A waste collection device for CNC machine tools that is convenient for chip removal

A waste collection, CNC machine tool technology, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of trouble, long processing time, delay time, etc., to achieve simple and convenient operation, low cost, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

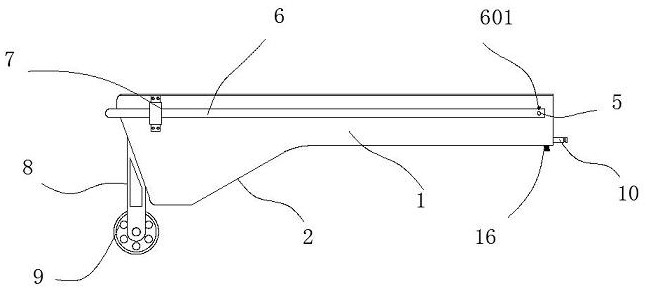

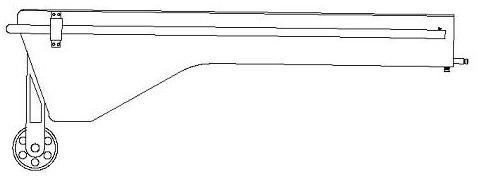

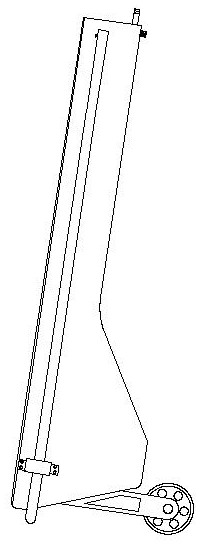

[0044] A waste collection device for CNC machine tools that is convenient for chip removal, comprising a tank body 1, a receiving part 2 is arranged on the left side of the tank body 1, and the depth of the receiving part 2 is greater than the depth of the tank body 1, When installing, the tank body 1 is inserted below the main shaft of the machine tool, and a partition 3 is arranged inside the tank body 1, and the right end of the partition board 3 is disconnected from the inner right side wall of the tank body 1, The front and rear sides of the tank body 1 are correspondingly provided with chute 101, and the chute 101 is arranged laterally. Inside the tank body 1, a scraper 4 is arranged above the partition plate 3. There is a rod 5 interspersed longitudinally inside the scraper 4, and the rod 5 and the scraper 4 are welded and fixed, and the rod 5 extends to the outside of the chute 101, and the rod 5 can be Sliding laterally along the chute 101 , the lower end of the scrap...

Embodiment 2

[0046] An upper baffle plate 12 is provided at the inner right side of the tank body 1, and the upper baffle plate has a material guide surface 13 inclined to the left and lower. When the scraper 4 moves to the right side to the extreme position, , located below the upper baffle 12; the function of the upper baffle 12 is to prevent chips from falling directly to the right side of the scraper 4 during machining.

Embodiment 3

[0048] The left end of the partition 3 is inclined and bent downward to form the first material guide surface 311; the first material guide surface 311 is inclined and then bent into the receiving part 2 to prevent chips from entering the partition 3 from the left side of the partition 3 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com