Drying equipment for improving efficiency of drying shoes

A technology of drying equipment and high efficiency, which is applied in cleaning equipment, cleaning of boots and shoes, and wardrobes, etc. It can solve the problems of shoe cabinets without drying function, difficult to discharge moisture, and poor comfort, so as to reduce drying time, Avoid waste and increase the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

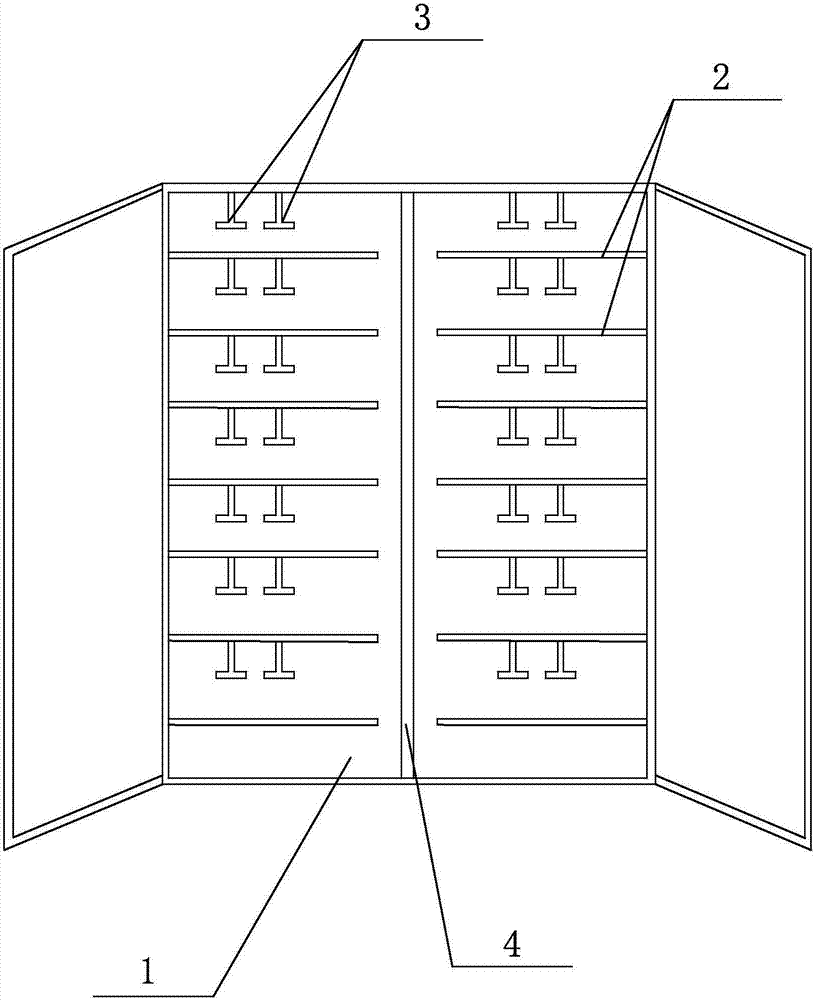

[0024] Such as figure 1 As shown, the drying equipment for improving the drying efficiency of shoes in the present invention includes a shoe cabinet body 1, the shoe cabinet body 1 is divided into a winter shoe area and a summer shoe area, and the winter shoe area and the summer shoe area are separated from the top A plurality of shoe boards 2 are provided in sequence from the bottom, and two drying sheets 3 are arranged above the shoe boards 2, and the drying sheets 3 are connected with the upper shoe boards 2 through telescopic rods; the winter shoes A heating rod 4 is arranged between the area and the summer shoes area, and an inductor is arranged on the shoe board 2, and the sensor is connected with a controller, and the controller controls the telescopic rod to perform telescopic movement; the shoe board 2 It is made of transparent material, and the shoe board 2 is provided with an ultraviolet lamp tube, and the ultraviolet lamp tube and the heating rod 4 are all connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com