Fruit and vegetable drying system and drying method

A drying system, fruit and vegetable technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problem of incomplete drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

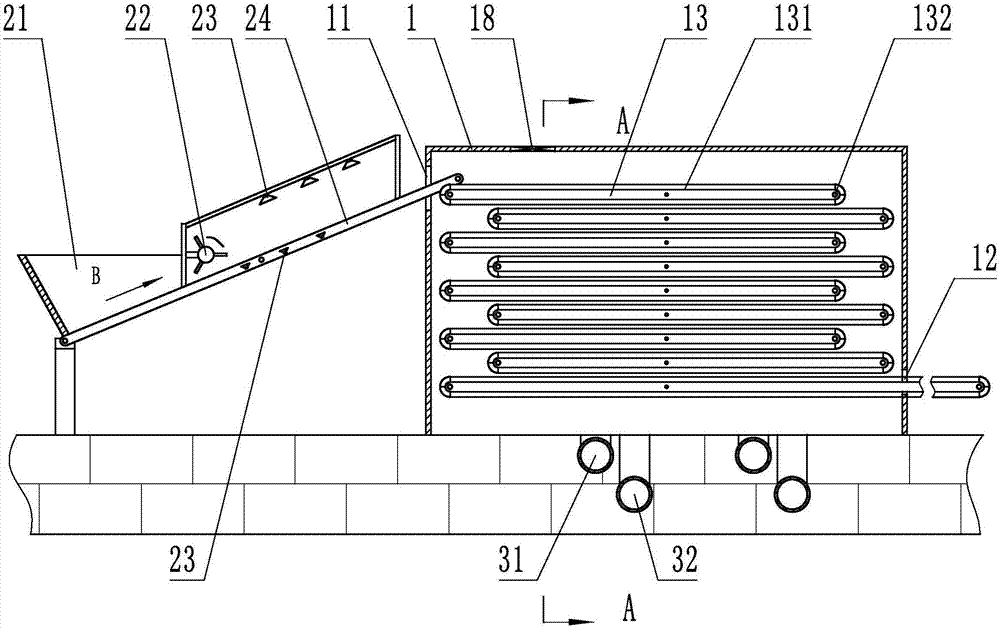

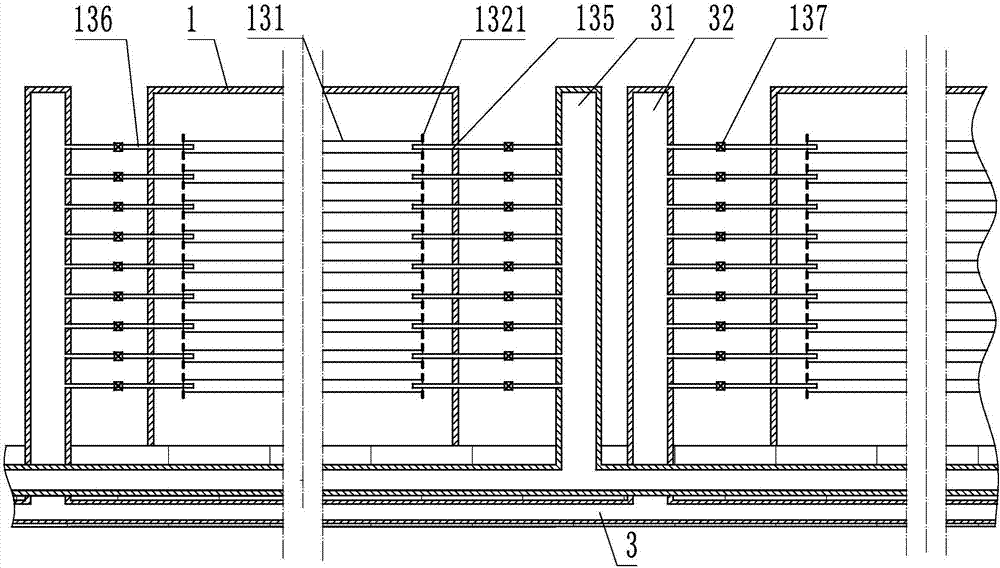

[0100] Embodiment 1: refer to figure 1 and 2 , is a structural schematic diagram of Embodiment 1 of the present invention, including at least one set of dryers, characterized in that: the dryer includes a drying bin 1, and the drying bin 1 is provided with a material inlet 11 and a material outlet port 12, the front end of the feed port 11 is provided with a feeding mechanism for feeding, the feeding mechanism includes a feeding conveying mesh belt 24 and a paving mechanism 22, and a conveying mechanism 13 is provided in the drying bin 1 The conveying mechanism 13 includes a transmission mesh belt 131 and a transmission mechanism 132, a chamber is formed between the transmission mesh belt 131 and the transmission mechanism 132, and a plurality of air supply channels 31 are arranged on one side of the drying bin 1. The air supply channel 31 is formed with the transmission mesh belt 131 and the transmission mechanism 132. An air inlet pipe 135 is arranged between the chambers. ...

Embodiment 2

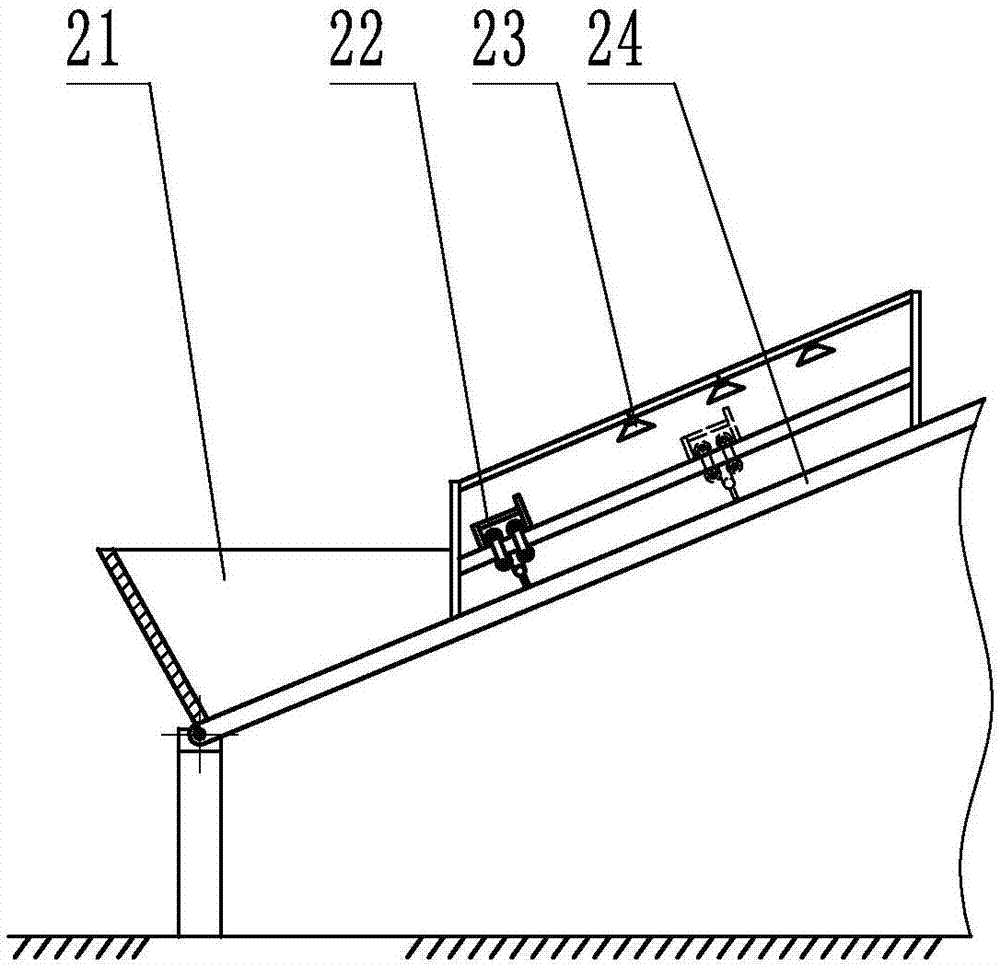

[0104] Embodiment 2: refer to Figure 3-6 , is a structural schematic diagram of Embodiment 2 of the present invention, the paving mechanism 22 includes a fixed shaft and a scraper arranged on the surface of the fixed shaft, the scraper radially extends outward of the fixed shaft, and the scraper is sheet-shaped, one of plate shape or tooth shape; or, the fixed shaft rotates or reciprocates along the conveying direction.

[0105] That is: the paving mechanism 22 is one of a circular roller provided with several scrapers in the radial direction or a slide block provided with a scraper at the bottom, and the circular roller can rotate above the feeding conveying mesh belt 24, so Said slide block can slide back and forth on the hopper 21 along the feeding direction of the feeding conveying mesh belt 24 .

[0106] In actual use: Rotate the scraper to rotate, or the slider drives the scraper to slide back and forth to level the material.

[0107] The sheet shape of the above-ment...

Embodiment 3

[0110] Embodiment 3: refer to Figure 7-10 , is a schematic diagram of the structure of this embodiment 3. The difference of this embodiment is that: the drying bin 1 is provided with a conveying mechanism,

[0111] Described conveying mechanism 13 comprises conveying mesh belt 131 and transmission mechanism 132, and described conveying mechanism is provided with and is used for blocking material and is scattered from the sealing mechanism of conveying mesh belt 131 both sides, and described blocking mechanism comprises blocking block 1312 and sealing mechanism. The block base 1311, the block block 1312 is arranged between the adjacent block block bases 1311, and the block block 1312 is arranged on the block block base 1311 to form a closed loop, the block block 1312 is a flexible block, the Said sealing block 1312 is a kind of in soft rubber plate, sponge block or canvas.

[0112] The above-mentioned blocking block base 1311 can be set on the transmission mesh belt 131 , or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com