Efficient household garbage incineration fly ash two-stage washing process

A technology of domestic waste incineration and fly ash, which is applied in the field of solid waste recycling, can solve the problems of high water consumption, influence of cement kiln mixing, and increased energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

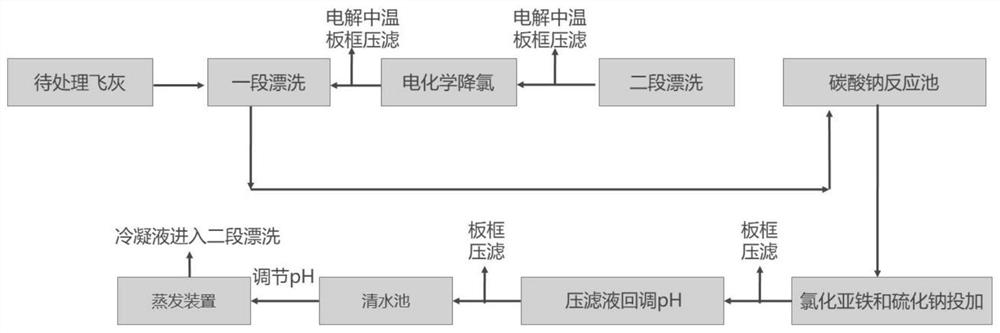

Method used

Image

Examples

Embodiment 1

[0036] A high-efficiency domestic waste incineration fly ash secondary washing process, comprising the following steps:

[0037] (1) Secondary rinsing: the press filtrate after the second-stage rinsing of fly ash (after electrolytic medium-temperature plate and frame press filtration) enters the dechlorination device for treatment, reduces the chloride ion content in the press-filtrate, and enters the first stage of fly ash rinsing treatment process; water The gray ratio (weight ratio) is controlled at 1.2:1~2:1.

[0038] (2) Wastewater treatment section: a section of press filtrate after rinsing enters the sewage treatment system, and through physical and chemical processes such as removal of heavy metals, calcium and magnesium ions, a mixed solution mainly composed of potassium chloride and sodium chloride is formed, and the solid-liquid separation adopts a plate frame Filter press, the water is clear and transparent;

[0039] (3) Evaporation and reuse section: Evaporation ...

Embodiment 2

[0042] For fly ash from a self-provided incineration plant of a listed company in Nantong, Jiangsu, the chloride ion content of the fly ash is 6.8%, and the specific surface area measured by BET is 7.38m 2 / g.

[0043] Table 1 Properties of fly ash from a self-provided incineration plant of a listed company in Nantong

[0044] Sample (mg / g) Al As Ba be Ca Cd Cr Cu Fe sample 1 113.5389252 0.08063812 1.464844 0.001363 4.688172 0.00227 0.102179 0.087601 60.50213 sample 2 111.9070529 0.08895567 1.562096 0.002017 4.688741 0.001707 0.114353 0.078822 49.93023 (mg / g) K Li Mg mn Na Ni P Pb Zn sample 1 8.316022099 0.20058764 4.85668 0.827225 6.652587 0.056953 0.644603 0.048714 0.091567 sample 2 9.140050378 0.22234786 5.248136 0.903393 7.367884 0.060979 0.715202 0.050777 0.088581

[0045] After being treated by the method of this embodiment, the two-stage washing time is set to 4 ho...

Embodiment 3

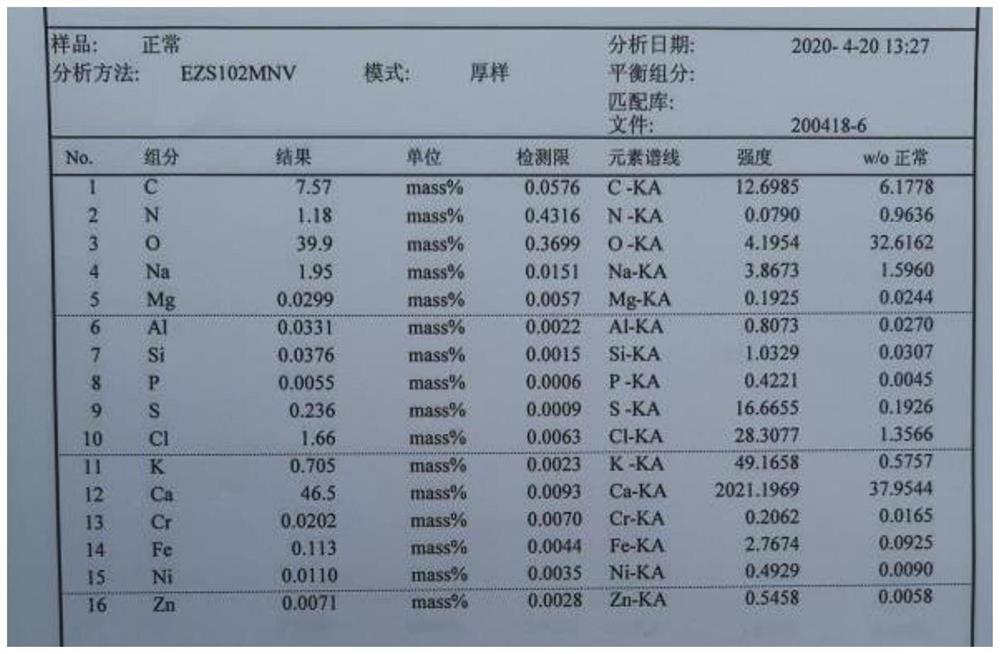

[0047] A high-efficiency domestic waste incineration fly ash secondary washing process, the main properties of the collected fly ash include:

[0048] Table 2 Property analysis of a certain fly ash in Jiaxing, Zhejiang

[0049] sample name(%) SiO 2

[0050] Through the two-stage water washing, the two-stage water washing time is set to 3.6 hours respectively, the water-cement ratio is 1.3:1, the temperature of the electrolytic medium-temperature plate and frame filter press is set to 65°C, and the electrolytic current density is 85A / m 2 , The chlorine content of the fly ash after electrolytic medium-temperature plate and frame pressure filtration is less than 0.8%, the molar ratio of sodium carbonate to calcium and magnesium ions is 1.8:1, and there is no need to add sodium sulfide and ferrous chloride. The pH value of the plate and frame filtrate is adjusted back to 7.3, so as to ensure that after the aluminum ions and other amphoteric ions are removed, the clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com