Clothing drying control method for clothing treatment device and clothing treatment device

The technology of a clothes processing device and a control method, which is applied to the control device of a washing machine, a washing device, a household clothes dryer, etc., can solve the problem of reducing the effect of top-tub laundry, so as to improve the drying efficiency, reduce the waiting time, and reduce the overall The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

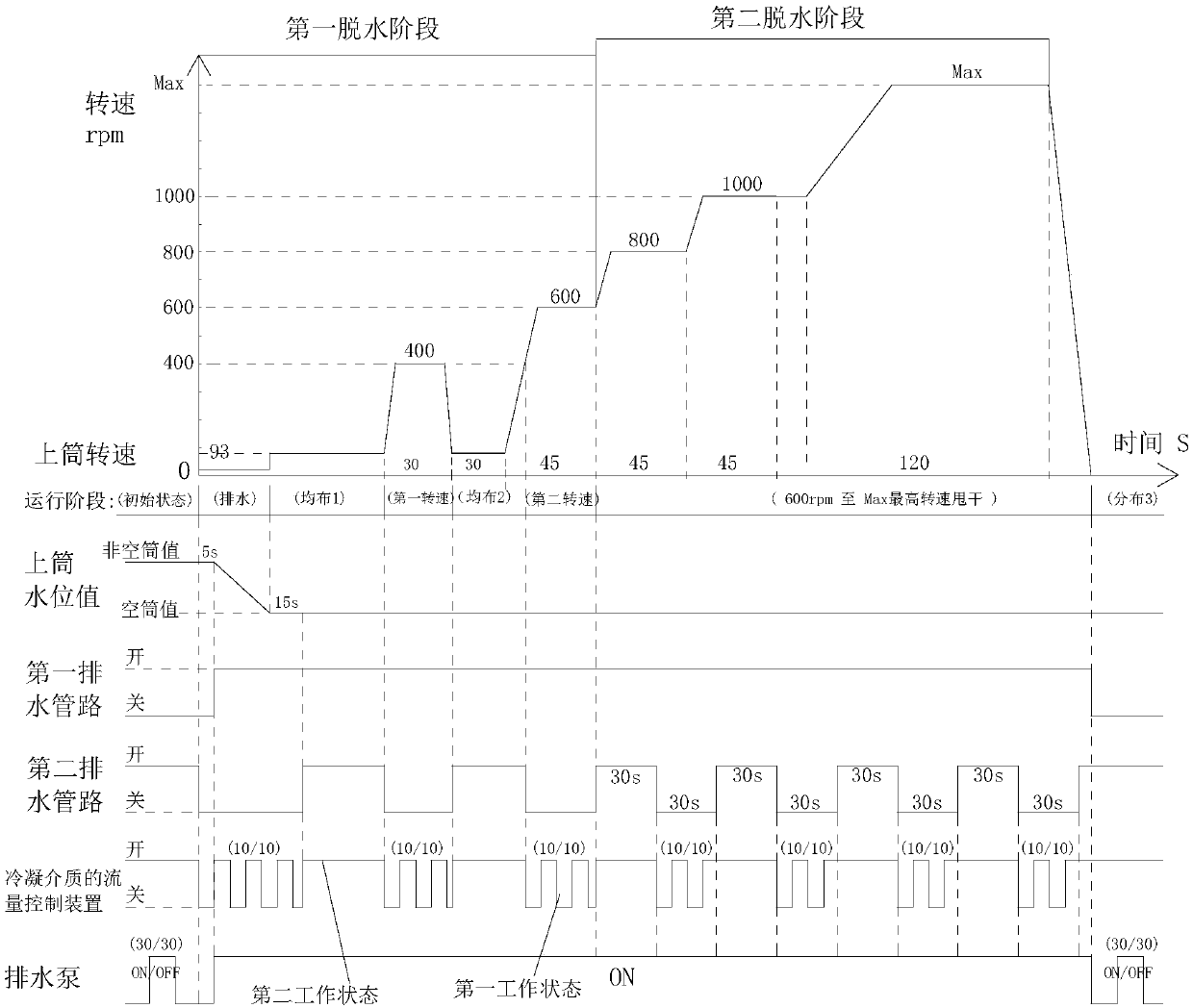

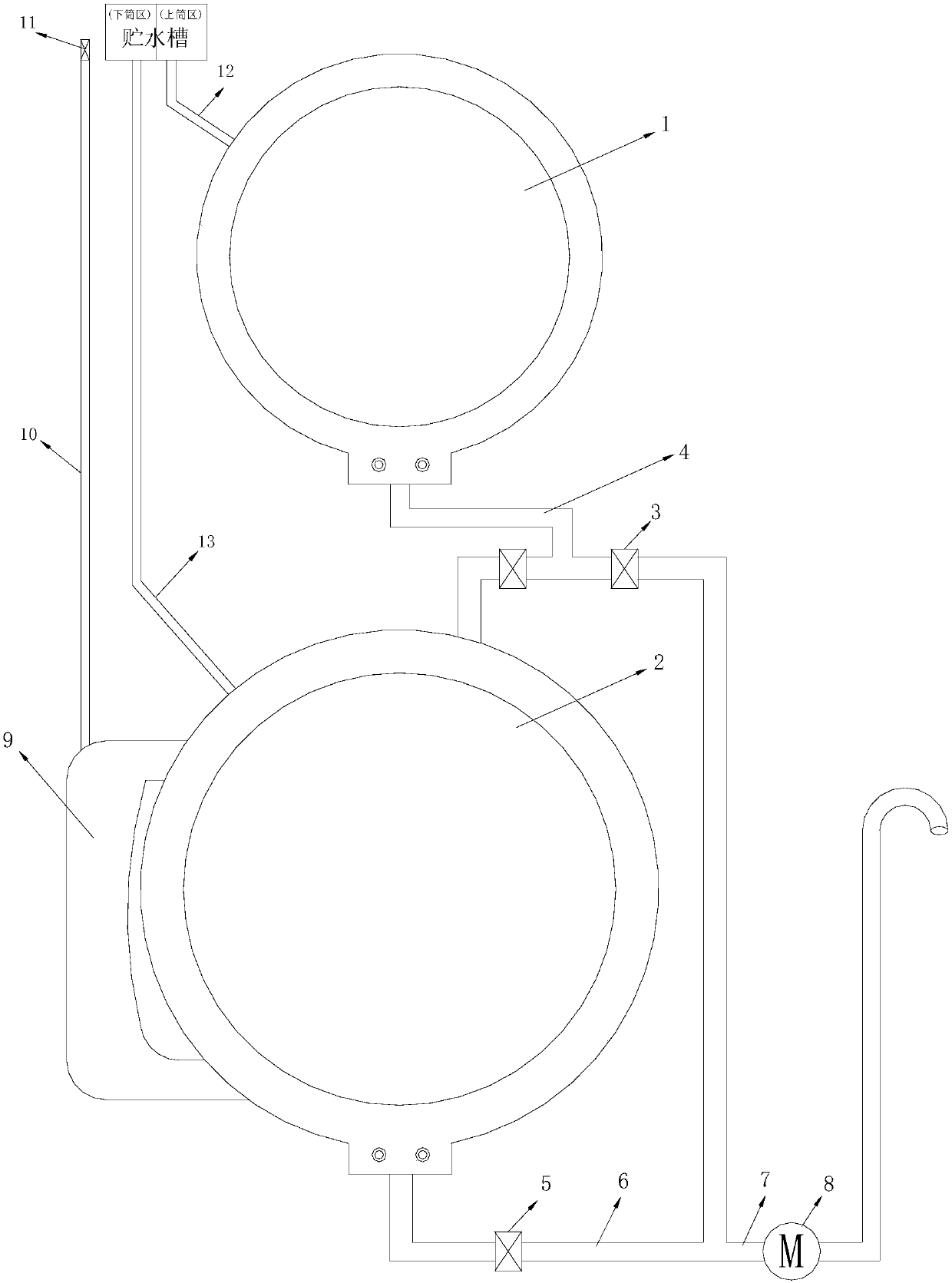

[0045] Such as Figure 1 to Figure 2 As shown, this embodiment discloses a clothes drying control method of a clothes treating device. The laundry processing device in this embodiment is a multi-tube laundry processing device, in particular, at least one of the laundry processing tubes is an integrated washer-dryer. Such as figure 2 As shown, at least the laundry treatment device includes a first treatment cylinder 1 and a second treatment cylinder 2 for treating clothes, the first treatment cylinder 1 has a first drainage pipeline 4, and the second treatment cylinder 2 has a second drainage pipeline 6 , the first drainage pipeline 4 and the second drainage pipeline 6 are connected to the same main drainage pipeline 7; and the washing water is discharged from the body through the main drainage pipeline 7. The second processing cylinder 2 in this embodiment is a condensation type washer-dryer with the function of drying clothes. The rotation speed of the processing cartridg...

Embodiment 2

[0096] This embodiment discloses a clothes treatment device applying the clothes drying control method of the clothes treatment device described in the above-mentioned embodiment 1. Such as figure 2 As shown, the clothes treatment device includes a housing, in which at least a first treatment cylinder 1 and a second treatment cylinder 2 for treating clothes are arranged, and the second treatment cylinder 2 is a condensing washing and drying machine.

[0097] The first drain line 4 and the second drain line 6 are respectively controlled by the independent first drain line drain valve 3 and the second drain line drain valve 5 to switch on / off states of the respective drain lines. Moreover, the first drainage pipeline 4 and the second drainage pipeline 6 are connected to the same main drainage pipeline 7, and the washing water is discharged from the machine body through the main drainage pipeline 7. The drainage height of the first drainage pipeline 4 in this embodiment is high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com