Efficient ultrahigh-molecular-weight polyethylene fiber drying device

An ultra-high molecular weight, drying device technology, applied in the direction of rayon cleaning/drying, etc., can solve the problems of uneven heating of materials, affecting the drying rate of materials, etc., and achieve the effect of improving heat utilization efficiency and reducing drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

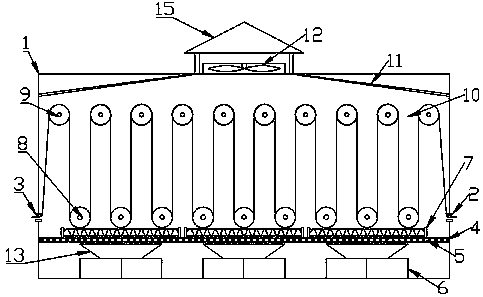

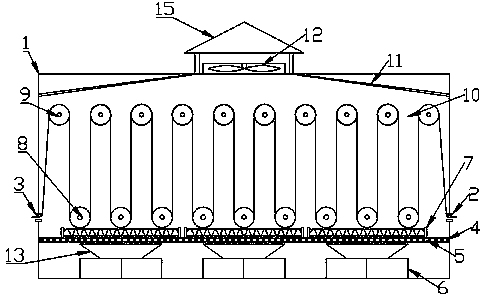

[0023] Example 1: When in use, the polyethylene extraction wire enters the box body 1 through the wire inlet 2, bypasses between the lower guide roller 8 and the upper guide roller 9 and passes through the wire outlet 3, the heating pipe 7 and the circulating fan 6 Start to work and burn to generate hot air, which flows inside the box 1 under the action of the circulating fan 6, and the hot air carrying water vapor flows to the inner top surface of the box 1. When the water vapor gathers into water droplets, the deflector 11 guides the water droplets to flow along the inner wall of the box 1 , to avoid that when the top surface of the box body 1 is flat, water droplets accumulate and directly drip onto the polyethylene wire, which will affect the drying effect.

Embodiment 2

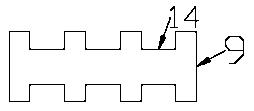

[0024] Embodiment 2: The upper guide roller 9 and the lower guide roller 8 are provided with card slots 14 at intervals, according to the polyethylene extraction wires are placed in the card slots 14 at intervals, and the slots 14 are placed with polyethylene extraction wires at intervals to prevent the upper guide roller 9 from And the lower guide roller 8 is segregated to one side during the rotation of the polyethylene extraction wire, thereby affecting the drying efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com