Drying device for film

A technology of drying equipment and drying cavity, which is applied in drying, drying machine, lighting and heating equipment and other directions, can solve the problems of inability to uniformly dry the film and the inability of the oven to adjust the temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

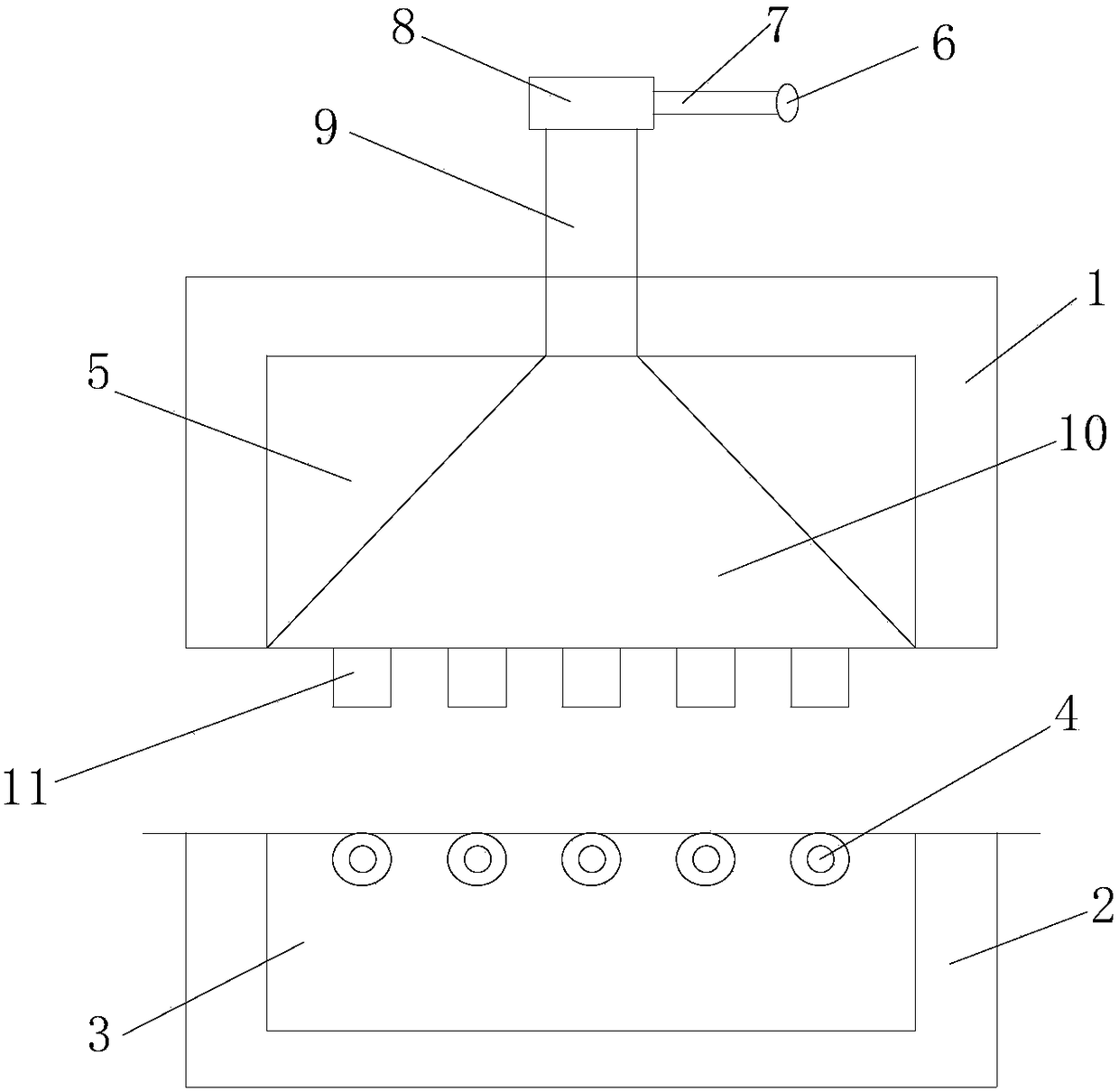

[0042] see figure 1 , which is a structural schematic diagram of a drying equipment for film in this application, including: an upper casing 1, a lower casing 2, a conveying frame 3, a conveying device 4, a drying frame 5, a fan 6, a first inlet Air pipe 7, heating assembly 8, second air intake pipe 9, drying chamber 10 and tuyere 11, the upper casing 1 is located directly above the lower casing 2, and the upper casing 1 is used to prevent dust from entering Inside the drying frame 5 , the lower casing 2 is used to prevent dust from entering into the conveying frame 3 .

[0043] The conveying frame 3 is arranged in the lower casing 2, the conveying frame 3 and the lower casing 2 are both rectangular frames, and the height of the conveying frame 3 is smaller than that of the lower casing 2 The height of the conveying frame body 3 is smaller than the width of the lower casing 2, and the upper plane of the conveying frame body 3 and the upper plane of the lower casing 2 are both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com