Metal nanocrystal modified composite electrode and preparation method and application thereof

A metal nanocrystal and composite electrode technology, applied in the field of nanomaterials, can solve the problems of no electrocatalytic modified electrode application invention, etc., and achieve the effects of environment-friendly repair treatment, high electrocatalytic activity, and short repair period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

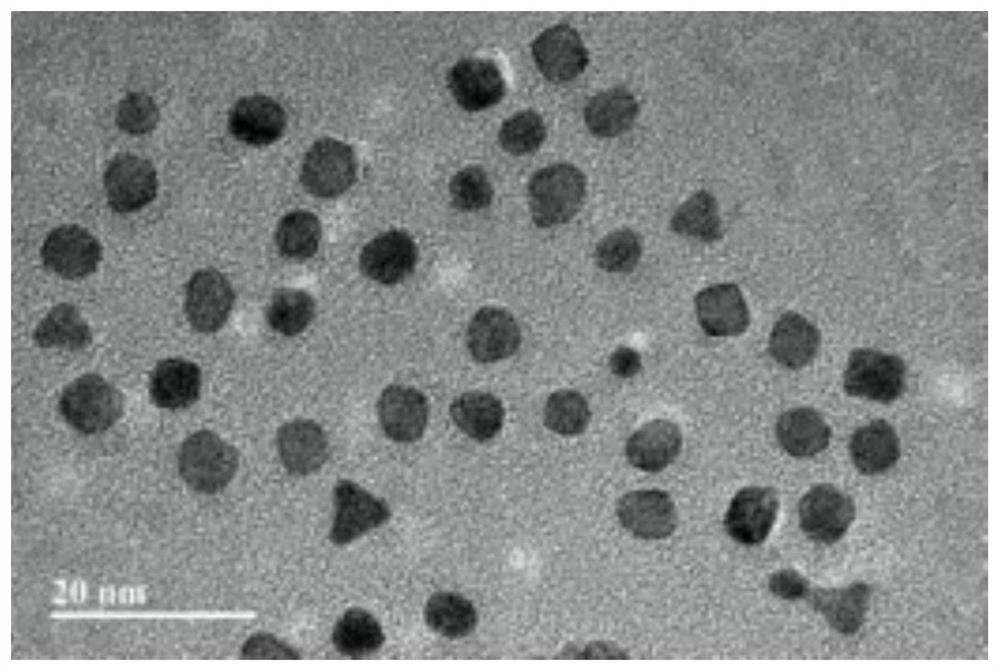

[0039] Prepare 50mmol L -1 AgNO 3 Solution, 0.1mol L -1 K 2 PdCl 4 The solution is ready for use. Put 1 mL of each of the two metal precursor solutions into 20 mL of polyethylene glycol PEG solution (PEG average molecular weight = 400) preheated at 130 ° C for 10 min. The reaction system is pre-added with an appropriate amount of KCl end-capping agent (molar ratio metal precursor body Ag: KCl=1:10), hexadecyltrimethylammonium chloride CTAC (total molar ratio of metal precursor: CTAC=1:2) as a surface stabilizer, etc., after a constant temperature reaction for 3 hours, it was washed by centrifugation , redispersed in 5mL aqueous solution. The nanocrystals can be observed by high-resolution transmission electron microscopy, such as figure 1 Shown are metal nanocrystals smaller than 10 nm. Ultrasonicate nanocrystals and catalytic carrier graphene (loading capacity 5wt%) in 15mL ethanol for 8h, add 10mL acetic acid at 50°C and stir for 24h to ensure complete and uniform mixi...

Embodiment 2

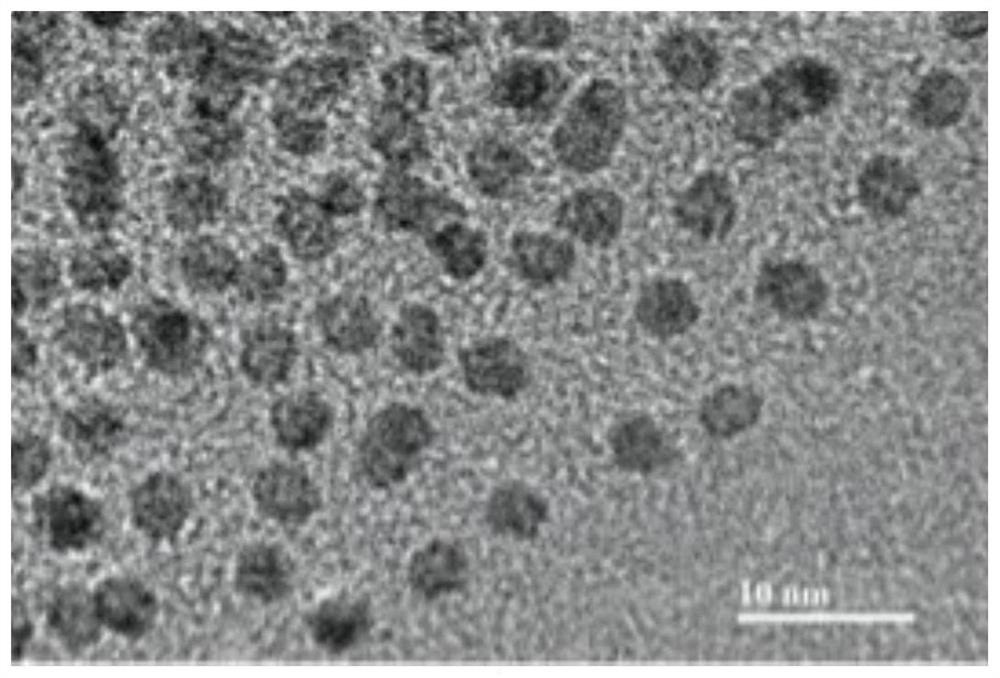

[0041] Contains a certain amount of surface stabilizer polyvinylpyrrolidone PVP (molar ratio metal precursor: PVP monomer = 1:10) and cetyltrimethylammonium bromide CTAB (molar ratio metal precursor: CTAB = 1:2) The 15mL ethylene glycol solution was first preheated at 150°C for 10min, and at the same time, 0.15mmol palladium acetylacetonate and 0.03mmol ruthenium trichloride precursor were added, and the constant temperature reaction was continued for 24h with stirring, followed by centrifugal washing, and dispersed in 6mL deionized water for later use. PdRu nanocrystals such as figure 2 As shown, it is a metal nanocrystal with uniform size below 5nm. Nanocrystals and catalytic carrier activated carbon (loading capacity 10wt%) were sonicated in 15mL of ethanol for 8h, and 15mL of acetic acid was added to fully stir for 24h to ensure complete and uniform mixing, then collected by centrifugal washing, and Nafion polymer isopropanol was added in proportion after drying at low te...

Embodiment 3

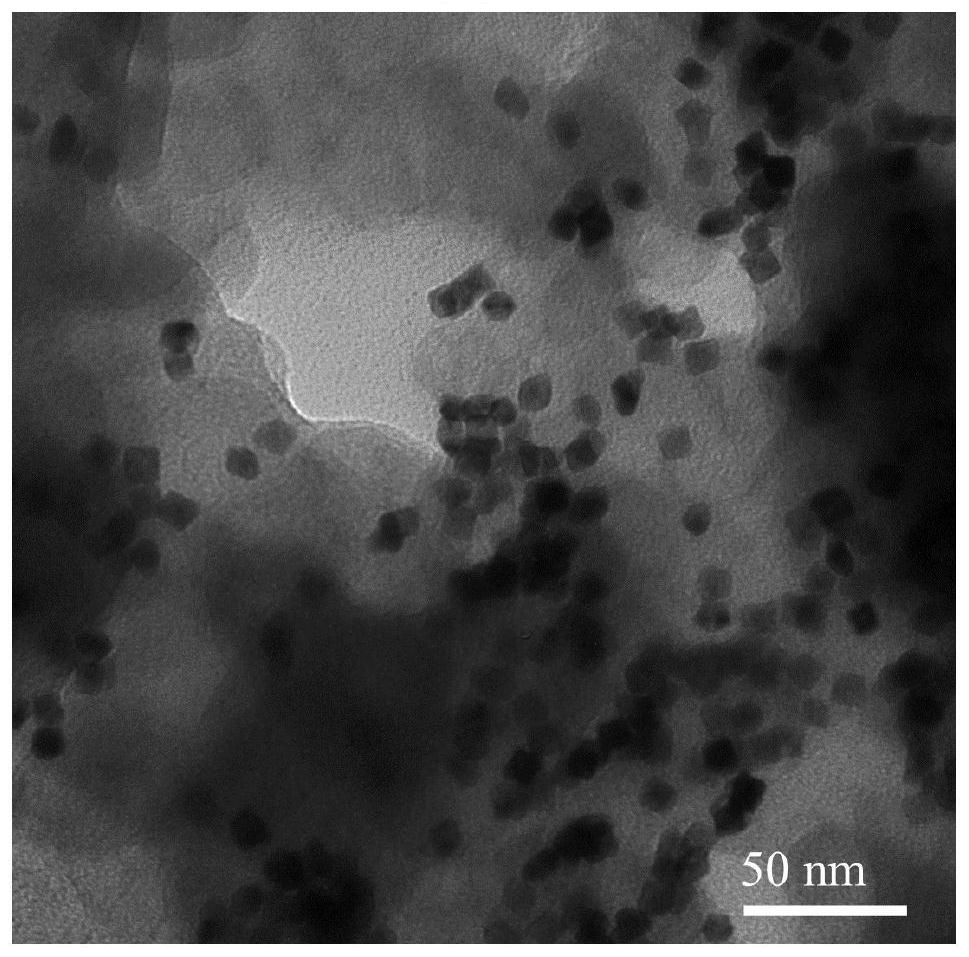

[0043] A 20 mL ethylene glycol solution containing 200 mg polyvinylpyrrolidone PVP and 270 mg potassium chloride KCl was preheated at 125 ° C for 10 min in a reaction glass bottle, then 0.2 mmol silver trifluoroacetate and 0.3 mmol platinum acetylacetonate precursor were added, and the reaction was carried out at a constant temperature It was carried out for 30 min under stirring condition, and then 0.1 mmol of palladium acetylacetonate precursor was continued to be added, and the reaction was continued for 6 h, after which it was washed by centrifugation and redispersed. Nanocrystals and catalytic carrier activated carbon (loading capacity 10wt%) were fully stirred in 15mL ethanol and 15mL acetic acid for 24h to ensure complete and uniform mixing, then collected by centrifugal washing, and added Nafion polymer isopropanol water mixed solution (0.1wt %Nafion,V 异丙醇 :V 水 =1:9), sonicated for 10 hours to form a homogeneous modification solution. Microscopic observation of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com