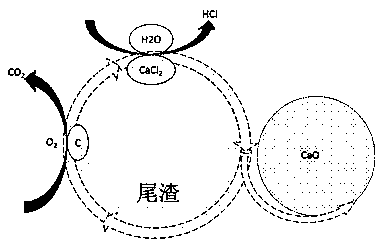

Dechlorination and decarbonization method for titanium extraction tailings through multi-phase reaction cooperation

A technology for extracting titanium tailings and multiphase reaction, applied in chemical instruments and methods, chlorine/hydrogen chloride, preparation with chloride, etc., can solve problems such as high cost of high-temperature calcination, low dechlorination efficiency, and activity of destructed slag. Achieve the effects of improving dechlorination efficiency, reducing the impact of glass phase and activity, and reducing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The low-temperature boiling chlorination titanium extraction tailings with a discharge temperature of 450°C, below 160 mesh, are discharged from the slag outlet and directly added to the fluidized bed reactor, and air is supplied as fluidized gas and carbon is burned. In the fluidized bed reactor, the titanium extraction tailings are fluidized and reacted to burn carbon to heat up, and the CO produced 2 The gas is precipitated from the tailings, and the carbon is burned with oxygen for 15 minutes, and the surface temperature of the titanium extraction tailings is controlled to be 510°C; the air supply is kept and the temperature is 15m 3 / h into, spray into 155 ℃ water vapor (according to the standard condition 0.4m 3 / h) React with calcium and magnesium chloride on the hot tailings surface interface, dissolve and evaporate to dechlorinate, and precipitate from the tailings in the form of HCl gas. The temperature during the treatment process is controlled at 505-555 ° C,...

Embodiment 2

[0035] The low-temperature boiling chlorination titanium extraction tailings with a discharge temperature of 540°C, below 200 mesh, are discharged from the slag outlet and directly added to the fluidized bed reactor, and the air used as the fluidizing gas is fed and carbon is burned to supply Oxygen burning carbon treatment for 10 minutes, control the surface temperature of titanium extraction tailings to 590 ° C, keep air supply and 15m under standard conditions 3 / h into, spray into 175 ℃ water vapor (according to the standard condition 0.43m 3 / h), the temperature of the treatment process was controlled at 555-595°C, and the treatment was maintained for 10 minutes; the specific treatment results are shown in Table 1.

Embodiment 3

[0037] Low-temperature boiling chloride titanium extraction tailings with a discharge temperature of 510°C, below 300 mesh, are discharged from the slag outlet and directly added to the fluidized bed reactor. The surface temperature of the hot titanium extraction tailings is 505-510°C , higher than 500°C, you can choose to directly operate step 2), and the access is 10m under standard conditions 3 / h of air, while spraying water vapor at 195°C (0.3m under standard conditions 3 / h), the temperature during the treatment process was controlled at 505-555°C, and the treatment was maintained for 10 minutes; the specific treatment results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com