Horizontal type anaerobic reactor

An anaerobic reactor and reactor technology, applied in the direction of gas production bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve secondary pollution, high energy consumption, Low biogas yield and other problems, to avoid mixed flow and reduce size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

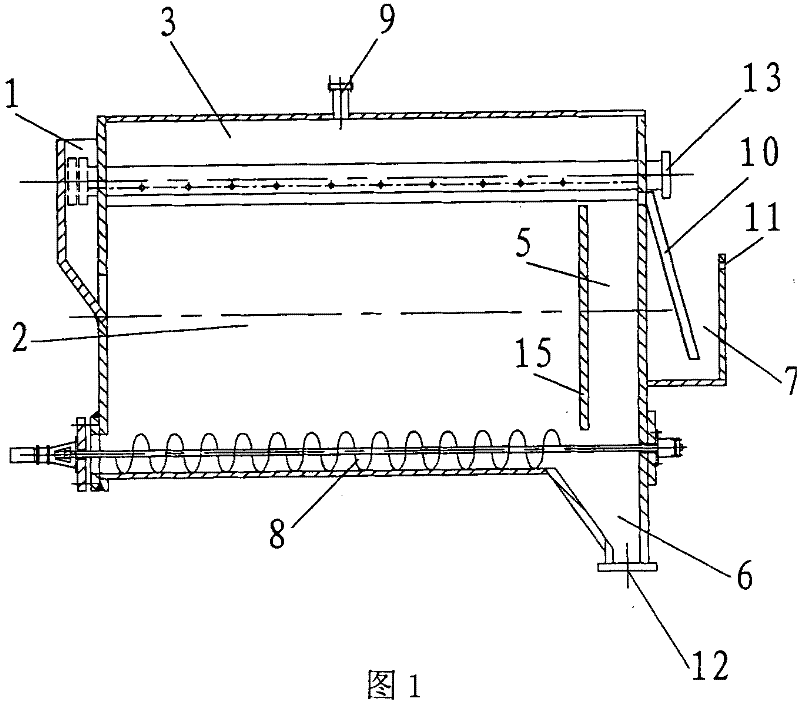

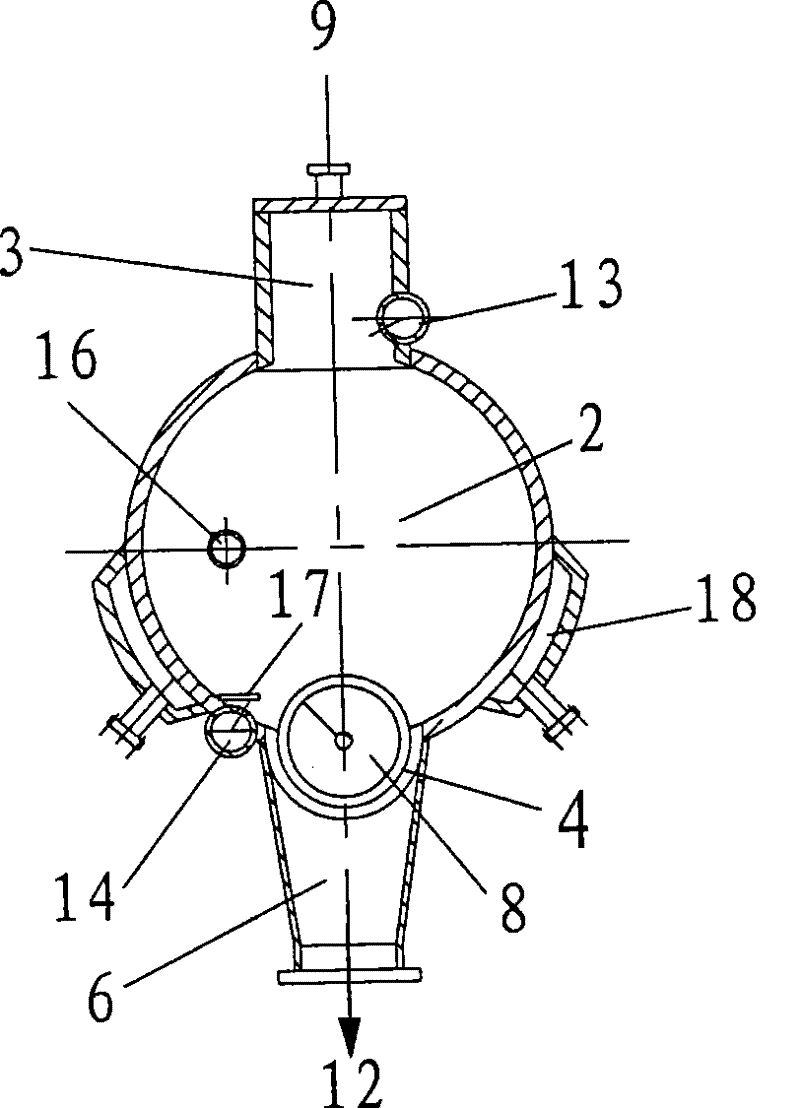

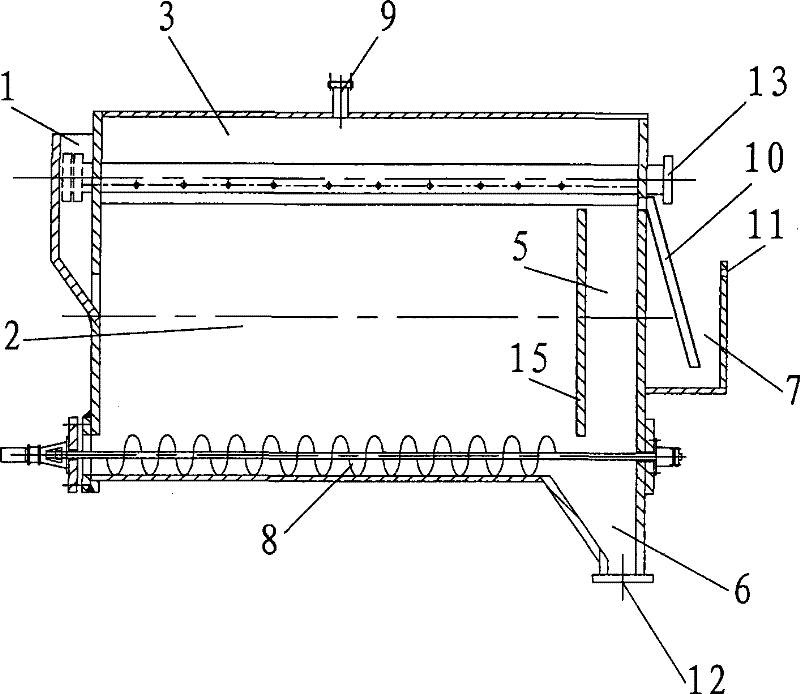

[0018] A horizontal anaerobic reactor, which is composed of a feed port 1, a reactor body 2, a gas collection chamber 3, a sediment area 4, a slag collecting bucket 6 and an overflow tank 7, and the reactor body 2 is a cylindrical structure, The top of the reactor main body 2 is provided with a cuboid-shaped gas collection chamber 3, the top of the gas collection chamber 3 is provided with a biogas outlet 9, the bottom of the reactor main body 2 is provided with a semi-cylindrical sediment area 4; one end of the reactor main body 2 is provided with an inlet The material port 1 is provided with an overflow tank 7 at the other end, and a discharge port 11 is provided on the overflow tank 7; The above-mentioned components can be connected by welding.

[0019] The gas collection chamber 3 above the reactor main body 2 is in the shape of a cuboid, which is convenient for gas-liquid separation; the middle part of the reactor main body 2 is cylindrical, which facilitates the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com