Method for degrading aryl halide organic pollutants

A technology for organic pollutants and halogenated aromatic hydrocarbons, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc. Low cost, low price, avoiding the effect of high temperature and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

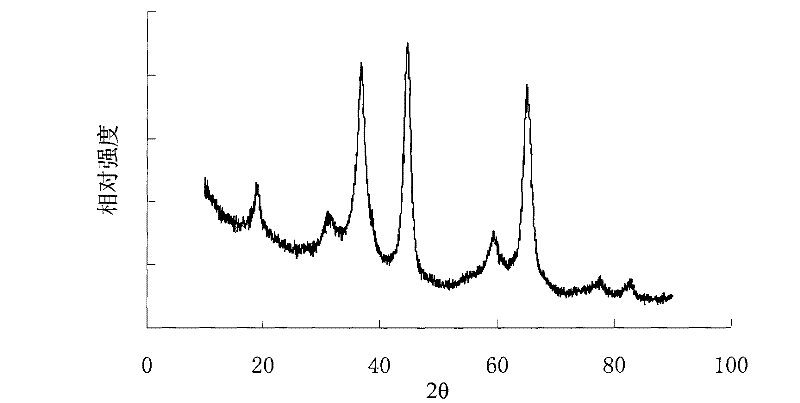

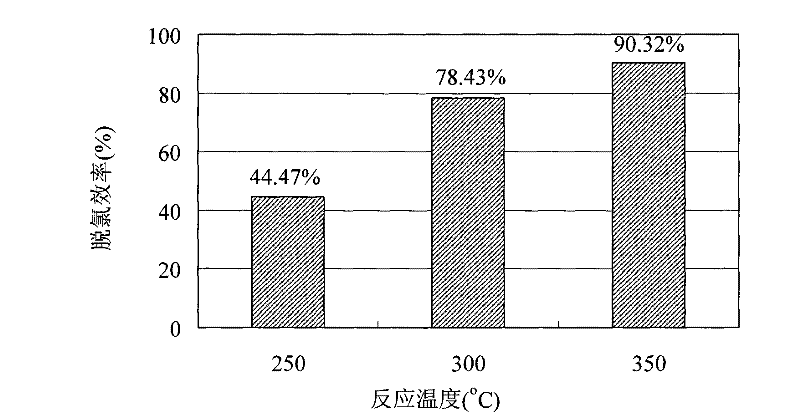

preparation example 1

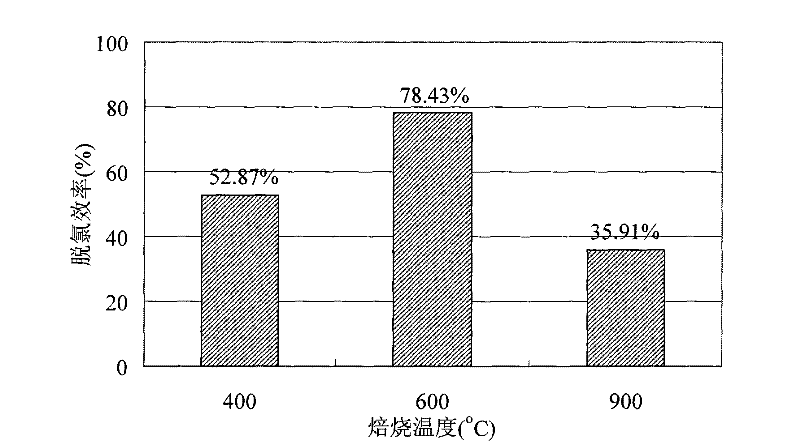

[0031] 5.12g Mg(NO 3 ) 2 ·6H 2 O and 15.01g Al(NO 3 ) 2 9H 2 O was dissolved in 200ml of distilled water, and then 0.6mol / l NH 4 Add the OH solution drop by drop into the above mixed solution, and keep stirring until the pH of the solution reaches about 8, and precipitates in the solution, then filter the solution, wash the filter with distilled water three times, put it in an oven, and bake it at 100°C for 24 hours to dry. The dried product is put into a muffle furnace and roasted at 600°C for 1 hour, and the product is a catalyst for the degradation of halogenated aromatics at low temperature, which is a magnesium-aluminum catalyst.

preparation example 2

[0033] 5.12g Mg(NO 3 ) 2 ·6H 2 O and 15.01g Al(NO 3 ) 2 9H 2 O was dissolved in 200ml of distilled water, and then 0.6mol / l NH 4 Add the OH solution drop by drop into the above mixed solution, and keep stirring until the pH of the solution reaches about 8, and precipitates in the solution, then filter the solution, wash the filter with distilled water three times, put it in an oven, and bake it at 100°C for 24 hours to dry. The dried product is put into a muffle furnace and roasted at 400°C for 1 hour, and the product is a catalyst for low-temperature degradation of halogenated aromatics, which is a magnesium-aluminum catalyst.

preparation example 3

[0035] 5.12g Mg(NO 3 ) 2 ·6H 2 O and 15.01g Al(NO 3 ) 2 9H 2 O was dissolved in 200ml of distilled water, and then 0.6mol / l NH 4Add the OH solution drop by drop into the above mixed solution, and keep stirring until the pH of the solution reaches about 8, and precipitates in the solution, then filter the solution, wash the filter with distilled water three times, put it in an oven, and bake it at 100°C for 24 hours to dry. The dried product is put into a muffle furnace and roasted at 900°C for 1 hour, and the product is a catalyst for the degradation of halogenated aromatics at low temperature, which is a magnesium-aluminum catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com