Process and device for reusing waste foundry sand

A technology of foundry waste sand and process, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of poor collapsibility of foundry waste sand, impact on ecological environment, occupation of land resources, etc., and achieve low cost and high recycling efficiency , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

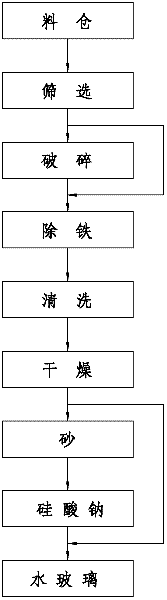

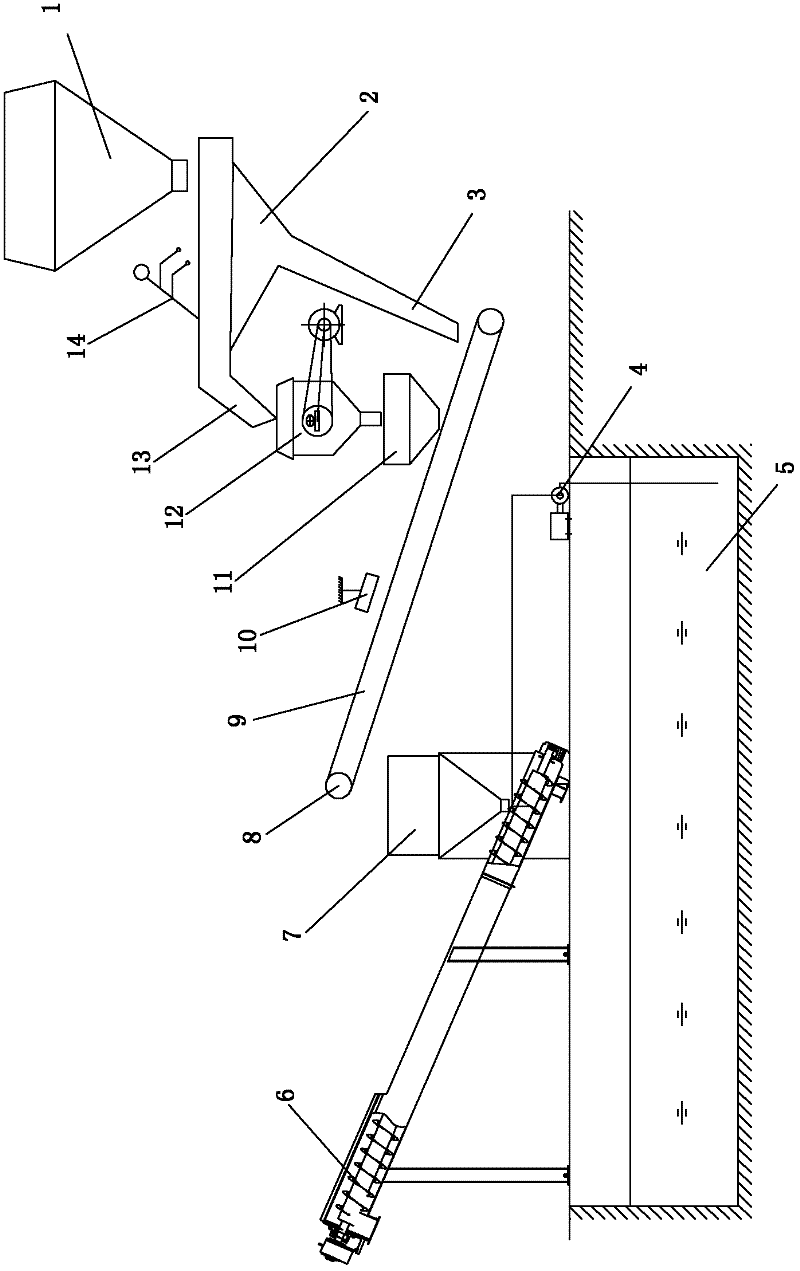

[0019] Such as figure 1 , 2 As shown, first put the foundry waste sand into the collecting hopper 1, and then screen the foundry waste sand through the vibrating screen I2 installed under the outlet of the collecting hopper. The vibrating screen I uses a two-stage sorting electromagnetic vibrating screen , the large particles sieved through the coarse discharge port 13 of the two-stage sorting electromagnetic vibrating screen enter the feed port of the crusher 12 for crushing; pass through the fine discharge port 3 of the two-stage sorting electromagnetic vibrating screen The screened qualified material falls on the belt conveyor 9, and is transported by the belt conveyor to the receiving bin 7 for concentration, and then enters the sand washing machine 6 from the outlet of the receiving bin, and the foundry waste sand Dust and other impurities are removed. The sand washing machine adopts a spiral sand washing machine, and the water pump 4 pumps water into the spiral sand wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com