Desulfurization slurry dechlorination technology

A desulfurization slurry and dechlorination technology, applied in degassed water/sewage treatment, water/sludge/sewage treatment, gas treatment, etc., can solve environmental pollution, serious problems, etc., and achieve the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

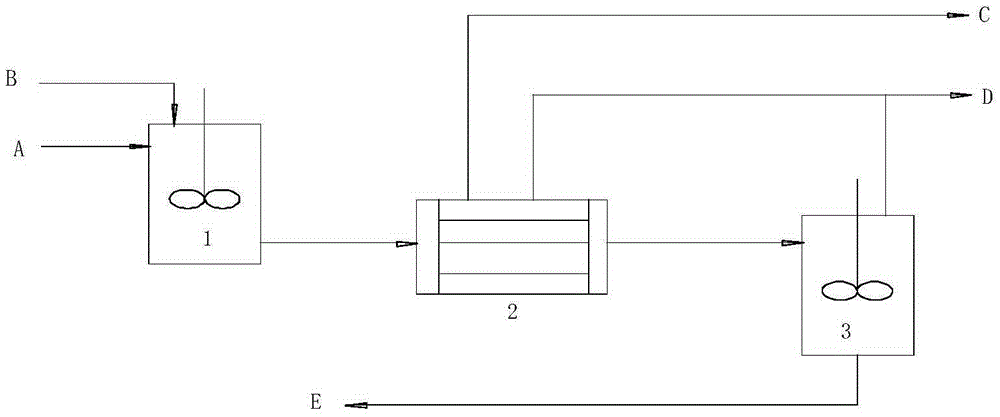

[0028] figure 1 Medium ammonium sulfate dissolution tank 1, electrolytic cell 2, stirring tank 3; filtrate A, ammonium sulfate B, hydrogen gas C, chlorine gas D, dechlorination filtrate E.

[0029] When the chloride ion content in the slurry is 5000mg / L, the supplemented ammonium sulfate B is dissolved in the filtrate A in the ammonium sulfate dissolution tank 1 to obtain a 25-35% concentrated ammonium sulfate solution; directly use the concentrated ammonium sulfate solution As a raw material, at a temperature of 30-60°C, Pt is used as an anode, Pb is used as a cathode, a polytetrafluoroethylene cationic membrane is used as a diaphragm, and 0.05% ammonium polyphosphate additive is added to the anode, and hydrogen gas C and Chlorine gas D is extracted separately and sent to post-processing; the chlorine-containing filtrate that is not released in time in the electrolytic cell is stirred at a high speed in the stirring tank 3, so that the liquid flow moves along the wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com