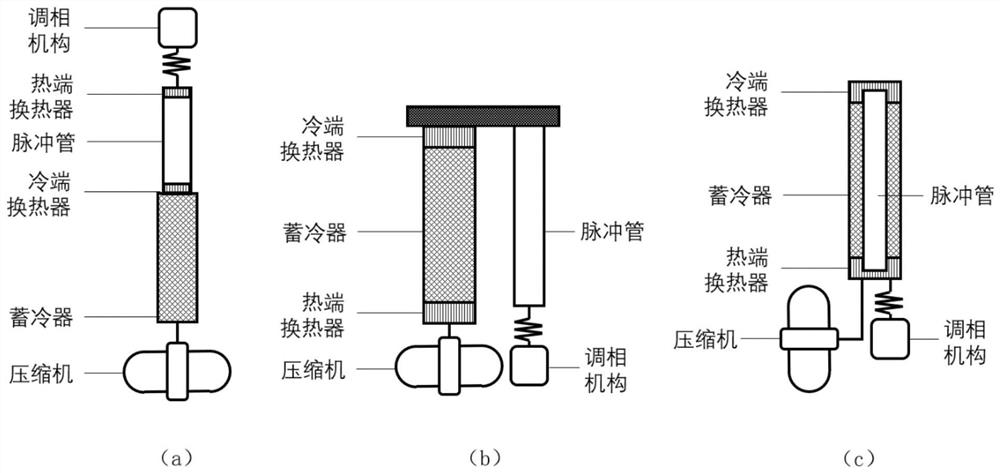

Multi-stage U-shaped gas coupling pulse tube refrigerator connecting tube type heat exchanger and implementation method

A pulse tube refrigerator and cold-end heat exchanger technology, which is applied in refrigerators, heat exchanger shells, refrigeration components, etc., can solve problems such as pressure loss, reduce pressure loss, reduce thermal resistance loss, and suppress The effect of turbulent disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

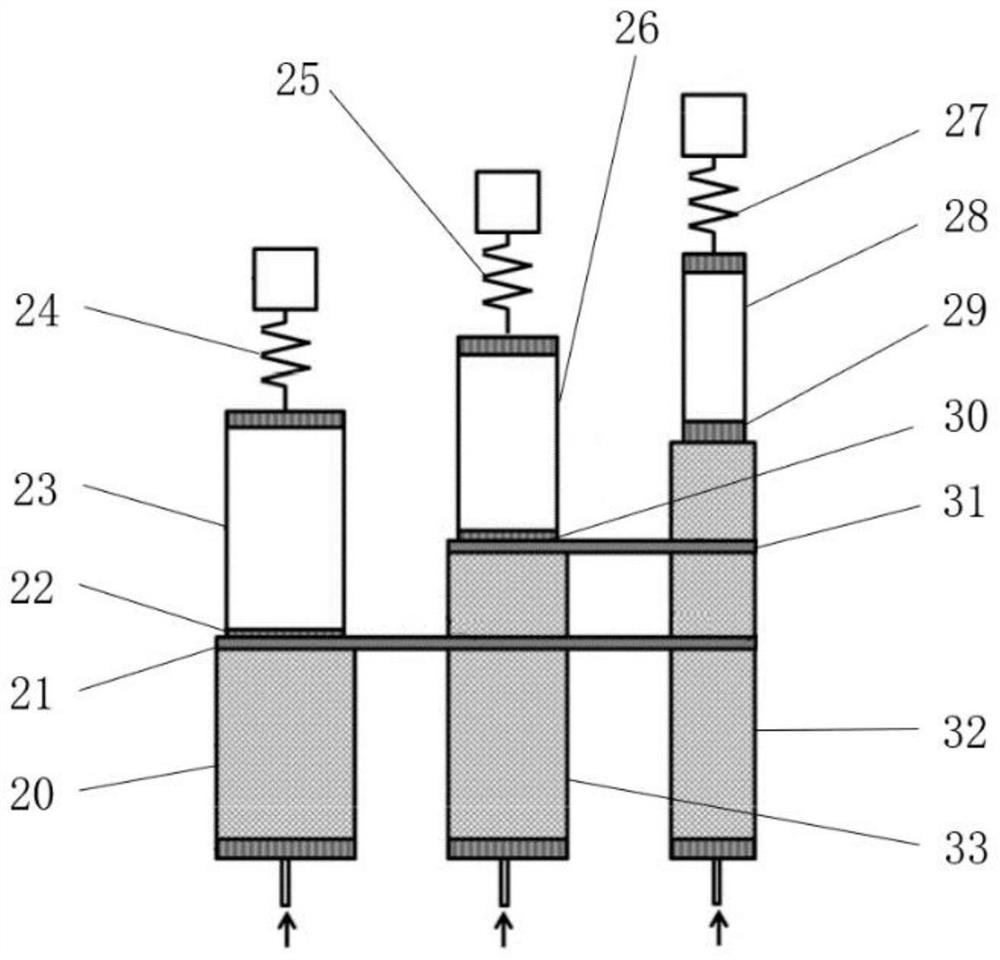

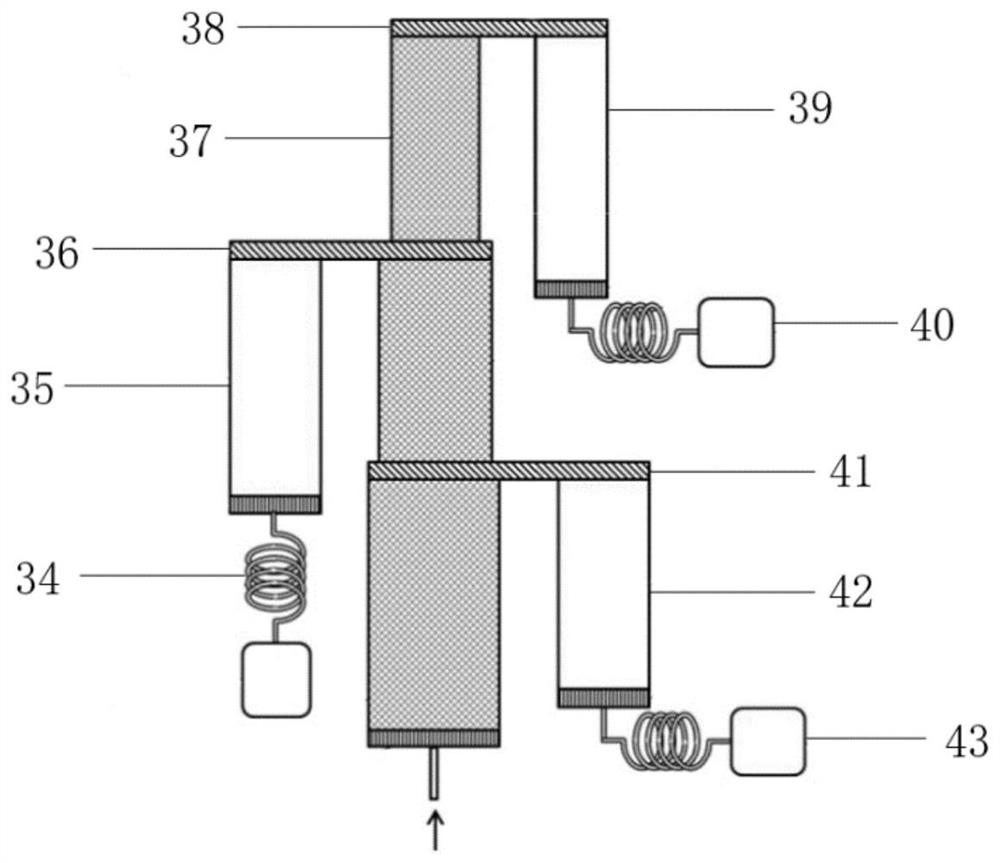

[0030] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

[0031] Figure 4 It is a partial sectional view of the tube-to-tube cold end heat exchanger of the invented U-shaped air-coupled pulse tube refrigerator. Invented U-shaped gas-coupled pulse tube refrigerator with tube-type cold-end heat exchanger shell 1, connecting tube 6, tapered slit body 19, through hole 1 18, laminar flow element 15, tapered slit body 2 11. Composed of through hole 2 14, it is characterized in that the heat exchanger shell 1 is used as the air coupling interface between the main heat exchange surface of the cold end heat exchanger and the front and rear cold fingers, and the slits are cut inside it and the external connection is connected. The tube 6 realizes the connection between the first-stage regenerator 17, the second-stage regenerator 3 and the first-stage vessel 13, and protects the internal taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com