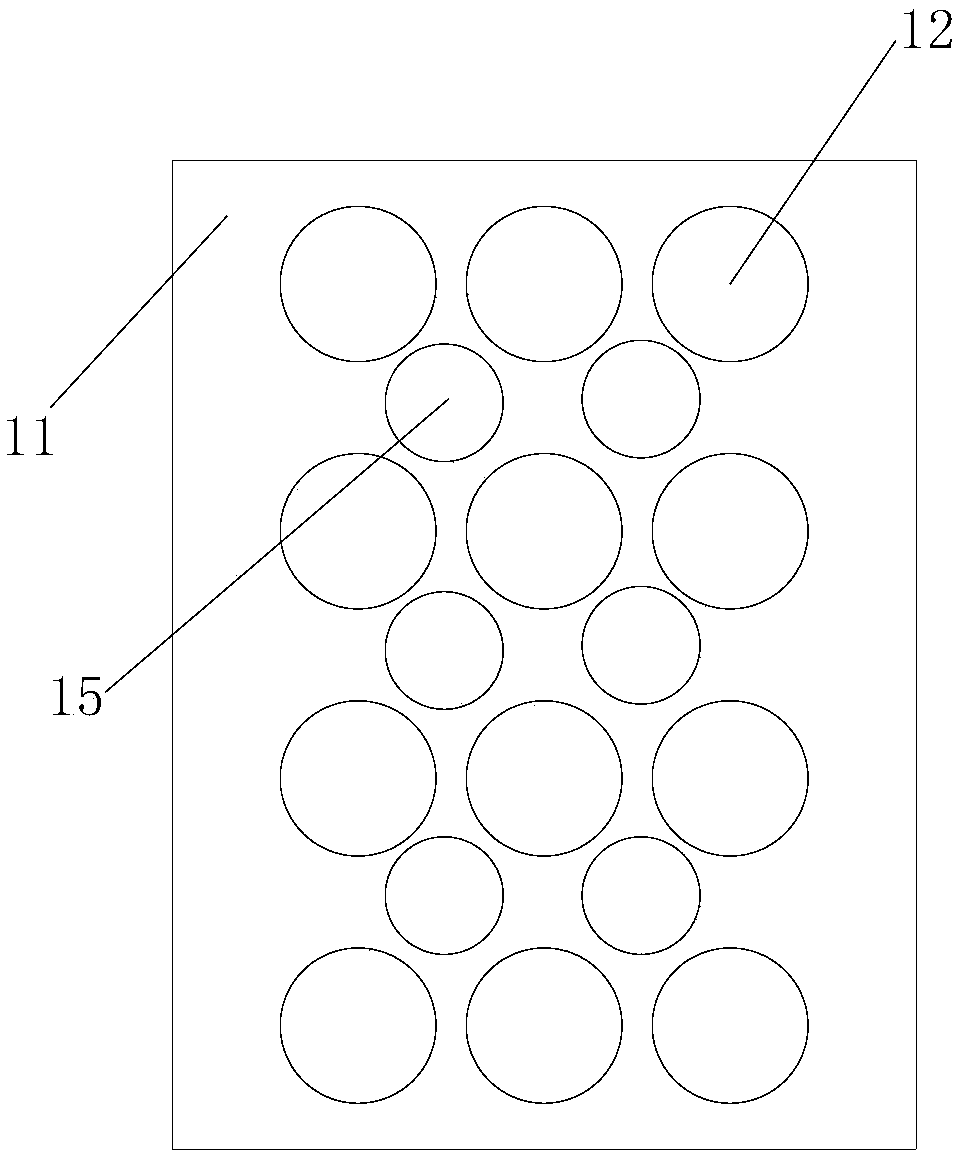

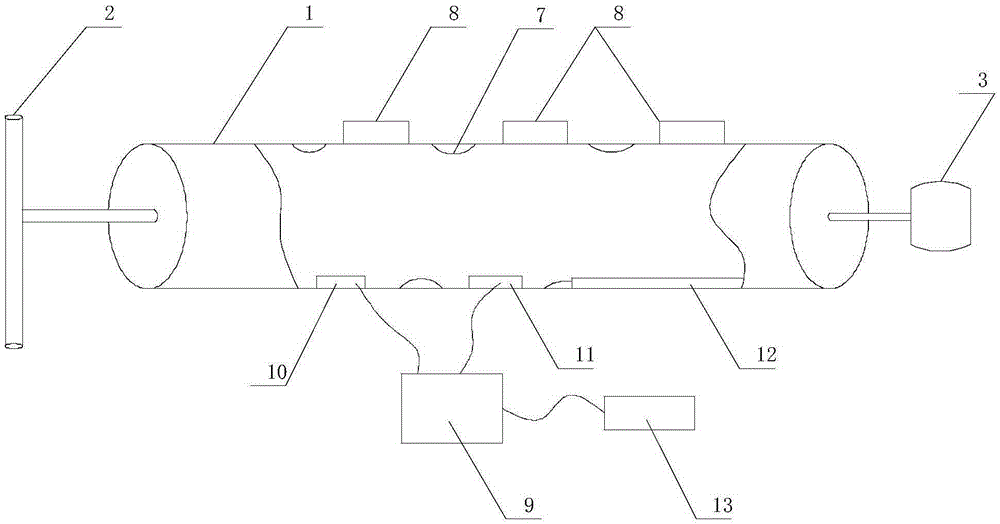

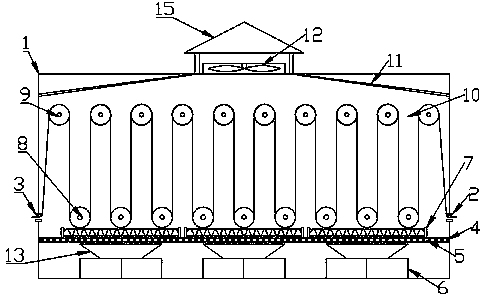

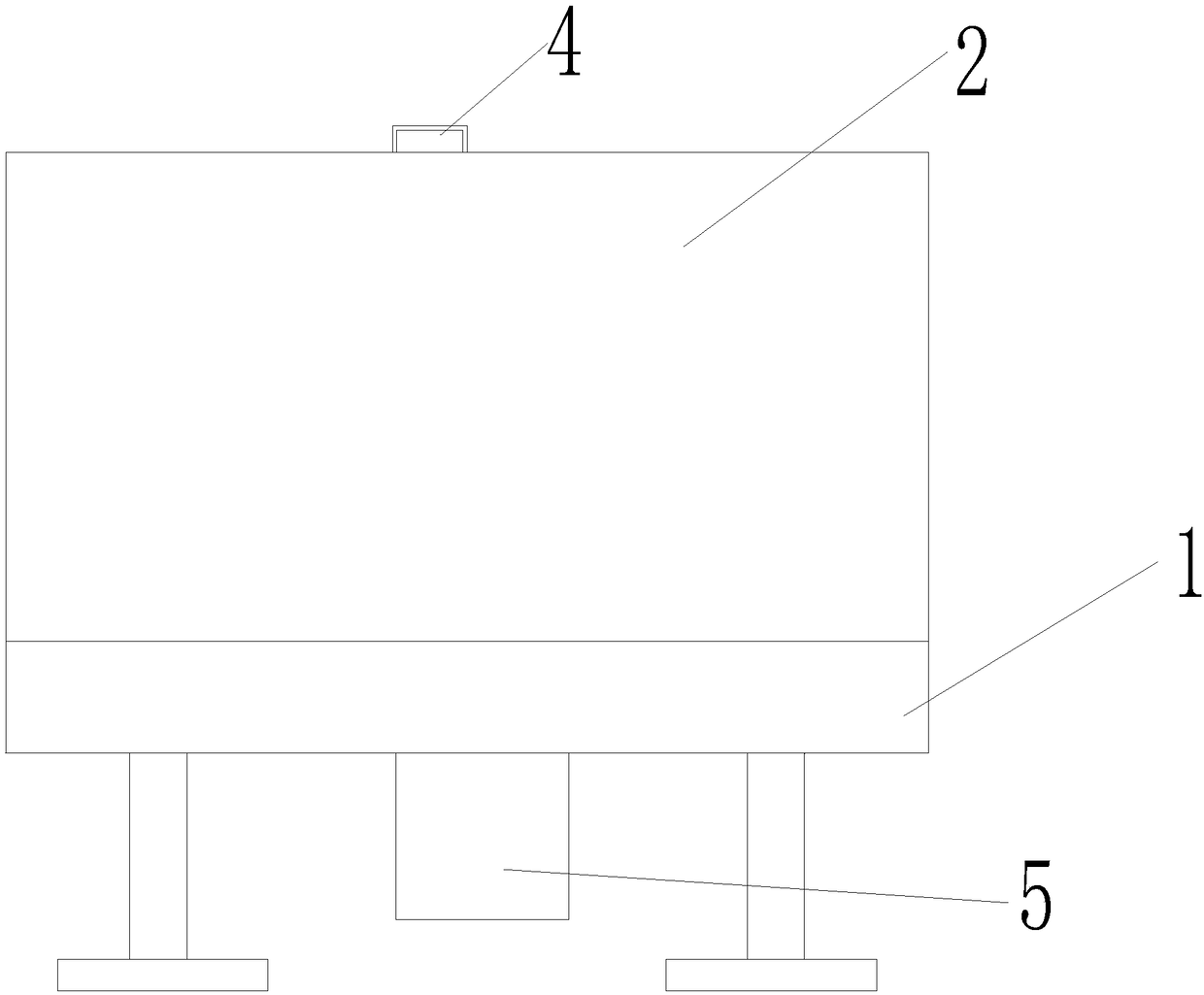

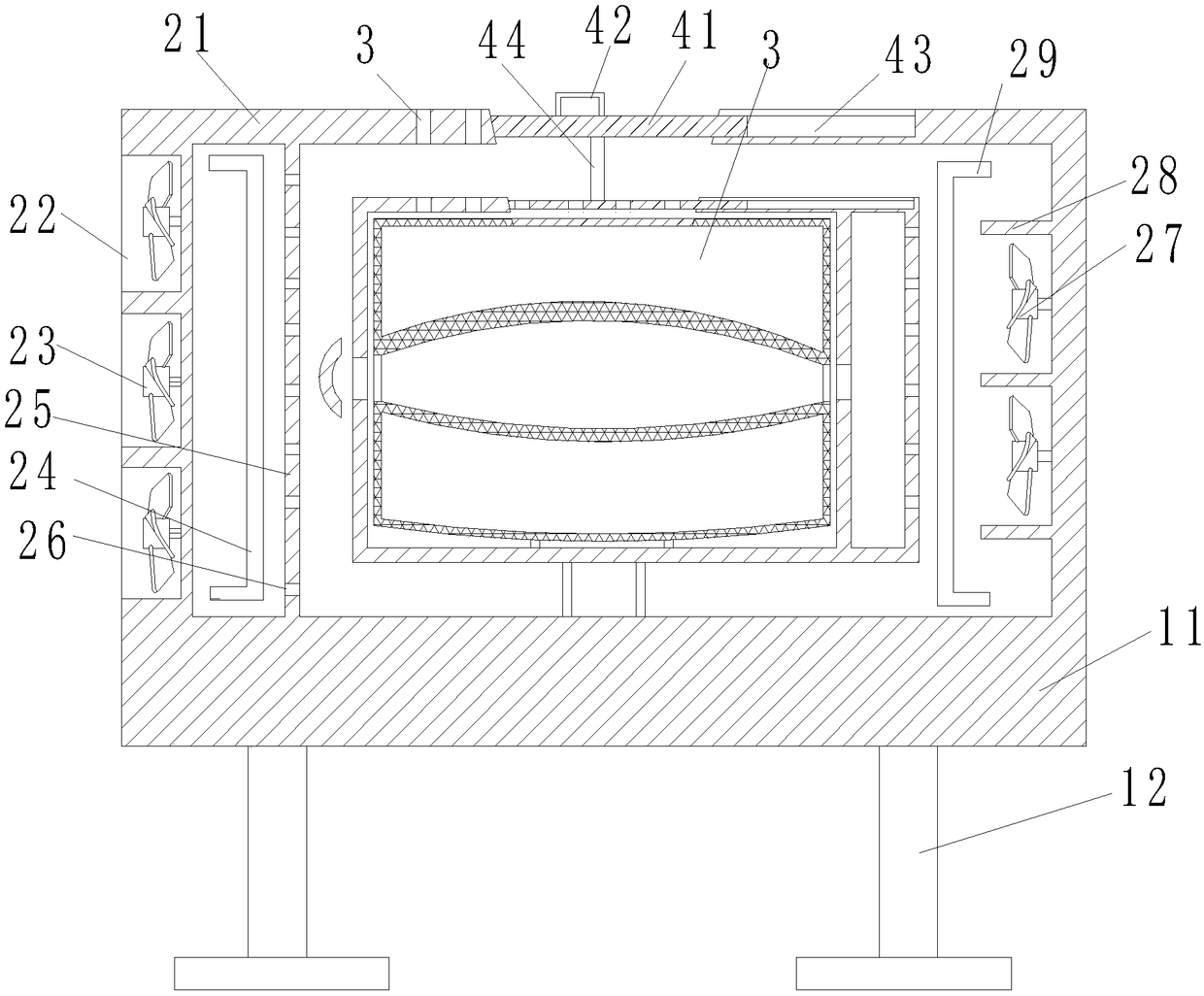

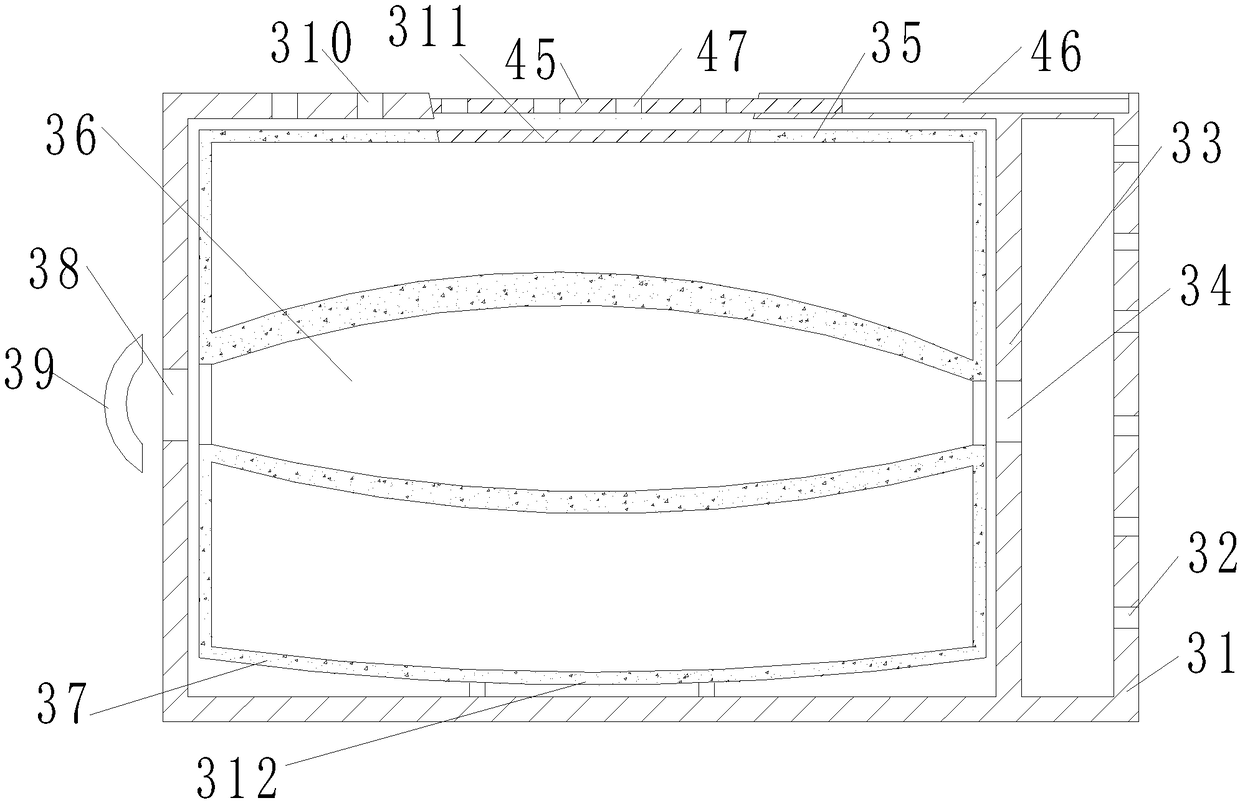

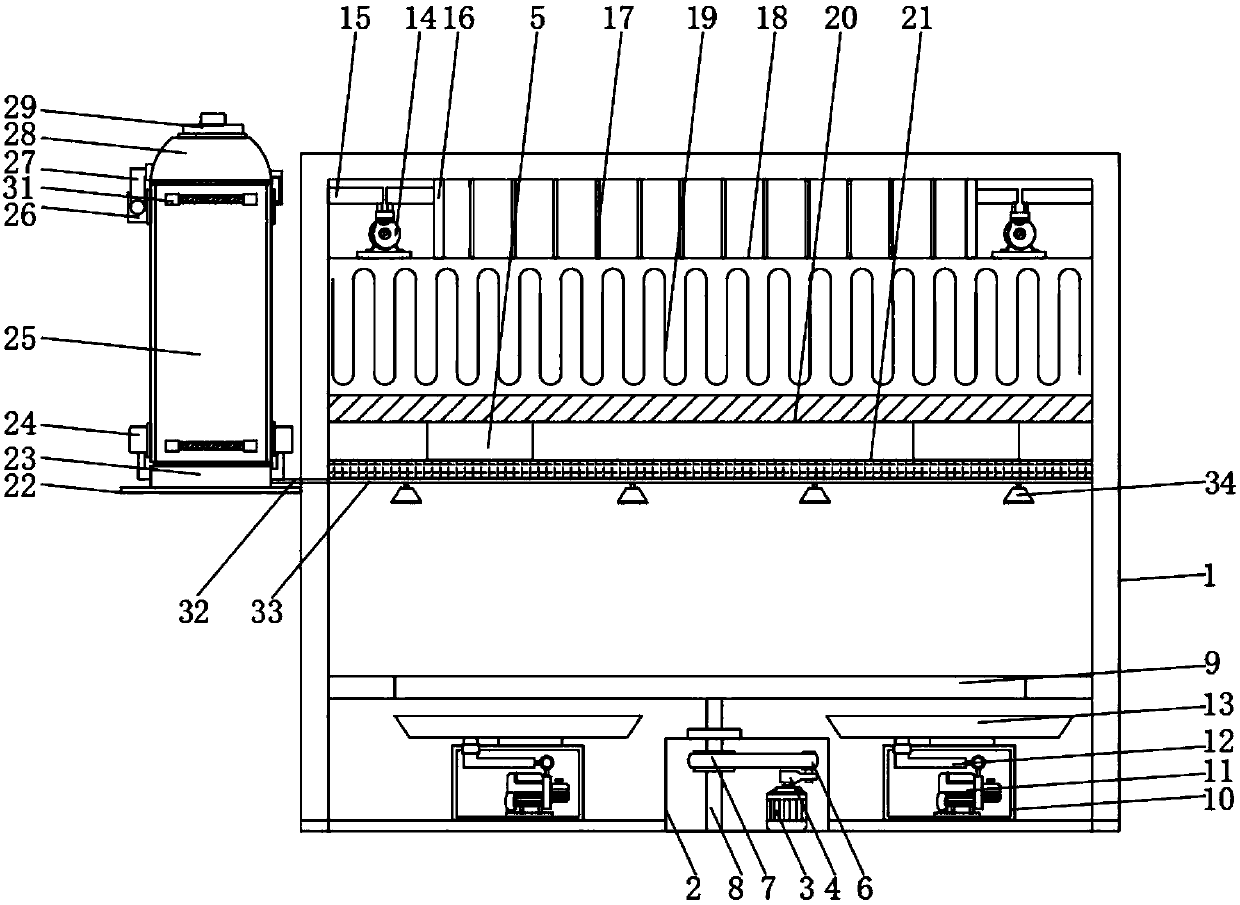

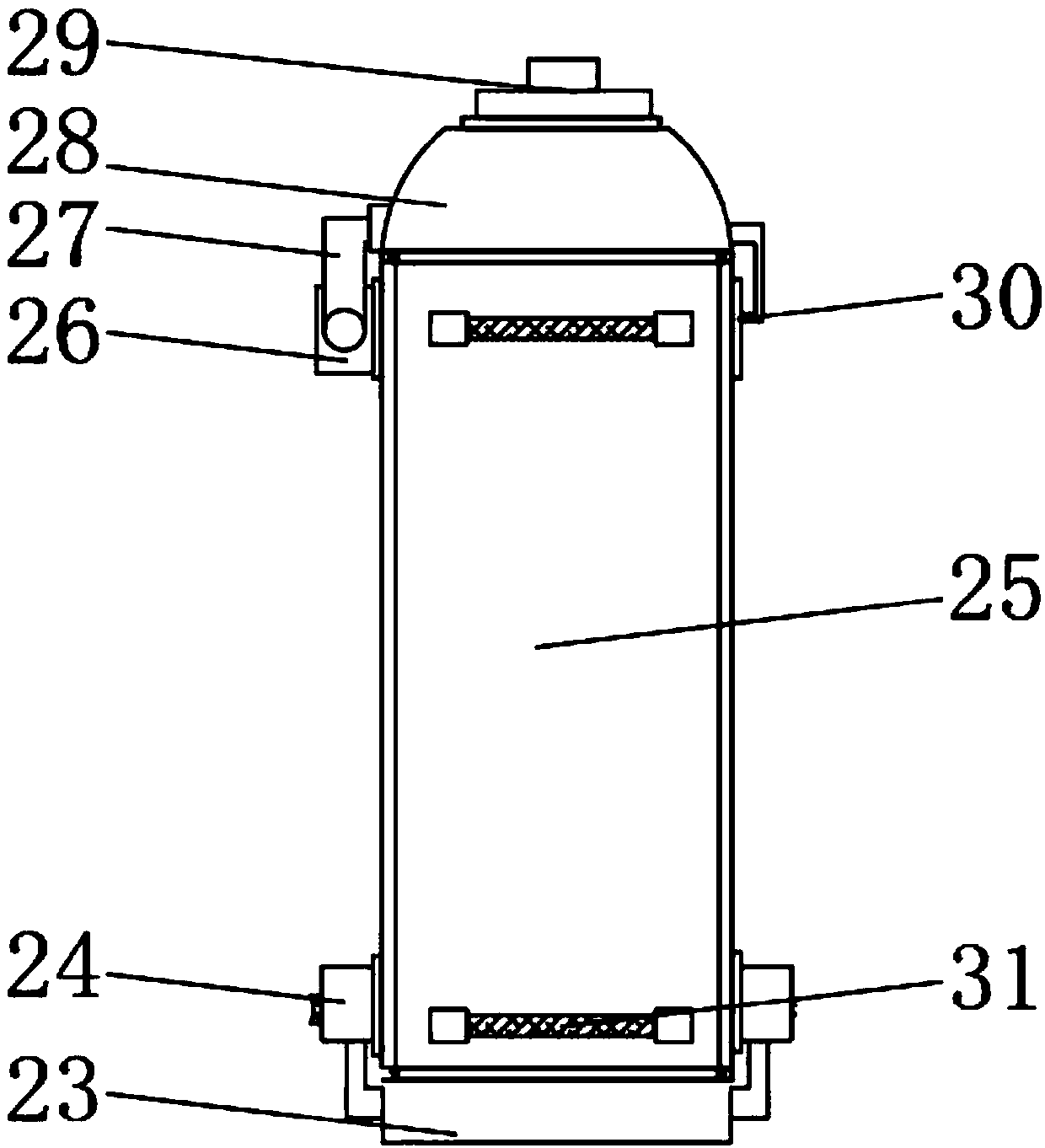

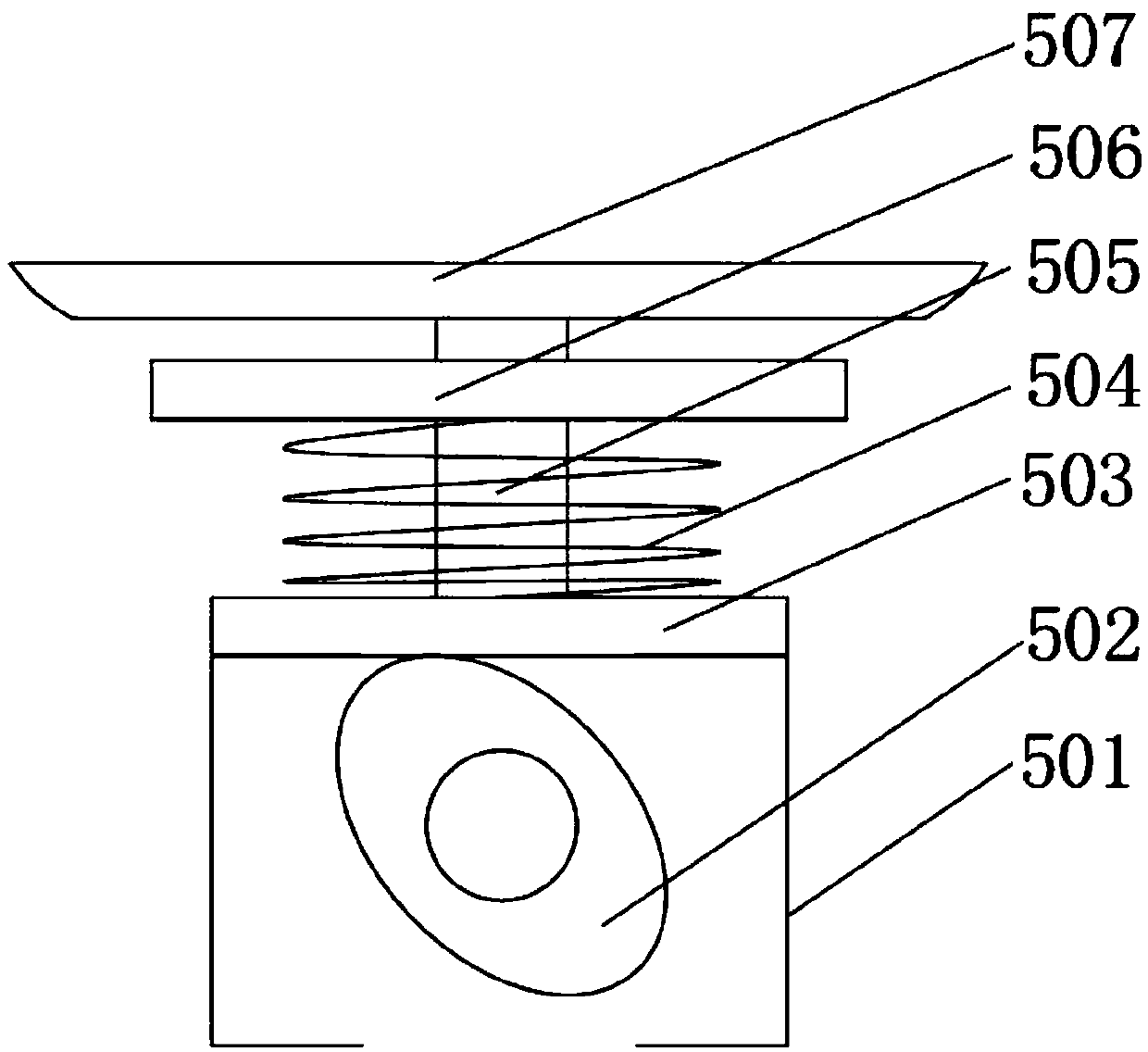

Drying device for film

InactiveCN108120263ADry evenlyRelieve pressureDrying gas arrangementsPretreated surfacesPulp and paper industryWind speed

The invention discloses a drying device for a film. The drying device comprises an upper casing, a lower casing, a conveying frame, a conveying device, a drying frame, a fan, a first air inlet pipe, aheating assembly, a second air inlet pipe, a drying chamber and air nozzles. The conveying device is disposed in the conveying frame, the fan and the heating assembly are connected through the firstair inlet pipe, the top end of the second air inlet pipe is connected with the heating assembly, and the bottom end of the second air inlet pipe is connected to the drying chamber. The lower plane ofthe drying chamber is provided with the plurality of air nozzles, the lower plane of each air nozzle is of a wind net structure, the lower plane of each air nozzle is provided with a plurality of first net ports, the first net ports on each air nozzle are evenly distributed on the lower plane of the air nozzle with a center line of the corresponding air nozzle as the center. The wind net structurecan effectively alleviate wind pressure, the wind speed of the heating assembly reaches a gentle state, the film surface drying efficiency is reduced, a coating in the film can be dried completely, and the temperature within the heating assembly can be controlled so that the film can be uniformly dried.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Multifunctional fertilizer pelletizer

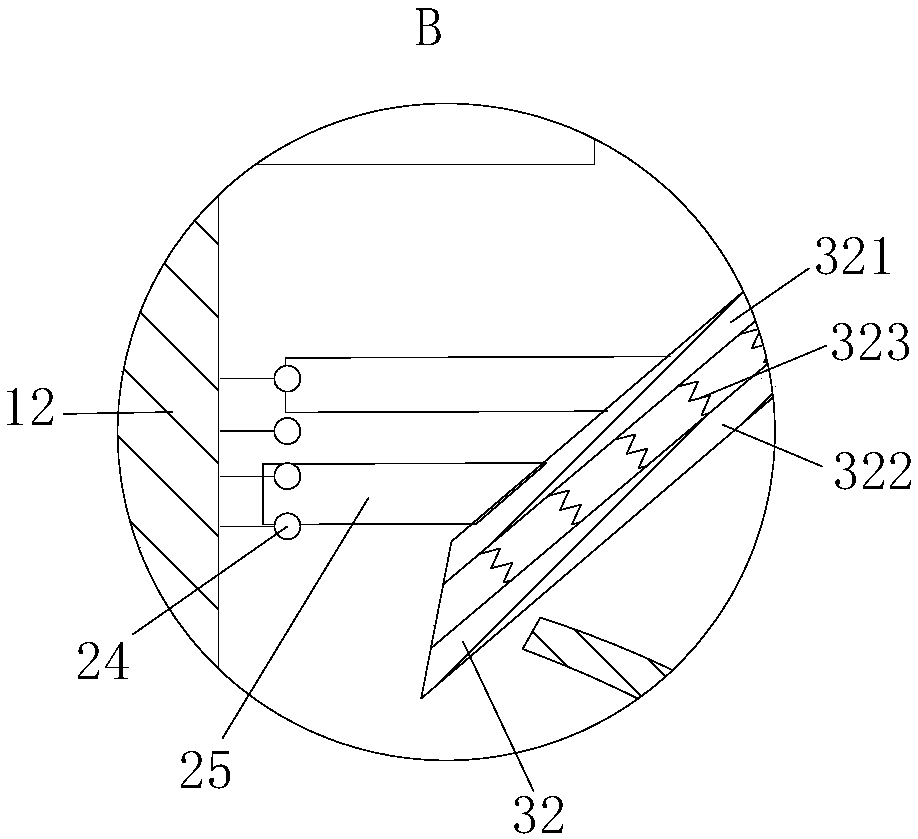

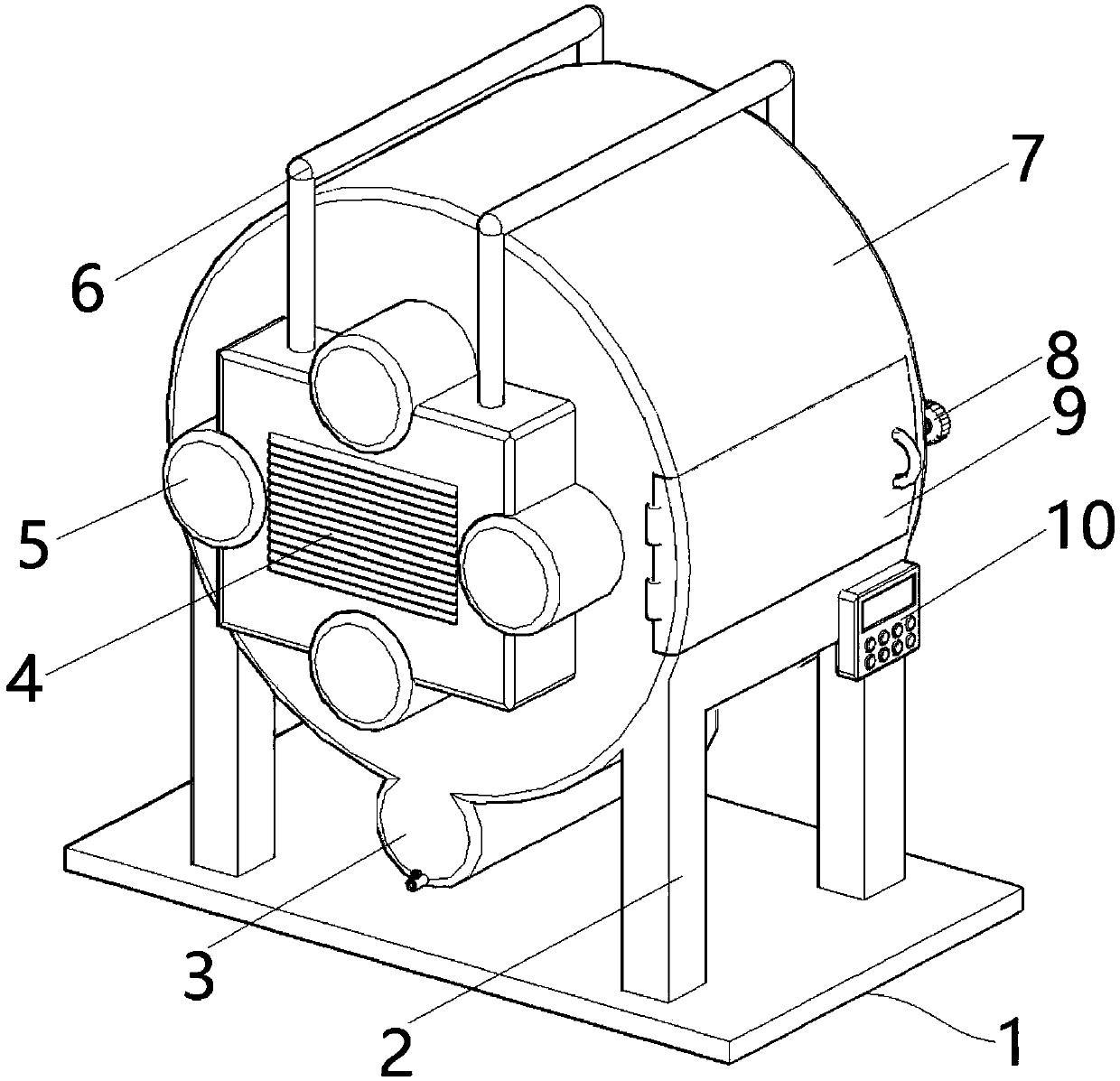

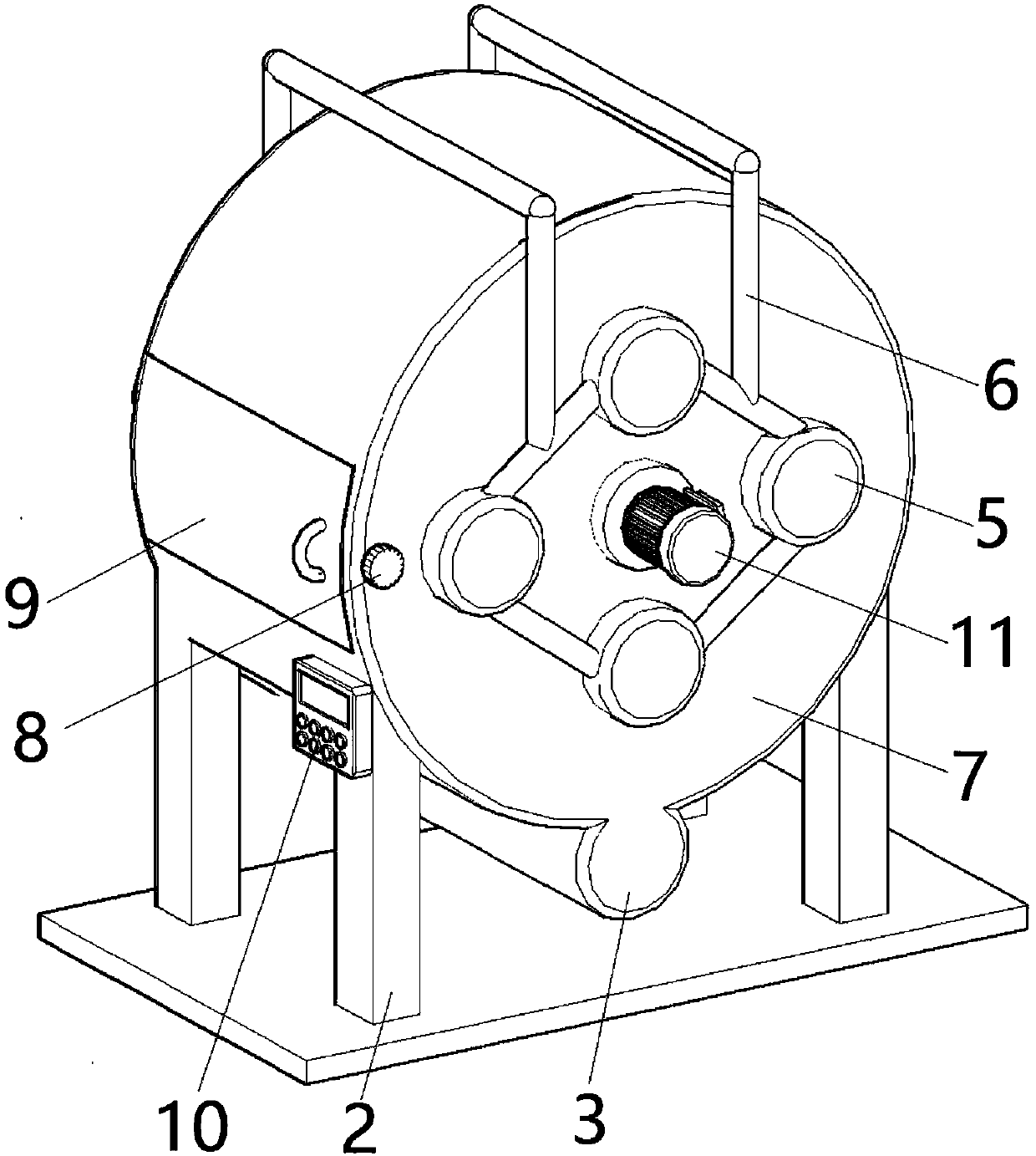

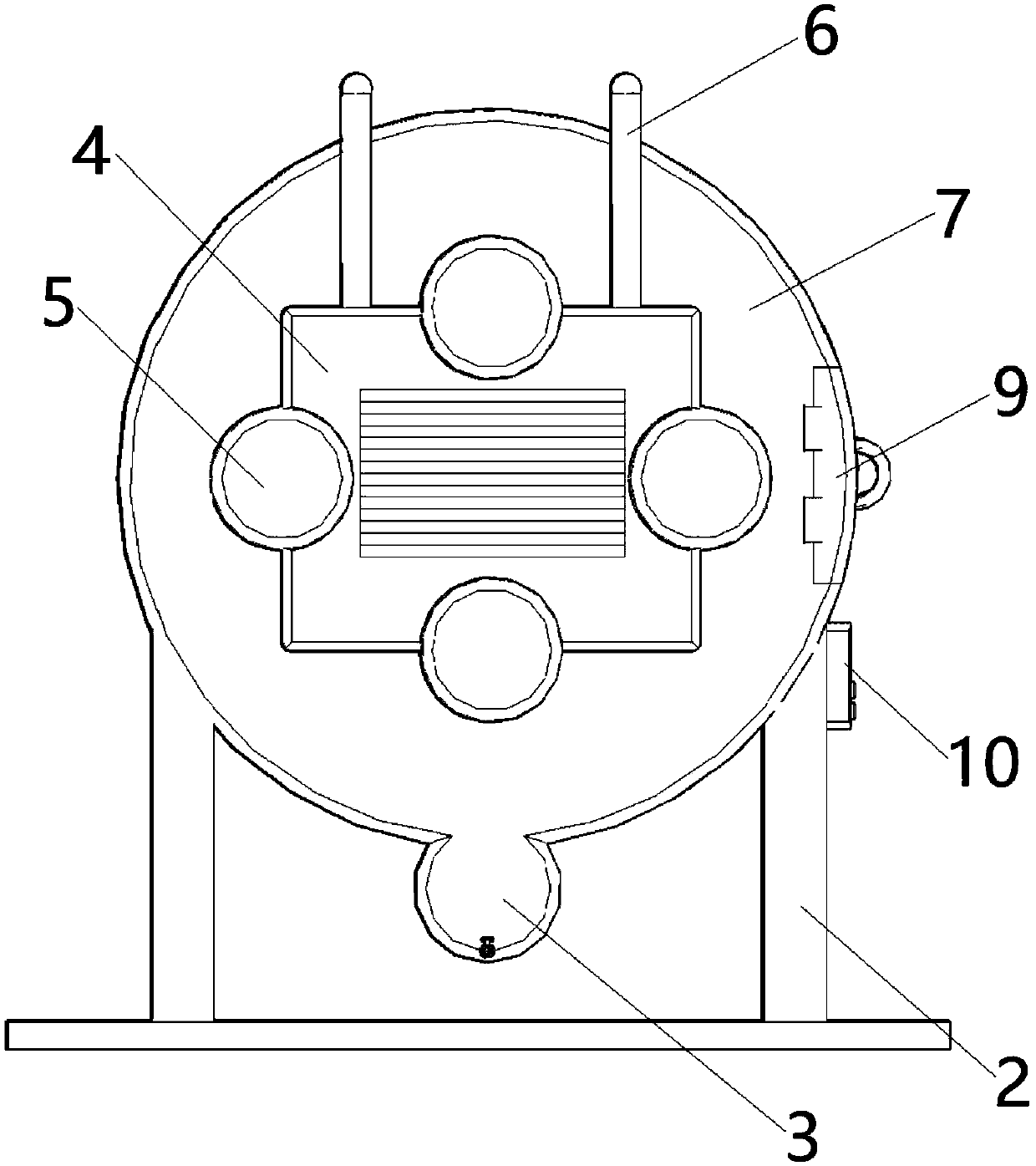

InactiveCN109499475AAvoid stickingAvoid affecting the granulation effectGranulation in rotating drumsGrain treatmentsDrive shaftAgricultural engineering

The invention belongs to the technical field of fertilizer pelletizing equipment and in particular discloses a multifunctional fertilizer pelletizer which comprises a frame and a controller, wherein atransmission shaft is fixedly connected with the rotating shaft of a motor; a crushing unit is arranged below a feeding hole; a pelletizing unit is formed below the crushing unit; the pelletizing unit comprises a pelletizing bucket, a conveying plate and a conveying tube; the pelletizing bucket is of elliptical design; a first discharge hole, a second discharge hole and a third discharge hole areformed in the lower surface of the pelletizing bucket; a drying unit is arranged below the pelletizing unit; the drying unit comprises a rotating disc, a fixing ring and a discharge ring; grooves areformed in both sides of the first discharge hole, the second discharge hole and the third discharge hole of the pelletizing bucket; the grooves are all fixedly connected with cylinders; the cylindersare communicated with a fifth cavity; extrusion blocks are fixedly connected with extension ends of the cylinders. The multifunctional fertilizer pelletizer is simple in structure and high in pelletizing efficiency, and a chemical fertilizer can be classified according to granule sizes after being pelletized and is applicable to different application purposes, thus being wide in application range.

Owner:汪通鲜

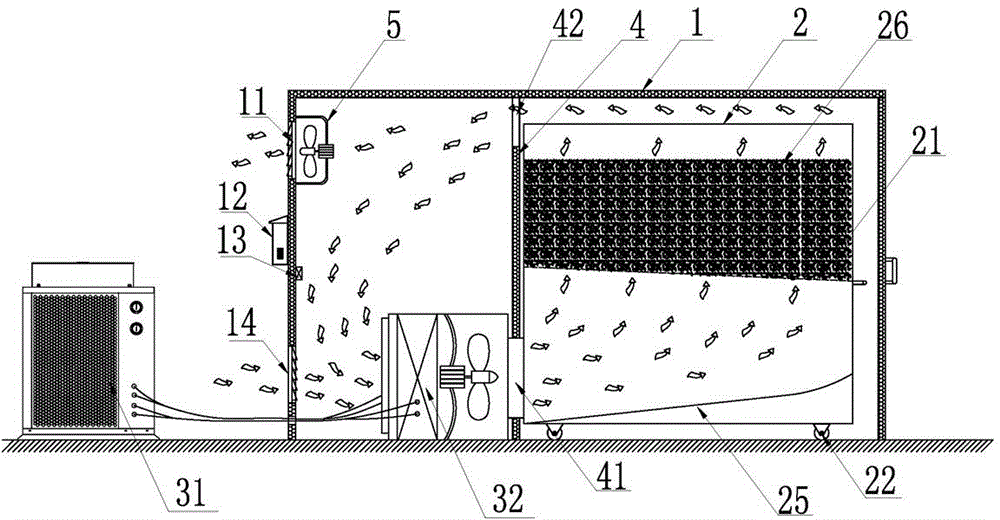

Agricultural vegetable-fruit drying equipment with wastewater collection structure

InactiveCN107736634ASmall footprintFlexible and convenient to useFood treatmentElectric machineAgricultural engineering

An agricultural fruit and vegetable drying equipment with a waste water collection structure, including a heat pump chassis, a drying box and a rotating motor; the bottom of the equipment body is set as a support base; one side of the support base is set on a support leg There is a control box; the upper end of the support base is fixed with a drying box; the bottom side of the drying box is fixed with a waste water collection box; the other side of the drying box is also symmetrically equipped with four sets of heat transfer fans , and the heat delivery fan and the heat delivery fan on the other side are also installed in a symmetrical structure, and the heat delivery fan is connected to the heat pump chassis through a hot air connecting pipe. The agricultural fruit and vegetable drying equipment with waste water collection structure is equipped with a drying box with a cylindrical structure, which is beneficial to rotate with the drying plate fixing seat at the upper end of the inner rotating shaft, and effectively saves space. This makes the device body more flexible and convenient to use and move.

Owner:吴奇勋

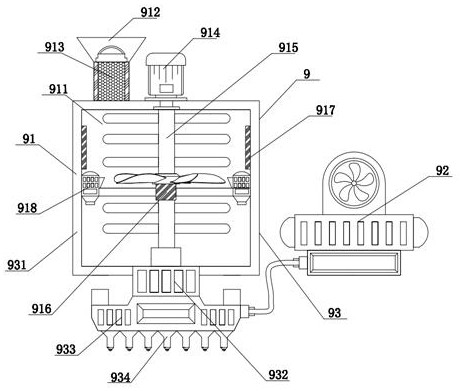

Chemical material drying equipment with stirring device

InactiveCN106482447AKeep dryReduce drying efficiencyGranular material dryingDrying gas arrangementsEngineeringInjection air

The invention provides chemical material drying equipment with a stirring device. The chemical material drying equipment comprises a tank. A drying cavity is arranged inside the tank, and an upper cover is arranged at a top opening; two material crushing devices are arranged on the top cover; an upper guide disc, a guide device, the stirring device and an air injection device are arranged in the drying cavity; the guide device comprises a first motor, a rotary shaft and a lower guide disc; the stirring device comprises a second motor, a stirring shaft and stirring blades; the air injection device comprises an air injection disc and an air inlet pipe; a dehumidification device is arranged on a side wall of the top of the tank. The chemical material drying equipment has the advantages that materials can be crushed and treated by the two crushing devices, and accordingly deterioration of the drying efficiency and the drying quality due to caked materials which are added into the tank can be prevented; the material spreading areas can be enlarged by the guide device, accordingly, the materials can be conveniently uniformly heated, and the material drying speeds can be increased; the stirring device is favorable for transferring heat and can bring convenience for drying the materials, and the chemical material drying equipment has a material mixing function.

Owner:郑州吉音动漫科技有限公司

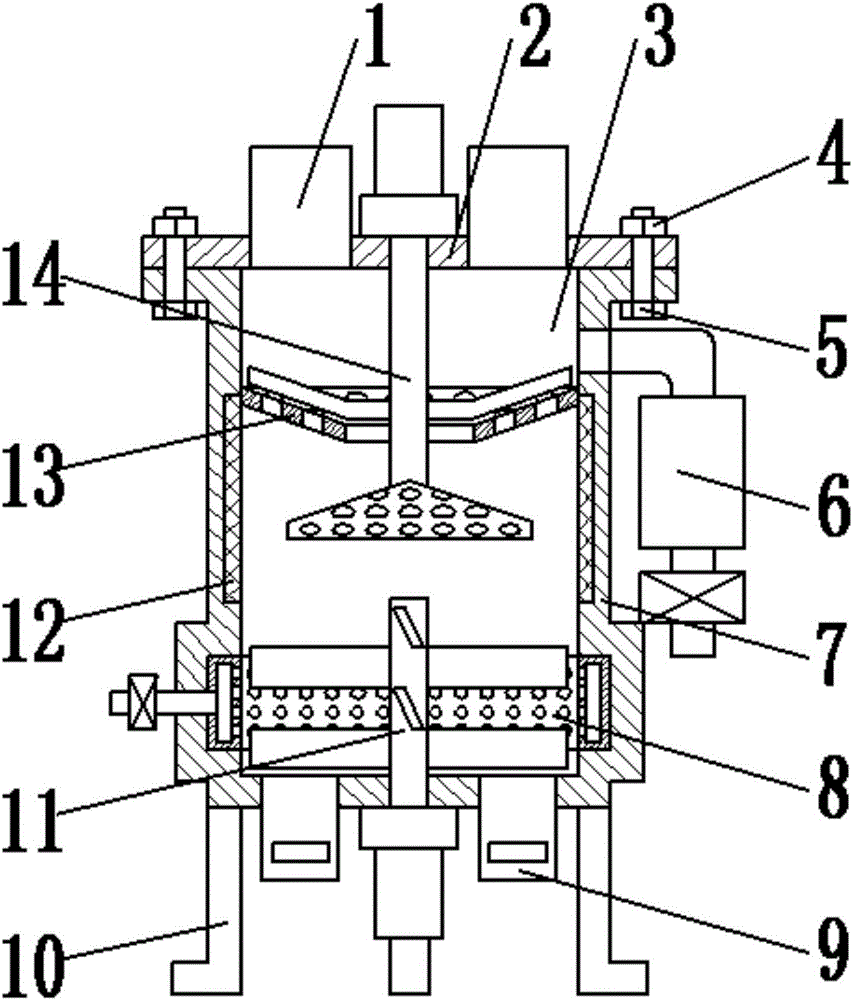

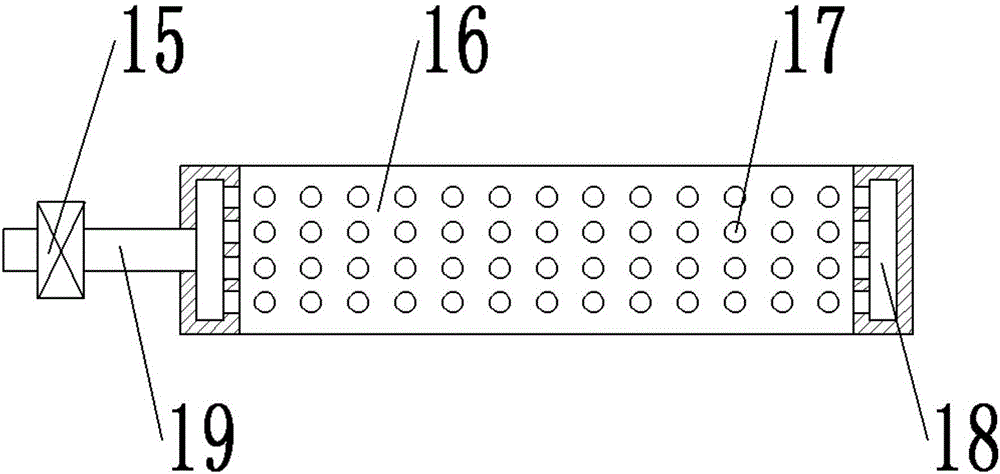

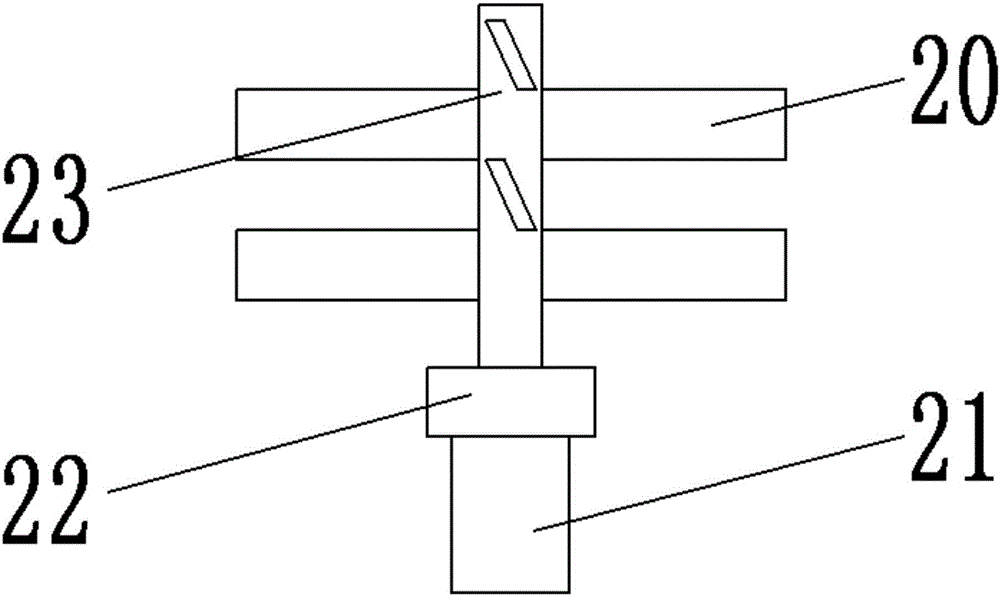

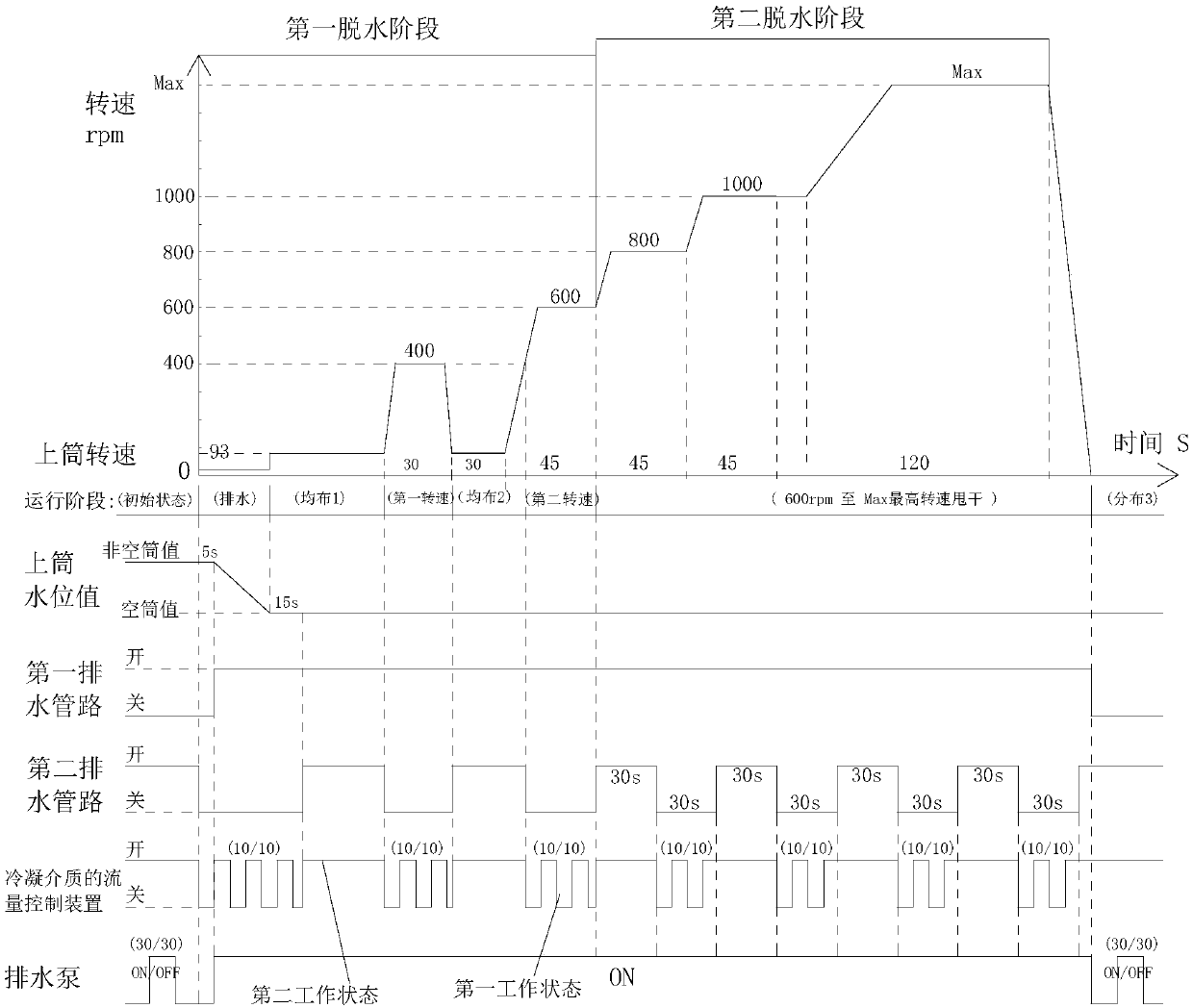

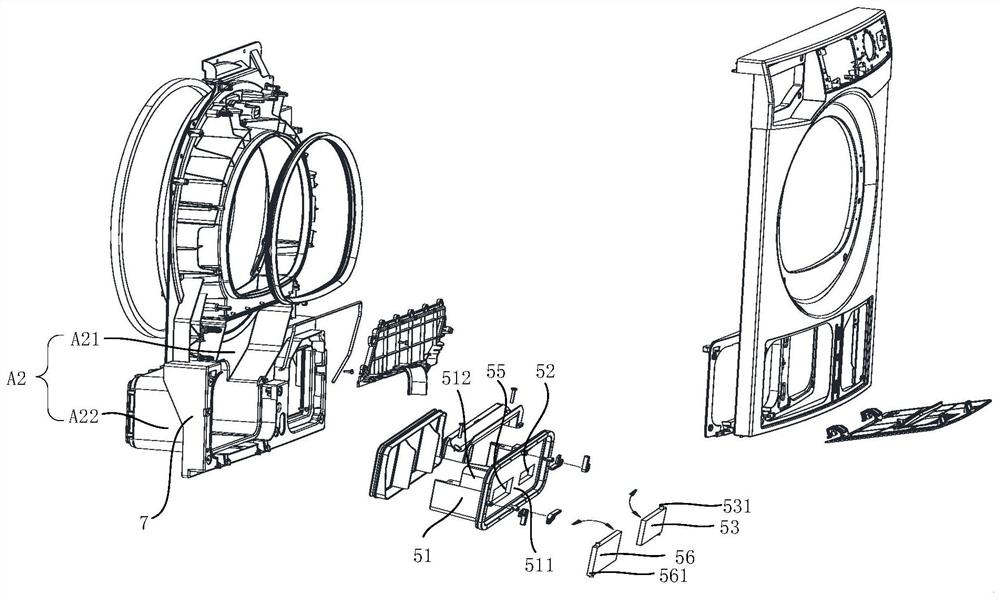

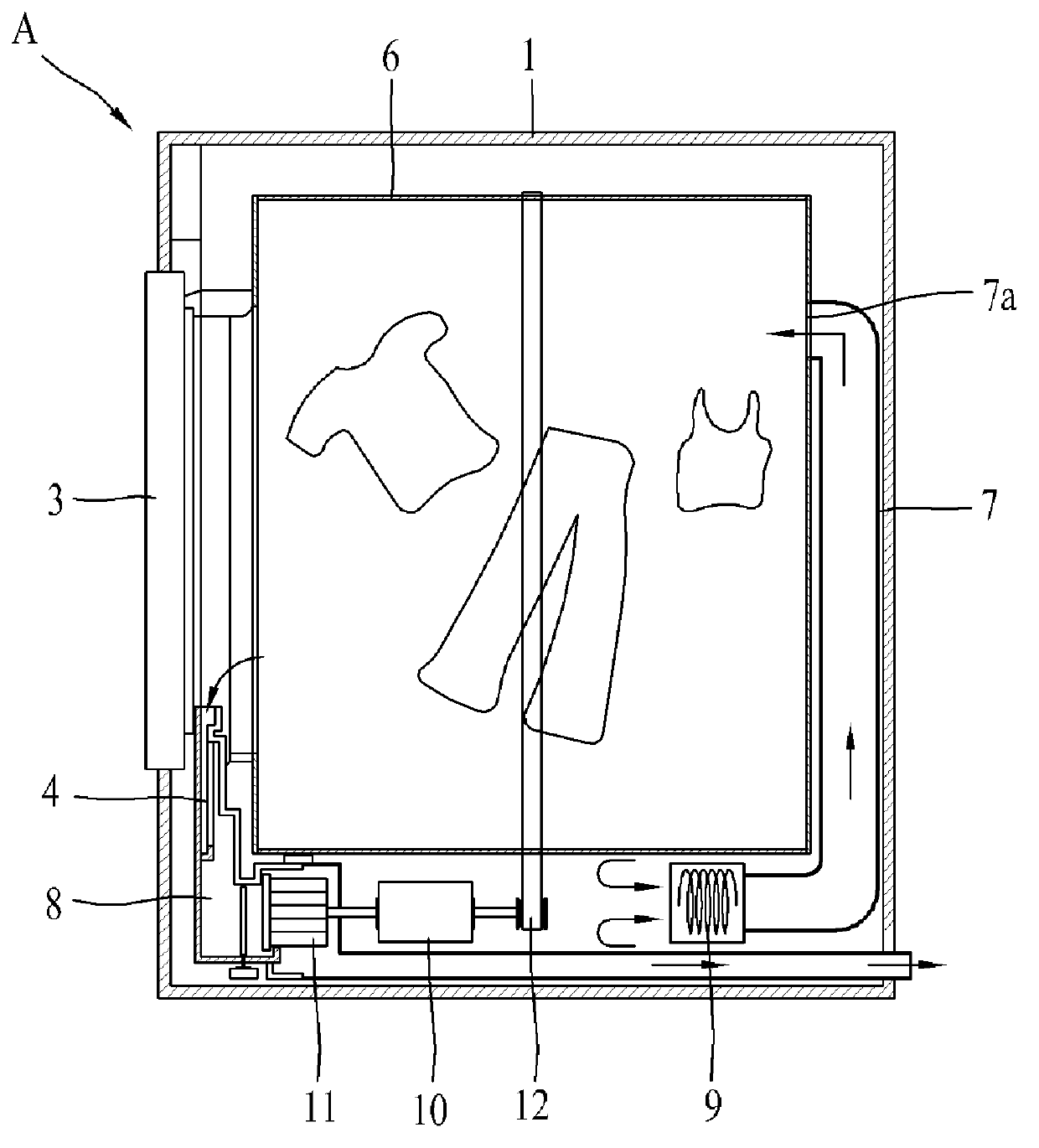

Clothing drying control method for clothing treatment device and clothing treatment device

ActiveCN110499608AAvoid mixed flowAvoid backwashing into the lower dryer drumOther washing machinesControl devices for washing apparatusPulp and paper industryDrainage amount

The invention discloses a clothing drying control method for a clothing treatment device and the clothing treatment device. The clothing treatment device is provided with a first treatment cylinder and a second treatment cylinder for clothing treatment, wherein the second treatment cylinder is a condensing-type washing and drying all-in-one machine, and the second treatment cylinder is provided with a control device which controls the flow of a condensing medium in a condensing device according to the switched state; the working state of the control device is switched along with the change ofthe rotation speed of the first treatment cylinder. Under the condition that the hardware and structure of the whole clothing treatment device are unchanged, the technical effect of normally running alower cylinder drying program on the premise of not influencing dewatering and drainage of an upper cylinder is achieved by controlling the working state of the control device for the flow of the condensing medium; the characteristics of drainage amount of different dewatering processes are fully utilized to realize effective linkage between the rotation speed of a washing drum and the condensingefficiency of a clothing dryer, the overall time of clothing treatment is shortened, and the user satisfaction degree is improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

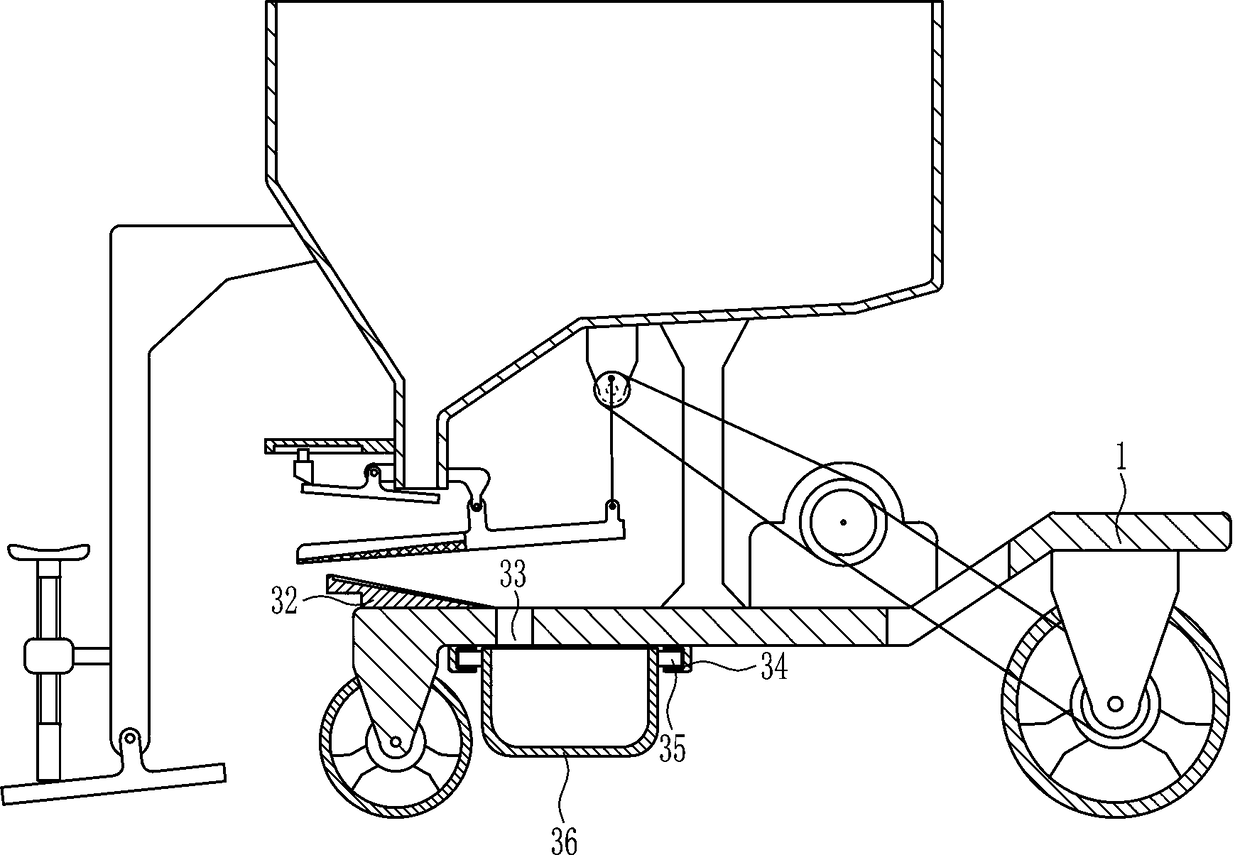

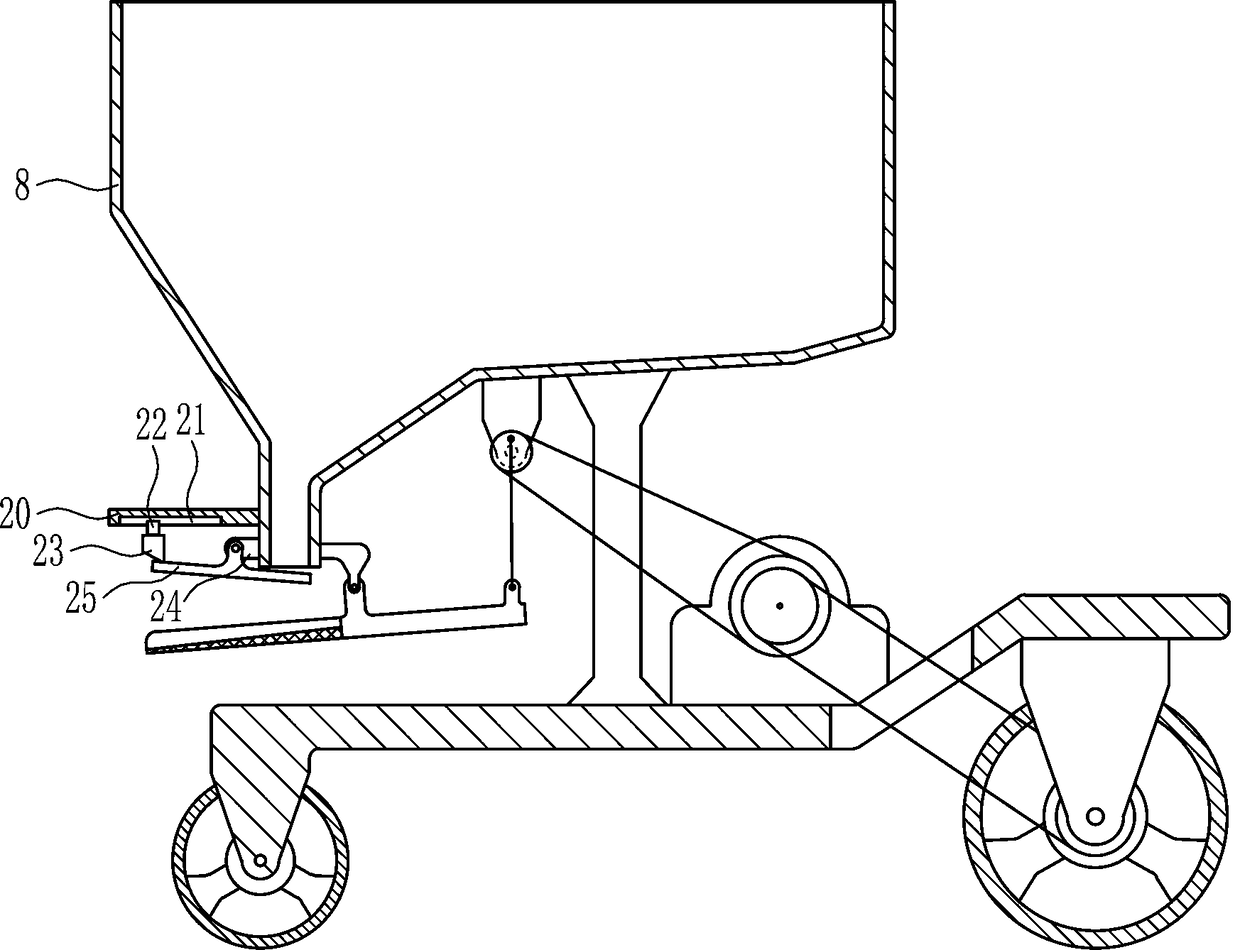

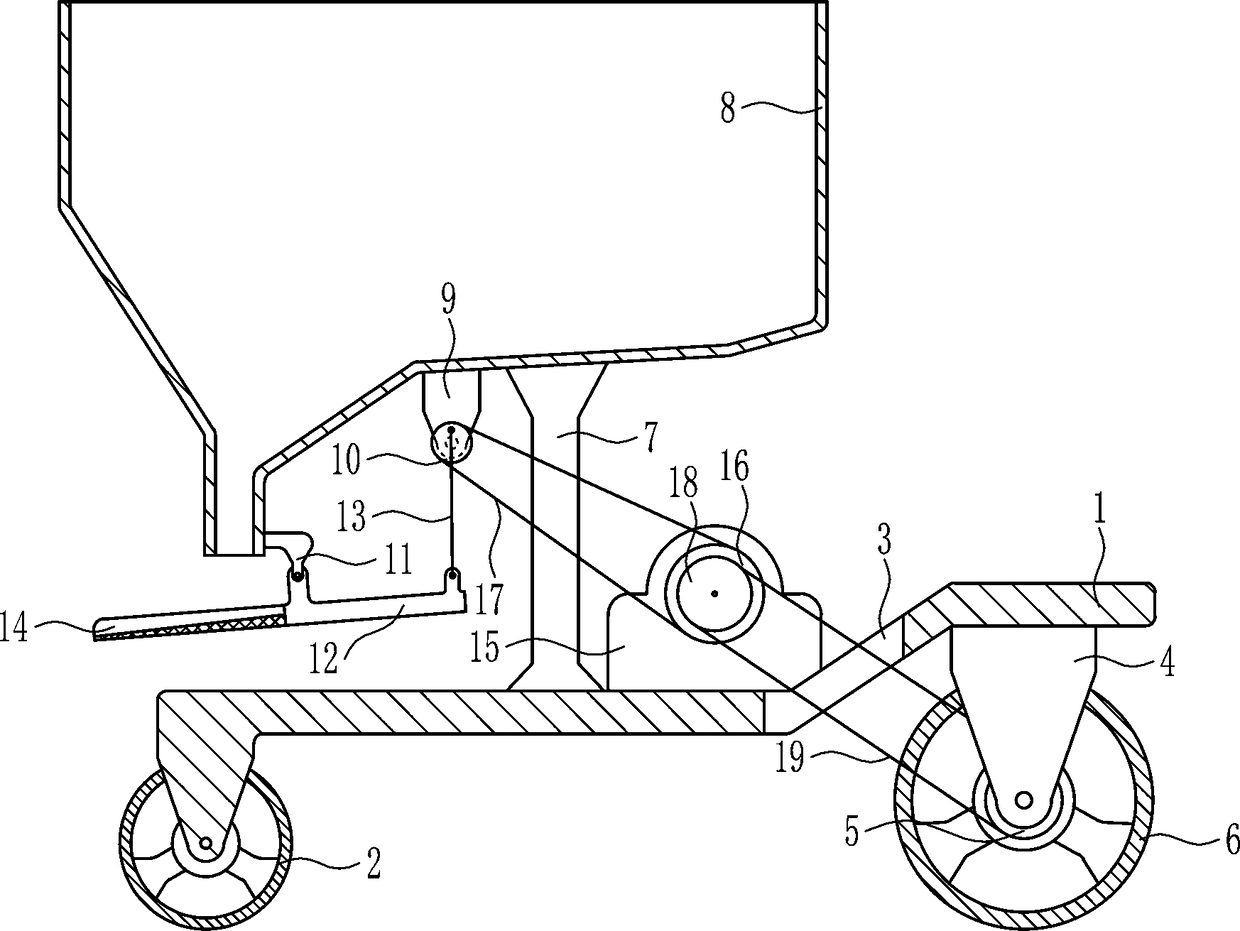

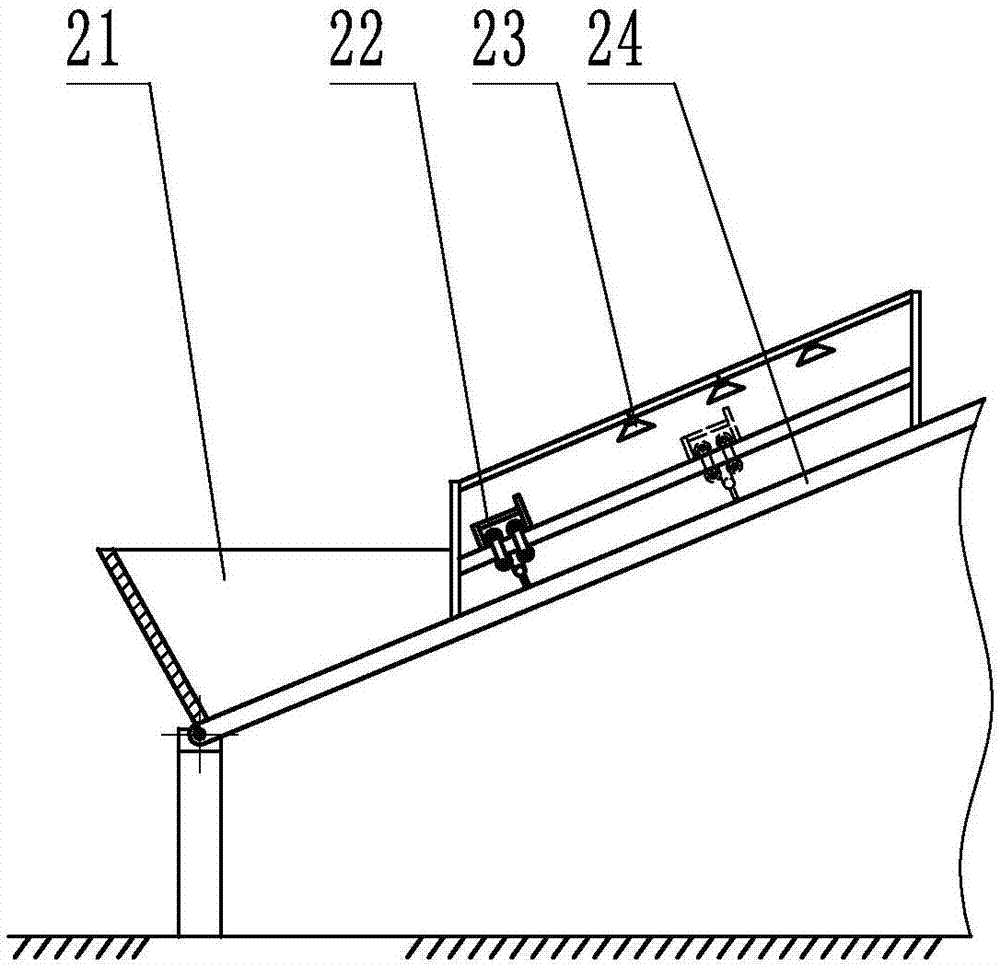

Paddy flattening and air-drying equipment for agriculture

The invention relates to paddy flattening and air-drying equipment for agriculture, particularly relates to paddy flattening and air-drying equipment for agriculture, and aims at solving the technicalproblem of providing the paddy flattening and air-drying equipment for reducing labor intensity and improving flattening efficiency. The equipment comprises a deck, a first roller, a first bracket, afirst belt pulley, a second roller, a second bracket, a discharge hopper, an assembly plate, a second belt pulley, an L-shaped bracket, a connecting plate and the like, wherein the first roller is arranged on the left side of the bottom of the deck; a first opening is formed in the right part of the deck; the first bracket is connected with the right side of the bottom of the deck; and the firstbelt pulley is in rotating connection with the lower part of the rear side of the first bracket. According to the equipment, paddy can be more uniformly flattened due to downward and upward swinging of a screen plate and can be screened, so that small stones and impurities in the paddy can be screened out; and a scraper can be fixed by downward movement of a screw rod, and the paddy on the groundcan be uniformly flattened.

Owner:胡莹

Organic fertilizer drying machine

InactiveCN106766753AFlip fullEvenly heatedDrying solid materialsDrying machines with non-progressive movementsAgricultural engineeringOrganic fertiliser

The invention discloses an organic fertilizer drying machine mainly used for solving the problems that fertilizer particles dried by the existing organic fertilizer drying machine in the prior art are heated non-uniformly and dust is easily generated during secondary use. The organic fertilizer drying machine comprises a drum, a fixed column and a motor; one end of the drum is rotatably connected with the fixed column, and the other end of the drum is rotatably connected with a rotating shaft of the motor; the inner wall of the drum is uniformly provided with a plurality of bulges; the distance between every two adjacent bulges is larger than the particle size of each fertilizer particle; the height of each bulge is smaller than or equal to 1 / 3 of the particle size of each fertilizer particle; and the outer wall of the drum is provided with at least one vibrator. According to the technical scheme, the aims that the fertilizer particles are heated more uniformly and the dust is not easily generated during secondary use are achieved, and the organic fertilizer drying machine has very high practical and popularization values.

Owner:华蓥市禄市镇小学

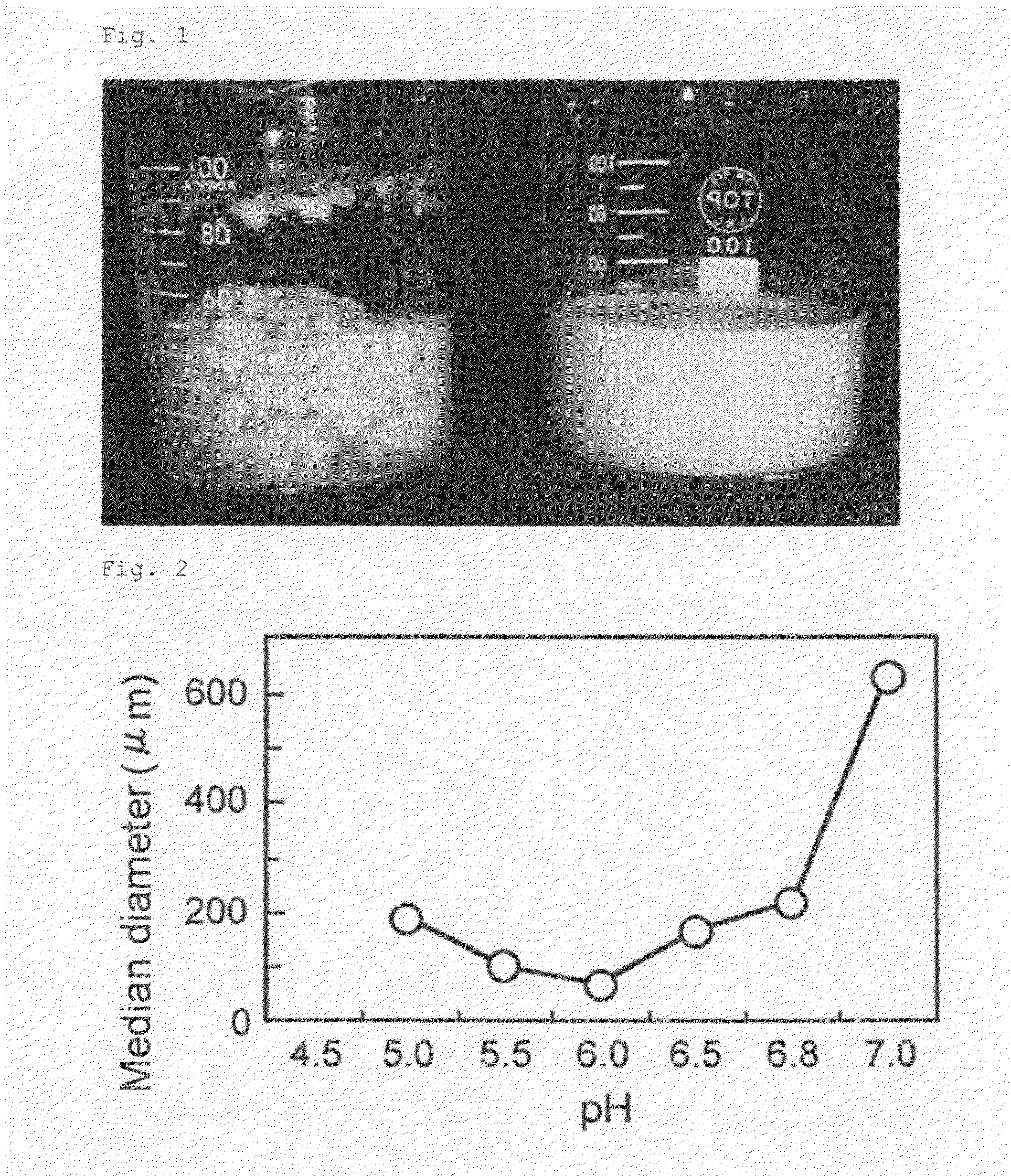

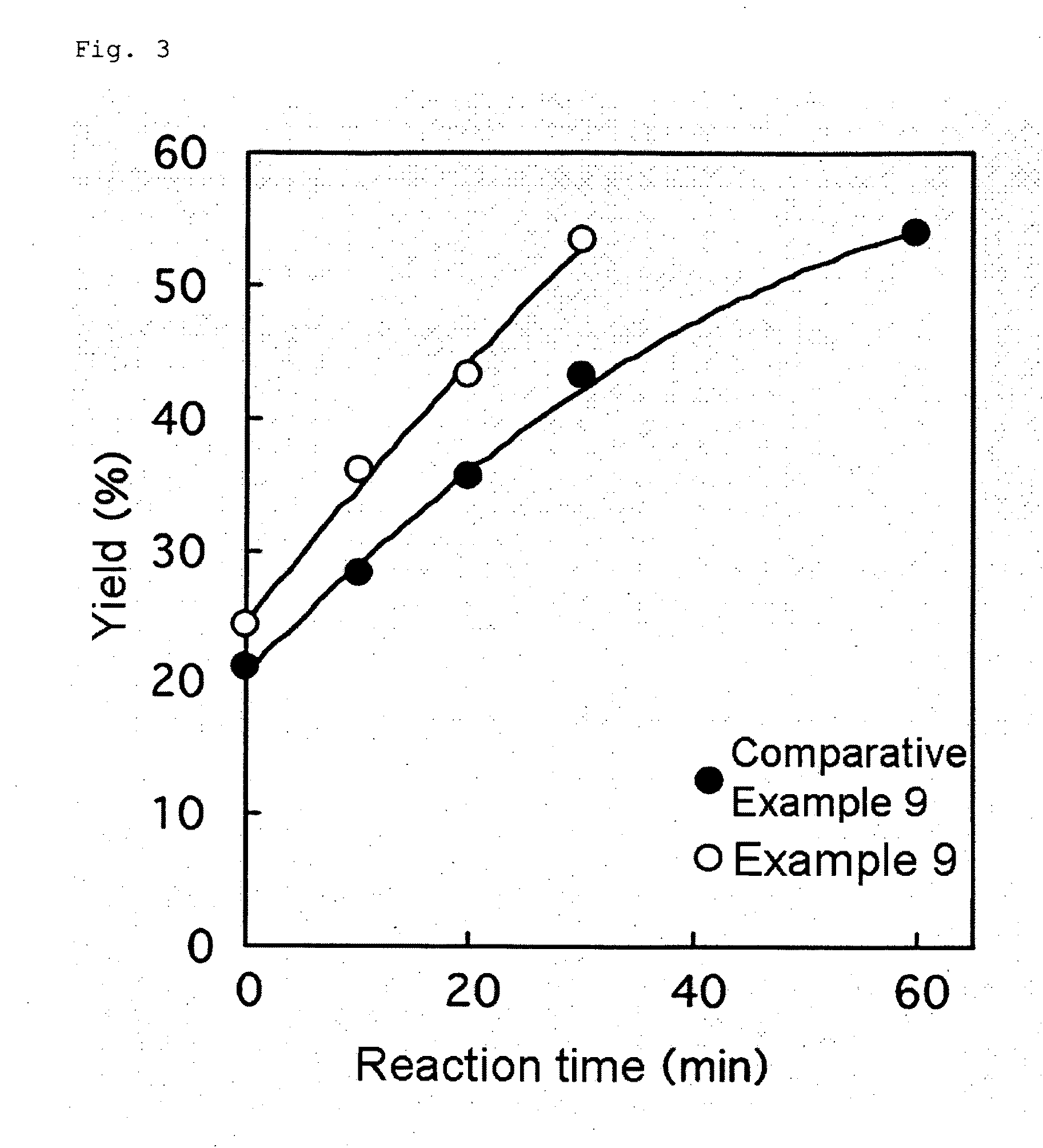

Dispersion improver for gluten, and dispersion solution of gluten

ActiveUS20100145019A1Reduce drying efficiencyGood dispersionDepsipeptidesPeptide preparation methodsProteolysisWater soluble

Disclosed is gluten having good dispersibility in water. Also disclosed is a method for producing active gluten, a gluten-containing food or a gluten gel efficiently by using a gluten dispersion solution. Further disclosed is a method for producing a gluten hydrolysate efficiently by preparing a gluten dispersion solution in a simple manner and hydrolyzing the dispersion solution. Gluten, which normally forms an aggregate in water, can be dispersed readily by mixing gluten with a water-soluble polysaccharide containing galacturonic acid. The gluten dispersion solution thus prepared can be used to produce active gluten, a gluten-containing food or a gluten gel efficiently, and can be also used to prepare a gluten hydrolysate in a simple manner, efficiently and stably.

Owner:FUJI OIL CO LTD

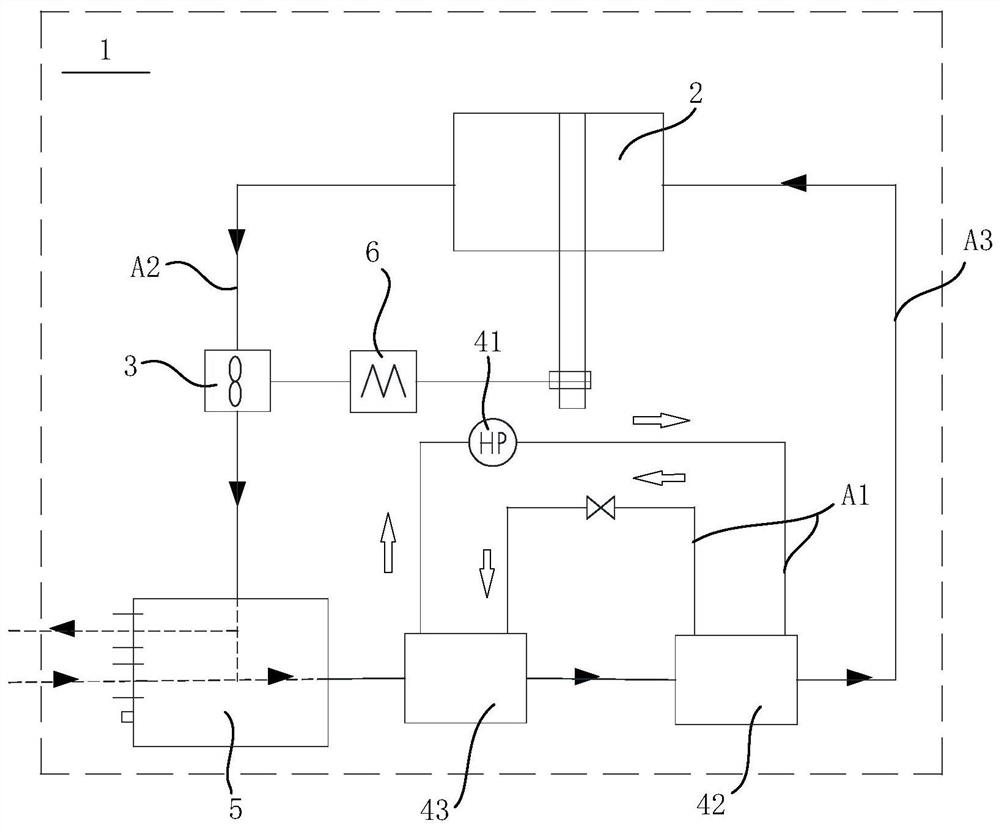

Heat pump clothes dryer and control method for heat pump clothes dryer

ActiveCN111676675AReduce exhaust temperatureReduce drying efficiencyTextiles and paperLaundry driersCold airThermodynamics

The invention belongs to the technical field of clothes drying, and particularly relates to a heat pump clothes dryer and a control method for the heat pump clothes dryer. The invention aims to solvethe problems that a compressor is started and stopped frequently and the drying efficiency is affected in the prior art. The heat pump clothes dryer provided by the invention comprises a drum, a heatpump system, a fan, a ventilation component, a temperature detection device and a control device, wherein the heat pump system comprises an air channel, a condenser and an evaporator; the fan is usedfor driving air to flow in the air channel and the drum; and the control device is used for controlling the ventilation component to introduce cold air outside the air channel into part air channel for connecting the evaporator and a hot and humid air outlet of the drum when the temperature detection device detects that the working temperature of the heat pump system is greater than a preset temperature. Through the arrangement above, the cold air is introduced into the air channel to mix with the hot and humid air so as to reduce the temperature of the hot and humid air which performs heat exchange with a refrigerant in an evaporator pipeline, thereby reducing the exhaust temperature of the compressor, and avoiding low drying efficiency caused by frequently starting and stopping the compressor caused by high load.

Owner:HEFEI HAIER DRUM WASHING MASCH CO LTD +1

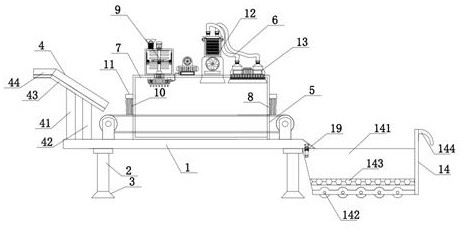

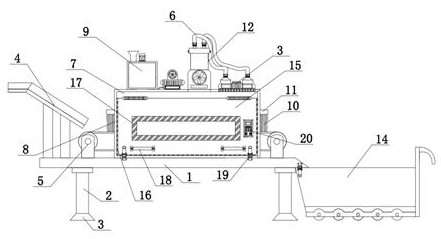

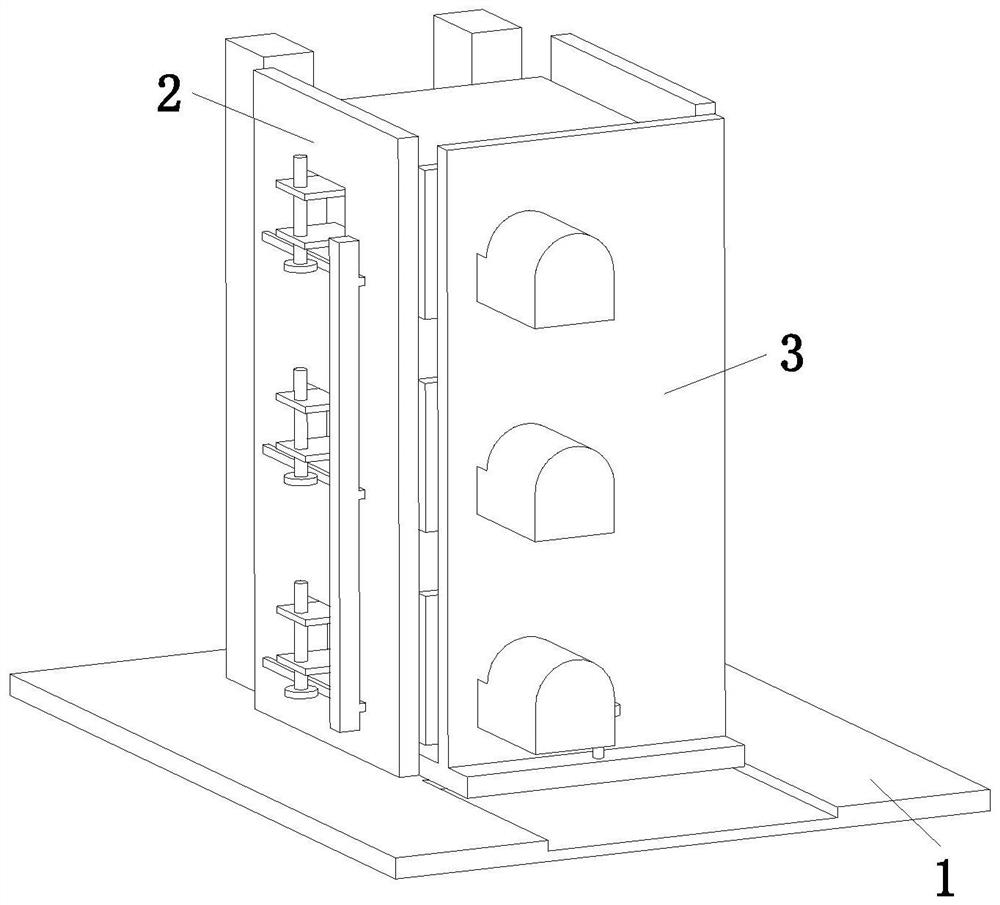

Production method of polymer powder coating

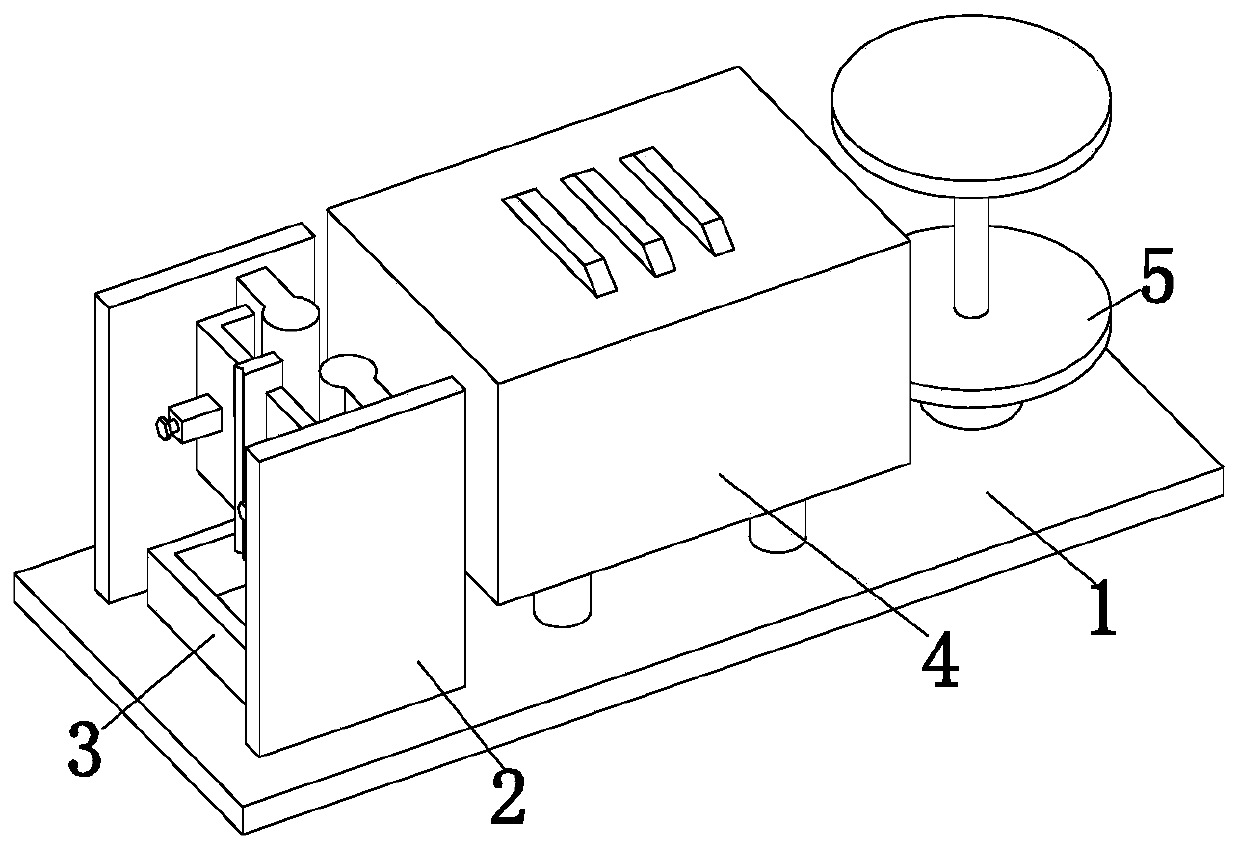

InactiveCN112212633AControl the degree of heatingReduce drying efficiencyDrying solid materialsDrying machines with non-progressive movementsPolymer sciencePolymer chemistry

The invention relates to a production method of a polymer powder coating. The production method of the polymer powder coating adopts a production device of the polymer powder coating. The production device of the polymer powder coating comprises a base, support columns, a mounting frame, a material receiving mechanism, a heating mechanism, a material storage mechanism and a displacement mechanism,wherein the support columns are respectively installed on the inner sides of corners of the upper end surface of the base, the mounting frame is installed between the top ends of the support columns,the material receiving mechanism and the heating mechanism are arranged on the upper end surface of the base and are located on the inner sides of the support columns in sequence from left to right,the material storage mechanism is installed on the inner side of the mounting frame, and the displacement mechanism is installed on the lower end of the material storage mechanism. In the process of drying the damped polymer powder coating in an airing and drying mode in the prior art, the drying efficiency is low or excessive drying is caused because the temperature cannot be adjusted; and the undried polymer powder coating is collected due to uneven spreading thickness, and the subsequent use effect is influenced.

Owner:宁波辉驰泰新能源科技有限公司

Heat pump clothes dryer

ActiveCN111676676AReduce the temperatureReduce exhaust temperatureTextiles and paperLaundry driersCold airEngineering

The invention belongs to the technical field of clothes dryers, and particularly relates to a heat pump clothes dryer. The clothes dryer aims to solve the problem that a compressor frequently starts and stops in the prior art, and drying efficiency is affected. The heat pump clothes dryer comprises a roller, a heat pump system, a fan and a ventilation assembly, wherein a dry hot wind inlet and a humid hot wind outlet are formed in the roller, the heat pump system comprises an air duct, a condenser and an evaporator, an inlet hole and an outlet hole capable of opening and closing are formed inthe ventilation assembly, the inlet hole is used to lead cold air outside the air duct into a first part of the humid hot wind outlet connecting the evaporator and the roller, and the outlet hole is used to exhaust part of hot and humid air in the first part. Through the above arrangement, the temperature of the hot and humid air exchanging heat with refrigerant in an evaporator pipeline is reduced, so that the exhaust temperature of the compressor is reduced, and the reduction of drying efficiency caused by frequent start and stop of the compressor due to high load is avoided.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Method for controlling dryer

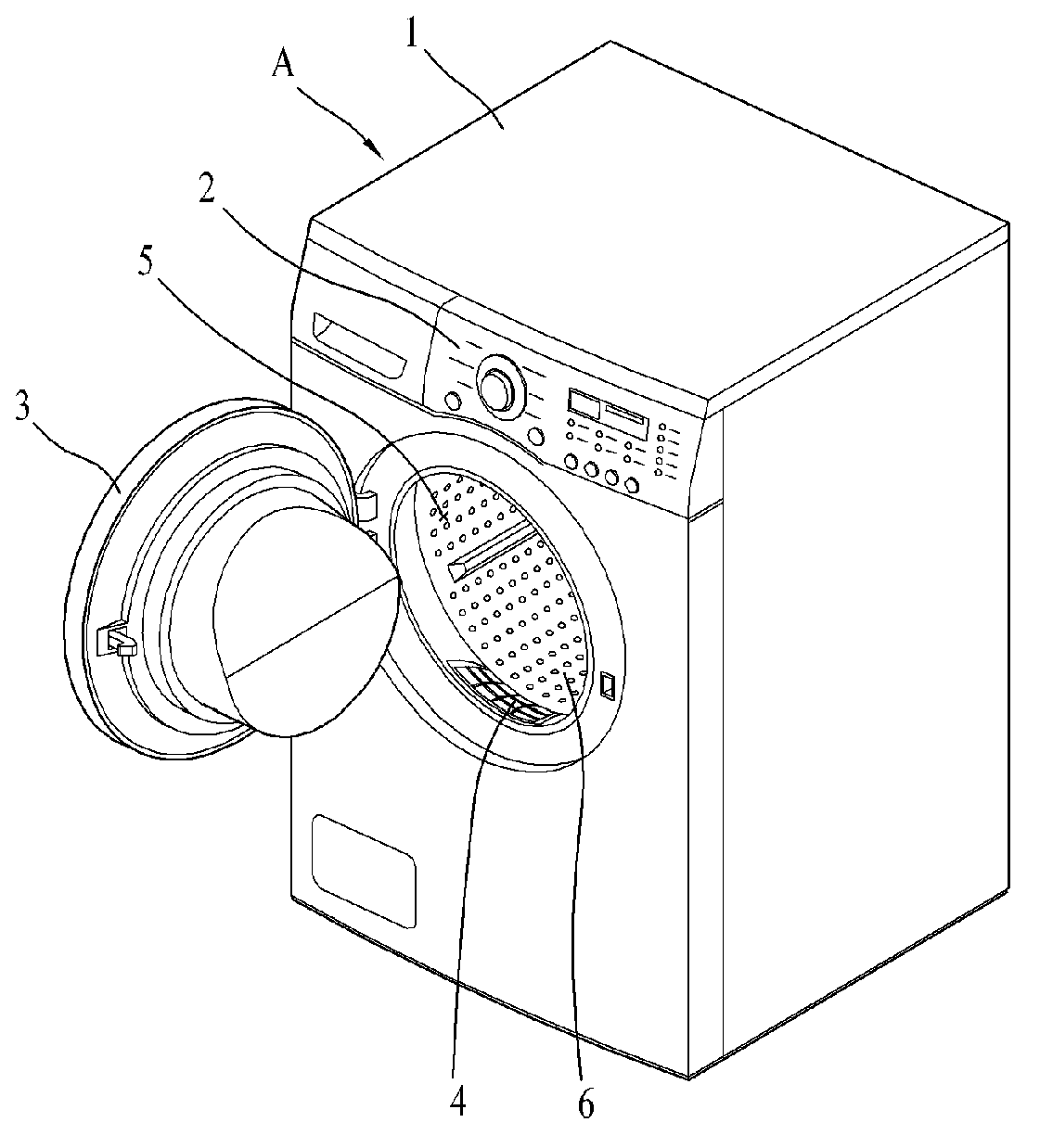

ActiveCN103328713AOperation stoppedReduce drying efficiencyDrying gas arrangementsTextiles and paperForeign matterEngineering

A method for controlling a dryer (A) includes putting a brush driving unit into operation, after putting the brush driving unit into operation, gathering information related to the operation of the brush driving unit, and controlling operation of the dryer (A) based on the gathered information related to the brush driving unit. The brush driving unit is configured to drive a brush (430) that separates foreign matter from a filter portion (420) of a filter assembly (4) positioned to contact air that has exited from a drum of the dryer (A).

Owner:LG ELECTRONICS INC

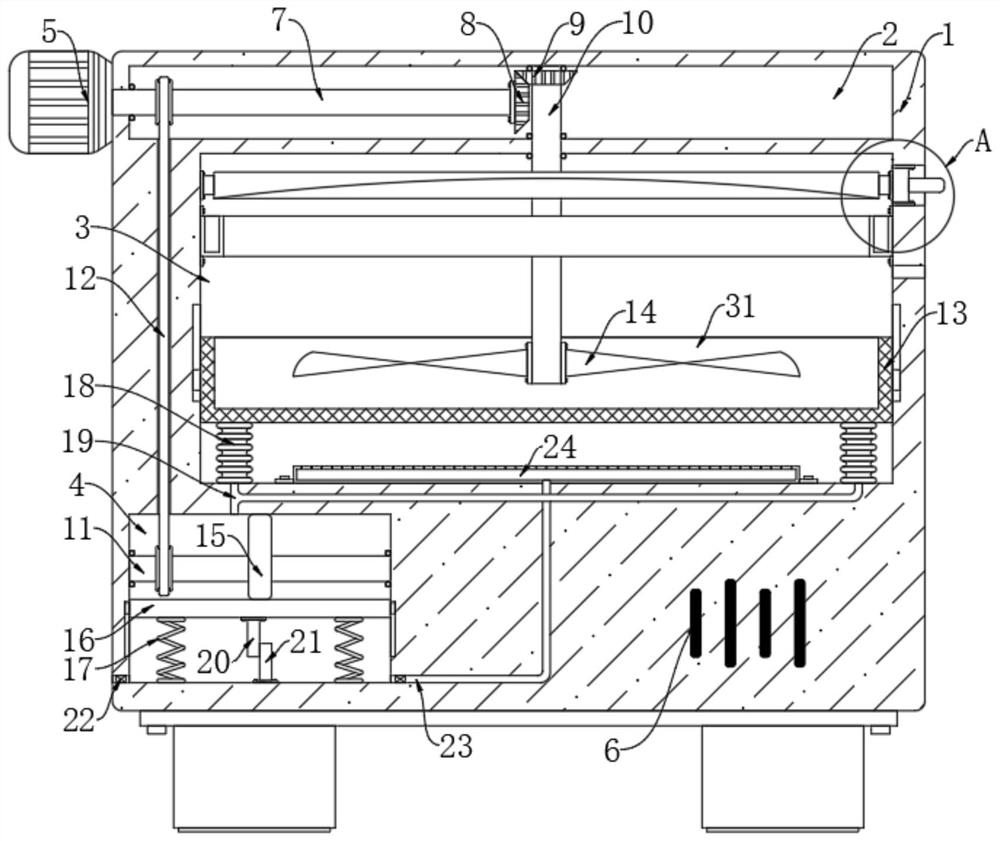

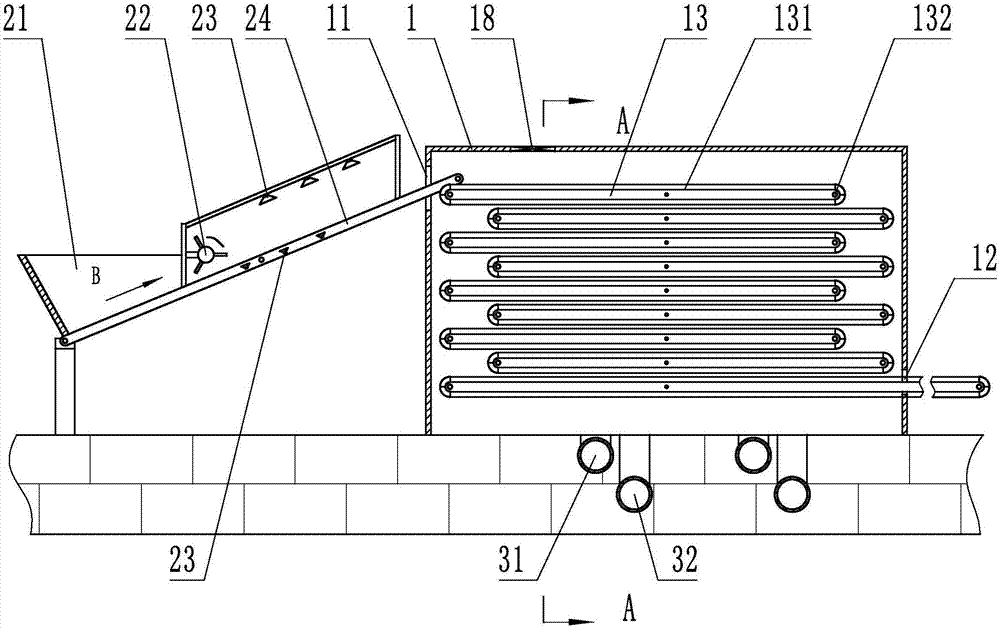

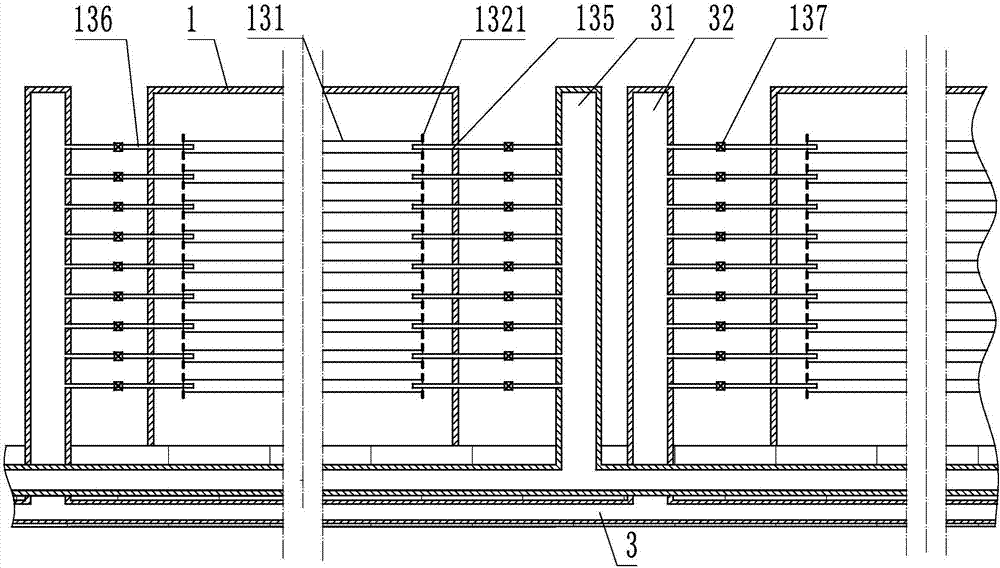

Crop drying device with rapid drying function

InactiveCN112696901APromote disturbanceEasy to dryDrying gas arrangementsSteam/vapor condensersAgricultural scienceAgricultural engineering

The invention discloses a crop drying device with a rapid drying function. The crop drying device comprises a box body and a triggering mechanism. The box body is sequentially provided with a rotating cavity, a working cavity and a moving cavity from top to bottom, an opening communicating with the outside is formed in the inner wall of the front side of the working cavity, and a sliding door is installed on the opening. The triggering mechanism comprises a first rotating rod horizontally arranged in the rotating cavity, a motor is installed on the left side wall of the box body, and the tail end of an output shaft of the motor extends into the rotating cavity. The device stirs and shakes crops, so that the crops are always in a flowing state, when hot air is sprayed to the crops, the crops can be dried in all directions, the drying effect is better, water vapor is condensed into water drops, the water drops are thrown into a collecting tank through centrifugal force to be collected, and the water drops are prevented from falling into the crops again.

Owner:吴丹丹

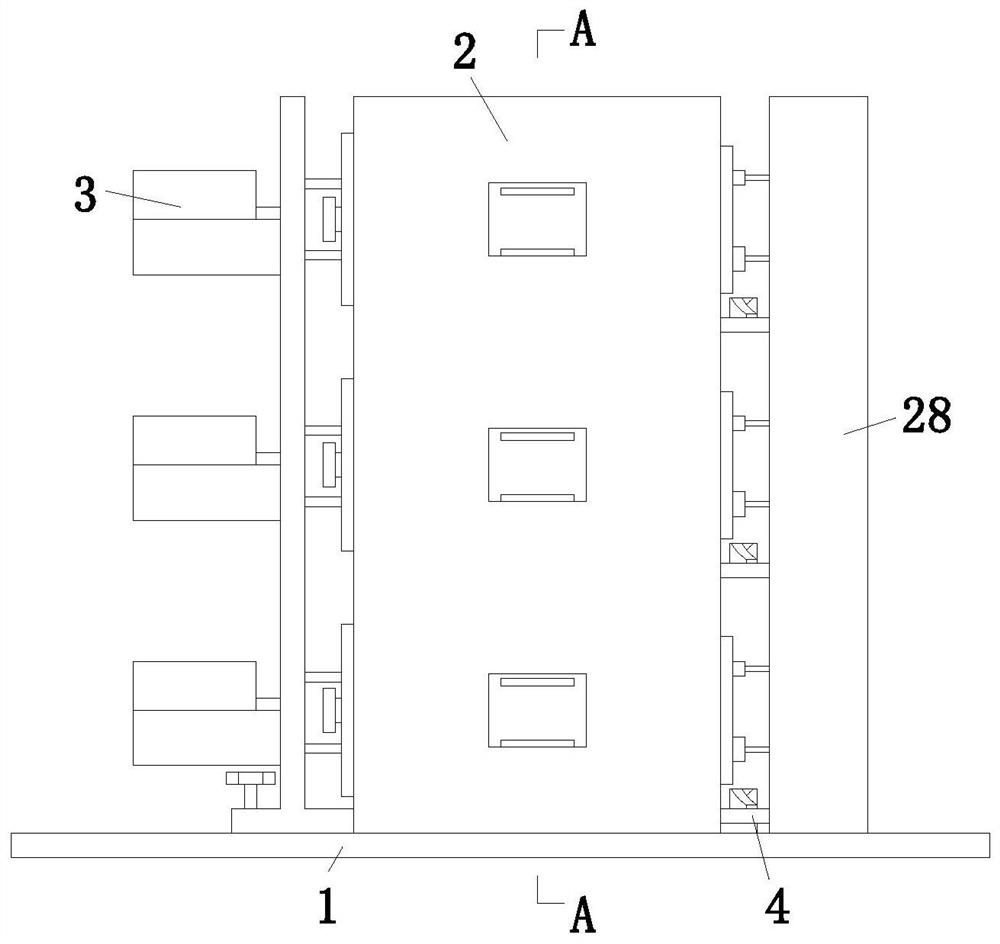

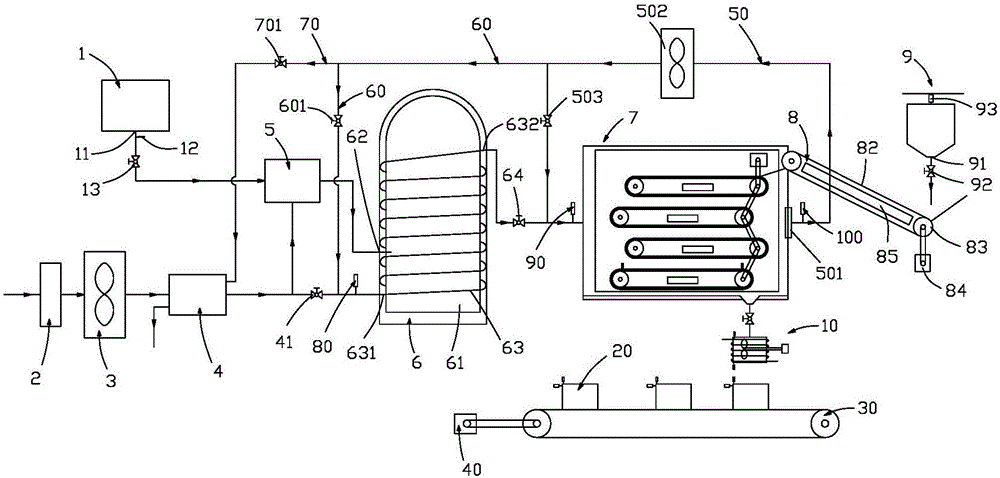

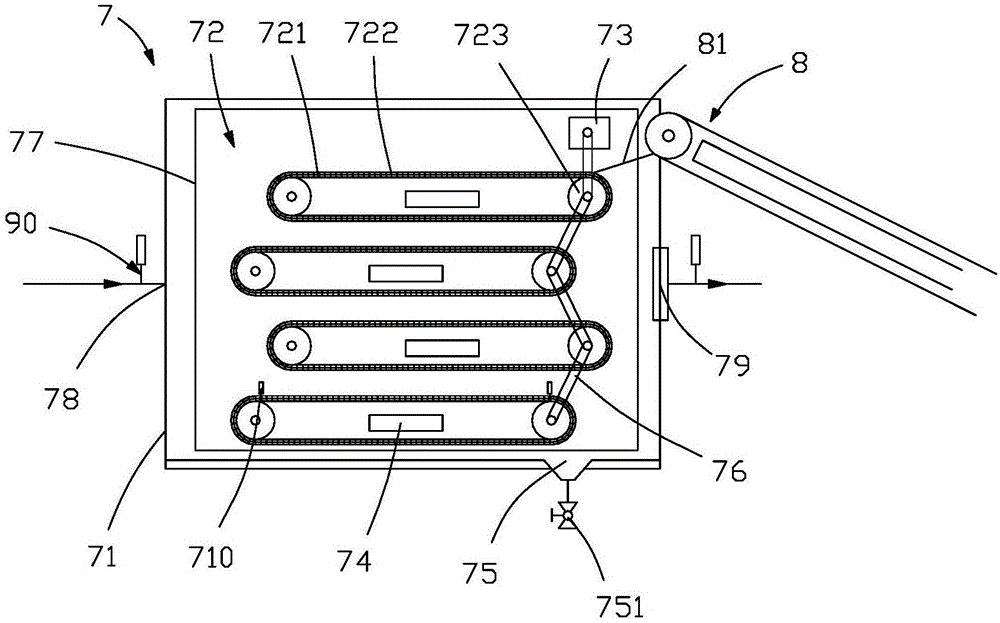

Fruit and vegetable drying system and drying method

InactiveCN106923361AReduce utilizationSolve the phenomenon of incomplete dryingDrying gas arrangementsDrying machines with progressive movementsWater contentDried fruits

The present invention discloses a fruit and vegetable drying system. The system specially comprises a heat supply mechanism (41), a raw material bin (42), drying devices (46), a moisture regaining material bin (44), a finished product material bin (45) and a material loading tower crane (43). The material loading tower crane (43) transfers the materials stacked in the raw material bin (42) into the drying devices (46) to conduct drying, the materials dried by the drying devices (46) are stacked in the moisture regaining material bin (44), after the stacking, the stacked materials are sent into the drying devices (46) again to conduct the drying, and finally, the dried materials are transferred into the finished product material bin (45). Compared with the prior art, the drying system can better dry fruits and vegetables, improve the labor efficiency, reduce the labor intensity, and avoid the problem that the water content of the dried fruits and vegetables is relatively large in difference.

Owner:SHAWAN GUORUI MACHINERY MFG +1

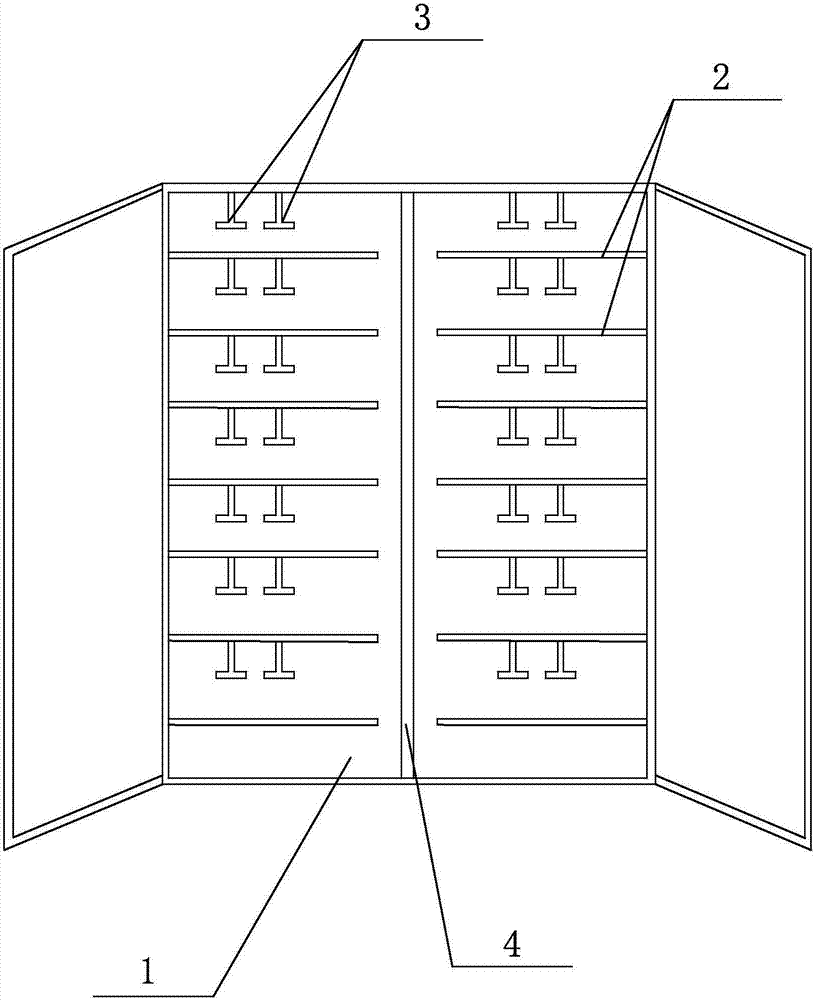

Drying equipment for improving efficiency of drying shoes

The invention discloses drying equipment for improving the drying efficiency of shoes, which comprises a shoe cabinet body, the shoe cabinet body is divided into a winter shoe area and a summer shoe area, and the winter shoe area and the summer shoe area are sequentially arranged from top to bottom. There are a plurality of shoe boards, and two drying sheets are arranged above the shoe boards, and the drying sheets are connected with the upper shoe boards through telescopic rods; There is a heating rod, the shoe board is provided with an inductor, and the sensor is connected to a controller, and the controller controls the telescopic rod to perform telescopic movement; the shoe board is made of transparent material, and the shoe board is equipped with an ultraviolet The lamp tube, the ultraviolet lamp tube and the heating rod are all connected with the controller. The intelligent drying shoe cabinet of the present invention can automatically dry and sterilize different shoes, has high drying pertinence, improves drying efficiency, and does not cause waste of resources.

Owner:四川丹露鞋业有限公司

Anti-corrosion spraying device for processed surfaces of logs

ActiveCN112705405AHigh activityPrevent precipitationPretreated surfacesCoatingsAir cleaningProcess engineering

The invention discloses an anti-corrosion spraying device for processed surfaces of logs. The anti-corrosion spraying device for the processed surfaces of the logs comprises a processing table, wherein supporting legs are fixedly mounted at four corners of the bottom of the processing table; a trapezoidal supporting foot is fixedly mounted at the bottom of each supporting leg; a guide mechanism is fixedly mounted on the left side of the top of the processing table; and a conveyor belt body is fixedly mounted in the middle of the top of the processing table. The anti-corrosion spraying device for the processed surfaces of the logs is relatively convenient to use, and can continuously process and spray logs; meanwhile, uniformity of a blending coating is improved, so that spraying precision is improved, and quality of the processed logs is effectively improved; an air purifying mechanism and a drying mechanism are matched with each other, so that inner air circulating adsorption is realized, leakage of harmful gas is effectively reduced, and life health of an operator is guaranteed; and meanwhile, air further can be heated and circulated, so that the coating on the surfaces of the logs is dried, and therefore, processing production efficiency is effectively improved.

Owner:日照京杭林产家具有限公司

Manufacturing method of artificial composite particle board

ActiveCN112414060AReduce drying efficiencyReduce drynessDrying gas arrangementsDrying chambers/containersCold airProcess engineering

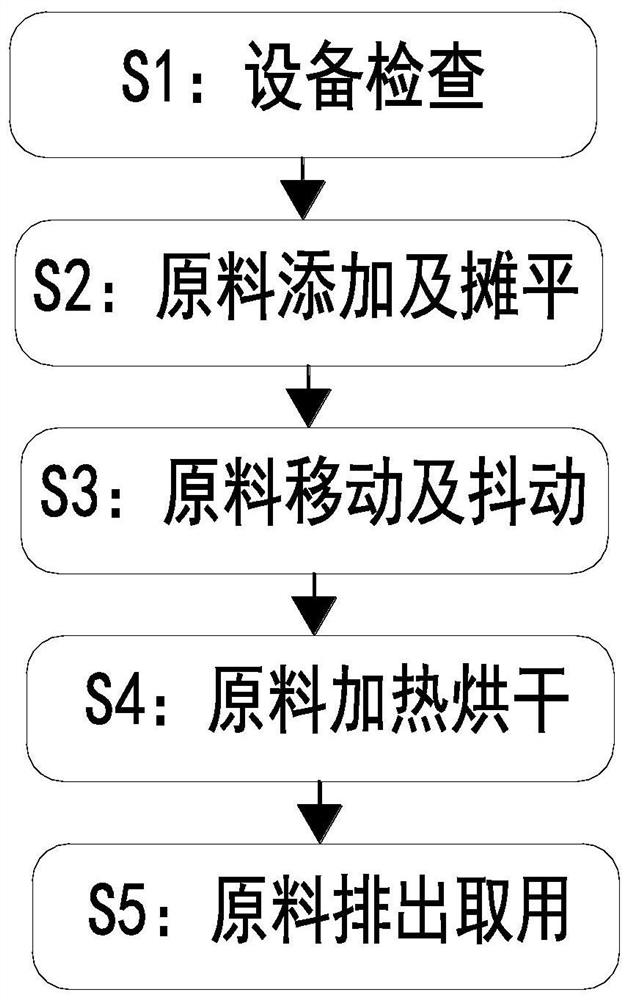

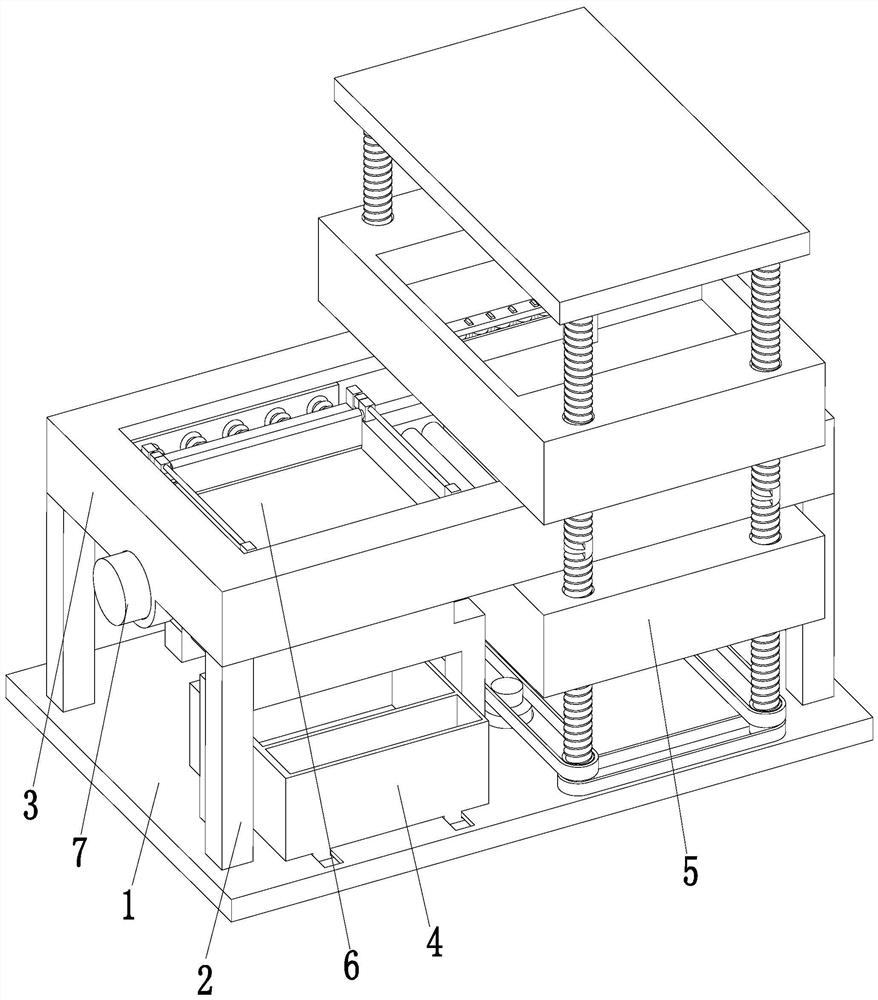

The invention relates to a manufacturing method of an artificial composite particle board. A bottom plate, a bearing device, a poking device and a vibration device are included, the bearing device isinstalled at the upper end of the bottom plate, the poking device is arranged on the left side of the bearing device, and the poking device is connected with the bottom plate in a sliding fit mode. According to the method, the problem that the situation that the wood chip drying efficiency is reduced due to the fact that the wood chips located inside cannot be completely dried due to the fact thattoo many wood chips are required to be dried appear easily due to the fact that the wood chips cannot be dried in a multi-station mode when existing equipment dries raw materials of the artificial composite particle board can be solved, meanwhile, the problem that drying treatment on the wood chips at the lower part is not facilitated due to the fact that wood chip particles located at the lowerpart cannot be overturned to the surface due to the fact that the wood chips cannot be poked when the wood chips are dried can be solved, and besides, the problems that the wood chip drying effect isreduced due to the fact that the wood chips are prone to scorching due to the excessively-high temperature due to the fact that hot air and cold air cannot be alternately used in the drying process and the like are solved.

Owner:临沂艾维新型装饰材料有限公司

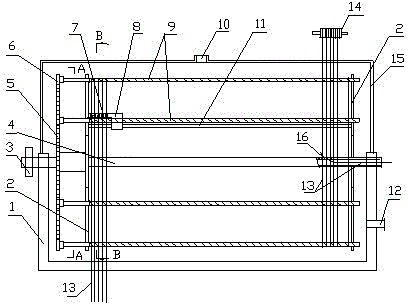

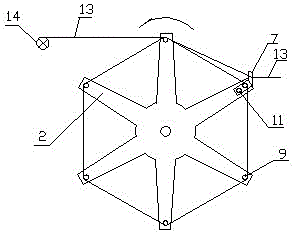

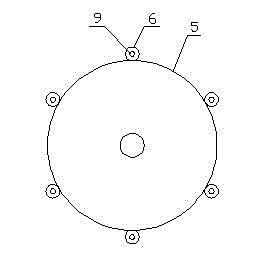

Lead wire rotary drying machine

InactiveCN103148697AReduce drying efficiencyReduce drying costsDrying solid materialsGear wheelSmall footprint

The invention discloses a lead wire rotary drying machine which comprises a rotating frame movably arranged on a box body; the rotating frame comprises a rotating shaft (4), a gear wheel (5), support plates (2), a nut sleeve (8), a guide rod (11) and screw rods (9); the screw rods are movably arranged between the two support plates at intervals in an annular manner; the support plates are arranged at the two ends of the rotating shaft; the gear wheel located on the left sides of the support plates are arranged at the left end of the rotating shaft; one end of each screw rod extends out of the supporting plate and is connected with a pinion wheel (6); the pinion wheel is meshed with the gear wheel; the nut sleeve is sleeved at one end of one of the screw rods; the lower end of the nut sleeve is supported on the guide rod; the two ends of the guide rod are arranged on the support plates; a magnetic clip capable of being penetrated by lead wires is fixedly arranged on the nut sleeve; and the screw rods can rotate with the gear wheel and can rotate simultaneously on themselves. The lead wire rotary drying machine provided by the invention has the advantages of simple and compact structure, small occupied area, convenience in manufacture and maintenance, high lead wire drying efficiency, low heat consumption, and low lead wire drying cost.

Owner:JIANGXI JIALIAN TECH

Processing method of piglet green grass feed

InactiveCN107183386AImprove the body's immunityPromote absorptionFood processingAnimal feeding stuffTO-18Microwave

The invention discloses a processing method of piglet green grass feed. The method is characterized by comprising the following steps of (1) major feed preparation: baijiu vinasse, bean pulp, corn starch and table salt are mixed to be prepared into major feed; (2) green grass water removing: water removing treatment is performed in a pressure cooker; (3) microwave drying: green grass is subjected to drying treatment at two stages; (4) green grass pulverization: the dry green grass is crushed and pulverized until the green grass can pass through a 30-mesh sieve net; (5) fermentation liquid culture: fermentation liquid is prepared and is cultured under constant-temperature condition; (6) green grass powder fermentation: under the constant-temperature condition, saccharification and fermentation treatment is performed; (7) drying and pulverization: drying is performed at low temperature until the water content is 14 percent to 18 percent; a crushing machine is used for pulverization treatment; (8) feed pelletizing: the major feed, the dry grass powder and the functional feed are mixed according to a mass ratio of 20:15:4 to be prepared into granulated feed.

Owner:ANHUI HESHENG WEIYE FEED CO LTD

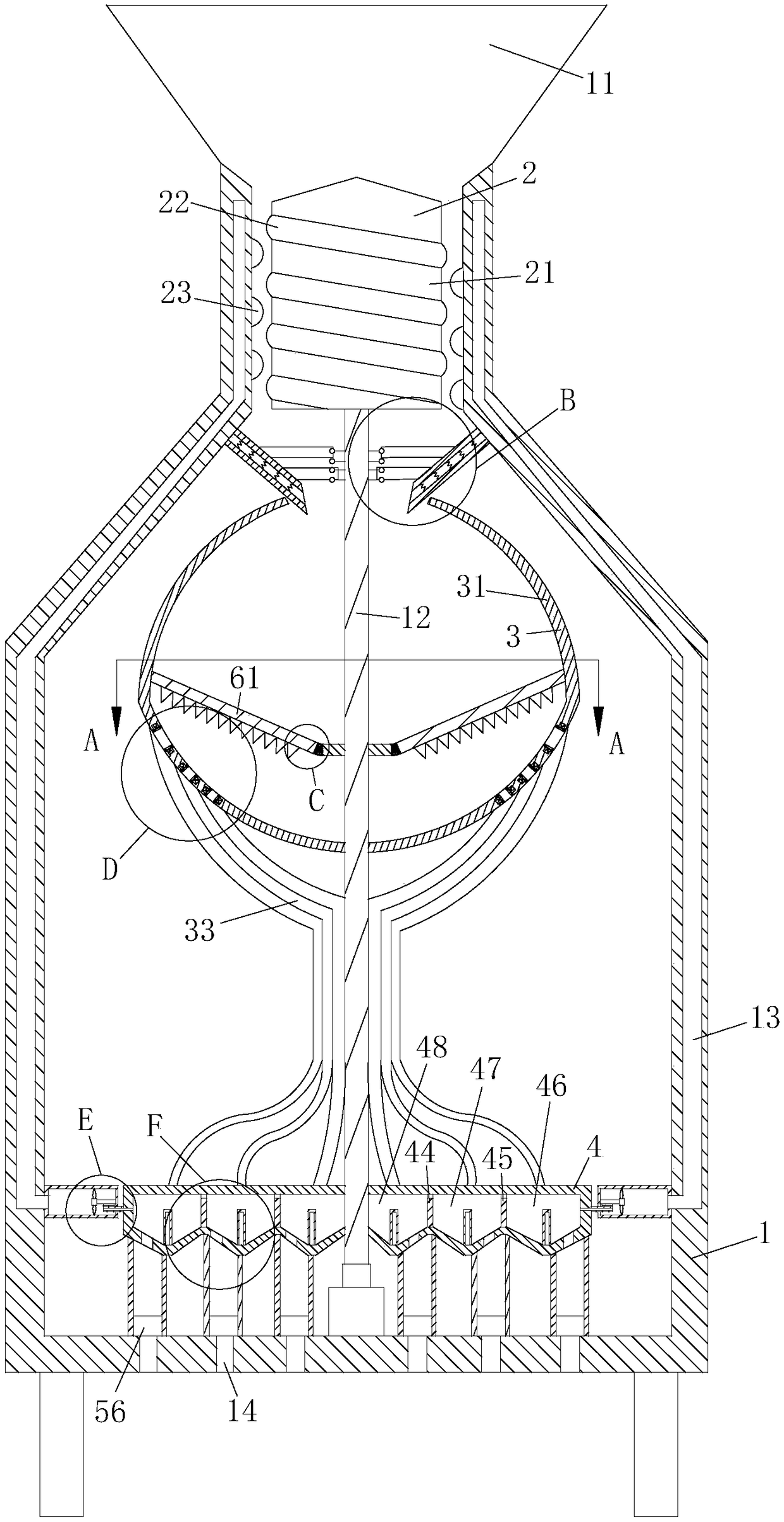

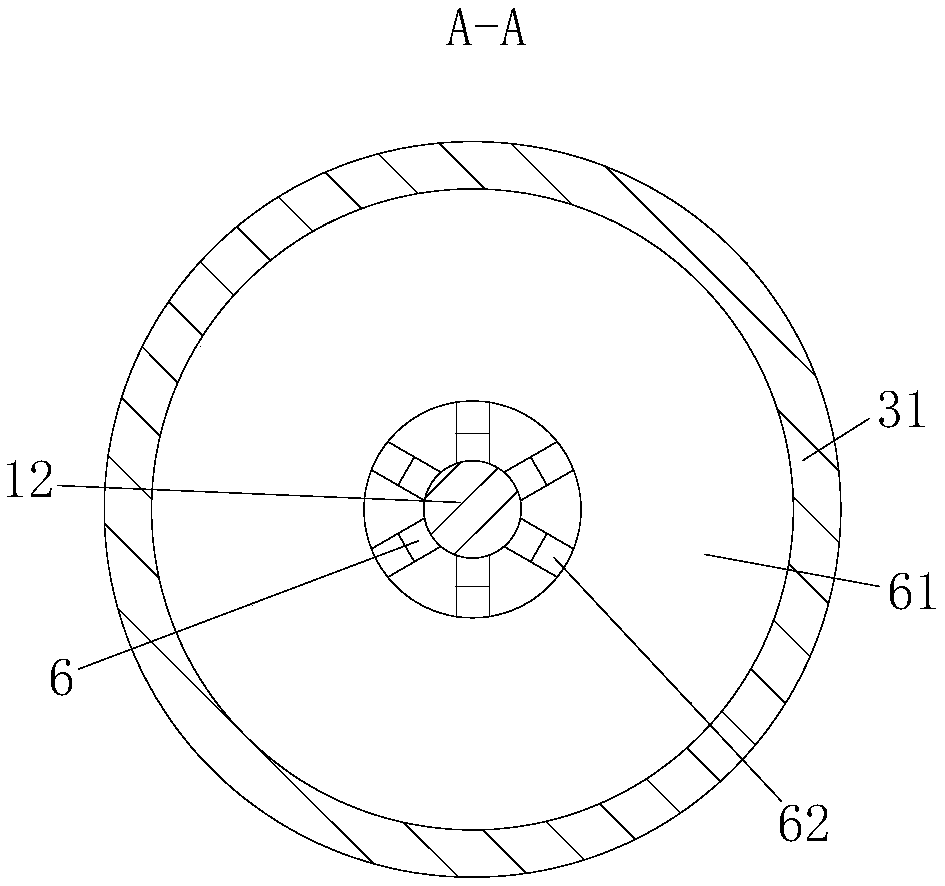

Areca nut baking device

InactiveCN103598664AUniform flowStable flowFood processingDrying gas arrangementsTemperature UnitEngineering

The invention discloses an areca nut baking device. The areca nut baking device is characterized in that the device comprises a baking chamber, a baking trolley is placed in the baking chamber, an areca nut placing partition net is arranged in the baking trolley, and an air inlet is formed in one lateral side of the baking trolley; the device further comprises a heat pump device providing hot air for the baking trolley, the heat pump device comprises an air source heat pump high-temperature unit placed outside the baking chamber and an indoor draught fan connected with the air source heat pump high-temperature unit, a hot air outlet is formed in the indoor draught fan, a partition board is arranged between the indoor draught fan and the baking trolley, an air supply port enabling the hot air discharged from the hot air outlet of the indoor draught fan to flow into the air inlet of the baking trolley is formed in the bottom of the partition board, and an air returning port is formed in the upper portion of the partition board. Due to the fact that the partition board is arranged between the indoor draught fan and the baking trolley, heat can be utilized more sufficiently, and more energy is saved.

Owner:GUANGZHOU DERON HEAT SOURCE FACILITIES

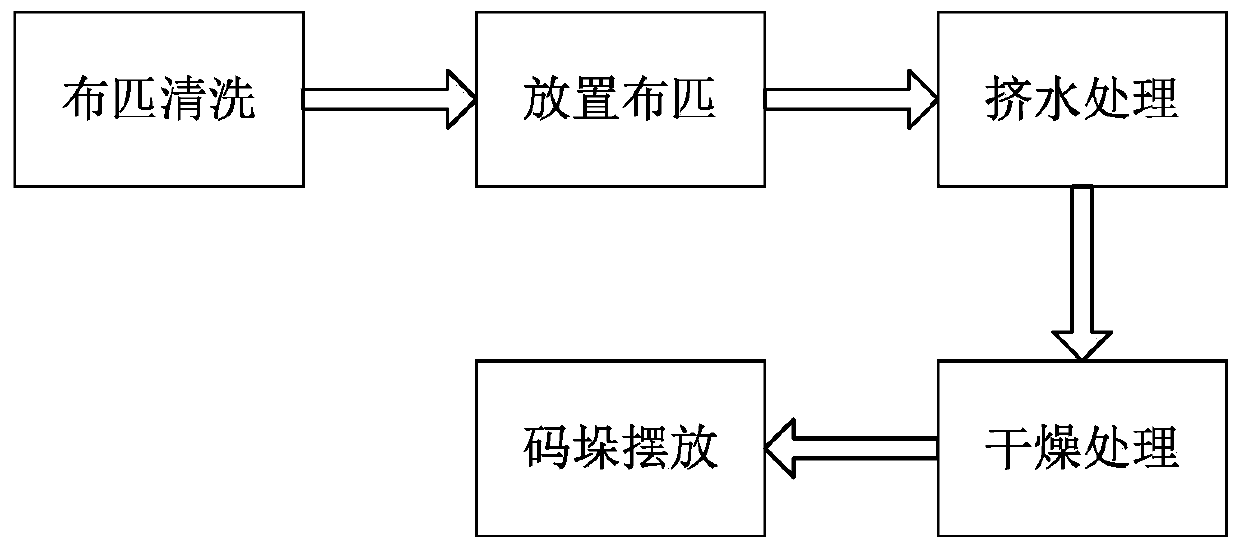

Textile cloth after-treatment process

InactiveCN111350042AReduce drying efficiencyReduced aestheticsDrying solid materials with heatDrying solid materials without heatEngineeringMechanical engineering

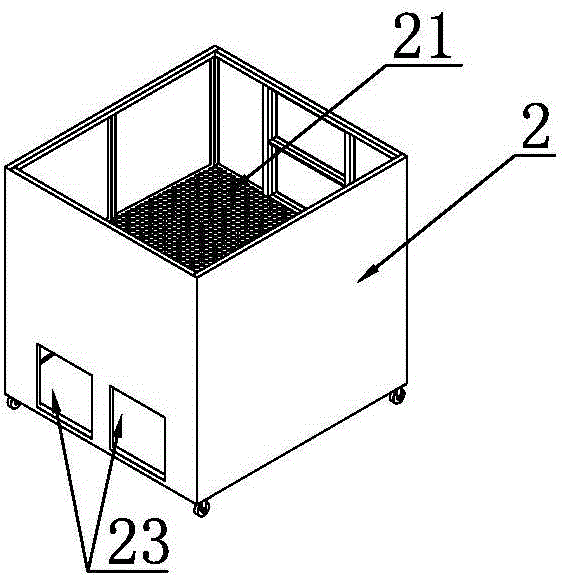

The invention relates to a textile cloth after-treatment process. The textile cloth after-treatment process comprises a bottom plate, a water squeezing device, a water collecting tank, a drying deviceand a traction device; the water squeezing device is installed at the upper end of the bottom plate; the water collecting groove is arranged below the water squeezing device; the water collecting groove is installed on the bottom plate; the drying device is arranged at the right side of the water collecting groove; the drying device is installed on the bottom plate; and the traction device is arranged at the right side of the drying device and the traction device is installed on the bottom plate. The textile cloth after-treatment process provided by the invention solves the problems that whenexisting equipment is used for drying the textile cloth, the cloth is directionally dried, hot air is easy to dissipate around, thus the efficiency of drying the cloth by the hot air is reduced, in addition, the drying time of the cloth cannot be increased in a limited space, thereby reducing the drying efficiency; and meanwhile, the cloth cannot be scraped while the cloth is dried, the cloth isprone to wrinkles after being dried, which reduces the attractiveness of the cloth after being dried and reduces the drying effect.

Owner:倪邦强

Double-helix type simple device for quickly drying leonurus

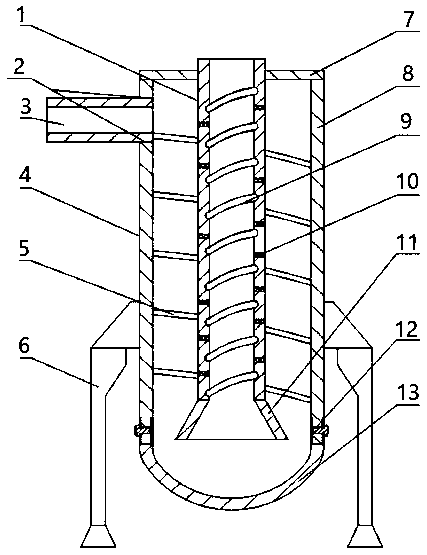

InactiveCN108302925AExtended stayImprove drying effectAntifouling/underwater paintsDrying gas arrangementsEngineeringHelix structure

The invention provides a double-helix type simple device for quickly drying leonurus, and belongs to the technical field of Chinese herbal medicine drying equipment. The device comprises an outer drying barrel and an inner drying barrel, wherein the inner drying barrel is arranged inside the outer drying barrel coaxially, the upper end of the outer drying barrel and the upper end of the inner drying barrel are connected through a top cover, the upper end face of the inner drying barrel is taller than the top cover, a barrel bottom is connected with the lower end of the outer drying barrel, a hot air pipe is connected with the upper part of the outer drying barrel, a support is connected with the part, on the lower part, of the outer wall of the outer drying barrel, a spiral guide plate isconnected with the inner wall of the outer drying barrel and the outer wall of the inner drying barrel, a spiral groove is formed in the inner wall of the inner drying barrel, and first heating elements are evenly distributed on the inner wall of the inner drying barrel. According to the double-helix type simple device for quickly drying the leonurus, the double-helix structure is adopted for airflow drying, the drying efficiency is high, and the leonurus is free of damage inside the drying elements. Because the surfaces of the drying elements are coated with anti-sticking paint, the leonurusor impurities are prevented from sticking to the drying elements, and the drying efficiency of the device is improved.

Owner:浦江县晶富农业科技有限公司

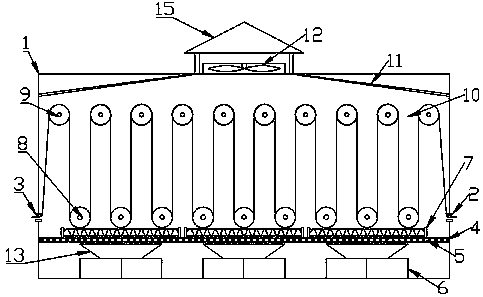

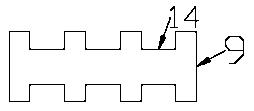

Efficient ultrahigh-molecular-weight polyethylene fiber drying device

InactiveCN110004505AAvoid damageAvoid accumulationArtificial filament washing/dryingFiberUltrahigh molecular weight polyethylene

The invention relates to the technical field of polyethylene fiber production equipment, in particular to an efficient ultrahigh-molecular-weight polyethylene fiber drying device which comprises a chamber. The lower portion of the left wall of the chamber is penetratingly provided with a fiber inlet, the lower portion of the right wall of the chamber is penetratingly provided with a fiber outlet,a partition plate with vent holes is arranged in the chamber, and circulating fans are arranged between the partition plate and the inner bottom of the chamber. Heating tubes are arranged on the top face of the partition plate, lower guide rollers are arranged above the partition plate, upper guide rollers are arranged between the lower guide rollers and the inner top face of the chamber, a gap isreserved between every two adjacent upper guide rollers, and the lower guide rollers are positioned below the gaps. Flow guide plates are arranged on the top face of the chamber, and an exhaust fan is arranged on the top face of the chamber. By the partition plate, broken polyethylene fibers are prevented from falling into the circulating fans; heat utilization efficiency is improved by the circulating fans; by corresponding arrangement of the heating tubes and the circulating fans, accumulation of heat at the partition plate can be prevented; by the flow guide plates, damp hot air can be guided to the exhaust fan, and condensate water can be guided to flow down along the inner wall of the chamber by the tangential flow guide plates.

Owner:JIULI ROPE

Constant temperature tea drying device

ActiveCN106382806ASolve pollutionKeep the fragrancePre-extraction tea treatmentTea dryingAgricultural engineeringMechanical equipment

The invention provides a constant temperature tea drying device, and belongs to the field of mechanical equipment for tea processing. The constant temperature tea drying device comprises a fuel storage bin, a first fan, a boiler, a drying box, a feeding device and a tea storage bin, wherein the fuel storage bin and the first fan are connected with the boiler; the boiler is connected with the drying box; the tea storage bin is sequentially connected with the feeding device and the drying box; a heat exchange pipe is arranged on the inner wall of the boiler; the heat exchange pipe is provided with a heat exchange pipe open end and a heat exchange pipe outlet end; a tea output is formed in the bottom of the drying box; a hot air inlet end is connected with the heat exchange pipe outlet end; a hot air outlet end is connected with a first hot air extension branch pipe through a second fan; the first hot air extension branch pipe is further connected with the heat exchange pipe open end; a tea cooling device is arranged below the tea output; and the tea cooling device is connected with the tea output through a cooling pipeline. According to the constant temperature tea drying device, tea drying and cooling after drying can be achieved, constant temperature drying is achieved during the drying process, full-sealing cooling is achieved during the cooling process, and the drying efficiency and quality of tea are improved.

Owner:湖北清江沁园茶业有限公司

Dedicated blade materials for line cutting of semiconductor materials

InactiveCN100360400CStrong resistance to crushingSharp particle shapeGrain treatmentsWet separationCycloneMicrowave

The invention discloses a specific cutting knife-material of semiconductor material wire (6H-SiC), which comprises the following steps: 1. grinding through cyclone; grading flow; 2. grading water pretreatment; grading finely for overflow; 3. wetting to blend; dehydrating eccentrically; separating; 5. drying through microwave continuously; 6. blending dryly. The invention is compatible with flexibility of black carbofrax, which improves anti-grinding property obviously.

Owner:河南晟道科技有限公司

Tea leaf drying and primary screening device

InactiveCN109105541AEvenly heatedIncrease heatSievingPre-extraction tea treatmentAgricultural engineeringPrimary screening

The invention discloses a tea leaf drying and primary screening device which comprises an engine base; the engine base is fixedly provided with a cylindrical heat supply cabin; the heat supply cabin is internally provided with a cylinder-like drying mechanism; the top of the heat supply cabin is provided with a cabin door mechanism; and the bottom of the heat supply cabin is also provided with anunloading and screening mechanism. By adopting the tea leaf drying and primary screening device, through matching arrangement of the heat supply cabin and the drying mechanism, warm air in the deviceforms circulation, so that the tea leaf drying quality is improved; with a tea leaf placement cabin, the amount of tea leaves at the middle part in the cabin is minimal while the contact area of tea leaves and the warm air is increased, so that the condition that the temperature of the warm air at the middle part in the device is relatively low is satisfied, and the drying effect is improved; andthe structure of the tea leaf placement cabin enables loading and unloading to be convenient and rapid, and the unloading and screening mechanism performs primary screening on dried tea leaves, so that the tea leaf processing efficiency is improved.

Owner:ANHUI XINXUTANG TEA CO LTD

Disinfection and drying equipment for medical apparatuses and instruments

InactiveCN107906903AThorough disinfection and dryingDecrease productivityDrying gas arrangementsDrying chambers/containersEngineeringDrying time

The invention discloses disinfection and drying equipment for medical apparatuses and instruments and relates to the technical field of medical apparatuses and instruments. The disinfection and dryingequipment comprises a working box. A rotating motor box is fixedly connected to the middle of the bottom of the inner wall of the working box. A rotating motor is fixedly connected to one side of thebottom of the inner wall of the rotating motor box. A speed reduction connector is fixedly connected to an output shaft of the rotating motor through a flat key. A first belt pulley is rotatably connected to the speed reduction connector through an output shaft. A second belt pulley is rotatably connected to the first belt pulley through a belt. A working platform is fixedly connected to the topend of a rotating shaft. Drying machine boxes are fixedly connected to the positions, at the two sides of the rotating motor box, of the bottom of the inner wall of the working box. By means of the disinfection and drying equipment for the medical apparatuses and instruments, the purposes that the medical apparatuses and instruments are disinfected and dried are achieved; and the effects that thedisinfected medical apparatuses and instruments are dried more comprehensively, drying time can be shortened, drying efficiency can be improved, comprehensive disinfection of the medical apparatuses and instruments can be guaranteed, work efficiency of the disinfection and drying equipment can be guaranteed, and the labor amount of workers is reduced are achieved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com