Automatic demolding injection mold for car trunk storage box assembly

A technology of automatic demolding and injection molding, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of inability to meet the needs of users, low applicability, single function, etc., to increase the use value and increase the heat dissipation capacity. speed, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

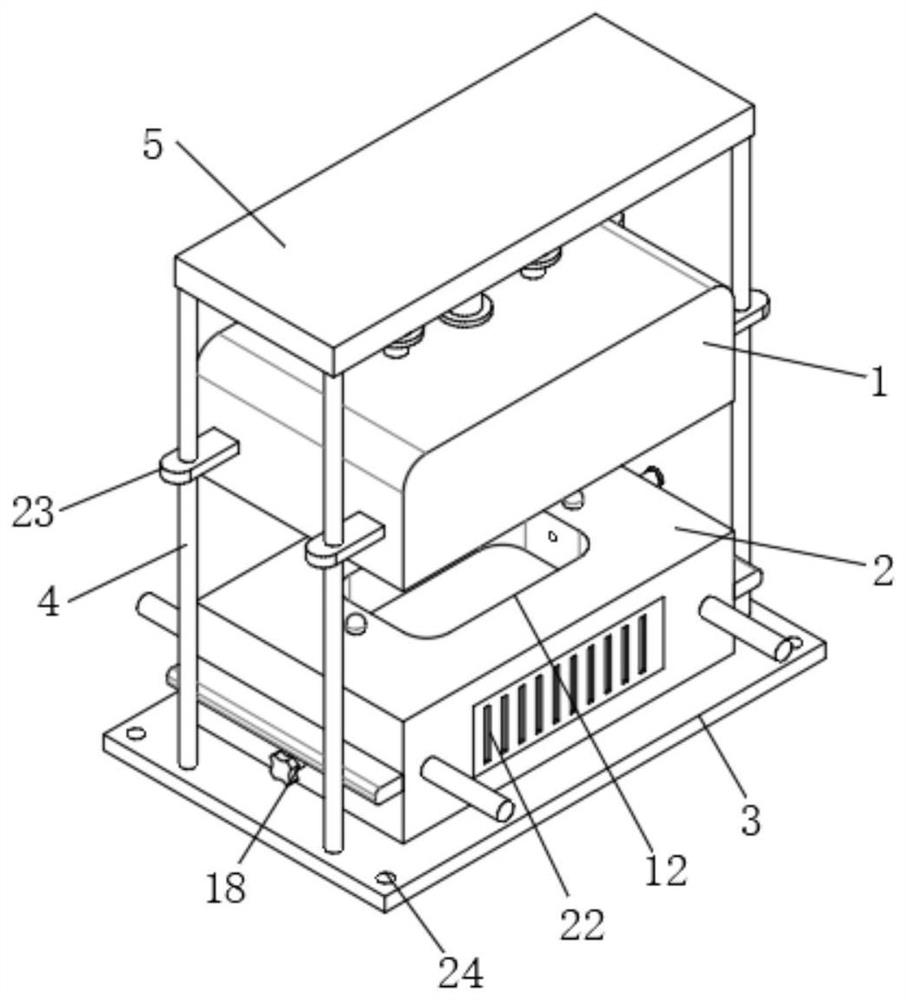

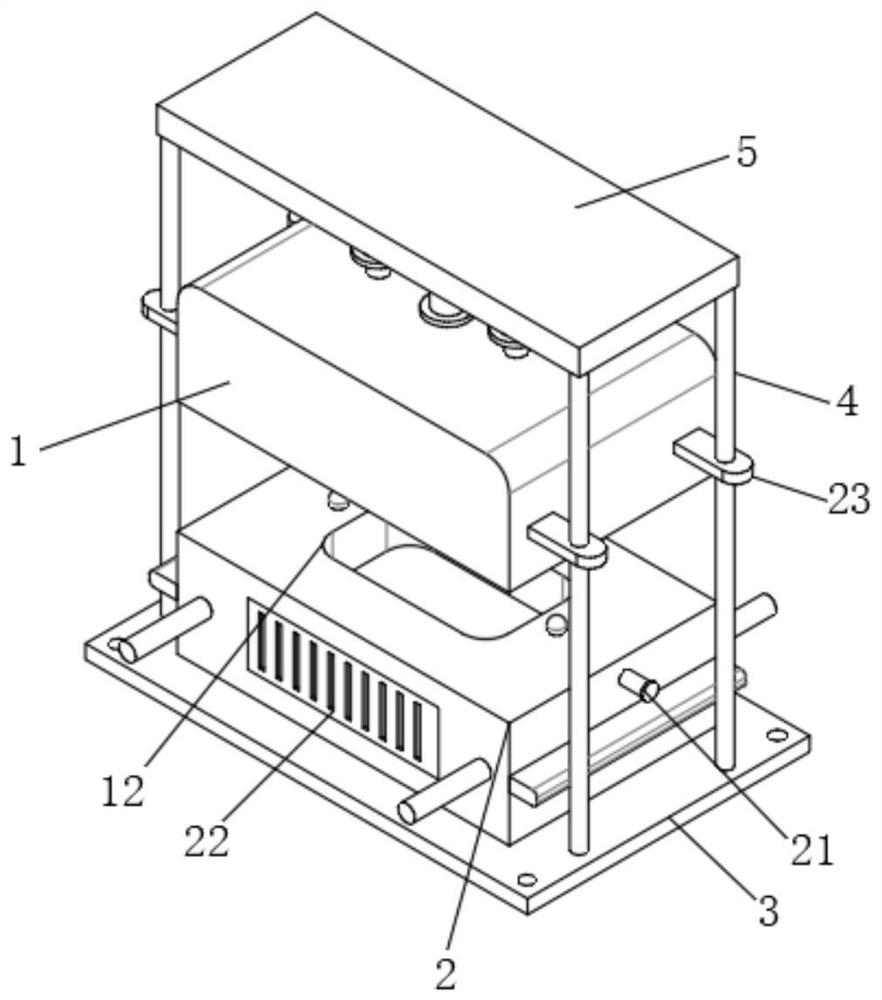

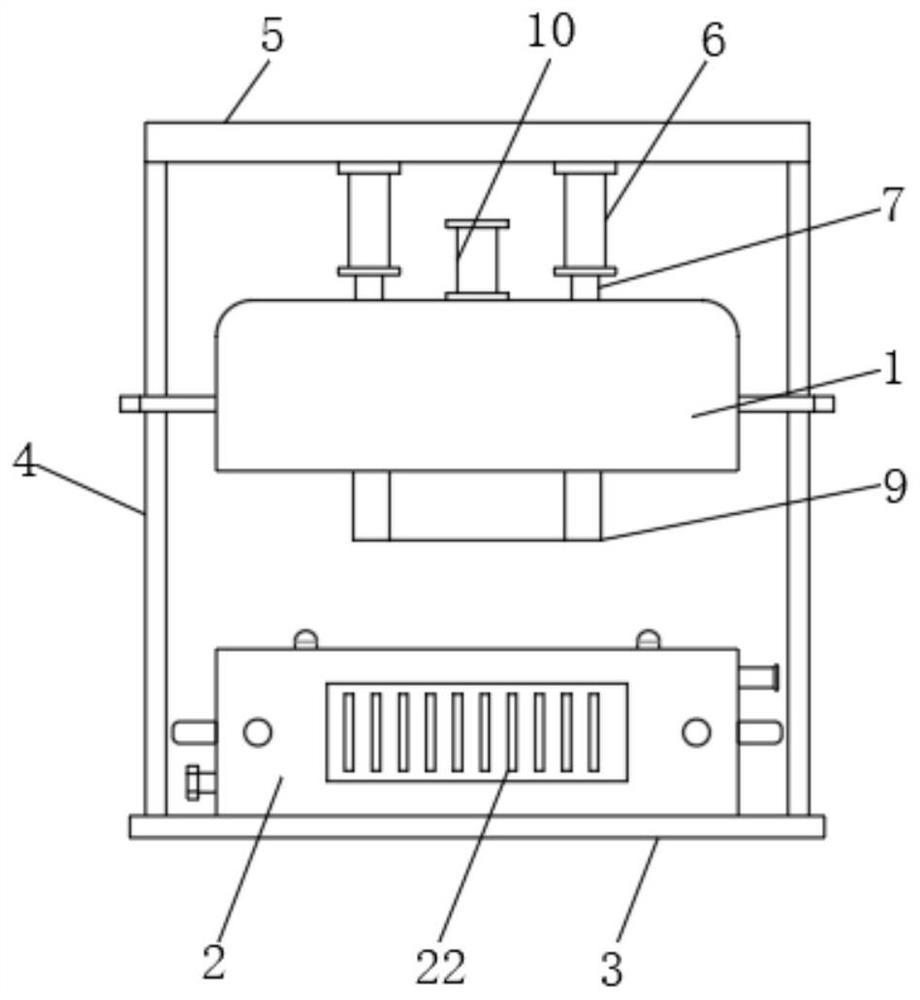

[0035] Such as Figure 1-5 As shown, the embodiment of the present invention provides an automatic demoulding injection mold for a car trunk storage box assembly, including a moving mold 1 and a supporting fixed mold 2, and the inside of the moving mold 1 is provided with a receiving groove 8 for providing a moving mold. The adjustment place of the mold core 9, and the depth of the storage groove 8 is greater than the height of the movable mold core 9, which is convenient for demoulding. The inside of the storage groove 8 is provided with a movable mold core 9, and the upper surface of the movable mold 1 is fixedly connected with a The electric push rod 10 is used to provide power for the movement of the movable mold core 9, and the telescopic amount of the second electric push rod 10 is controlled by PLC, and the movable end of the second electric push rod 10 is fixedly connected with a second movable rod 11, The bottom of the second movable rod 11 extends to the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com