Organic fertilizer drying machine

A drying machine and organic fertilizer technology, which is applied in the direction of drying machine, drying, and drying solid materials, etc., can solve the problems of easy dust generation and uneven heating of fertilizer particles, and achieve dust reduction, uniform heating, and convenient secondary use The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

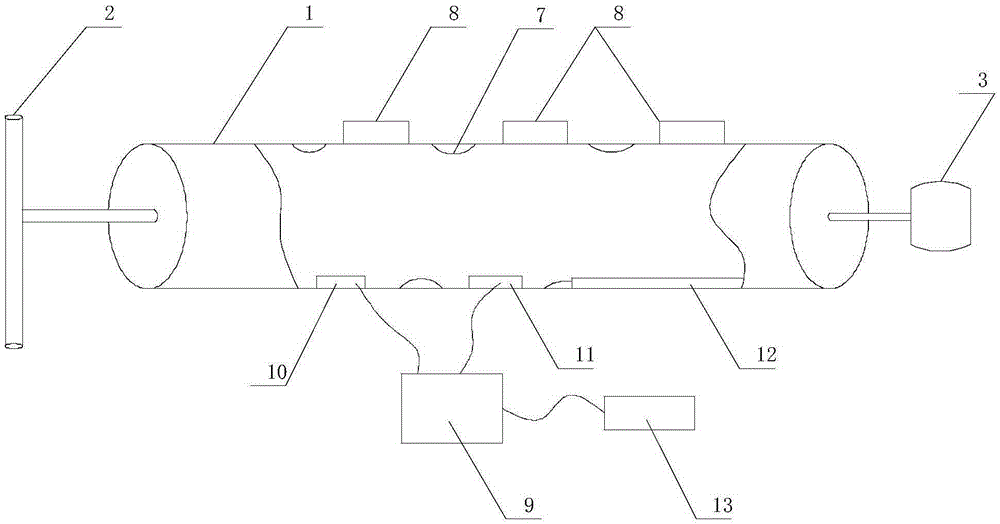

[0016] Such as figure 1 As shown, the organic fertilizer dryer includes a drum 1, a controller 9, a fixed column 2, a motor 3, a temperature sensor 10 and a humidity sensor 11 all arranged in the drum 1; one end of the drum 1 is connected to the fixed column 2 in rotation, and its The other end is rotationally connected with the rotating shaft of the motor 3; the inner wall of the drum 1 is evenly provided with a plurality of protrusions 7; the distance between adjacent protrusions 7 is greater than the particle diameter of the fertilizer grain; the height of the protrusion 7 is equal to three times the diameter of the fertilizer grain One-third of the fertilizer grains will not be stuck between the protrusions 7; the height of the protrusions 7 can also be less than one-third of the grain diameter of the fertilizer grains; three vibrators 8 are arranged on the outer wall of the drum 1; the vibrator 8 It can be replaced by other equipment with vibration function, and its quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com