Heat-pump module and clothes dryer

A technology of a heat pump module and a clothes dryer, which is applied in the field of clothes dryers, can solve problems such as large differences in clothes dryer structure, reduced drying efficiency, and insufficient lint filtration, and achieves shortened drying time, simplified assembly process, Effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

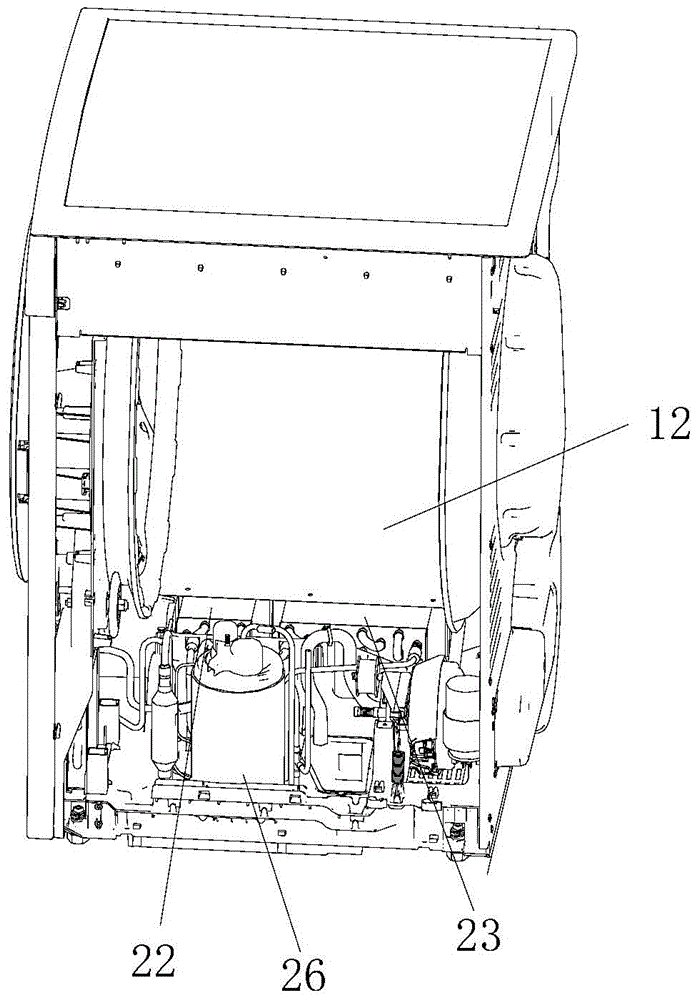

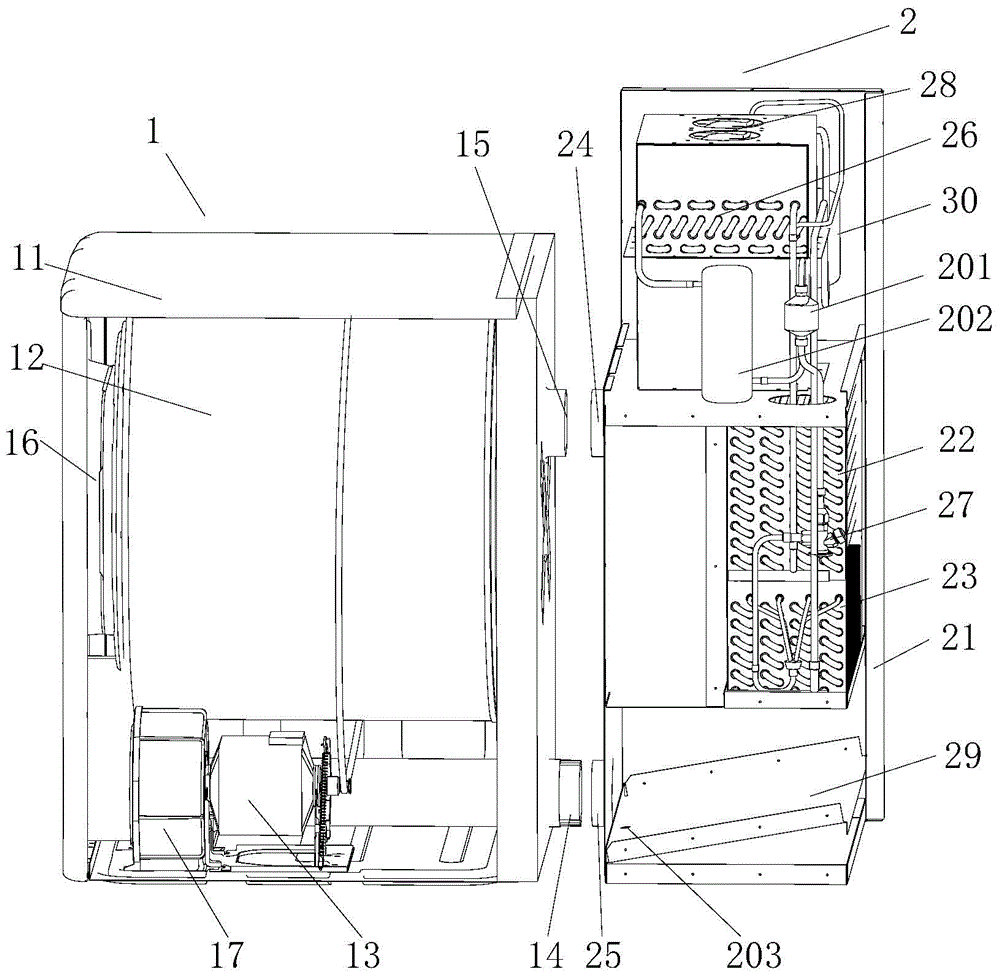

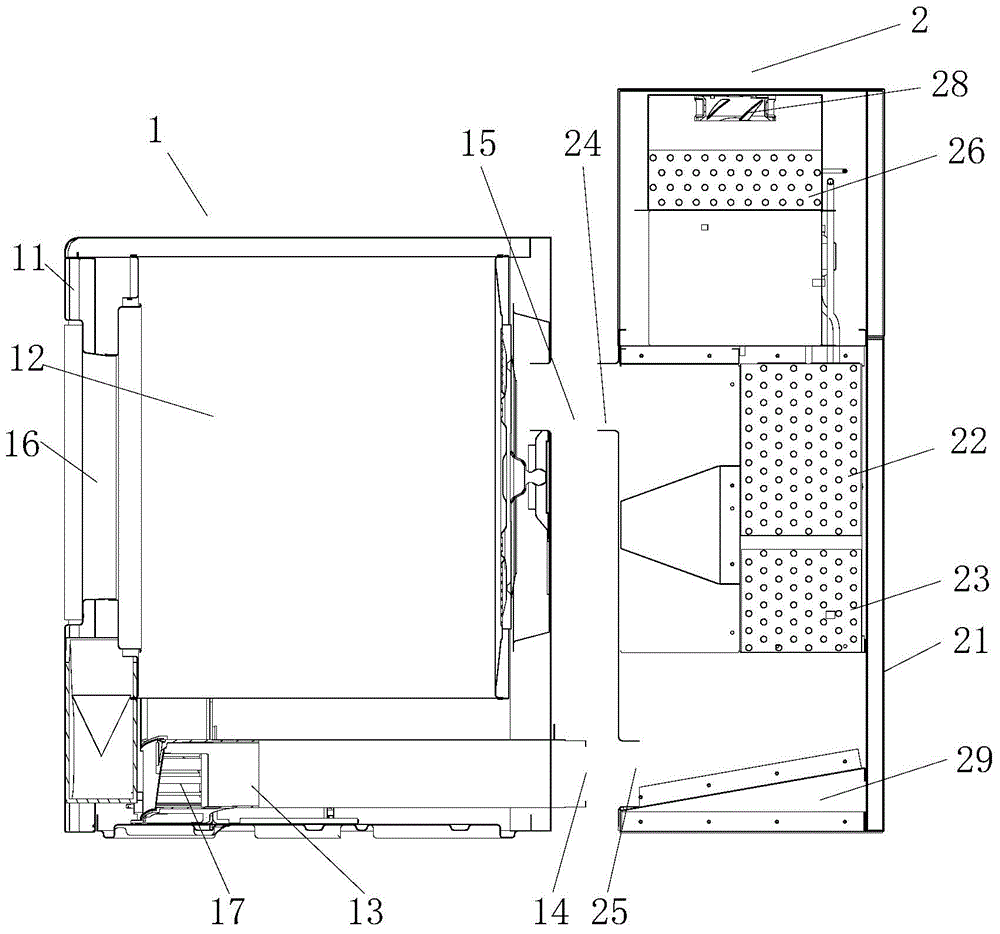

[0031] Such as figure 2 , image 3 As shown, a modular heat pump clothes dryer according to the present invention includes a clothes dryer body 1 and a heat pump module 2, and the clothes dryer body 1 includes a first shell 11 and a clothes dryer drum 12 inside the first shell 11 1. The driving device 13 of the drying drum 12, the first housing 12 is provided with a first air outlet 14 and a first air inlet 15 leading to the outside of the first housing 11; the heat pump module 2 includes a second housing 21, a second The evaporator 23, the condenser 22, the compressor 30 and the throttling device 27 in the casing 21, the second casing 21 is provided with a second air outlet 24 and a second air inlet 25 leading to the outside of the second casing 21; The clothes dryer body 1 and the heat pump module 2 are two separate and independent modules, which can be connected through the first air outlet 14 and the second air inlet 15, and the first air inlet 15 and the second air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com