A boring auxiliary tooling

An auxiliary tooling and boring technology, applied in the direction of boring/drilling device, boring head, feeding device, etc., can solve the problems of high price, unfavorable development of processing plants, boring processing, etc., to improve profitability, and the transformation process is simple and easy Operation, the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

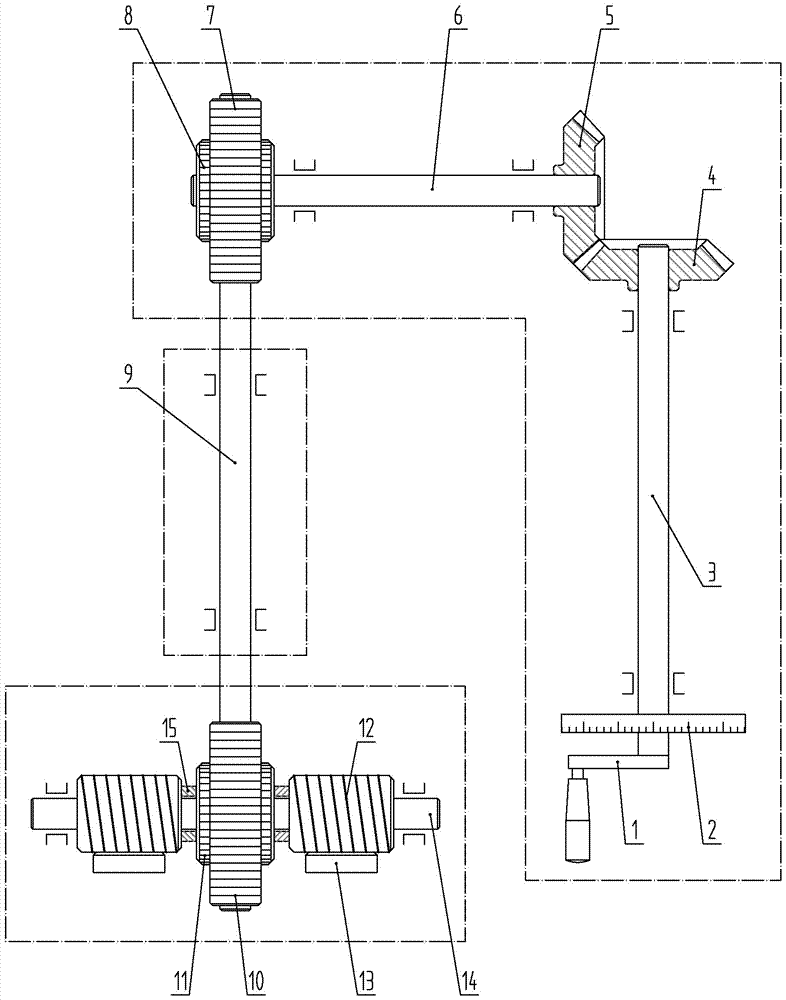

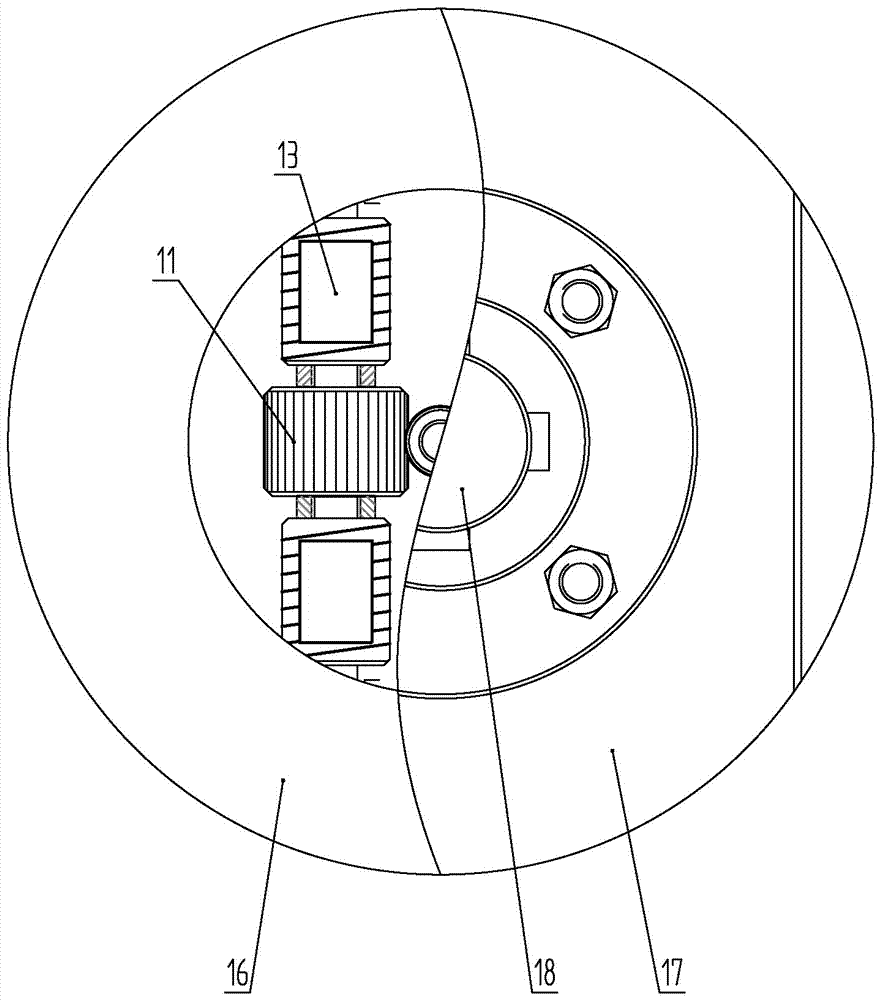

[0022] Such as figure 1 and 2 As shown, a boring auxiliary tooling includes a boring assembly and a transmission assembly.

[0023] The boring assembly includes a boring disc 16 , a ram 17 and a boring tool 18 . The ram 17 is slidably mounted on one side surface of the boring cutter disc 16, and the boring cutter 18 is installed at the center of the ram 17.

[0024] The transmission assembly includes a first transmission shaft 3 , a second transmission shaft 6 , a connecting shaft 9 and a fixed shaft 14 . The front end of the first transmission shaft 3 is equipped with a handle 1, and its rear end is equipped with a first driving bevel gear 4. The front end of the second power transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com