Lead wire rotary drying machine

A dryer and lead wire technology, which is applied in drying, drying solid materials, lighting and heating equipment, etc., can solve the problems of long drying time for lead wires, high labor intensity, large floor space, etc., and achieve the cost of lead wire drying Low cost, easy manufacturing and maintenance, and low heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

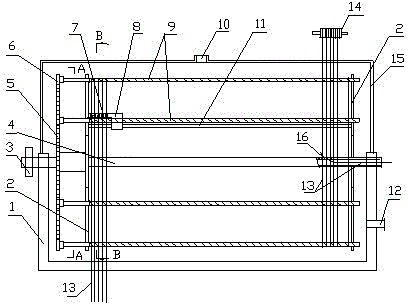

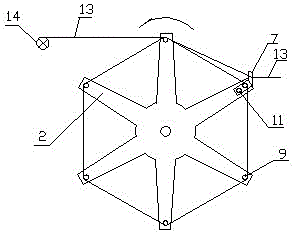

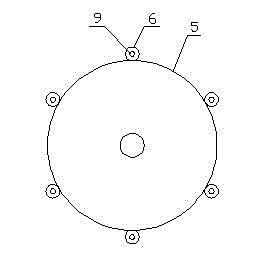

[0011] exist figure 1 , figure 2 and image 3 Among them, the lead wire rotary dryer includes a turret movably arranged on the box body, the box body is composed of an upper box body 15 and a lower box body 1, and the box body is provided with a hot air hole 12 and an air outlet hole 10 , the hot air hole is connected to the hot air source through the pipe, and the air outlet is connected to the exhaust device through the pipe. The temperature of the hot air can be controlled at 50--60°C. The turret includes a rotating shaft 4, a gear plate 5, a support plate 2, a nut sleeve 8, Guide rod 11 and screw mandrel 9, described turret is preferably positive hexagonal, and support plate is made up of six rib plates and central circular plate, and six screw mandrels are arranged on six corners of two support plates in the form of annular intervals. The turret can also be set as a regular square (four screw rods) or pentagon (five screw rods) or other regular polygons. The number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com