Catalytic conversion method for directly processing high-chlorine raw material

A catalytic conversion and high chlorine technology, applied in the petroleum industry, refining with non-metals, refining with metals, etc., can solve the problems of ineffective removal of chlorides, etc., to improve product selectivity, increase conversion rate, and high dechlorination rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

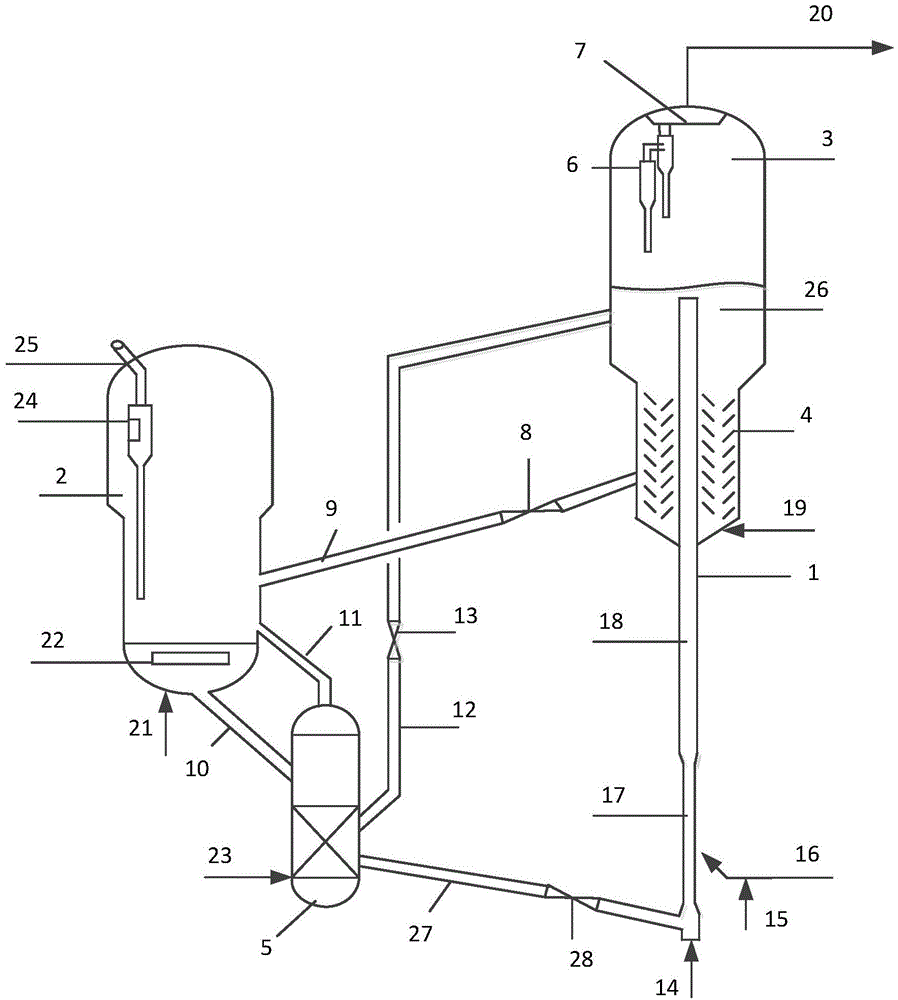

[0067] According to a preferred embodiment of the present invention, the catalytic conversion method comprises the steps of:

[0068] The high-temperature regenerated catalyst is injected into the pre-lift section of the riser reactor, and under the action of the pre-lift medium, it flows upward into the initial reaction zone at the lower part of the riser reactor, and the preheated high-chlorine raw material enters the initial reaction from the lower part of the riser reactor In the zone, it contacts, reacts and goes up with the high-temperature regenerated catalyst; the formed oil mixture enters the main reaction zone of the riser reactor, and continues the hydrocarbon conversion reaction in the main reaction zone; the formed oil mixture enters the fluidized bed The reactor is in contact with the high-temperature regenerated catalyst from the regenerator to continue the hydrocarbon conversion reaction. After the reaction, the stream enters the cyclone separator in the settler...

Embodiment 1

[0086] This example is used to illustrate the catalytic conversion method for directly processing high-chlorine raw materials according to the present invention.

[0087] according to figure 1 The process shown in the test was carried out on a medium-sized catalytic cracking unit. The high-chlorine feedstock oil was preheated to 350°C and injected into the initial reaction zone of the riser reactor through pipeline 15, and was mixed with the high-temperature regenerated catalyst (660°C ) contact reaction in the initial reaction zone, wherein the weight ratio of agent to oil is 6:1, the reaction time is 0.8 seconds, the reaction temperature is 535°C, and the weight ratio of water vapor to high chlorine feedstock oil is 0.05:1. The oil mixture generated in the initial reaction zone continues upward into the main reaction zone to continue the reaction, wherein the reaction temperature is 525°C, the reaction time is 1.5 seconds, and the ratio of the riser diameter of the initial r...

Embodiment 2

[0091] This example is used to illustrate the catalytic conversion method for directly processing high-chlorine raw materials according to the present invention.

[0092] according to figure 1 The process shown in the test was carried out on a medium-sized catalytic cracking unit. The high-chlorine feedstock oil was preheated to 220°C and injected into the initial reaction zone of the riser reactor through pipeline 15, and was mixed with the high-temperature regenerated catalyst (650°C ) contact reaction in the initial reaction zone, wherein the weight ratio of agent to oil is 30:1, the reaction time is 0.2 seconds, the reaction temperature is 560°C, and the weight ratio of water vapor to high chlorine feedstock oil is 0.05:1. The oil mixture generated in the initial reaction zone continues upward into the main reaction zone to continue the reaction. The reaction temperature is 540°C, the reaction time is 3 seconds, and the ratio of the diameter of the riser in the initial rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com